White Sugar Stick Packing Machine: The Complete Buying Guide In 2025

The crystalized white sugar is used in every second product which we consume on daily basis encompassing a cup of tea, coffee, dessert, cookies, and chocolate. Similarly, we don't want to miss these essentials even during traveling and when on work desk. Therefore, a White Sugar Stick Packing Machine is designed to supply you with beautifully packed white sugar stick packs.

This machine is automatic in technology and has efficient performance with wide applicability. It suits the vary needs of industries and is available in multiple types. You can get benefits from using it by simply knowing in depth its features, working process, structure, and maintenance etc., which are all provided below. So, take start and read it thoroughly!

1.What Is White Sugar Stick Packing Machine?

Allpack- APK-220 Automatic Vertical single lane sugar stick packing machine

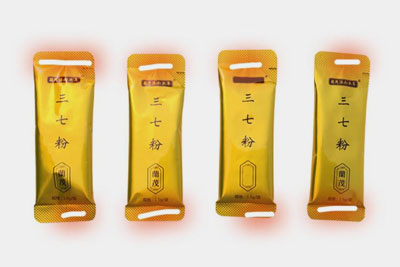

To know about a white sugar stick packing machine, it is important to have a brief information about what white sugar stick pack is. It refers to the single serving, small, tubular stick pack inside which a precise amount of white sugar is encased for user convenience. Similarly, a machine which pack such bags is known as white sugar stick packing machine.

It is an electromechanical machine which perform white sugar stick packing task by independently forming stick packs from a layer of film, filling these packs with desired sugar amount, and adding a secure seal to the openings. Since, the machine is food grade, automatic, and has an enclosed body, the material being processed is completely safe and have a longer shelf life.

2.Explain The Benefits Of A White Sugar Stick Packing Machine?

As white sugar stick packing machine is automatic and adaptable, you can get myriad of benefits from it after knowing its features. So, let's know some of these in detail:

Efficient Performance

Efficient performance- Picture Courtesy: chengyipacking.com

Keeping in view the growing demand of manufactures associated with high output, white sugar stick packing machine is made with automatic technology. It undertakes all the processes of sugar stick packing from bag formation to finishing.

Advanced Design

Allpack- APK-220 Automatic Vertical single lane sugar stick packing machine

The design of machine is most advance with all parts being made from quality material including stainless steel body, user-friendly touch screen, and multiple forming, filling, and sealing units fitted in one line for simple operation.

Safety Features

Emergency stop- Picture Courtesy: blog-ansi.com

White sugar stick packing machine has numerous safety features for both product and operator safety. In this way, emergency stop, film-end alarming, and alarm light are fixed in the machine for user, while as, corrosion resistant stainless steel, transparent window, and sensors help dealing with material waste and its quality protection.

Accurate Packaging

Sugar stick packs- Picture Courtesy: Behance

Another most significant attributes of a white sugar stick packing machine is the it maintain high accuracy in terms of packaging. With specialized filling system, sealing system, and detection mechanism, it discharges exact amount of sugar and pack all bags by creating strong sealing.

Highly Adaptable

Multiple stick packs holding different materials- Picture Courtesy: blog.invpack.com

White sugar stick packing machine is known for its utmost resilience to pack range of materials along with sugar such as instant coffee, milk powder, protein powder, and condiments etc. Moreover, it can produce eclectic style stick packs with vibrant sealing and cutting which enhance the packaging charm in the eyes of customers.

3.What Stick Packing Options re Offered By A White Sugar Stick Packing Machine?

Well, a white sugar stick packing machine deals with the implementation of different packaging styles. These are highlighted below:

Seal Shape Options

Stick packs with side neck seal- Picture Courtesy: yellowimages.com

Although, the standard shape of stick pack is determined by its tubular design, however, sugar stick packs can be formed in multiple shapes through the sealing options of a white sugar stick packing machine. For example, the machine can create side-neck, straight, rounded neck, and central neck shape sugar stick packs. It can also form stick packs in beautiful irregular shape.

Seal Side Options

Back side sealed sugar stick packs- Picture Courtesy: Creating a Storm

The number and side of seal also affect the white sugar stick packs look. In this way, a white sugar stick packing machine is capable of making 3 side seal stick packs, 4 side seal stick packs, and back side seal stick packs.

Cut Type Options

Zigzag cut stick packs- Picture Courtesy: creativemarket.com

It refers to the type of cutting being made on sugar stick packs after they get sealed. So, depending upon the type of cutting blades fitted in a white sugar stick packing machine, you can have zigzag cut, flat cut, round cut, or any special shape cut on your sugar stick packs.

Seal Type Options

Square sealed white sugar stick pack- Picture Courtesy: earlyyearsresources.com

In addition to cut type option, white sugar stick packing machine support the sealing of eclectic designs on stick packs. In this way, some of the notable examples of stick pack seal options include diamond, serrated, linear, and square etc.

Easy-Open Options

Easy tear stick pack- Picture Courtesy: youniqueproducts.com

When customized, the machine can add Easy-Open options to sealed sugar stick packs for convenient opening such as tear notch, micro-perforation, and v-cut etc.

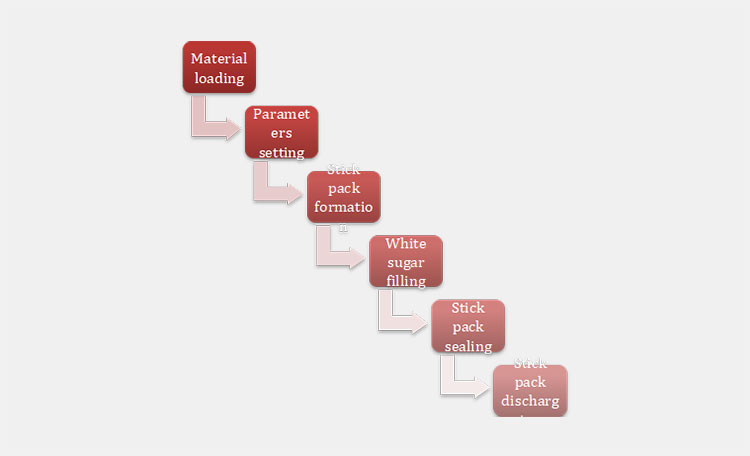

4.What Are The Working Principles Of A White Sugar Stick Packing Machine?

A white sugar stick packing machine is extremely profitable for your business, if you operate it in a right way. So, what's the right way for operating it? It's simple! You just need to follow the underlying working principles:

Material Loading

So, the very first step required for operating a white sugar stick packing machine is the feeding of machine with sufficient amount of white sugar powder or granules. For this, you need to pour the sugar inside hopper and make sure to leave at least 1/3 part of the hopper empty for smooth working.

Parameters Setting

Parameters setting- Picture Courtesy: chengyipacking.com

Once the hopper gets loaded, the second step you will take is to set the basic parameters of the machine regarding amount of sugar for single stick pack, the size and length of stick packs, and temperature of heat sealing jaws etc. Along with this, have a look towards the external setting of machine for maintaining structural adjustment.

Stick Pack Formation

Stick pack formation- Picture Courtesy: chengyipacking.com

Now, the actual process of machine begin with turning it on. As soon as the machine is switched on, the motor will energize different parts of machine for undertaking associated tasks. Here, the initial step is stick pack formation when the film reel fitted into film roll frame start unfurling and is guided by various pulleys. Similarly, this film is turned into multiple stick packs by cutting and sealing.

White Sugar Filling

White sugar filling- Picture Courtesy: chengyipacking.com

Upon stick pack formation, the next principle is white sugar filling. During this phase, firstly, sugar is weighed inside the hopper and adjoined weighing pump or measuring cups through constant rotation of an auger filler. Afterwards, the precisely weighed amount of white sugar is delivered into multiple individual stick packs.

Stick Packs Sealing

Stick pack sealing- Picture Courtesy: chengyipacking.com

Once filled, the white sugar stick packs will be tightly sealed with the help of heated sealing jaws. This sealing is horizontal which close the opening of stick packs. When sealing is introduced to stick packs, these stick packs are then separated from one another through cutting blades

Stick Packs Discharging

Stick packs discharging- Picture Courtesy: chengyipacking.com

At the end, when white sugar stick packs are ready to use, they are discharged from the machine and processed for further packaging, so, as to display on the shores of the shelves.

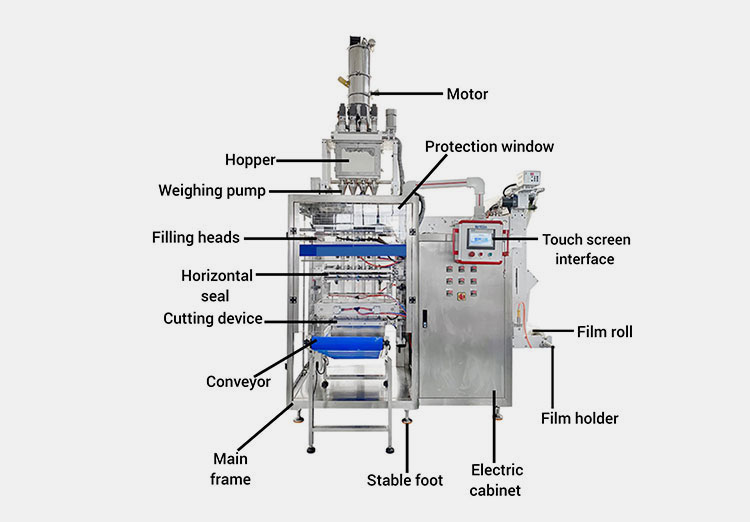

5.Describe The Components Of A White Sugar Stick Packing Machine?

White sugar stick packing machine is composed of several small to large components. Each part performs a specific roll to make the white sugar stick packing possible. All of these components are explained below in detail:

Components of Multi-lane four sides sealed packaging machine- Picture Courtesy: samfull.net

Motor

Motor is one of the crucial parts of a white sugar stick packing machine situated on machine top. Its function is to energize various parts of machine by providing power force. In addition, it is the motor which regulates the auger shaft movement inside hopper, the unwinding of film, weighing pump, and sealing etc.

Hopper

Another part of machine is hopper which is also located on the top of machine for the purpose of supplying sugar during operation. Therefore, large amount of white sugar is placed in hopper before starting the machine.

Weighing Pump

Weighing pump is one of the critical parts of the machine which is integrated to the machine in a way that it is connected with the hopper on upper side, while as, to that of filling heads on the bottom side. Its main function is to measure the amount of sugar as fixed by the operator and then deliver it to filling heads.

Filling Heads

Filling heads are stainless steel tubes through which weighed white sugar is transported from the weighing pump into the formed stick packs.

Horizontal Seal

It is a part of machine characterized by the combination of two sealing jaws. These sealing jaws, when come together holding between them the film, create strong sealing. Thus, the task of horizontal seal is to create the top and bottom sealing of white sugar stick packs.

Cutting Device

Cutting device is yet another tool of the machine known by its sharp blades. The number of cutting blades vary from one type of machine to another such as single lane machine only has one cutting device which is used to split the finished packages. On the other hand, multi-lane machine has dual cutting tool segments: one for dividing single film layer into many small films and the other for separating final stick packs.

Conveyor

Conveyor is an auxiliary device attached to the main machine for assisting in finished stick packs transportation from the machine towards discharging or further packaging.

Main Frame

Main frame refers to the supporting structure of machine. It is made from stainless steel and keep the machine running smooth.

Stable Foot

White sugar stick packing machine has multiple foot attached to its lower body through which it stands stable on surface.

Electric Cabinet

It is an electric enclosure that encases the electrical components of machine including wires, fuses, and switches etc.

Film Holder

Film holder is a device attached to the machine where a film stock is supplied to the machine by fitting into film holder. When machine is started, the film rolls over holder begin unwinding.

Film Roll

Film roll is a stock of film layer rolled in form of a reel. It is an important part of a white sugar stick packing machine which enable the machine to form individual stick packs by unrolling the film.

Touch Screen Interface

It refers to the control unit of a machine through which you can set up commands in machine by contacting this part. Touch screen interface will provide you with multiple options for getting the amount of white sugar for each pack, number of stick packs, and sealing heat etc.

Protection Window

Protection window is a transparent window fitted into the machine. It keeps the ongoing process of white sugar stick packing free from dust and pollution while allowing user to observe the operation easily.

6.What Is The Classification Of A White Sugar Stick Packing Machine?

White sugar stick packing machine can be classified into two types which are explained below:

Single Lane White Sugar Stick Packing Machine

Allpack- APK-220 Automatic Vertical single lane sugar stick packing machine

Single lane white sugar stick packing machine is automatic machine that comes with single lanes for sugar stick packing. This machine by Allpack can be customized and another lane can be added for efficiency. Moreover, it has a small footprint with easy-to-use operation, and easy cleaning, and maintenance. It is cost-effective and suitable for small to medium level enterprises.

Structure

The structure of machine is compact and cover less space. It is characterized by a single lane solely responsible for stick pack forming, filling, and sealing.

Working Principles

To operate this machine, user is required to load the hopper of machine and set machine. Afterwards, bag forming, filling, sealing, and cutting is done automatically by using the single vertical lane. In the end, machine will discharge the finished stick packs.

Multi-lane White Sugar Stick Packing Machine

Allpack- APK 6-480 Multilane stick packing machine for granule

Multi-lane white sugar stick packing machine is high power, fully automatic machine that is featured with multiple lanes for meeting high production targets. That's why, it is a bit expensive but can benefit your business by extending production. The machine support eclectic designs and formats for stick packing through employing different types of sealing and cutting.

Structure

The machine adopts modular design with many parts accommodating automatic changeover for performing different functions. Overall, its body is vertical, complex, and compact with all parts interconnected.

Working Principles

It follows a simple working procedure where single film layer is turned into multiple stick packs by folding the film and creating a bottom and side seal. Afterwards, these packs are filled, sealed, and disjoined.

7.Where Can A White Sugar Stick Packing Machine Be Employed?

A white sugar stick packing machine can be used anywhere where there is processing and packaging of powders and granules especially in single serving stick packs. In this way, few prominent industries are highlighted below:

Sugar Processing Industry

White sugar presentation idea- Picture Courtesy: drhyman.com

Sugar processing industry is an area where sugar is produced and also packed. Similarly, places where sugar is required in single serving stick packs like hotels, restaurants, and aeroplane etc., manufacturers used to pack sugar in stick packs. Thus,a white sugar stick packing machine is relevant here.

Coffee Processing Industry

Various instant coffee stick packs

Another application of a white sugar stick packing machine is coffee processing industry. As coffee is popular among masses, people like to carry a small handy bag of instant coffee wherever they go. That's why, this machine is perfect in meeting this growing demand with its super efficient performance.

Condiments Industry

Spices stick packs- Picture Courtesy: packagingoftheworld.com

Different types of condiments and dressings like pepper, salt, chilli powder, and instant noodle seasonings are often delivered in small quantity for which the use of a white sugar stick packing machine is realized.

Confectionery Industry

Sugar confectioneries- Picture Courtesy: legionathletics.com

Confectionery industry is an area where range of sugar based products are processed like candies, bubble gum, and chocolate etc. Therefore, a white sugar stick packing machine can be simply employed here to pack powered and granulated gum, milk powder, chocolate chips, and other confectioneries.

Nutraceucal Industry

Protein collagen powder stick packs- Picture Courtesy: popsugar.com

To restrict the side effects of high dosage medication, medical industry is now promoting the use of nutraceuticals against pharmaceuticals. Therefore, most of the valuable extracts are gathered in form of powders and granules. To process them, nutraceucal industry is taking help of a white sugar stick packing machine.

Beauty Care Industry

Vanilla beauty plant based collagen stick pack- Picture Courtesy: copinaco.com

Among other sectors, beauty care industry is the notable one. Many cosmetic products like bleach powder, hair dye, facial powder, and wax granules are the common examples of materials which can be packed in stick packs by using a white sugar stick packing machine.

8.What Are The Cleaning And Maintenance Requirements Of A White Sugar Stick Packing Machine?

To enable your white sugar stick packing machine function for a longer period of time, it is essential to take measures on regular basis for its cleaning and maintenance. It is simple to do, you need to follow underlying guidelines:

Maintenance of machine- Picture Courtesy: twi-global.com

Cleaning:To ensure that your machine process white sugar stick packs efficiently and precisely, cleaning is inevitable. In this way, it is very important to conduct a regular cleaning for your machine.

Only use the cleaning products which are recommend by the manufacturer such as type of detergent, water, and cleaning method. During cleaning, take care of removing all the residues and dust from both internal and external parts.

Maintenance:Keep the machine maintained by adjusting its structural parts and tight the nuts and screws properly. Apart from structural adjustment, it is very essential to regularly set the internal setting of machine like its weighing quantity and stick packs length and size etc.

Lubrication:Keep lubricating your white sugar stick packing machine to avoid any kind of friction, wear and tear. However, make sure to use the type of grease and oil which is suggested by the vendor.

Parts Changeover:When operating a white sugar stick packing machine for longer, there may a time come when anyone of its parts or tool become damage or out of order. In such a case, it is very important to change that part on time or it will cause machine malfunctioning and will affect other parts.

9.Troubleshoot The Common Errors Of A White Sugar Stick Packing Machine?

You may experience difficulties or failures with your white sugar stick packing machine during operation. However, it is possible to troubleshoot these issues with much ease. You simply need to understand the problem, its causes, and then apply a solution. Consider the table below for detailed information:

| i. Inaccurate sealing | ||

Highlighting inaccurate sealing of stick packs- Picture Courtesy: chengyipacking.com |

Cause:

Damaged or disconnected sealing bar wire. Too low temperature Loose sealing jaws. Sealing jaws are untidy. |

Solution:

Replace the wire with new suitable one or connect it to electricity accurately. Increase the temperature of sealing bars to desirable level. Tight the sealing jaws. Clean the sealing jaws. |

| ii. Filling inconsistencies | ||

Encircled filling nozzles- Picture Courtesy: landpack.com |

Cause:

Incompatible filling system for sugar. Accumulated of debris in filling head. Low time duration for stick pack filling. |

Solution:

Use the right type of filling system for machine. Clean the filling nozzle. Increase the time duration for filling each stick pack. |

| iii. Stick packs leaking | ||

Leak stick pack- Picture Courtesy: Freepik |

Cause:

Stick packs are not sealed properly. Stick packs are separated through wrong cutting. |

Solution:

Adjust the temperature of sealing jaws and adjust its structure by tightening screws. Adjust the distance between sealing jaws and cutting blades. |

| iv. Variations in stick packs sizes | ||

Variation in stick packs sizes- Picture Courtesy: chengyipacking.com |

Cause:

Faulty data setting in machine regarding stick packs width and length. Unparallel positioning of stick pack forming and separating tools. |

Solution:

Set the right data in machine regarding stick packs sizes with the help of control unit. Position these stick pack forming and cutting units. |

| v. The film is unwinding inaccurately | ||

Displaying film unwinding error- Picture Courtesy: samfull.net |

Cause:

Unparallel dancer's arm and film unwinding wheels. Wrongly positioned film roll. Excessive tension of film holder. |

Solution:

Position the dancer's arm and film unfurling wheels in a way that both are parallel to each other. Release the tension of film holder. |

10.Tips For Choosing The Best White Sugar Stick Packing Machine?

Every manufacturer strives for having the best machine and products at their disposal. Similar is the case with a white sugar stick packing machine which is favored by many entrepreneurs. However, getting the right machine is not a child's play. So, what you need to do is to consider some factors and make sure to purchase the outstanding machine. In this way, below tips will be helpful:

Check Machine Specifications

Checking the different specifications of a white sugar stick packing machine is the most important thing to do. It will simply include looking into the sealing jaws, cutting system, forming mechanism, and optional printing system.

Examine Efficiency

Multiple coffee stick packs- Picture Courtesy: chengyipacking.com

Another vital tip for selecting the right machine is to consider its production rate per minute or per hour. After all, you are about to extend your manufacturing. In such a case, you are bound to ask the vendor for efficient machine. In addition, the efficiency of machine also depends upon its type such as single lane machine can pack 40 bags per minute, while as, multi-lane machine can pack 240 bags in just a minute.

Customization

Consumer pouring white sugar in tea- Picture Courtesy: chengyipacking.com

Customization is another crucial aspect to be paid heed for. It means to check the machine's adaptability to support different stick packing designs in cutting and sealing. Also check if the machine can process both powder and granulated products with all distinct properties.

Quality Certification

FDA quality standard icon- Picture Courtesy: reuters.com

White sugar stick packing machine which you want to purchase should be of high quality. But how will you know that? It can be known simply by checking the machine's certifications which are given by national and international quality standards including GMP, FDA, and ISO etc.

11.What Are The Future Prospects For A White Sugar Stick Packing Machine?

Future icon- Picture Courtesy: clipart-library.com

The world has entered in a phase where every second person aim for getting readymade products even for regular consumer goods such as tea, coffee, and meal etc. In such a case, the business of eatable things is on rise which has a direct impact on the rise in demand for relevant packaging machines.

Similarly, white sugar stick packing machine is among one of them. Its need is realized, and its role is admired on small to large scale manufacturing facilities. So, the future trends for a white sugar stick packing machine are promising. Customers are looking for more customized packaging for which this machine is fully updated.

Conclusion

To wrap up, this buying guide about a a white sugar stick packing machine is a comprehensive one that has covered essential details about the machine. We hope it has enlightened your knowledge regarding the significance of stick packing especially in food sector. Besides this, the machine is fulfilling all the prerequisites for being an efficient, hygienic, and automatic one. So, be ready to buy a new sophisticated white sugar stick packing machine offered by Allpack which is a mark of sophisticated technology and come up with one year of long warranty. Stay in contact with us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide