What Are The Advantages Of Wet Granulation?

Whether is it pharmaceutical industry, food industry or cosmetic industry, the use of powders and granules is a routine practice. Now, these powders are not always used in their fine form instead they are turned into granules for effective processing. Similarly, wet granulation is said to be the best method employed for granulating powders in various areas. But have you ever tried to know the reasons behind? If not! Then we are here to explain What Are The Advantages Of Wet Granulation.

Wet granulation is one of the oldest and simplest ways of granulation. It offers myriad of techniques to deal with all kinds of granulation. Moreover, the materials which it processes remain safe throughout operation, hence, their essence could be well retained with this method of granulation. So, stay tuned and keep reading to know further about wet granulation!

1.What Is Wet Granulation?

Wet granulation- Picture Courtesy: pharmaexcipients.com

Wet granulation is a technique popularly used in pharmaceutical industry for the formation of large entities from powder called granules. In this method, liquid binders are used as principal agents to make coalescence of active ingredients and excipients. When liquid binders are added, the fine particles of powder form agglomeration. This mixture is turned into uniform granules which are then dried to desired level.

Granules produced through wet granulation are uniform in structure and have good flow properties due to which they are helpful in the manufacturing of solid dosage form such as capsules and tablets. Moreover, wet granulation has several types for granulation as a result of which now it can be used for products made in industries like pet food, chemical, and detergent industry.

2.What Are The Advantages Of Wet Granulation?

Wet granulation is the most widely used method for granulation despite the presence of other methods like dry granulation. The only reason is its numerous benefits which are associated with your long term ease and profit. So, let's know some of the important advantages of wet granulation!

Structural Uniformity

Uniform granules- Picture Courtesy: blogger.googleusercontent.com

Granules produced by wet granulation are highly uniform in their structure with round appearance. It is due to the homogeneous distribution of binder and particles which give you desired size of granules, enabling manufacturers to ensure content uniformity in the end product.

Better Flowability

Throughout wet granulation, you will get the granules with high density and consistent spherical shape. Both these factors leads to the smooth flowing of granules during tablets formation and other formulations.

Dust-free Particles

Pharmaceutical powders- Picture Courtesy: gea.com

Hygiene and environmental safety is one of the primary concerns of pharmaceuticals practitioners. While it is not possible when dealing with dry granulation due to excessive dust, dry granulation offers you dust-free particles. These granules are strongly made with presence of moisture which prevent the emergence of dust, protecting both the product and users involved.

Facilitate Compression

Uniformly compressed tablets- Picture Courtesy: gea.com

Air entrapment is one of the greatest challenges to tablets compression that is common in dry granulation. However, this problem can be easily solved by switching to wet granulation. It will not only reduce the risk of air entrapment to zero but will also facilitate compression by requiring low compression force.

Improved Bioavailability

There are large number of hydrophobic APIs which have low bioavailability thereby limiting therapeutic effect. Such ingredients require liquid binders and advanced granulation methods such as spray drying and hot melt extrusion. In this way, wet granulation is the only way to create these granules with porous surface, enhancing their dissolution rate and curing outcomes for patients.

Easier Coating

Coated pills presentation idea- Picture Courtesy: pharmacentral.com

Most of the times, drugs require coating due to unpalatable taste, odor, and the need for its slow release. Therefore, it becomes necessary to mask their original properties by applying coating. This step cannot be carried out in dry granulation due to its limitation to expose liquid, while as, wet granulation is best suitable for such post processing of granules.

3.Is There Any Alternative To Wet Granulation?

Dry granulation- Picture Courtesy: Fitzpatrick

The answer to your question is yes! There are certain other methods which can be used as alternative to wet granulation. However, among them the most prominent one is dry granulation.

Dry granulation, as the name indicates, is a technique in which powders are turned into granules without any exposure to liquid. It simply involves the compression of active ingredients and excipients into strips or slugs (large tablets). Similarly, these compressed strips and slugs are crushed to form granules.

Despite having simple procedure and cost-effective way of granulation, dry granulation is rarely used in pharmaceutical industry as compared to wet granulation. The reason is because it has certain limitations by using special binders, creation of dust during operation, compression issues, and nonuniform structure of granules.

4.What Is The Process Of Wet Granulation?

The process of wet granulation is a bit lengthy by involving certain equipment. It follows few steps to form granules. These are enlisted below for your understanding:

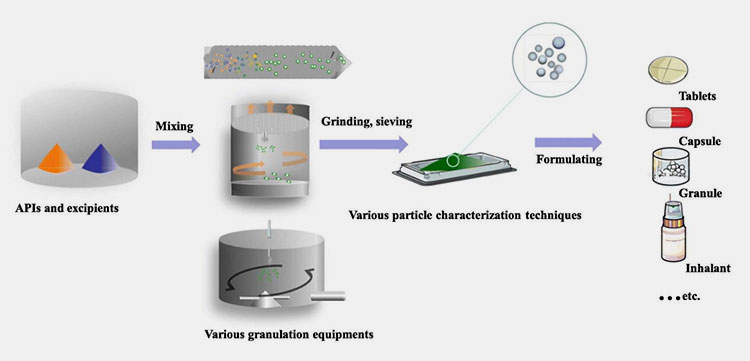

Process of wet granulation- Picture Courtesy: sciencedirect.com

Ingredients Weighing

First, you need to collect the various ingredients required for formulation. It will include active ingredients and excipients along with binders. Weigh them properly before mixing to ensure a uniform formulation.

Powder Mixing

The second step involves proper mixing of the powder ingredients taken. It must be carried out appropriately.

Binder Addition

Now, the liquid binder is introduced to powder mixture in form of spray. Depending upon the latest techniques being introduced in wet granulation, the binder may be added to powder in different ways like steam, foam, or melted solvent.

Agglomeration

As the liquid binder get in contact with powder, the process of nucleation takes place and multiple tiny powder particles gather to form agglomerates.

Consolidation

At this point, the formed granules are further strengthen and consolidated by the continuous agitation of agitator. Similarly, this is a critical phase to determine the tensile strength, disintegration rate, and hardness of granules.

Granules Formation

Now, the consolidated large agglomerates are broken down to form uniform granules. This is the stage where the size of granules is finalized.

Granules Drying

As granules passed through wet granulation process, they are subjected to drying to remove out excess moisture content and reach a desired level.

5.What Equipment Are Needed For Wet Granulation?

In order to carry out wet granulation, you will need two types of equipment: one for granulation and the other for drying. In this question, we have discussed the tools required for both manual and automatic way of wet granulation:

Equipment for Manual Practice

Sieve

Mesh sieve- Picture Courtesy: Schneider GmbH

Sieve is a kind of utensil having a perforated sheet surrounded by metallic frame. It is primary tool being used by practitioners when conducting wet granulation manually. The wet mixture is placed in a sieve after which it is rubbed. This continuous rubbing of agglomeration result in the formation of granules which fall from the lower side of the sieve.

Drying Tray

Granules drying tray- Picture Courtesy: LABCONCO

As wet granulation produce wet granules, they should be dried before further processing. In this way, hygienic drying trays are needed to safely make these granules dry.

Equipment for Industrial Practice

Wet Granulation Machine

Allpack- HLSG Series High Speed Wet Mixing Granulator

Wet granulation machine is the core machine required for wet granulation on industrial level. It manifests robust and hygienic structure which is made up of several components including a stainless steel tank, stirring blade, cutter, and binder spraying tool.

The machine is automatic in technology by following simple operational procedure along with providing a safe environment for granules formation. All the steps of wet granulation including mixing, agglomeration, consolidation, and attrition are carried out simultaneously in one machine. Moreover, the growing advancements has introduced many types of wet granulation machines to cope up with granulation complexities.

Pharmaceutical Drying Machine

Allpack- FG Series Fluid Bed Dryer

Pharmaceutical drying machine is a spectacular equipment employed to facilitate the drying of wet granules. It is a comprehensive solution to reduce the moisture content of granules by necessary level while taking care of the granules properties.

It simply works by circulating hot air around the wet granules which in turn start evaporating the moisture. Resultantly, in a very short period of time, granules are dried. The machine is widely applicable to pharmaceutical, nutraceucal, food, and chemical industry for wet granulation.

6.What Are The Advancements In Wet Granulation?

Wet granulation is popularly undertaken in pharmaceutical industry. Therefore, to enhance the drugs sustainability, bioavailability, and essence, certain advancements have been made in wet granulation to produce granules with more strong characteristics. These advanced methods or techniques are enumerated below:

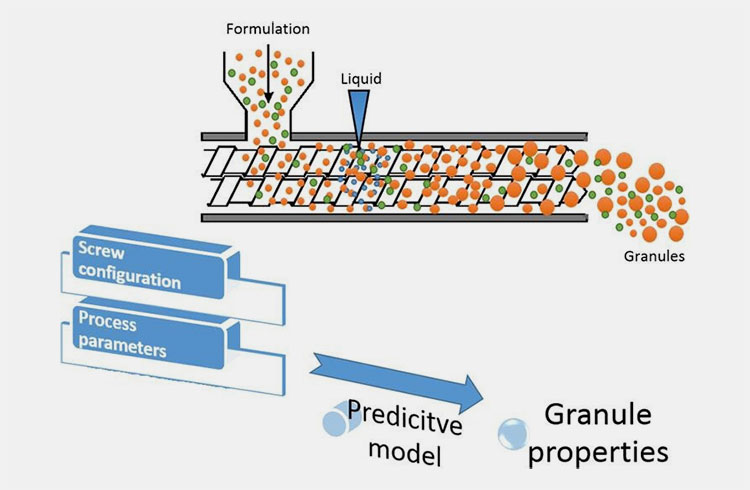

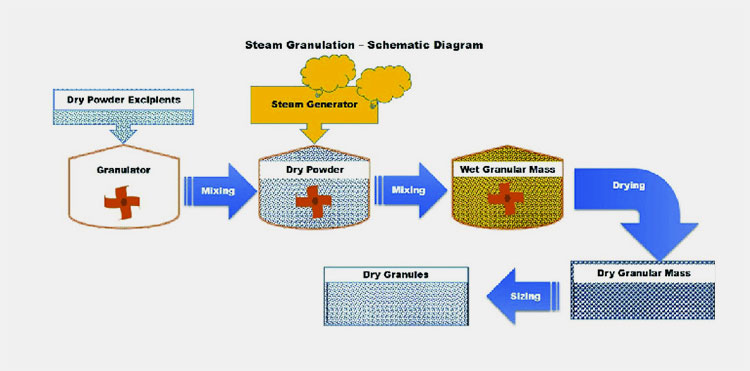

Steam Granulation

Steam granulation- Picture Courtesy: researchgate.net

This is one of the first advanced techniques of wet granulation in which steam technology is used instead of conventional liquid binders. The steam is replaced with liquid and it performs the function of binding by agglomerating the powder ingredients.

Use:It is suitable for creating spherical granules with quick drying properties due to its gaseous nature that absorb instantly into powder.

Limitation:Steam granulation method is undesirable for heat-sensitive drugs and drugs requiring high tensile strength.

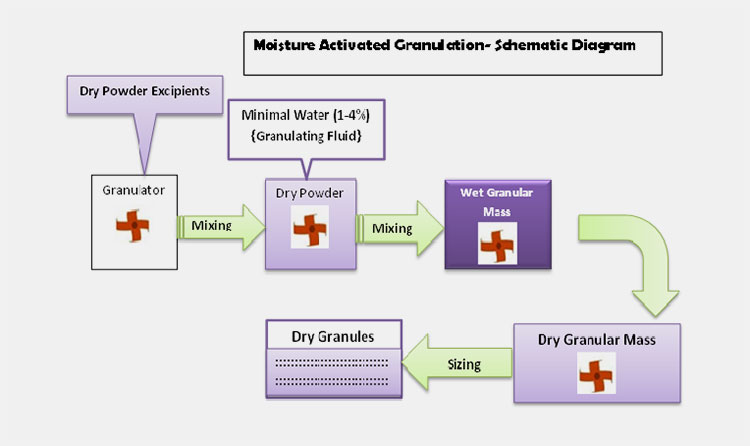

Moisture Activated Dry Granulation (MADG)

Moisture activated granulation- Picture Courtesy: semanticscholar.org

Moisture activated dry granulation is another type of wet granulation with its distinct method where first the mixture of active ingredients, excipients, and liquid binder is prepared. Then silicon dioxide or microcrystalline cellulose is added to the same preparation for moisture absorption.

Use:This method is useful in a way that it reduces the chances of lump creation.

Limitation:It is not suitable for hydroscopic drugs.

Thermal Adhesion Granulation (TAG)

This method of wet granulation utilizes a bit unconventional way for granulation by using low amount of pharmaceutically accepted liquid binder for mixing with powder and excipients. However, to fill this gap of using less amount of solvent, heat is used to expedite the granulation process.

Use:Thermal adhesion granulation is admired for its self drying process and creation of granules with high tensile strength.

Limitation:This technique cannot be used for thermolabile ingredients.

Melt Granulation

Melt granulation is a size enlargement process where solid binders are used instead of liquid binders. These binders get melted with relatively low temperature and therefore form agglomeration in combination with powder and excipients for creating granules. This method of wet granulation eliminate the use of water thereby ending additional drying process.

Use:It is best suitable for moisture sensitive drugs.

Limitation:Like many other techniques of wet granulation, it has also a limitation for the processing of heat sensitive drugs.

Foam Granulation

Foam granulation & wet granulation- Picture Courtesy: pharmtech.com

Foam granulation is yet another notable way of applying wet granulation. As the title illustrates, it transform the solvent in form of foam which is then introduced over powder ingredients. Resultantly, the powder ingredients quickly surround the foam and uniform granules are produced.

Use:This process of foam granulation is beneficial for water sensitive drugs. Moreover, it is quick in granules formation and use a little amount of binder.

Limitation:Requiring high energy and additional resources, this is comparatively an expensive method.

Freeze Granulation

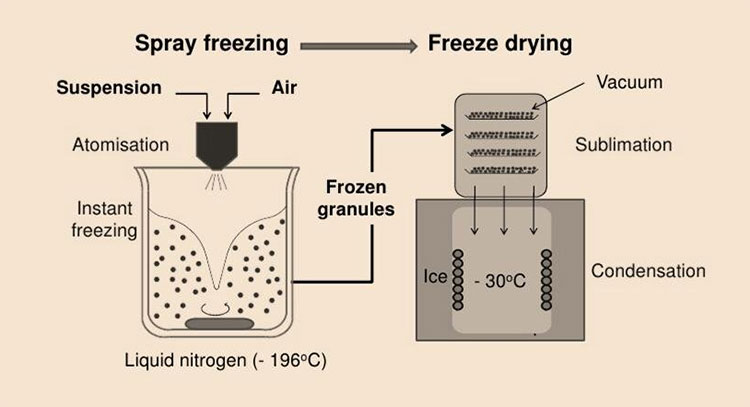

Freeze granulation- Picture Courtesy: researchgate.net

Freeze granulation is among other innovative methods of wet granulation being practiced on industrial level. Under ultra-low temperature environment, powder suspension is sprayed over nitrogen as a result of which the freeze droplets are produced. These freeze drops are then pass through sublimation where ice is freeze dried and only granules are left.

Use:For making granules with controlled density and homogeneous property, freeze granulation is perfect.

Limitation:In this process, use of organic binders is preferred over water due to which it may form granules with low bioavailability.

Reverse Wet Granulation

Reverse wet granulation is referred to as the latest technique of wet granulation that involves two steps for granules formation. In the first step, active powder ingredients are mixed with solvent which is then processed through granulator. These granules are now ready for another phase where the excipients are added and final granulation stage is achieved.

Use:This recent advancement is good for making granules with controlled breakage, flow, and even dissolution especially for tablets formulation.

Limitation:Compared to other methods, reverse wet granulation produces granules with low intragranular porosity.

7.Are There Any Drawbacks Of Wet Granulation?

Despite having many advantages, there are certain limitations of wet granulations including:

Moisture sensitive ingredients- Picture Courtesy: caleva.com

Complex Process

Wet granulation has lengthy process which become more complicated without use of machines. Even with machines, you will have to intervene in the process for granules administration and drying etc.

Expensive

This process of wet granulation require multiple machines, extensive energy, and capital sources. Together, these expenses may not be bearable for medium to low level businesses.

Product Degradation

As wet granulation entirely depends upon the use of liquid binders, there is possibility that it may degrade the product quality and essence due to constant exposure to humidity and heat.

8.Factors Affecting Wet Granulation?

While practicing wet granulation, it is important to consider some of the essential factors or else you may face challenges in form of inappropriate granules formation. In this way, prominent factors which may affect wet granulation are as follows:

Pharmacist examining powder for granulation- Picture Courtesy: ct5prr2.findtwep.de

Amount Of Water

The first and foremost thing that may affect wet granulation process is the amount of water being used for granules formation. It is important to take note of the characteristics of various ingredients taken for granulation and use water in accordance with them. Otherwise, excessive water can cause lumps that may badly affect the properties of final granules.

Choice of Binder

Binders are very critical components in wet granulation without which granules of uniform properties cannot be created. Therefore, selecting right binder for your formulation will determine the cohesive and adhesive forces of your granules.

Temperature Intensity

Another factor that has influence on wet granulation is temperature intensity. It is evident that drying is compulsory step in wet granulation which is mostly done through heat. However, most of the drugs ingredients are susceptible to heat, so, temperature must be kept under control to reduce the possible damage to drug essence.

Apart from this, different methods within wet granulation like foam granulation or moisture additive dry granulation can be used.

Conclusion

So, we are going to conclude this blogspot with a hope that you have got the idea about wet granulation and able to answer the question What Are The Advantages Of Wet Granulation? The importance of wet granulation can be realized in almost every industry dealing with powder encompassing pharmaceutical, spices, detergent, and chemical industry. Most importantly, its scope is extending in drugs industry day by day due to the growing advancements to facilitate easy solid dosage formation. Paying heed to critical factors and adopting further relevant modification can enhance its worth. If you are eager to learn more just contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide