What’s V Blender Working Principle?

Searching out for the detailed working mechanism of V blender? That's great! You have finally landed on the relevant page! Purchasing a sophisticated and advanced V blender is not a surety for its successful performance but operating it on right working principles does assure its optimal production output. You might be wondering What's V Blender Working Principle? Well, the answer is pretty easy.

You just need to give this blogpost a thorough review which will disclose the V blender working principle along with construction design and features. Not only it will enable you to understand the V blender working mechanism but to operate it by yourself. So, make sure to not miss this piece of writing!

1.What Is V Blender?

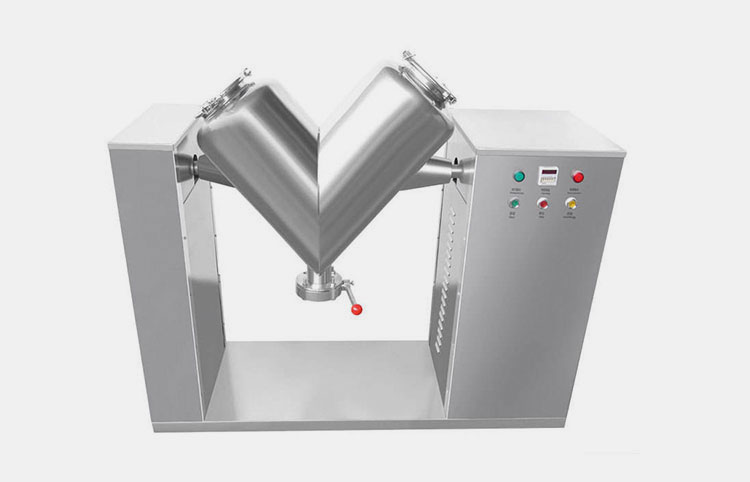

Allpack- VH-50 V type mixer

V blender is a type of tumble mixer which is characterized by its V shape. It is employed for the mixing and blending of solid-solid substances such as powders and granules. The blender has twin shells which meet at about 80 to 90 degree, making a V shape.

It is made up of quality stainless steel with low shearing tools to best deal with soft to hard materials. As the need for mixing powders and granules is inevitable in almost every sector whether pharmaceutical, food, cosmetic, and chemical industry, the blender can be a perfect equipment to safely and efficiently produce uniform mixture.

2.Enumerate The Advantages Of A V Blender?

V blender carries with it substantial benefits which ultimately leads to the enhancement of its value in almost every sector that is directly or indirectly engaged in powder processing. Below we have highlighted few notable advantages which every V blender possess:

Precise Structure

Allpack- V blender VH-2 mixer

The utmost benefit of V blender is its alluring and beautiful design made up of twin shells. The blender is extremely convenient to handle with its precise structure and simple design. Moreover, you can use separate inlets for pouring two different types of materials and get them out through a single outlet.

Enhanced Safety

Fine powder handled in aseptic environment

V blender offers your product extra level safety with its quality stainless steel body which is fully safe against corrosion and bacteria. In addition to it, the absence of sharp blades make it more feasible to process powders which are not suitable for particles size minimization.

Wide Application

Various types of powders

Every manufacturer has a desire to buy a machine which can deal with as many materials as they want. This theory can be simply applied to V blender which is perfectly suitable to process all kinds of sterile to hard substances such as sensitive medicine powder and abrasive chemicals.

Feasibility of Usage

Operator using machine

V blender offers intensive convenience in its usage as well as maintenance. The unprocessed ingredients can be simply added into the twin shell via individual infeed unit to avoid contamination. Similarly, the discharging of finished mixture is also very easily done.

Accuracy

Precisely blended powders- Picture Courtesy: trail.recipes

It maintains high accuracy in terms of blending various materials by breaking down the lumps through effective paddle rotation. Along with that, it avoid deformation of substances. Eventually, it produces uniform mixture where each particle is a manifestation of fine blending.

3.What's V Blender Working Principle?

V blender follows extremely easy working principles for conducting its operation. They can be easily understand by looking into the underlying steps:

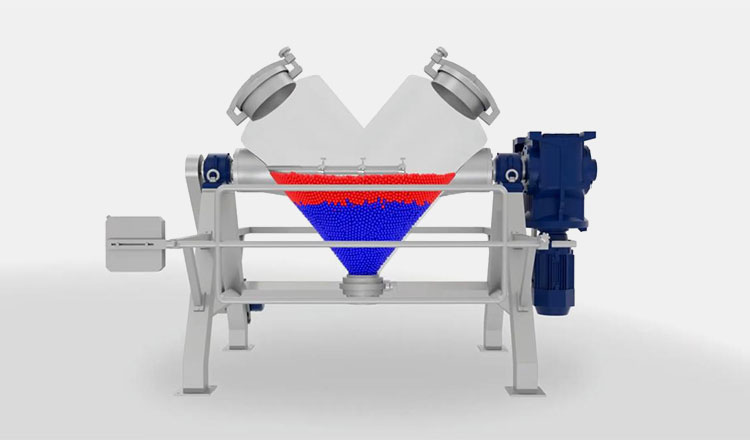

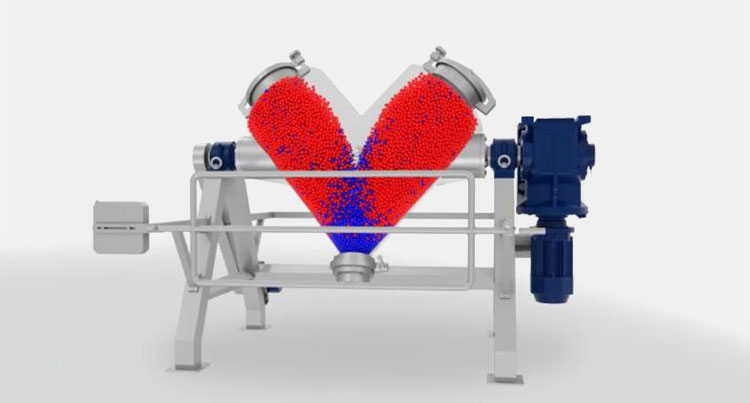

Working process of V blender- Picture Courtesy: PerMix

Material Loading

The first step simply involves loading of material into the V shell. It is done by using separate infeed units. While loading the V blender, make sure to keep 40 to 50 percent area of the vessel empty as it will help in the efficient and effective blending. After loading material, close the opening of vessels.

Blender Setting

Now, the setting of V blender is supposed to carried out. It will include the setting of machine parameters such as the time for each cycle, speed of the paddle, and number of revolution per minute. Usually, the speed of V blender is anywhere from 10 to 25 rotation of vessel per minute.

Blender Rotation

Once the setting is completed, V blender is ready to be started. As soon as the blender is powered on, the v shell vessel begin revolution at 360°. This constant rotation of the V shell lead the inside content to fall back and forth for mixing. The repeated movement of substances towards and away from the center of the shell result in the homogeneous blending. After fixed time is passed, the vessel stop rotation.

Material Discharging

At the end, well blended mixture is ready to be discharged by the machine. It can be discharged either manually by opening the butterfly valve or controlled pneumatically.

4.How Would You Describe The Construction Of A V Blender?

V blender is composed of several components which together form its construction. These primary parts are described below:

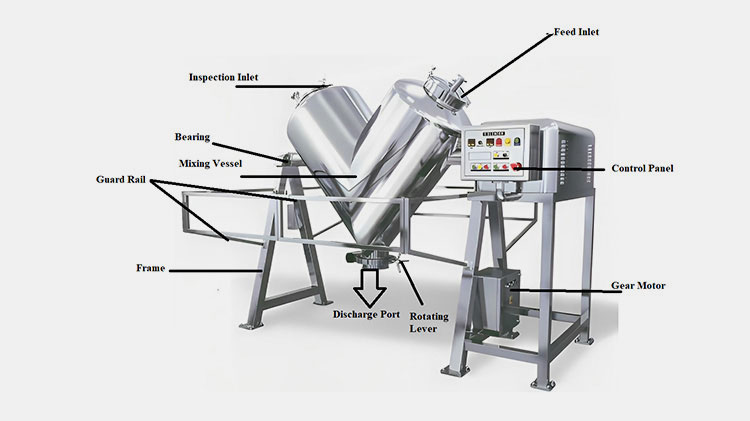

Construction of a V Blender

Feed Inlet

Feed inlet is an opening over the V shell which is used to feed the material into vessel. The material can be supplied either manually or by connecting the feeding system in case of large vessel.

Inspection Inlet

Inspection inlet is another opening of the twin shell which can also be used for feeding. However, in most cases it is used for the inspection of material fed and the cleaning and maintenance of vessel.

Bearing

Bearing is also called sprockets which connect the V shell with side frame. It thus helps in the consistent rotation of vessel as well as the movement of paddle inside V shell.

Mixing Vessel

Mixing vessel is also known as V shell due to its shape. It is composed of two shells which join together at single point leading to the creation of V shape vessel. Inside it, there is a paddle which rotates during operation to break the lumps and blend ingredients. This part of V blender play instrumental role in the overall blending process.

Control Panel

Control panel is considered the brain of V blender which a computer like device that display over it multiple data information. It has various buttons, indicators, and sensors which together help in the controlling of V blender working. Operator fix the speed and time of rotation via control panel.

Gear Motor

Gear motor is located in the support part of the V blender. It is run by electricity after which it energizes the vessel through mechanization.

Discharge Port

Discharge port is located at the end of V blender where twin shell meet. It is regulated by a butterfly valve to discharge the finished mixture. Thus, the separate discharge ports help in the contamination-free flow of material.

Rotating Lever

It is attached to the discharge port for its closing and opening.

Guard Rail

Most of the medium to large size V blenders have an integrated guard rail system which is attached to ensure operator safety against electricity during operation.

Frame

The main frame of blender is made up of corrosion resistant stainless steel. It constitutes the lateral area, supporting stand, and other such parts.

5.What Are The Uses Of A V Blender?

A V blender is capable of processing wide range of materials in food and non food sector. Some of the prominent uses of a V blender are enlisted below:

Condiments Industry

Large number of seasoning bottles- Picture Courtesy: godairyfree.org

Condiments and spices are often blended to create new type of seasonings. However, their spicy nature is hazardous for human health if get into the nose or eyes. That's why, to eliminate their possible flow into air, V blender is always preferred to carry out the safe blending task in an enclosed environment.

Baking Industry

Baking industry- Picture Courtesy: itfaq.global

Baking industry is also among the users of V blender as baking involves the mixing of several powdery materials. Since, it is not possible to manually mix large volume of substances, V blender is a good choice. Moreover, the flour and other such ingredients used in baking are often lumpy due to long time storage for which the processing of V blender is essential.

Pharmaceutical Industry

Various capsules with powder formulation

All kinds of solid dosage including tablets, capsules, and pills, granules and powders are inevitable. Now, these ingredients are collected to form a uniform mixture for which V blender is perfectly suitable as it can better deal with sensitive particles.

Cosmetic Industry

Various cosmetics- Picture Courtesy: sephora.com

Among other areas, cosmetic industry is also in need of V blender. Here, products like powder hair dye, compact powder, eye shadow, and glitters needs to be well blended for their preparation which can be ideally done by this equipment.

Chemical Industry

Silica gel- Picture Courtesy: science.howstuffworks.com

In chemical industry, various abrasive materials are produced in form of powders and granules such as pesticides, detergent powder, pigments, and gun powder etc. There manufacturing require thorough processing of which blending is the core step. Hence, V blender is safe to process such substances.

6.Factors Affecting V Blender Performance?

There are different factors which can affect the performance of V blender in both negative or positive way. So, if you want to make its working more effective then follow the upcoming guidelines:

Loading Mode

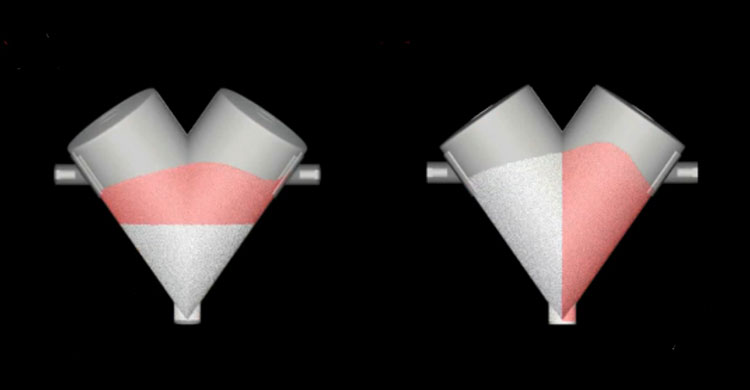

Loading modes of V blender- Picture Courtesy: Rockey DEM Particle Simulator

The way you load material into V blender greatly influence its performance. For instance, dumping two different types of materials into vessel at once may not satisfy you with the final results. While as, loading the same substances in symmetrical fashion by making their layers can give you extremely good results in form of uniform mixing.

Cycle Time

The cycle time has also greater impact on the performance of V blender. In general, 10 to 15 minutes are given to the completion of each cycle. Thus, the longer time may give you great results than that of limited time.

Mixing Speed

Mixing speed of zv blender- Picture Courtesy: PerMix

The speed of the rotation of blender and that of paddle needs to be considered for achieving extra results when operating V blender. In addition, the excessive speed can lead to minimization of particles size while that of low speed may ask for longer revolution time. Therefore, following the universal mixing speed for V blender which is 10 to 25 revolution per minute is a good choice.

Material Properties

Powdered seasoning- Picture Courtesy: glebekitchen.com

Material properties greatly influence the end product. So, you should take note of their flow properties and size. Usually, free flowing particles are easily mixed by V blender, while as, adhesive or fine particulates are hard to turn into homogeneous mixture.

Fill Level

Fill level is another factor that should be paid heed. In most cases, we do not care for the blender size and overfill the vessel which only results in the failure of mixing. Thus, it is necessary to load 2/3 material level to the size of blender and leave at lease 30% to 40% area of the twin shell empty for adequate material diffusion during rotation.

Conclusion

The bottom line is that V blender has simple working procedure with enormous benefits and uses in range of industries. With growing production, its use is also increasing and the right way for its operation is also very critical. So, what's V Blender Working Principle? We hope it's no more a rocket science for you. In case you find any difficulty in understanding V blender or if you are looking forward for a sophisticated V blender, then don't forget to leave a message. We will contact you ASAP with cutting edge solutions of V blender by Allpack!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide