What Is Flexible Packaging?

Flexible packaging is applied on materials that are irregular in shape or on materials whose shape can be readily changed during the filling process. It is a highly efficient and precise way of packaging popular around the globe these days. Mostly plastic, paper, and aluminum are used to make pouches, rolls, bags, etc. for flexible packaging.

Flexible Packaging - Picture Courtesy: Bioplastics News

Industries like food, beverages, pharmaceutical, cosmetics, chemical are widely involved in doing flexible packaging on their products.

Does your business involve flexible packaging and want to learn more about flexible packaging and its methods? Read this article to get your queries solved related to flexible packaging

1.What Is Flexible Packaging?

Pet Food Flexible Packaging- Picture Courtesy: C-P Flexible Packaging

Flexible packaging is a unique type of packaging technique used globally these days to be applied on those products that have irregular or improper shape. Flexible packaging can adapt the exact shape and size of product that makes it highly versatile and has many benefits.

The packaging provides complete protection to the material against the environmental factors and also makes it easier to be transported. Different types of pouches, bags, sachets and wraps of plastic and other materials can be made through this type of packaging.

2.Why Is Flexible Packaging Important?

Flexible Packaging- Picture Courtesy: PakFactory

Flexible packaging holds a greater importance in terms of providing product sustainability and to contribute in attracting large group of customers. Products that undergo flexible packaging are lighter in weight and gives greater support when their logistics takes place. This is why many manufacturers prefer flexible packaging on their products to make their product economical and reliable.

3.What Are Benefits Of Flexible Packaging?

Some of the benefits of applying flexible packaging on products are

Product Shelf Life

Food Waste – Perfect Flexible Packaging - Picture Courtesy: Perfect Packaging

The most important benefit of a flexible packaging is that it preserves the freshness of products and also prohibits the entrance of environmental factors to increase the shelf life of product. Products that have flexible packaging on them have good barriers against factors like humidity, dust, moisture and etc.

Adaptability

Flexible Packaging Construction - Picture Courtesy: Labels & Labeling

Material used for flexible packaging are highly adaptable when it comes to their feasibility with variety of shapes and sizes. Products that are smaller in size are easily packaged using flexible packaging this makes it highly versatile.

Product Branding

Why Is Flexible Packaging Important - Picture Courtesy: Stark Packmate

High quality packaging has a brilliant appearance to product details and manufacturer related information. Flexible packaging due to this benefit allows the manufacturer to influence the customer with its attracting packaging and help the consumer know each and every thing related to the customer. Flexible packaging can increase the number of consumer due to efficient and attractive product branding.

Cost Reduction

Reduce Packaging Cost- Picture Courtesy: East West Manufacturing

One of the most important reason is that flexible packaging does not require specific type of thick and costly material for its process. Light weighted and cheaper materials can be used to apply on products and also makes it feasible when transported.

Product Designing

Flexible Packaging - Picture Courtesy: PBFY

As flexible packaging makes the product easy to be placed anywhere and reduces carbon footprints, this also supports the manufacturer to do creative designing and packaging solutions. Products with unique designs are always visible when placed in shelves of wholesale or retail stores. Design can be done according to the handling and customer expectations.

4.Common Mistakes Done While Doing Flexible Packaging?

Flexible packaging requires high concern and attention while the process is carried out. Some of the most common mistakes done while doing flexible packaging are

Poor Material Supply

Bad Flexible Packaging - Picture Courtesy: The Guardian

The most basic reason for having an improper flexible packaging is the flow of material within the system. Once the roller releases the packaging material there should be no interruption in material supply other wise wrinkles and holes can give poor packaging.

Wrong Material

What Are Flexible Packaging Material?

Selection of inadequate material that can lead to breakage, leakage or spoilage is also a reason to have improper flexible packaging. This is why the packaging material should be selected with complete satisfaction and also by getting is properties.

Improper Sealing Application

Sealing Issues In Flexible Packaging Products - Picture Courtesy: Qenos

Selection of right material and machine for sealing is also a common mistake done my manufacturers while doing flexible packaging. Poor seal as a result of this can cause material spoilage and also can reduce the standards of quality.

5.How Is Flexible Packaging Done?

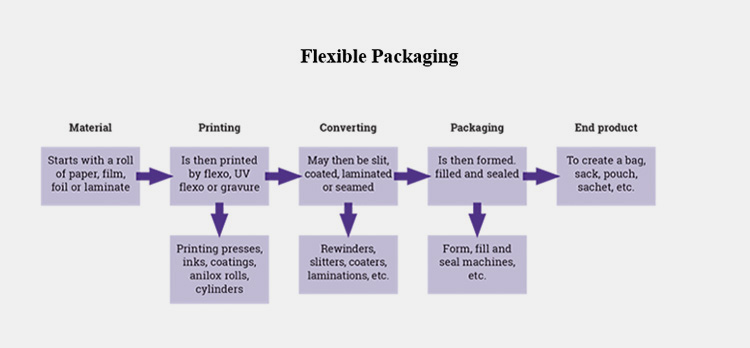

Flexible Packaging: An Introduction - Picture Courtesy: Labels & Labeling

The first processing step for flexible packaging material is to be designing and printed through specific methods like flexography, digital printing and rotogravure printing. It provides various types of flexible options that contains all necessary product and manufacturer information on it.

The processing packaging material according to the requirement than has application of different layers of material that are laminated together to form a thick and resistive covering. This thick layer blocks environmental factors to enter the packaging. As the shape from thick material is formed it is filled with the material and sealed to be transported globally in cartons and boxes.

6.What Are The Types Of Products Flexible Packaging May Contain?

Some of the products that can easily be packaged using a flexible packaging are

Powders

High Performance Flexible Packaging - Picture Courtesy: Huhtamaki

Powders that are solid in state like coffee beans, tea mixtures or sugar material are ideal to be packed using flexible packaging as it provides protection against the moisture content and maintains their aroma and flavor.

Granules

Flexible Packaging - Picture Courtesy: Biotef

Granules are also solid in state and can easily be packed in different sizes of bags and pouches of flexible packaging. The internal properties of these granular substances need high blockage form humid and radioactive conditions and that is provided by this flexible packaging. Salt, fertilizer granules, and other substances can be packed highly efficient using flexible packaging.

Medical Devices

Medical Flexible Packaging - Picture Courtesy: Perfect Packaging

Electronics and instrumentation devices that are used in medical industry required high level of protection as their processing can be disturbed if any moisture, oxygen or humid condition enter their vicinity. Flexible packaging is ideal in this situation to keep it safe from this condition and increases their life. Other than these devices medical bandages, syringes, sterilizer and etc. are also packed using flexible packaging.

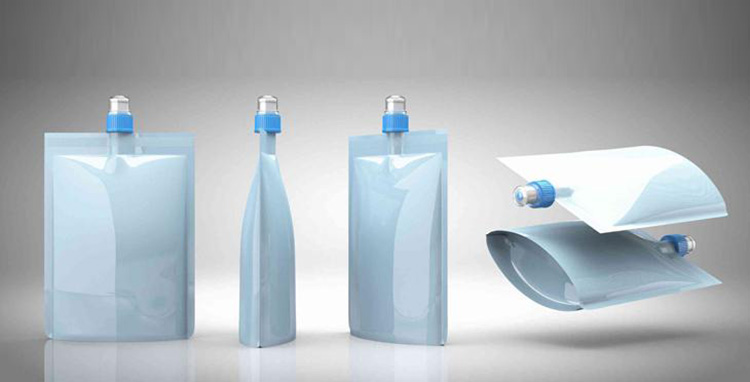

Liquid Gels

Hand Washing Liquid Travel Flexible Packaging

Liquid gel, creams and pastes undergo flexible packaging as it gives airtight seal and avoid any type of leakages. Liquid products are packed in different sizes and shapes of pouches, sachets, bags and tubes of flexible packaging.

7.What Materials Are Used For Flexible Packaging?

Variety of materials can undergo flexible packaging depending upon their requirement and material handling properties. This is an integral and important part to select the best suitable type of material to prevent any kind spillage or leakage while they are transported. Some of the materials used for flexible packaging are

Polyester

Clear Polyester Flexible Packaging Film- Picture Courtesy: ACPO

The most unique and widely used material for flexible packaging is polyester due to its transparent nature and excellent bonding strength. Sachets and pouches of beverages and food products are mostly packed in this type of flexible packaging material.

Polypropylene

PP Flexible Packaging Film

Most of the confectionary items are packaged in a polypropylene material due to its high melting point property. This material can barrier high temperature conditions and also can resist the entrance to any kind of microbial organism that can cause contamination.

Polyvinyl Chloride

Flexible Plastic Packaging- Picture Courtesy: Plastivision

Other type of plastic material that is available globally die to its economic benefit and readily availability is polyvinyl chloride. Most of the materials that are lighter in weight prefer PVC flexible packaging to give extended shelf life and good barrier against environmental conditions.

Paper

Paper Flexible Packaging- Picture Courtesy: C-P Flexible Packaging

Some of the products do use paper flexible packaging due to its environment friendly property. Most of the times it is difficult to bend a paper board but soft and thin types of paper can be used for packaging of dry food and snack products.

Aluminum

Flexible Packaging Foil - Picture Courtesy: Interalco

Other than plastic and paper, aluminum also has greater sustainability when used for flexible packaging. They do not allow any entrance to moisture or humid condition and this is why the products packed using aluminum flexible packaging last for longer periods even if moved to longer distances and temperature conditions.

8.How To Choose Quality Flexible Packaging Material?

How To Choose - Picture Courtesy: Rocky Mountain Radar

Checking and choosing for the best quality flexible packaging material is always a challenge to be done. Manufacturers have to keenly monitor all the aspects related to it starting from the material property to its barrier property against different type of environmental conditions. The manufacturer should select the quality material according to its product that whether it would be compatible or not in any condition.

Why Flexible Packaging - Picture Courtesy: Beyond Print

Further, the sealing property of the material is also a concern as it has to travel longer distances and if this seal is not applied proper it can cause material wastage. Finally, in current movements in favor or environment friendly products, the material should be biodegradable and eco-friendly to meet the global standards.

9.How Flexible Packaging Maintain Quality Of Products?

Out of numerous methods how quality packaging can maintain product quality, some are

Sealing Property

Heat Seal In Flexible Packaging- Picture Courtesy: Packaging Strategies

Quality flexible packaging material that gives high quality sealing property proves to be a barrier against environmental conditions and supports the product to last long. It prevents any sort of contamination and gives high quality resistance.

Environment Friendly

Compostable Flexible Packaging- Picture Courtesy: Perfect Packaging

Quality flexible packaging material do not produce any sort of carbon footprints or emissions that helps the environment and product both remain safe and helps in forming an eco-friendly brand.

Adaptability

Paper Flexible Packaging- Picture Courtesy: Packaging Gateway

One of the important factors that quality flexible packaging offers is its adaptability. It can fit into any shape and maintains the internal original shape of product so that no space is left.

Product Life

How To Extend Shelf Life With Flexible Packaging- Picture Courtesy: ePak Flexible Packaging

Product and its life can be increased to a greater level if it is packed using a quality flexible packaging. As it provides proper sealing options and barrier to the contaminants, this feature makes it suitable to use for material that are to be consumed in extended durations.

Conclusion

Flexible packaging is a reliable mode of packaging that can adapt the shape and size of any product. This article completely tells about what flexible packaging is what amazing benefits can be taken out of it. It can not only provide a pleasant look to the product but also can save it from any type of contamination. It is always important to select the right material and right machine to apply efficient flexible packaging. If you still require more information regarding what is flexible packaging, you can contact our customer representatives, they are always available 24/7 for your guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide