What Are The Mixing Process In Pharmaceutical Industry?

Why Mixing Process Is the Main Objective Behind Any Pharmaceutical Product?

Various active pharmaceutical ingredients, adjuvants, and excipients are mainly combined to form pharmaceutical formulations, such as solid preparation, liquids, topical, or inhalation dosage. What is common in all of them? Yes, that’s mixing!

The market trend of pharmaceutical mixing is increasing day by day with high profitability expectations. In the article ‘What Are The Mixing Process In Pharmaceutical Industry, we will talk about important aspects of the mixing process and its role in the pharmaceutical industry.

If you’re a manufacturer, or a newbie in this field; stay with us! Here, you will find important knowledge that will be really helpful in various areas of manufacturing.

1.How to define a mixing process?

Mixing Process in Pharmaceutical Industry

The term mixing actually means the combination or randomization of dissimilar particles in a combined system that gives a particular uniformity to the content. Mixing is an important entity behind the formation of the product without which it is not possible to obtain a good formulation.

Therefore, every pharmaceutical product is formed by the process of mixing. In other terms, mixing exactly means to put compounds together, whereas the term blending means to make an inseparable or smooth mixing of two compounds. However, the terms blending and mixing are considered as interchangeable terms.

2.What are the mixing process in pharmaceutical industry?

Before going to discuss the mixing process, I would like mention that the pharmaceutical formulation is basically formed by any of the state, such as dry, liquids, a semi-solid.

Therefore, we are going to discuss the mixing process in pharmaceutical industry by mentioning these three states one by one.

Dry Mixing

Dry mixing

By its name, it is mainly involved with solid powders mixing under a controlled procedure. scientifically, it is also categorized into free-flowing and non-free-flowing powders. This mainly impacts on mixing process, and the behaviour of both these categories has an influence on mixing therefore it is also important to understand the flow properties when opting for dry mixing.

Dry Mixing Process in Pharmaceutical Industry

When it comes do you know about the mechanism of the mixing process in the pharmaceutical industry, dry powder is mainly divided into 3 mixing types:

- Convection Mixing

- Shear Mixing

- Diffusive Mixing

Convection Mixing

This is known as ‘Macro Mixing’ which is mainly the formation of macroscopic mixing powder by circulating flow of substances. You can consider it as the mixing of the bulk quantity of the powder from one part of the powder bed to another.

Here, the transferring of the powder particles occurs from one part of the machine to another part of the machine by means of large mixing components such as the blade or the paddle of the equipment. but for the final formulation of dry mixing, the following powder bed will require mixing to get the finer mixing.

Shear Mixing

shear mixing- Picture Courtesy: mixquip

This mixing refers to the mixing that occurs in the form of layering. A shear mixing is the high shear force created between the particles with the help of a mixing blade or any impeller that imparts between the particles and makes them mix properly. This means, that one layer of the powder moves over another layer of powder to create the right mixing.

The shear forces are responsible for the mixing of material, and this mainly occurs by the application of an agitating arm or the blast of air. It is mainly used when you are subjected to create a formulation that requires rigid and high force to mix and a stable product.

For example, if you are making an emulsion; you will need to mix the oil phase and water phase, and here you’re required with high shear mixing to intensify each particle to mix with the other phase. This can form a product that is semi-microscopic, and this may be termed intermediate mixing.

Diffusive Mixing

Diffusive Mixing

This is known as ‘micro mixing’ or random all phenomenon, and it is considered an ideal mode to achieve true mixing of individual particles.

It is mainly achieved by random mixing. During the mixing of the pharmaceutical process, the diffusion of power particles randomly moves over one another within the powder bed and forms a uniform state.

Here, the materials may be tilted over one another using a gravitational force that slides the layer of particles to form a uniform mixing bed. The rate of mixing as compared to convective mixing is slower but you can obtain the finest results in the term of homogenization that gives microscopic mixing. In some cases, conventional and diffusive mixing is used to get an effective result.

Equipment of Dry Powder Mixing Process in Pharmaceutical Industry

Dry powder is a crucial and integral entity to manufacture any product related to pharmaceutical dosage preparation. There is a certain list of equipment that is mainly used to mix them properly. Discussed below are the various types of mixing equipment, have a look!

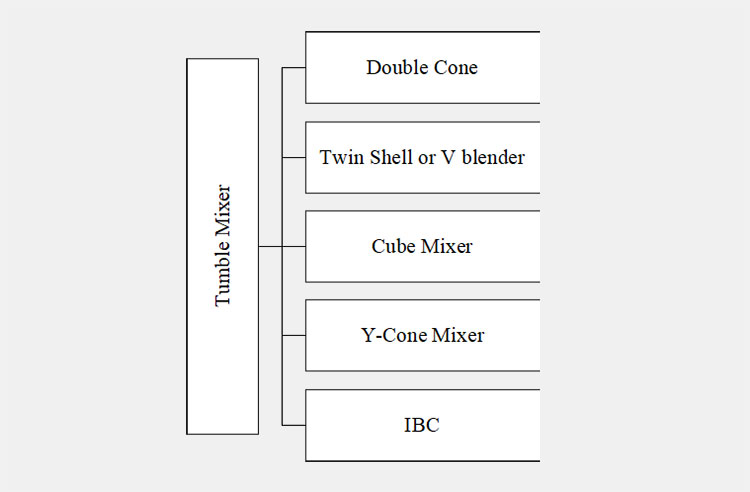

Tumble Mixer

This is the type of mixer that rotates in the different motions and causes the powder bed to mix properly without damaging the substances or creating any heat. This type of mixer does not contain any impeller or agitator. Just a simple rotational mode is suitable for mixing powder sufficiently. There are following sub-types of tumble mixer that we have mentioned below:

Double Cone Mixer

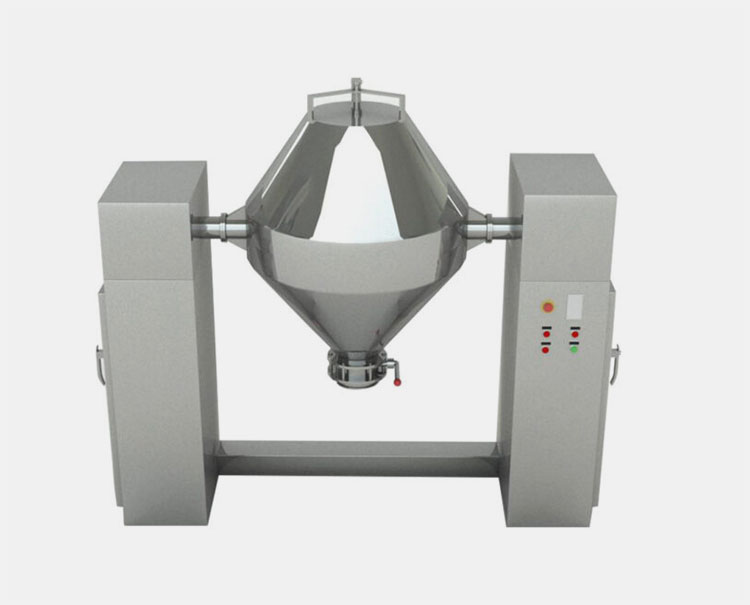

Aipak Double Cone Mixer

This is mainly featured with two cones or a conical design which is fixed at the base. That’s why it represents the shape of two cones and is popular as double cone mixer.

This unit ensures you with the gentle motion of a powder bed where there’s no need for utilization of high shear forces or agitators. This machine is ideal for the mixing process in the pharmaceutical industry when it comes to dealing with free-flowing powders.

Thus, you can attain mixing of powder by simple rotation motion of a double cone tank that keeps mixing the powder and making even distribution of particles and ensuring you that they won’t be segregating once the system stops.

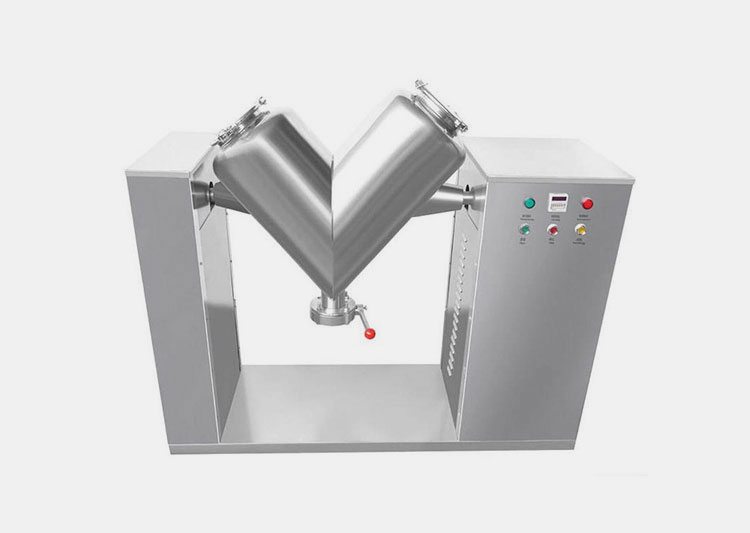

V Blender

Allpack V-Blender

This is the commonly used equipment for powder tumbling action. The machine design features a V shape connected to hollow cylinders facilitating the tumbling of powder with a simple rotational force of the unit. This is suitable for mixing not only pharmaceutical items but various foods, cosmetics, and related formulation. The gentle movement of the V blender for an optimized time ensures you that powder mixing is uniform and not capable of de-mixing or segregation.

Cube Mixer

Cube mixer- Picture Courtesy: GMP

A cube mixer which is designed in a way that looks like a cube. It is a simple and very effective mode of mixing that ensures gentle mixing without any proportion of segregation. The square or cubic shape mixer is filled with powders and works by revolving the tank at its fixed axis that supports its motions as well as the mixing. Due to its multi-directional movement, homogenous powder particles are formed that is suitable for pharmaceutical preparations.

Y-Cone Mixer

Y- Cone Mixer- Picture Courtesy: Flagma

This type of mixer has a unique shape that looks like a ‘Y-shape’ cone. The main reason behind its shape is to provide smooth blending of the powder with lower frictional force. That’s why it is mainly used for mixing pharmaceutical substances that are heat-sensitive. At the top of angle 90 ° V shape cones are meant for mixing of powder thoroughly while lower part is meant for short mixing require relatively lower energy.

IBC (Intermediate Bulk Container) Mixer

IBC Mixer

This is an ideal mixer type which is used for large powder blending and therefore for large pharmaceutical industries, this is the right choice for mixing powders. The mixer of IBC works by rotating the tank just around the fixed axis and it is facilitated with an internal agitator that supports the thorough blending and provides promising blending.

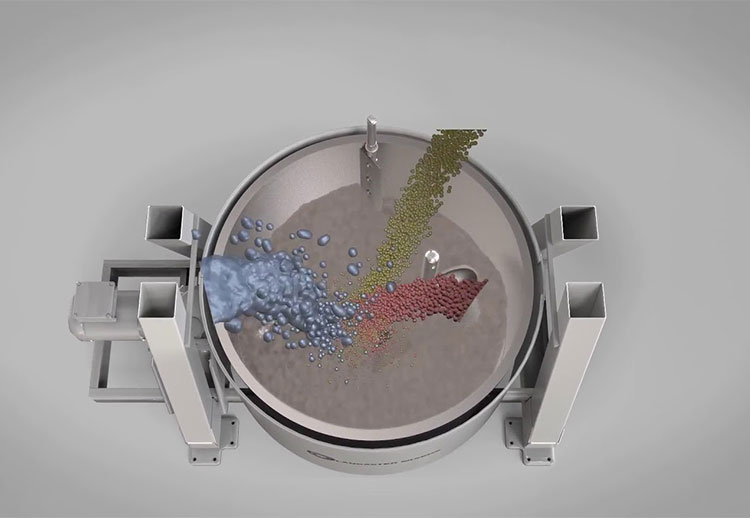

High-Speed Mixer Granulator

Allpack High-Speed Mixer Granulator

This machine is equipped with impellers and agitators that help you in the process of creating granules and making smooth and uniform particle sizes. In the pharmaceutical industry, this equipment is utilized to achieve mixing and granulation of particles improving the flow properties of powders.

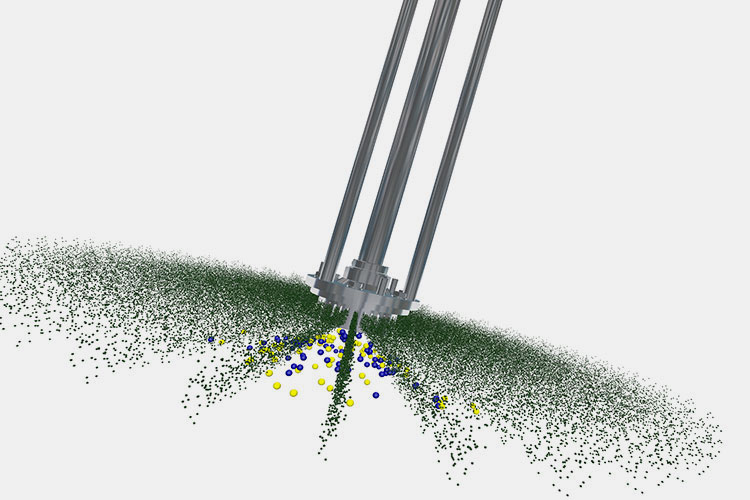

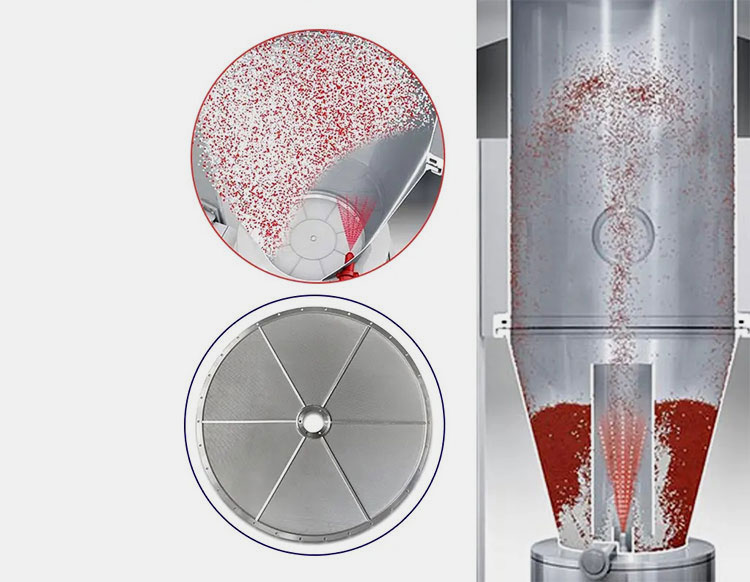

Fluidized Bed Mixer

Fluidized bed mixer- Picture Courtesy: Kerone

A high-efficiency and innovative mixer where powder particles are suspended in the air and behave like it is in fluidized states. This type of mixer is considered as the fastest mixing process among other. The following working principle is followed and used to get a uniform mixing of powders that are heat sensitive. The fluidized bed mixer ensures greater particle intermingling and ensures excessive particle distribution and mixing.

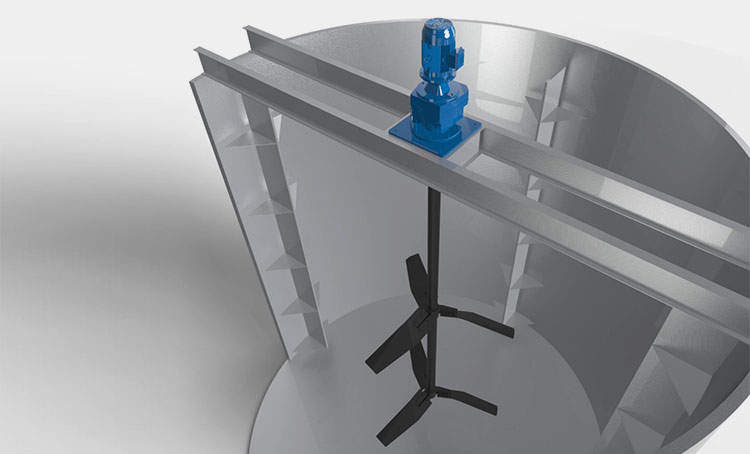

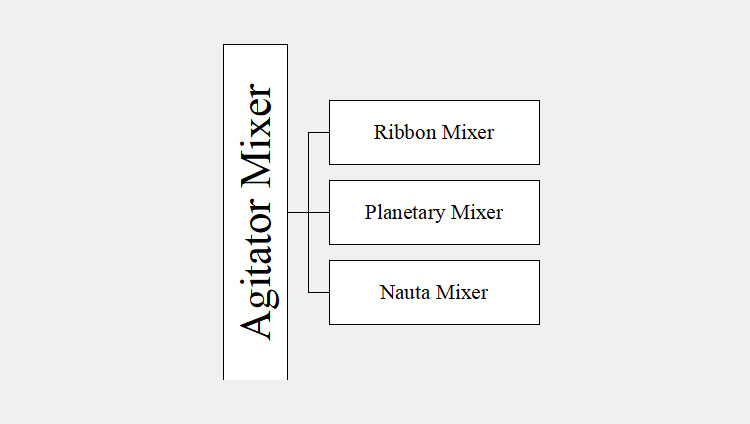

Agitator Mixer

Agitator Mixer- Picture Courtesy: Mixtec

For various dry powders where particle sizes are associated with non-free flowing properties or may be tough or challenging to mix; for such cases, an agitator mixer is used to reduce the particle sizes and allow homogenous mixing. There are main types of agitator mixer. For example:

Ribbon Mixer

Ribbon Mixer- Picture Courtesy: Fenan Fair Importer

The mixer is designed with a helical central screw that produces convection mixing once it rotates around the fixed axis. The mixing medium consists of inner and outer mixing ribbons which ensures pulling and pushing powders to give an ideal mixing. This is considered as an ideal tool for blending various pharmaceutical powders as it is super hygienic, simple, and can mix a large number of powders in a timely manner.

Planetary Mixer

Planetary Mixer- Picture Courtesy:Hospitalityhub

The name planetary for this mixer comes from its design and working of powder mixing. The mechanism is based on the constant rotational motion of powder during whisking or beating. It is mainly composed of a large bowl which is suitable for processing thick formulations such as mixing of powder for creams, pastes, and ointments to bring a sophisticated and homogenous output.

Nauta-Mixer

Nauta-Mixer- Picture Courtesy: Hosokawa Micron

This is another important unit belonging to an agitator mixer that is designed with a conical tank where a helical screw is fixed in a centre known as a Nauta screw. The purpose of the Nauta screw is to provide a rotational gateway to the powder bed and ensure gentle blending to particles of various densities.

3.What things to be considered to get an ideal mixer selection in pharmaceutical industry?

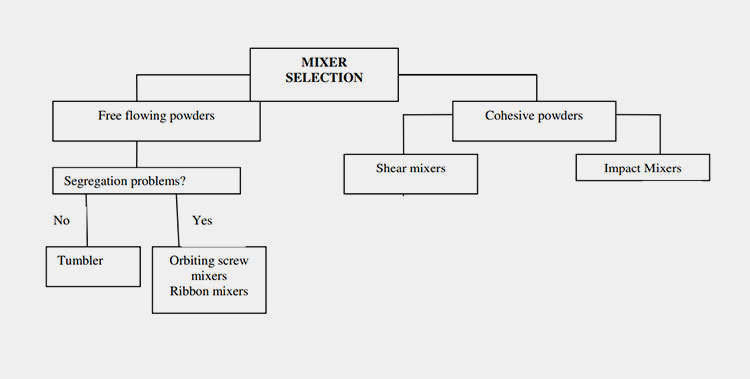

Mixer selection chart

When selecting a mixer, you should keep in mind that an ideal unit should be suitable for giving an excellent mixing output without forming dust or exposing your product in the environment and should be compact in the terms of structure as well as time and energy saving. But this is not possible in one machine. therefore, you should craft the selection criteria and move for logical points that should be based on the type of powders, and related properties that we discussed in:

Types of Powder

Types of powder- Picture Courtesy: Nutrabay

This is integral to knowing what is characteristic of powder substances. If it is free-flowing, then you should move of tumbler mixers. Moreover, if it is not non-free flowing then high shear mixing, or impact mixer is required to bring the mixing task efficiently.

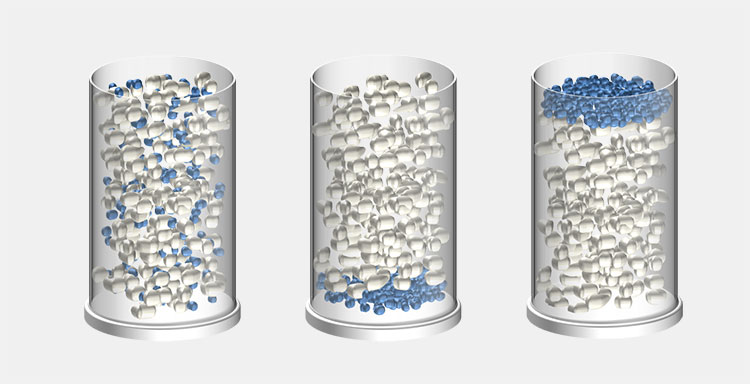

Demixing or Segregation

Segregation

What is the nature of powder, it is prone to separate or segregate? If yes, then it is recommended to select a machine with an already screw of mixing rod inside. For instance, ribbon mixer, planetary mixer, etc allow thorough or vigorous mixing in order to ensure the product form won’t be de-mix or segregated later.

Batch Size

Powder mixing size- Picture Courtesy: Capital Resin

Are you a newbie or belonging to a larger enterprise? Buying a larger machine for a new business or a small production is not worth it. For this reason, you should move for smaller or medium mixing options. Similarly, estimation of batch size would be helpful in selecting the specific and right equipment.

Conclusion

When preparing pharmaceutical formulations on a large scale, the mixing process is unavoidable. Every manufacturer's goal is to attain a mixer that yields promising results without chances of segregation. When selecting a mixer, it should be based on particle size, nature of powder, operation, production capacity, and density. Always remember to focus on one-time investment to get lifetime profitable and time-saving outcomes. Are planning to get one? Why not contact our experts? Allpack is the one-stop solution for offering a large series of mixers and blenders. Which one is your requirement? Let's discuss this now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide