What Is The Difference Between Blister Packaging And Four-Sided Sealing Packaging?

Whether in the production of medicines or the packaging of daily necessities, blister packaging and four-sided sealing packaging are two important packaging methods. Whether in the pharmaceutical industry, food industry, hardware industry, etc., they can be seen.

Difference Between Blister Packaging And Four-Sided Sealing Packaging-sourced: pharmaworks

In addition, due to their high cost-effectiveness, use of cheap raw materials and high production efficiency, they are also suitable for consumer goods such as electronic products, toys and tools. This post will explain in detail the difference between blister packaging and four-sided sealing packaging and their characteristics. Let’s take a try now!

1.What Is Blister Packaging And Four-Sided Sealing Packaging?

Blister packaging and four-sided sealing packaging are both forms of unit dose packaging that use heat-sealed materials to package different products.

Blister Packaging

Blister Packaging-sourced: howtobuypackaging

Blister packaging refers to a packaging method that uses a transparent plastic shell made mainly of PVC or polypropylene and is sealed with a heat-sealed lid. It can be adhered to a blister card, a double-sided card, or just slid onto a card. Blister packaging is commonly used for packaging of tablets, capsules, food, hardware, and electronics to protect them from moisture, contamination, and tampering.

Four-Sided Sealing Packaging

Four-Sided Sealing Packaging-sourced: gloex

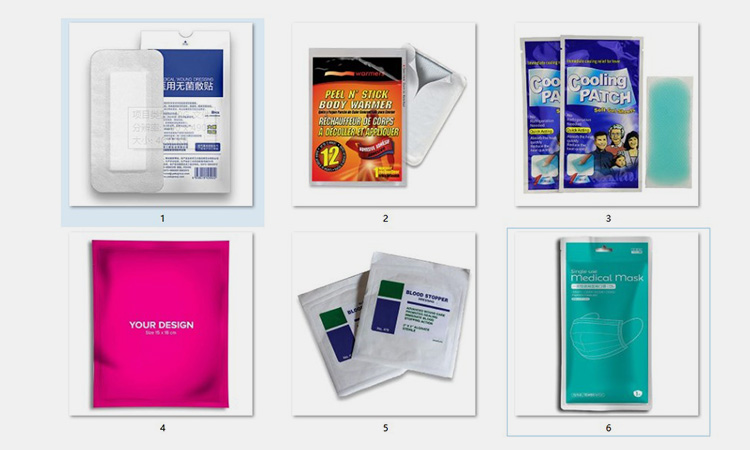

The four-sided sealing packaging is also called a flat bag or pouch. It can seal all four sides around the product to package the product. This packaging method is suitable for single-serving packaging and packaging granular sugar, flour products, and pills, etc. It can also be used for sheet products such as facial masks, rapid test kits, and facial masks.

2.What Are The Applications For Blister Packaging And Four-Sided Sealing Packaging?

Blister packaging are widely used in different products, such as:

Pharmaceuticals

Pharmaceuticals-sourced: pharmaworks

Blister packaging is often used for unit dose packaging of capsules or tablets. The special material it uses can be used to block water vapor and protect capsules and tablets from light and oxygen, thereby extending the shelf life of medicines;

Food

Food-sourced: slgfoods

Various dairy products, meat products, fresh fruits and vegetables that require good preservation effects may use blister packaging to help keep food fresh.

Consumer Goods

Consumer Goods-sourced: szblisterpackaging

Blister packaging can be used to package a wide variety of consumer goods, mainly including toys, hardware, electronic products, toothbrushes, etc. For example, packaging electronic watches between cardboard and transparent plastic can protect them from damage during transportation and facilitate display;

Cosmetics

Cosmetics-sourced: panicplastics

Blister packaging can be used to package various skin care products, such as lipstick, sunscreen, hand cream, eye cream, essence, serum, etc. It is convenient for display and can protect against dosage pressure.

The four-sided sealing packaging can be used for a variety of products, including:

Food

Food-sourced: landpack

All kinds of snacks, candies, coffee, granulated sugar, flour products, frozen foods, meal sets and ready-to-eat foods can be packaged in four-sided sealing packaging.

Medical

Medical-sourced: Dynarex

All kinds of medicines, such as capsules, tablets, oral liquids, external plasters, etc. can use four-sided sealing packaging. In addition, various medical tools, such as scalpels, injections, needles, surgical instruments, masks, etc. can use four-sided sealing packaging.

Beverages

Beverages-sourced: flistaa

All kinds of juices, carbonated drinks, water, instant soups and other liquids can use four-sided sealing packaging.

Household Daily Chemical Products

Household Daily Chemical Products-sourced: amcor

Shampoo, liquid soap, detergent, disinfectant and other semi-liquid products can use four-sided sealing packaging.

Others

Others-sourced: gozenpackaging

Pills, and pet food can also use four-sided sealing packaging.

3.What Is The Difference Between Blister Packaging And Four-Sided Sealing Packaging?

Blister packaging and four-sided sealing packaging are different in the following ways:

| Items | Blister Packaging | Four-sided Sealing Packaging |

| Samples |

Blister Packaging-sourced: clamshell-packaging |

Four-sided Sealing Packaging-sourced: worldepack

|

| Descriptions | l Refers to a packaging method that uses a transparent plastic shell made mainly of PVC or polypropylene and is sealed with a heat-sealed lid. | l Seal all four sides around the product to package the product. |

| Materials | l Typically made of hard, clear plastic, such as PVC or polypropylene, aluminum foil, laminated aluminum foil, or paperboard. | l Usually made of plastics, paper, metal, laminated film, etc. |

| Purpose | l Blister packaging is commonly used for pharmaceutical products, such as tablets and capsules, to protect them from moisture, light and air. | l Four-sided sealing packaging is commonly used for sheet products such as facial masks, face shields and rapid test kits. |

| Tamper Protection | l Once the card and cover of the blister pack are separated, they will be damaged, which can prevent tampering; | l The four-sided sealing packaging cannot be restored once it is torn; |

| Packaging Types | There are many types of blister packagings, including: face seal blister, clamshell, thermoformed blister, trapped blister, blister cards, blister packs. | The four-sided sealing packagings include quad seal bags, 4 side fin seal sachets, 4 side seal pouches. |

4.What Are The Advantages And Disadvantages of Blister Packaging And Four-Sided Sealing Packaging?

The advantages and disadvantages of blister packaging include:

Advantages and Disadvantages of Blister Packaging-sourced: leakpack

| Advantages | Blister Packaging |

| Individual Packaging | It provides an economical solution for single-dose drugs.

Each capsule or tablet can be placed in a separate cavity, which can maintain the quality of the drug and the integrity of the remaining dose. |

| Maintaining Product Integrity | The film and lidding materials used in blister packaging can help the product isolate moisture, oxygen and light.

Prevent external contaminants from penetrating and prevent solar radiation from changing the integrity of the drug. |

| Tamper Protection | Blister packaging has tamper-proof function to protect the safety of the drug. |

| Visibility of Product | Blister packaging is usually used for retail products.

The transparent material it uses makes it easy for you to see the product, thus arousing your desire to consume. |

| Suitable For Various Products | Blister Packaging is suitable for various products that are too large or have strange shapes. |

| Disadvantages | Blister Packaging |

| Environmental Unfriendly | The non-biodegradable plastic material used in blister packaging is difficult to recycle. |

| High Cost | Blister packaging is more expensive than other packaging options. It requires special equipment and materials to make and package. |

| Air Trapped | There are more air trapped in the blister packagings. |

| Children-resistant | It is more children-resistant than the four-sided sealing packaging. |

Four-sided sealing packaging has several advantages and disadvantages, including:

Advantages and Disadvantages of Four-sided Sealing Packaging: leakpack

| Advantages | Four-sided Sealing Packaging |

| Good Protection | Four-sided sealing packaging protects products from moisture, oxygen and light.

Helps products maintain freshness and quality. |

| Structural Integrity | Four-sided sealing packaging can provide a stable and strong structure for products.

Offers you convenient packaging and transportation. |

| Package Security | Four-sided sealing packaging can provide good anti-leakage security. |

| Easy Access | With a tearing hole, it can be easily opened and closed. |

| Brand Recognition | Convenient for brand printing related information to improve brand awareness. |

| Product Presentation | Provides a fashionable appearance and is convenient for display. |

| Economical Storage and Transportation | Four-sided sealing packaging can be economical for storage and transportation. |

| Disadvantages | Four-sided Sealing Packaging |

| Small Content Volume | The internal volume of four-sided sealing packaging is relatively small. |

| Low Space Utilization | The entire perimeter is tightly sealed, and the space utilization rate in the bag is low.

Not suitable for large-sized products. |

| Takes More Space | Compare with the blister packaging, the four-sided sealing packaging takes more space. |

| Not Friendly to Elderly People | It is difficult for elderly people or people with finger arthritis to use. |

| Easy to be Damaged | The four-sided sealing packaging is easier to be damaged. |

5.What Materials Are Used For Blister Packaging And Four-Sided Sealing Packaging?

The blister packaging is usually made of a combination of plastic and aluminum foil. Its materials mainly include:

| Materials | Images | Blister Packaging Material Description |

| Aluminum Foil |

Aluminum Foil-sourced: rottaprint |

Aluminum foil is a material specially used by blister packaging to package medicines.

It is easy to tear and has strong barrier properties. It is non-toxic, corrosion-resistant, heat-resistant and moisture-proof. |

| Laminated Aluminum Foil |

Laminated Aluminum Foil-sourced: wisenano |

Laminated aluminum foil is mainly made of aluminum, PVC and polyamide or polyester film and other materials.

It mainly adopts cold forming process. It not only eliminates water vapor permeability, but also can store medicines with long life. |

| Plastic |

Plastic-sourced: packlahoma |

Plastic blister packaging is mainly made of polyvinyl chloride (PVC), polyvinylidene chloride (PVDC) or composite materials.

It has good waterproof, steam-proof and light-proof barrier properties. It is usually used as packaging for hardware, cosmetics, and daily necessities. |

| Paperboard |

Paperboard-sourced: carmex |

Paperboard blister packaging is mainly made by coating paperboard with a water-based heat-seal coating.

It is an excellent environmentally friendly material. |

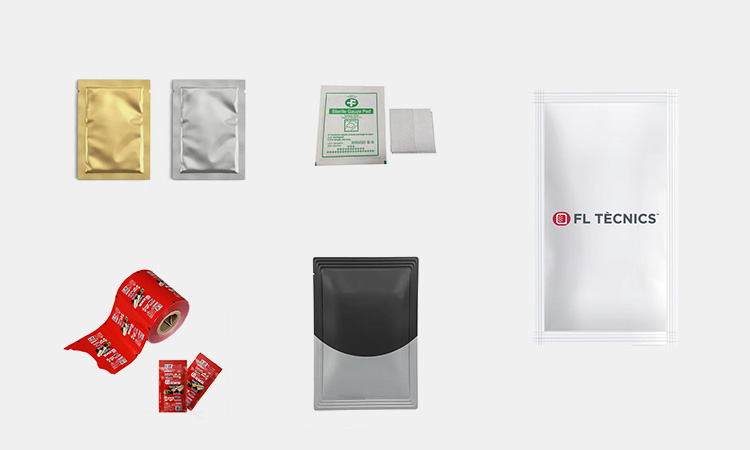

Four-sided sealing packaging, also known as 4-side sealed bags. It can be made of a variety of materials:

| Materials | Images | Four-sided Sealing Packaging Description |

| Plastic |

Plastic-sourced: lankerpack |

Four-sided sealing packaging commonly used plastic materials include: polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC); |

| Paper |

Paper-sourced: packingmachine |

Four-sided sealing packaging use paper to package food.

It is safer and recyclable. By adding other materials, the strength, hardness and printability of the packaging can be increased. |

| Metal |

Metal-sourced: shutter |

Metal bags can be used to package products that need to be oxygen-proof or moisture-proof, such as coffee and tea.

Aluminum foil can also be used to package sheet products such as masks and rapid test kits. |

| Laminated Film |

Laminated Film-sourced: pouchesbags |

Four-sided sealing packaging often uses laminated film to package medicines, medical products, nutritional products, household chemicals, food, etc. |

6.What The Machines Can Be Applied For Blister Packaging And Four-Sided Sealing Packaging?

To fulfill your high and stable production needs, there are blister packaging machine and four-sided sealing packaging machine for your use.

| Items | Blister Packaging Machine |

| Images | |

| Product Samples |

Product Samples-sourced: implasticfree |

| Description | Blister packaging machine can create blister packs to package pills, capsules, injections, vials, syringes, meals, cosmetics, toys, hardware, etc. It can be used in many industries, including pharmaceutical, cosmetics, and food, etc. |

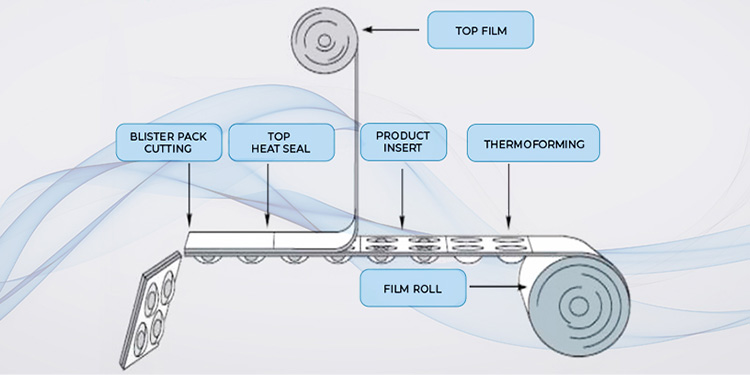

| Working Process | Blister packaging machine includes multiple stations that can complete the process of forming, feeding, sealing, embossing, perforation, and punching.

|

| Types of Blister Packaging Machine | Manual blister packaging machine, semi-automatic blister packaging machine, fully automatic blister packaging machine. |

Different four-sided sealing packaging machine may offer you different functions:

| Items | Four-Sided Sealing Packaging Machine |

| Images |

Four-Sided Sealing Packaging Machine-sourced: jochamp |

| Product Samples |

Product Samples-sourced: lankerpack |

| Description | The four-sided sealing packaging machine, also called as sachet packing machine, is a small sachet packaging machine. It is able to pack various products in compact square or rectangular bags. |

| Working Process | The working process of four-sided sealing packaging machine involves product loading, film feeding, product adjustment, sealing, labeling, etc. |

| Types of Blister Packaging Machine | There are plenty types of four-sided sealing packaging machine, including vertical four-sided sealing packaging machine, horizontal four-sided sealing packaging machine, sachet four-sided sealing packaging machine, and multi-lane four-sided sealing packaging. |

7.What Are The Process Of Blister Packaging And Four-Sided Sealing Packaging?

The process of blister packaging can be either hot or cold formed:

Process of Blister Packaging-sourced: rhysley

Forming

Thermoforming of plastic films such as PVC or cold forming of laminated aluminum films into blister boards. All formed blister boards have formed cavities on them to facilitate the encapsulation of tablets and capsules.

Product Loading

Before performing the product loading, you need to consider the batch size like types of products and characteristics, blister design like types of barrier, and the loading way like manual feeding, semi-automatic feeding, or universal automatic feeding, etc.

Sealing

Control the appropriate temperature and use a thermal coating to properly seal the base and sealing material together through pressure and temperature.

Coding

Important information such as product batch number, manufacturing date, expiration date, MRP and weight are printed on the package.

Perforation

Punch a row of small holes or tears in (paper/plastic/aluminum) so that the user can easily tear the tears when using it.

Cutting

The last step of blister packaging is cutting. The blades on the equipment can separate the connected products from each other to facilitate the subsequent boxing.

The process of four-sided sealing packaging:

Process of Four-Sided Sealing Packaging-sourced: landpac

Film Unwinding

Loading a roll of film into the four-sided sealing packaging machine, and Unwind the film and guide the film through the machine. Watch out for tearing or misalignment of the film.

Printing and Coding

Print product-related information on the film in advance, such as a barcode or expiration date, product batch number, manufacturing date, etc.

Forming

The film is neatly folded into shape using a forming ring or forming plate to facilitate subsequent heat sealing and cutting. When folding the film, you need to confirm that the forming ring or plate is correctly installed and that the bag size and shape are neat and uniform.

Product Filling

Depending on your own materials, different filling systems can be used to quantitatively load the product into the formed bag. For filling powder products, you can use an auger filler. For filling liquid products, you can use a piston filler.

Sealing

The machine heats the sealing blade to the appropriate temperature and then applies heat and pressure to the edges of the bag. The quadrilateral bag is hermetically sealed.

Cutting

The sealed bag is cut along the edges and then packaged. You need to pay attention to whether the bag has clean and accurate cut edges.

Conclusion:

After knowing all about the differences between blister packaging and four-sided sealing packaging through this post, you may know how to choose the blister packaging and four-sided sealing packaging and also the blister packaging machine and four-sided sealing packaging machines. If there are more you want to know, please contact us now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide