Wine Beverage Bottling Line: The Complete Buying Guide In 2025

Are you looking for the best bottling solution for your wine beverages and other types of liquid? Are there any wine beverage bottling tools and accessories for your choice? Do you want to know the wine beverage bottling process? How are their quality maintained?

Wine Beverage Bottling Line-sourced: jordanwinery

What is the wine beverage bottling line and are there any different process for different wines? We will delve into the answers below, as well as depict the wine beverage bottling process to facilitate your understanding of wine beverage bottling line and bottling process. Let’s find out the answer together!

1.What Is Wine Beverage Bottling Line?

What Is Wine Beverage Bottling Line-sourced: tcwequipment

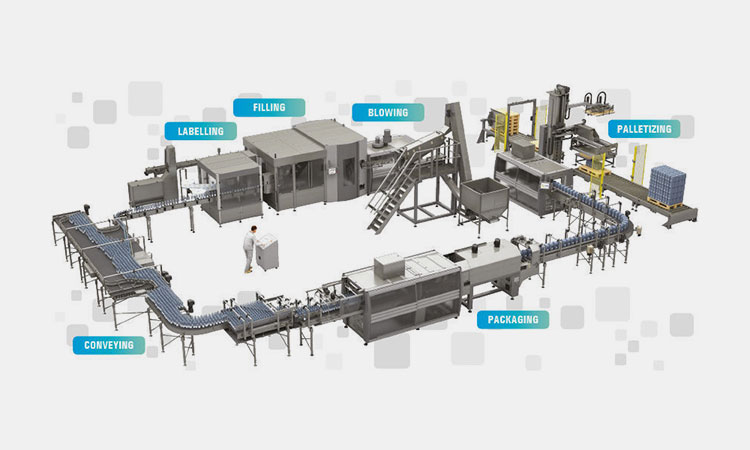

The wine beverage bottling line is a specially designed production line that can fill your product, generally a wine beverage, into bottles on a large scale. It integrates the most efficient and cost-effective complete bottling and packaging production line and can basically for all your bottle filling and packaging needs.

In addition to wine beverage, it can also meet the bottling production and filling of various beer, whiskey, water, soda water and etc. The wine beverage bottling line roughly consists of cartoning or palletizing machines, filling machines, capping machines, labeling machines, cartoning machines, carton sealing machines.

2.What Are The Application Of Wine Beverage Bottling Line?

The wine beverage bottling line can meet the bottling line filling and capping requirements of almost all liquids in most industries. These include:

Beverage Industry

Beverage Industry-sourced: wineonsale

The wine beverage bottling line can satisfy your filling and packaging of all beverage liquids, including milk, beer, water, coffee, energy drinks, juices, soft drinks, tea, sparkling drinks, milkshakes, smoothies, tonic water, cider, hard alcohol, bubble tea, spirits, coconuts, etc.

Food Industry

Food Industry-sourced: sks-bottle

There are food products can also be handled by the wine beverage bottling line, including sauces, syrups, marinades, oils, ketchup, vinegar, curry, yogurt, mayonnaise, mustard, honey, ice cream, hot chocolates, olives, etc. for your needs.

Pharmaceutical Industry

Pharmaceutical Industry-sourced: aphenapharma

In pharmaceutical industry, there are plenty of application for pharma liquids and pastes including liquid supplement, nutrition drinks, cough syrup, vitamin supplement solution, saline, glucose, solutions, suspensions, elixirs, syrups, and etc.

Beauty Industry

Beauty Industry-sourced: eltamd

Many liquid products that are very popular with women are bottled and labeled through the wine beverage bottling line, and finally labeled. These products include lotion, cream, cosmetics, gels, cleaner liquids, serum, face oil, moisturizer, toner, eye cream, shampoo, body wash, etc.

Chemical Industry

Chemical Industry-sourced: salepeaket

With long-term professional R&D and accumulated experience, the wine beverage bottling line can also be applied for your chemical liquids bottling and capping. The chemical liquids include laundry cleaners, disinfectants, sanitizers, dish liquids, car washers, car polishes, glass cleaners, engine coolants , janitorial cleaners, bleach, etc.

Agricultural Industry

Agricultural Industry-sourced: bareground

In agriculture, the wine beverage bottling line also has a very wide range of applications. It can be used to fill and cap your agricultural liquids such as law and garden liquids, fertilizer solutions, pesticide liquids, suspension fertilizers, agricultural water, nitrogen fertilizer, etc.

3.What Kind Of Bottles Can Wine Beverage Bottling Line Handle?

The wine beverage bottling line can perform automatic liquid filling, labeling or packaging processes for your various glass bottles, PET containers or cans. It provides you with customized system solutions for every container type and every beverage category.

Glass Bottles

Glass Bottles-sourced: bonappetit

The glass bottles are all made of glass. It can be used to store and sell beverages, food, cosmetics, etc. In the wine beverage bottling line, it is the most commonly used liquid container. It is not only resistant to storage, but also resistant to high temperatures, and can well protect your products in the container.

PET Bottles

PET Bottles-sourced: niagarawater

PET bottles are clear, durable and versatile plastic containers. It can be recycled and reused and is a very environmentally friendly material. The PET bottles are the most commonly used beverage bottle containers in life. In the wine beverage bottling line, it is widely used and is often used to fill your water and beverages.

Cans

Cans-sourced: liquor

Can or drink can, is a special metal container. It is often used to fill and contain your liquid products such as carbonated soft drinks, alcoholic beverages, juices, teas, herbal teas, energy drinks, etc. In addition to liquid products, it can fill and store a variety of contents, such as food, beverages, oils, chemicals, etc.

Drums

Drums-sourced: joinwell

Drums can be used for liquid filling in many industries, including food and beverage, building products, chemical, paint and coatings, adhesives, and sealants. They are mainly made of steel or plastic, and can range in size from 60 to 250 liters.

4.What Can The Wine Beverage Bottling Line Bring You?

There are a lot of benefits that the wine beverage line can bring you, including:

Precise Filling

Precise Filling-sourced: thegrapevinemagazine

The wine beverage bottling line uses fully automated systems to accurately measure and accurately fill each bottle. It ensures you even filling levels of your products, maintaining consistency throughout the batch.

Efficient Capping

Efficient Capping-sourced: g3enterprises

The entire line adopts a high-efficiency capping and closure system to ensure you a safe and beautiful seamless seal for each bottle cap. It minimizes the risk of spills and ensures a tight seal for optimal wine preservation.

Tailored Solutions

Tailored Solutions-sourced: ridgewine

The wine beverage bottling line can provide you with unique customized solutions to address your individual needs. Many of its parts and components enable the design of a bottling system with specific specifications based on your specific needs. These include labeling machines, cartoning machines, etc.

High Efficiency

The wine beverage bottling line is an optimized complete line system and solution. In addition to increasing the throughput of your bottling line, it also maintains a high quality of your bottled products.

Perfect Reliability

Perfect Reliability-sourced: wineonsale

Most manufacturers now provide state-of-the-art bottling equipment and bottling lines that are durable and durable. With good usage and maintenance, different bottling lines can provide you with long-term stable operation.

Full Configuration

Full Configuration-sourced: cartoriodeferraz

The wine beverage bottling line can provide you with a bottling line including all the necessary components and equipment to create a seamless production process. This will greatly increase the efficiency and automation of your bottling line.

5.What Are The Types Of Wine Beverage Bottling Line?

According to the difference of automation, the wine beverage bottling line can be divided into:

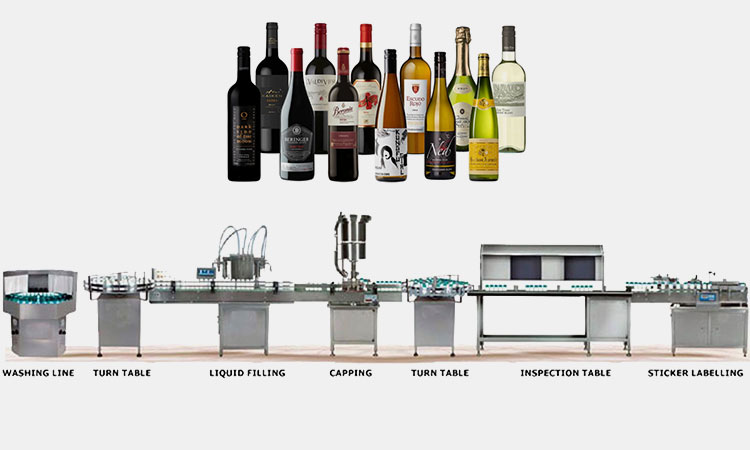

Semi-automatic Wine Beverage Bottling Line

Semi-automatic Wine Beverage Bottling Line-sourced: ipecengg

The semi-automatic wine beverage bottling line is engineered to fill your wine bottles and beverage bottles. It mainly consists of the semi-automatic rotary rinsing machine, rotary bottle unscrambler, liquid filling machine, capping machine, turn table, inspection table, labeling machine.

This complete line has a compact structure, high efficiency, elegant appearance and diverse functions. It meets all your requirements for cleaning and filling wine bottles.

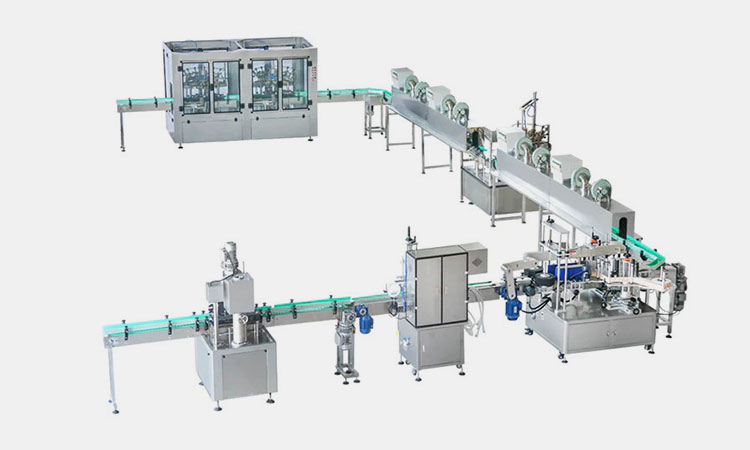

Fully-automatic Wine Beverage Bottling Line

Fully-automatic Wine Beverage Bottling Line-sourced: micmachine

The fully automatic wine beverage bottling line ensures you precise bottling levels for each product, thus preserving the unique characteristics and flavors of each wine variety.

It mainly consists of the automatic rinsing machine, bottle unscrambler, automatic filling machine, marks sprayer, automatic bottle inverted sterilizer, blow drying machine, automatic shrink labeling machine, conveyor, and automatic shrink packaging machine.

This complete line is suitable for wines of all sizes Filling of wine bottles and other liquids, and achieving accurate and efficient filling.

6.What Are The Different Parts Of Wine Beverage Bottling Line?

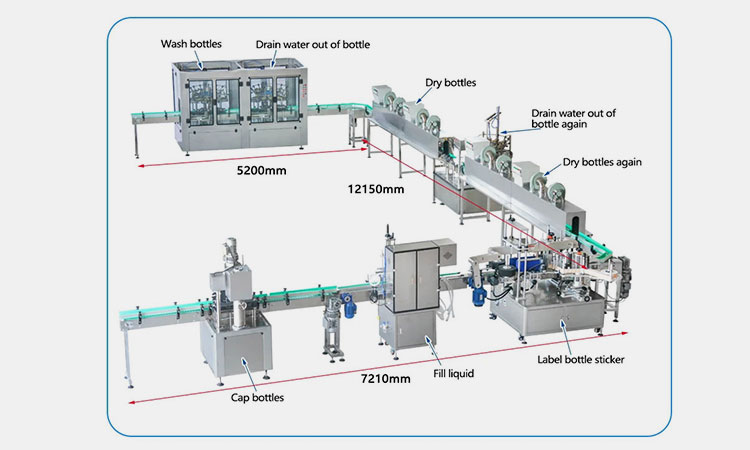

What Are The Different Parts Of Wine Beverage Bottling Line-sourced: zonesun

Through learning the different parts of wine beverage bottling line, you may know their precise filling and high efficiency for your good production. The different parts of wine beverage bottling line are:

Different Parts Of Wine Beverage Bottling Line-sourced: zonesun

Bottle Unscrambler

The automatic bottle unscrambler has a large stacking table, which can automatically sort your bottles to be washed and dried onto the conveyor belt sorting table. Through the rotation of the sorting table, the wine bottles can maintain a certain distance from each other and be transferred to the automatic bottle rinsing machine.

Automatic Bottle Rinsing Machine

The automatic bottle rinsing machine is mainly applied for washing bottles and draining water out of bottle. There are stacking tables at the entrance and exit of the automatic bottle washing machine, which can help you pick and place wine bottles online and offline.

Bottle Drying Tunnel

The bottle drying tunnel is used for draining and drying the water from inside and outside the bottles. This can keep the product in a sterile environment during the filling process and maintain product quality.

Bottle Sticker Labeler

After the bottles have been dried, the bottle orientation system helps rotate the bottles to avoid placing labels on the bottle's welds, ensuring highly consistent, flawless packaging. The bottle sticker labeler is mainly used for labeling your bottles. It can be placed in front or behind the filling machine according to your production needs.

Automatic Liquid Filling Machine

Depending on the type and viscosity of your own products, as well as filling speed and automation requirements, you can choose different liquid filling machines. If it is alcohol or liquid, you can use gravity liquid filler, pressure liquid filler, or overflow liquid filler. They can all guarantee your filling speed and filling accuracy.

Capping Machine

The capping machine is also called closure system. It is primarily responsible for keeping the lids securely on your bottles and preventing any potential leaks.

7.Are There Different Wine Beverage Bottling Fillers For The Whole Line?

There are various fillers for your wine beverage bottling line, including:

Semi-automatic Filler Types

Semi-automatic Paste Filling Machine

ALLPACK Semi Automatic Paste Filling Machine

The semi-automatic paste filling machine mainly performs bottle filling of liquid and paste through cylinder-driven piston pumping. It is mainly suitable for your filling high-concentration pastes and sauces. And the paste filling machine can be equipped with different filling containers, mainly including bottles, fillings and bags.

Vacuum Filler

Vacuum Filler-sourced: vkpak

The vacuum filler is primarily used to fill oxygen-sensitive products such as wine and beer by creating a vacuum inside the bottle and then drawing the product into the bottle. It mainly consists of product hopper, filling nozzle, vacuum pump and control system.

Pressure Filler

Pressure Filler-sourced: vkpak

The pressure filler mainly uses a pump to create a pressure difference between the filling material and the product, and then causes the product to flow into the bottle. It is widely used for filling your products with higher viscosity, such as sauces, syrups, honey, ketchup and oils.

Automatic Filler Types

Gravity Filler

Gravity Filler-sourced: vkpak

The gravity filler mainly uses gravity to fill products into bottles. It mainly relies on the weight of the product you need to fill to move the material into the filling container. It is mainly suitable for free-flowing products such as water, juice and wine. Gravity filling machines usually consist of product hoppers, filling nozzles and control systems.

Overflow Filler

Overflow Filler-sourced: vkpak

The overflow filler adds product to the bottle up to a certain level and then drains the excess. The way it works is ideal for products that are suitable for foaming or require very precise filling levels. It ensures that every bottle is filled to the same level.

Pump Filler

Pump Filler-sourced: vkpak

The pump filler is driven by a servo motor to fill liquid or paste, and a high-precision stainless steel rotor pump is used to measure the liquid capacity. It has a very wide range of filling products with high precision, simple equipment structure, simple operation and easy maintenance.

8.What Is The Working Process Of Wine Beverage Bottling Line?

Working Process Of Wine Beverage Bottling Line-sourced: pestopack

Bottle Rinsing and Cleaning

The first step in wine beverage bottling is cleaning, which is a basic element to ensure your product hygiene. This bottling line is equipped with advanced cleaning agents and automated cleaning systems that work together to disinfect bottling equipment and containers to meet the hygiene standards required by the industry.

Bottle Unscrambling

When filling bottles are cleaned and disinfected, they will be transferred to the bottle unscrambler via the conveyor belt, where they will be sorted and arranged to facilitate the subsequent filling process.

Bottle Filling

The wine beverage bottling line can provide you with the highest precision liquid filling. It can also adjust different filling equipment according to your product type to provide you with high-precision liquid measurement and distribution. It minimizes your product waste.

Bottle Capping

Bottle capping is primarily responsible for securely capping your bottles and preventing any potential leaks. By utilizing torque sensors, the bottle capping is able to tighten bottle caps to the level of precision required to maintain the highest quality standards.

Bottle Labeling

The main purpose of labels is to provide users or you with product-related information, and it can also achieve a certain level of aesthetics, thereby attracting customers to make additional purchases. With high-speed labeling machines equipped with cutting-edge technology, it gives you clean, beautiful labels while promoting your brand.

Quality Control

Through an automatic inspection system equipped with cameras and sensors, the quality control system will carefully check the details of each bottle filling, capping and labeling to ensure the high quality of your products.

Package

Products that have passed quality inspection and control will enter the packaging process. By optimizing material use, reducing waste and minimizing environmental impact, you can use environmentally friendly materials for product packaging, improving the efficiency and sustainability of the wine beverage bottling.

Palletizing

The final step in the wine beverage bottling line is palletizing. It helps your products be professionally stacked and ready for distribution.

9.Are There Any Wine Beverage Bottling Tools And Accessories For Your Choice?

The wine beverage bottling line is a delicate and complex project. It can add or reduce different accessories or tools according to your product filling needs. Let's take a look at the following!

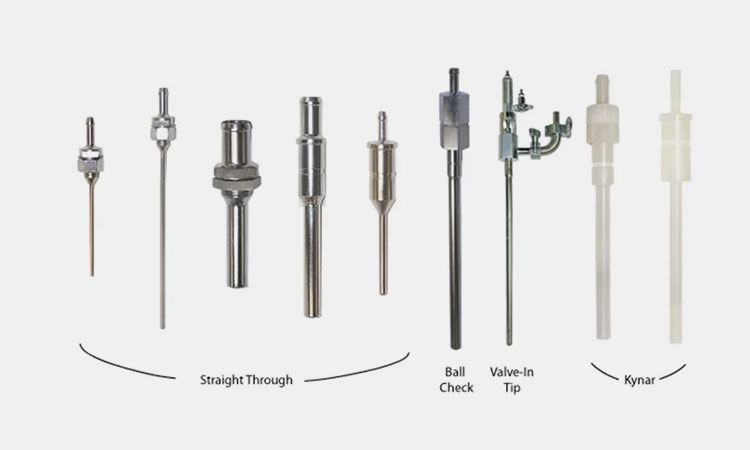

Filling Nozzles

Filling Nozzles-sourced: vkpak

The filling nozzles are machine parts specifically responsible for dispensing product into bottles. Different filling nozzles are suitable for filling different kinds of products. It is very important to equip the nozzle suitable for your product according to your own needs.

Conveyor

Conveyor-sourced: redlinesystems

A customized and efficient conveyor can bring great help to your wine beverage bottling line. It helps you move moving bottles along the production line and below the filling nozzle. The speed and frequency of movement are both adjustable.

Corking Machine

Corking Machine-sourced: apacks

Most wines such as red wine or champagne require a cork for sealing and then final capping. Therefore, if you have this kind of demand, you can set up a corking machine behind the filling machine to add corks to the bottles.

Case Packers

Case Packers-sourced: wayneautomation

After wine and beverage bottles are filled, capped, and well labeled, they also need the carton packaging for future storage and transportation. You need a case packer to help you arrange and fill bottles into the cases and carton boxes.

10.What Are The Challenges And Solutions Of Wine Beverage Bottling Line?

Challenges And Solutions-sourced: betterplace

There still are common challenges during the bottling line operation and working process. They are:

| No. | Challenges | Solutions |

| 1 | l Maintain consistency in product filling accuracy and quality; | l By installing an advanced vision system for filling and scanning, the filling height of bottles can be checked; |

| 2 | l Achieve higher filling accuracy and speed; | l Minimize downtime, use automated systems and real-time data monitoring as much as possible; |

| 3 | l The complexity of filling products with higher alcohol content; | l Alcoholic products with higher alcohol content. Remove as much oxygen as possible before bottling and add safety precautions; |

| 4 | l Proper maintenance; | l Check equipment, lubrication points and cleaning systems weekly; |

| 5 | l Ensuring health and safety standards; | l Try to use solutions that are efficient, precise and hygienic; |

11.How To Troubleshoot And Maintain The Wine Beverage Bottling Line?

Troubleshooting-sourced: wavex

The Wine Beverage Bottling Line Troubleshooting:

| No. | Problems | Solutions |

| 1 | Leakages | l Bottles loaded incorrectly or nozzles or valves clogged;

l Clean and check the nozzles or valves of the equipment in a timely manner; |

| 2 | Incorrect Filling Levels | l Need to calibrate the machine's nozzles;

l Adjust the speed and position of the conveyor belt; |

| 3 | Jamming | l The bottles may be loaded incorrectly, or the nozzles may be clogged;

l Adjust conveyor and bottle loading system; l Clean up the filling nozzles; |

| 4 | Electrical Issues | l It could be because the air filter is clogged or the air compressor is not working properly;

l Check and adjust air filters and compressors promptly; l Regularly maintain and regulate air filters and compressors; |

Maintaining-sourced: realpropertymanagementsaltlakecity

The Wine Beverage Bottling Line Maintaining:

| No. | Items | Techniques |

| 1 | Cleaning | l Regularly remove any product residue and prevent contamination;

l Regularly disassemble worn parts of the machine for inspection and replacement; l Clean machines weekly; |

| 2 | Lubrication | l The moving parts of the machine, such as gears and bearings, should be lubricated regularly to ensure smooth operation and prevent wear; |

| 3 | Inspection | l Machine calibration is performed once a month to ensure it dispenses the correct amount of product; |

| 4 | Pneumatic and Hydraulic Systems | l Be sure to inspect and maintain the machine's pneumatic and hydraulic systems in accordance with the manufacturer's instructions and instructions; |

12.Things To Consider Before You Purchasing A Wine Beverage Bottling Line

Your Bottling Requirements

Your Bottling Requirements-sourced: nytimes

Determine your own bottling requirements, including filling product type, filling speed, filling capacity, filling type, closure type, package type, type of filling container, degree of automation, whether manual labor is required, etc. Determine the model of wine beverage bottling line you need based on your own various needs.

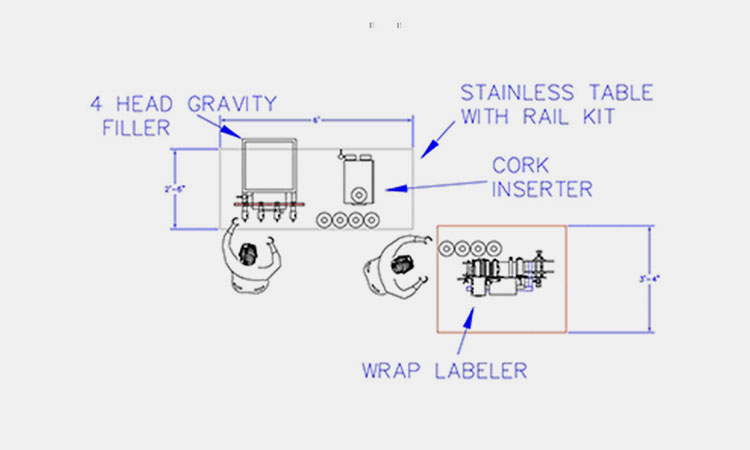

Space and Layout

Space and Layout-sourced: apacks

In addition to ensuring the quality and efficiency of the equipment itself, the layout and space occupied by the equipment itself are also a test. You will need to investigate the space and layout of the equipment's electrical and compressed air connections, such as ceiling heights, columns or revolving doors.

Budget and Scalability

Budget and Scalability-sourced: alabama

You need to evaluate your upfront costs, and then consider the machine model and productivity you need based on your equipment space layout and equipment costs, as well as subsequent equipment productivity and future expansion potential.

Technical Support

Technical Support-sourced: flexjobs

A good wine beverage bottling line equipment manufacturer, in addition to providing you with technical support and maintenance services that may sometimes be needed for the capping and filling production line, can also provide you with lifelong counting support and personnel training services.

Applicability

It is important to have a wine beverage bottling line that is compatible with your other equipment and can be integrated into the line. It improves the utilization and efficiency of your equipment.

Conclusion:

Through this complete buying guide of wine beverage bottling line, you may get the differences between them and the other bottling line. When you invest in a wine beverage bottling production line, it is also very important to find a supplier with a good reputation for product quality and reliability. If you have any expectations for cooperation, you are welcome to consult us anytime!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide