Net Weight Filling Machine: The Complete Buying Guide In 2025

Net Weight Filling Machine: The Complete Buying Guide In 2025

Have you ever felt frustrated trying to get the exact amount of product into a bag or container? If so, then you need to learn about the amazing benefits of net weight filling machines! These incredibly fast and accurate automated systems are efficient solutions for businesses needing precise portioning. Whether your products come in powder, granules, or liquids form, this revolutionary device can provide reliable performance with every single fill.

In this blog post, we will bring you some insight into what net weight filling machines are, how they work, their advantages over manual weighing methods, as well as some potential downsides to consider when deciding if they're right for your business. Therefore, keep reading to discover why net weight filling machines are quickly becoming an essential piece of equipment in many production facilities!

1.What Is A Net Weight Filling Machine?

The net weight filling machine is a specialized piece of equipment used in industrial processes for weighing and packaging ingredients, liquids or pastes into containers. This device is designed to dispense predetermined amounts of liquid or solid materials into various types of containers.

Net weight filling machines are used in many industries including food processing, cosmetic industry, chemical manufacturing, and pharmaceutical production. These machines can fill containers with very precise weights or volumes of products depending on how they are set up.

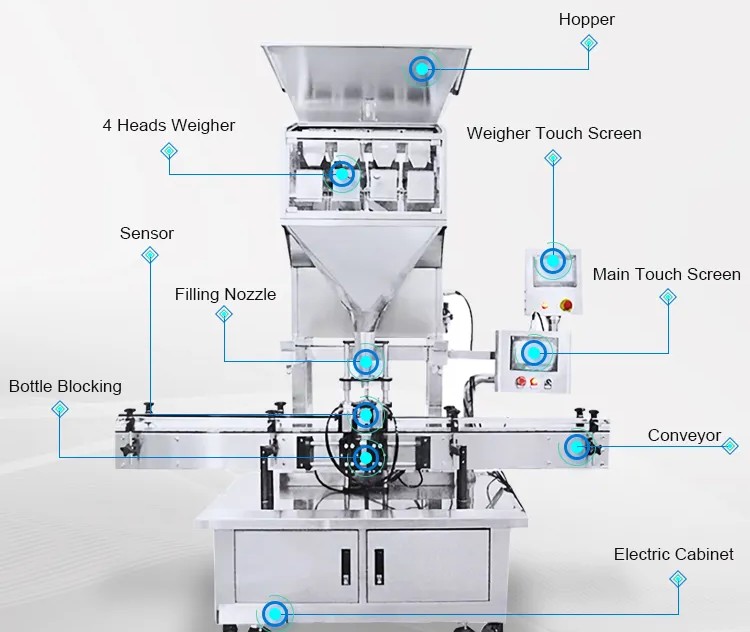

2.What Are The Components Of A Net Weight Filling Machine?

Supply Hopper

The supply hopper is the main ingredient storage unit for a net weight filling machine. The storage capacity of the hopper can be adjusted depending on how much product needs to be filled into packages.

Vibrating Feed Pan

The vibrating feed pan is attached to the supply hopper and helps regulate the flow of product into the filling machine. This helps ensure that the exact amount of product is being filled into each package.

Weigh Hopper

The weigh hopper is where the product actually gets weighed before being filled into packages. It is usually connected to a scale and the amount of product that goes into each package can be adjusted according to the readings on the scale.

Discharge Funnel

The discharge funnel is connected to the weigh hopper and helps feed product into the filler nozzles. This ensures that the exact amount of product is being filled into each package.

Logical Controller

The logical controller helps to regulate the speed of the conveyor belt. This helps ensure that product is being filled at a consistent rate, allowing for accurate filling and minimal waste.

Spout

The spout is connected to the weigh hopper and helps guide product into the filler nozzles. This ensures that the exact amount of product goes into each package without any overflow or loss.

Standard Chassis

The standard chassis is the base of the net weight filling machine. It holds all of the components together and helps provide a stable platform for accurate and consistent filling.

Foot Switch

The foot switch is an optional safety feature that can be added to a net weight filling machine. It allows the operator to quickly stop the filling process if something goes wrong or if incorrect amount of product is being filled into a package.

3.What Are The Benefits Of Using A Net Weight Filling Machine Over Manual Or Other Automated Processes?

Flexible Filling Capacity

A net weight filling machine offers a wide range of flexible filling capacities to suit different product requirements. This means that the production line can be quickly adjusted without having to invest in a new net weight filling machine.

Accuracy

When it comes to measuring and dispensing products, net weight filling machines offer high accuracy and consistency meaning less wastage and a better product for the consumer.

Semi-Automatic or Automatic Functionality

Net weight filling machines can be used in either semi-automatic or automatic processes, meaning operators have the flexibility to choose which configuration is most effective for their needs.

Increased Productivity

In terms of productivity, weight filling machines can fill multiple containers quickly reducing production times and increasing the overall productivity of a facility.

Reduced Waste

Net weight filling machines are equipped with sensors that help to reduce product losses due to overfilling or spillage, resulting in less wasted product.

Cost Savings

In terms of cost net weight filling machines can help to reduce expenses associated with product returns and wasted product, resulting in long-term cost savings for a business.

4.What Are The Applications Of A Net Weight Filling Machine?

Common industries where net weight filling machines can be used include:

Food Industry

Net weight filling machines are often used to package food items such as cereal, coffee beans, and pet treats. Filling these items with precision is important to ensure optimal taste and consumer satisfaction.

Pharmaceutical Industry

In the pharmaceutical industry, net weight filling machines help to accurately dose medications in highly regulated doses. This ensures patient’s safety when taking these medications.

Chemical Industry

These machines can also be used in the chemical industry for packaging products such as detergents, bleaches, and cleaning solutions. It is important to accurately fill these items in order to ensure product safety.

Cosmetic Industry

Net weight filling machines are often used in the cosmetic industry as well. These machines help quickly and precisely fill cosmetics such as lotions, creams, perfumes, and other beauty products.

5.How Does A Net Weight Filling Machine Work?

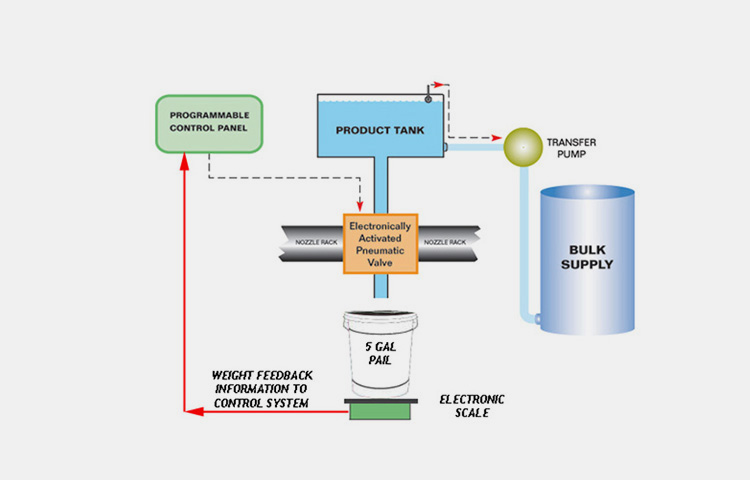

A net weight filling machine works by first weighing each empty container on an electronic scale, then filling it with the desired amount of product, before finally weighing the filled container to confirm that the desired weight has been achieved.

The process begins with product entering the hopper, which contains a load cell that measures the weight of the product. The load cell then sends a signal to a motor that adjusts the flow rate of the product so it stays within tolerance.

Once the desired weight is achieved, the machine stops filling and moves on to the next container. If the final weight is not correct, the machine can be programmed to automatically adjust accordingly and fill the containers with more or less product as needed.

6.What Are The Different Types Of Net Weight Filling Machines Available On The Market?

The different types of net weight filling machines include:

Automatic Net Weight Filling Machine

An automatic net weight filling machine is a type of filling machine that uses a volumetric or gravimetric method to fill a container with a predetermined amount of product. The machine can be programmed to accurately control the flow and quantity of material being filled.

Semi-Automatic Net Weight Filling Machines

A semi-automatic net weight filling machine is an automated device that uses a programmed digital scale and volumetric or gravimetric methods to fill receptacles with predetermined amounts of product. This type of machine offers the accuracy and precision of automatic machines, but requires manual operation throughout the process.

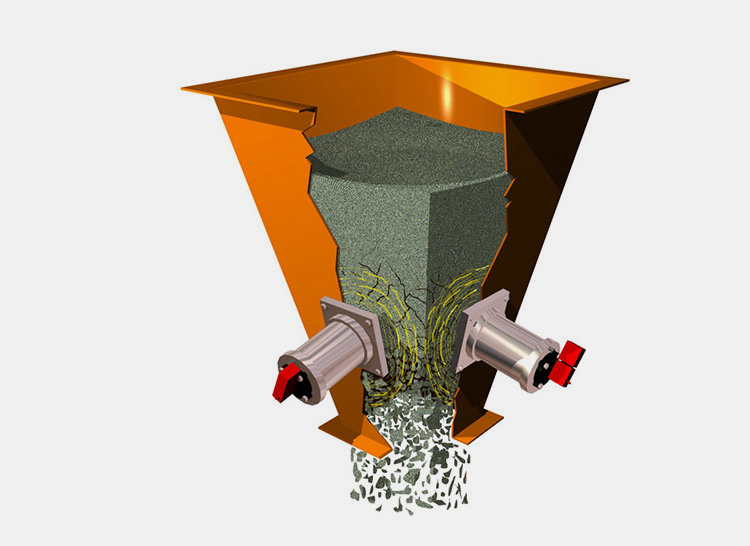

Auger Net Weight Filling Machines

This type of machine is designed to fill containers with a measured dose of product using an auger-type mechanism. It is used mainly in applications that require accurate dosing, such as pharmaceuticals and cosmetics.

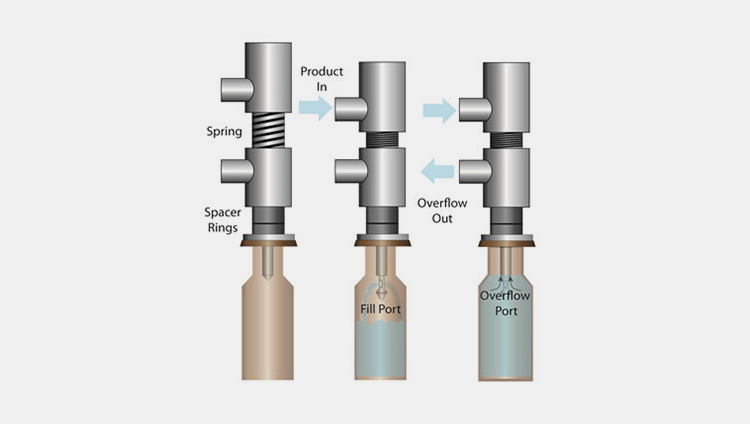

Piston Net Weight Filling Machines

Piston net weight filling machines use a piston-like device to fill containers with precise amounts of product at high speeds. The piston is adjustable and can be moved up or down to accommodate different sizes of containers, while its tight seal prevents any leakage during the filling process.

Gravity Net Weight Filling Machines

These machines take advantage of force of gravity to fill containers with product. A hopper is mounted above the container, with the weight and speed at which it dispenses product being adjustable.

Vacuum Net Weight Filling Machines

These machines use air pressure to create a vacuum inside a chamber that sucks up and fills containers with liquid or powder products. The speed and volume of the product being filled can be adjusted to meet different production needs.

Volumetric Net Weight Filling Machines

Volumetric net weight filling machines use a combination of weight and volumetric measurements to ensure accurate filling of containers. The amount of product dispensed is determined by the size of the container, as well as its capacity.

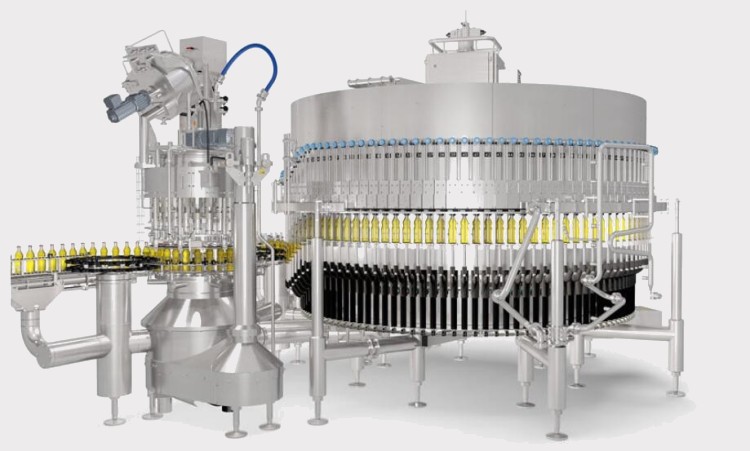

Continuous Motion Net Weight Filling Machines

Continuous net weight filling machines are designed to fill multiple containers at once using a continuous motion mechanism. They are typically used in applications where products need to be filled quickly and accurately, such as food and beverage packaging.

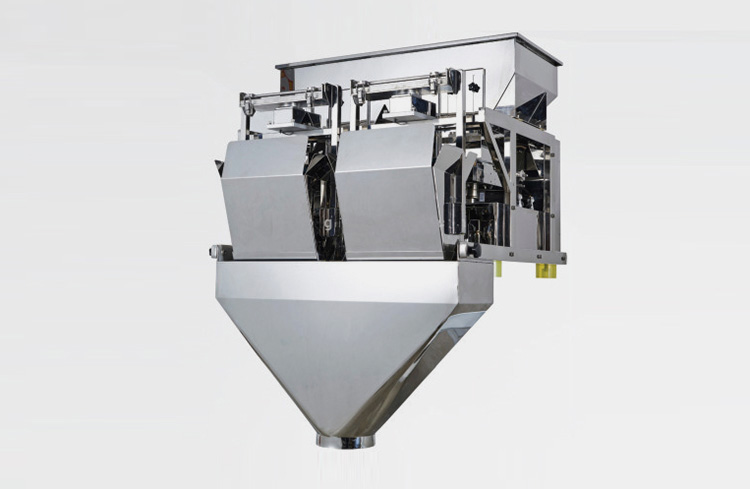

Multi-head Net Weight Filling Machines

This type of machine is used for filling containers with pre-weighed materials, such as powders, granules and liquid products. The material is filled into multiple hoppers at the top of the machine and then dispensed into the container below in a controlled.

7.What Is The Difference Between An Automatic Net Weight Filling Machine And A Semi-Automatic Net Weight Filling Machine?

An automatic net weight filling machine is a fully automated, computer-controlled equipment that utilizes precision technology for accurate measurements and fills packages with a given net weight. This process is fast and efficient as it requires minimal user input and has a high level of accuracy.

A semi-automatic net weight filling machine, on the other hand, still requires manual input to some extent even if’s just setting up the measurement parameters before beginning production. You are also required to make sure that the product is being filled as desired and with the correct net weight.

8.What Is The Difference Between A Piston Net Weight Filling Machine And An Auger Net Weight Filling Machine?

The biggest difference between these two machines is in their filling technique. The piston net weight filling machine uses a plunger mechanism to dispense the material into a container, while the auger net weight filling machine uses an auger screw system to move the product into a container.

Also, the piston net weight filling machine is more suitable for dispensing thin liquids or products with small particles, such as powders, due to its smooth plunger action. On the other hand, the auger net weight filling machine is better for thicker liquids or products with larger particles, due to its ability to apply pressure on the material.

In terms of speed and accuracy, both machines can provide high-precision results. However, the piston net weight filling machine is usually faster than the auger net weight filling machine. This makes it ideal for large-scale production, such as food or beverage factories.

9.What Is The Difference Between A Gravity Net Weight Filling Machine And A Volumetric Net Weight Filling Machine?

A gravity net weight filling machine uses an automatic weighing system where a predetermined amount of product is delivered into a container using a stream of air or other gas. This method is more accurate than a volumetric filling machine as it ensures that each container receives the exact same amount of product without any human interference.

A volumetric net weight filling machine uses a motor-driven valve to dispense a predetermined amount of product into containers. It is less accurate than a gravity system, and can be more susceptible to variations caused by human error. This type of machine is better suited for products that have a high-level of tolerance when it comes to variations in the fill weight, such as sauces and condiments.

10.What Type Of Products Can Be Filled With A Net Weight Filling Machine?

A net weight filling machine can be used in many industries to accurately fill containers with a variety of products. The most common materials that can be filled with a net weight filling machine include:

Powders

A variety of food powders including cocoa powder, flour, spice and baking powder can easily be filled with a net weight filling machine. This machine can also be used to fill pharmaceuticals and other chemical powders.

Granules

Seeds, grains, nuts and other granular materials can be filled into containers with a net weight filling machine.

Liquids

Net weight filling machines are often used in the food, beverage, and personal care industries for filling liquids such as sauces, lotions, oils, syrups, juices, and more.

Pastes

Products like peanut butter, jelly, honey, jam and other paste like substances can also be filled with a net weight filling machine.

11.What Type Of Packaging Materials Can A Net Weight Filling Machine Be Used With?

A net weight filling machine can be used with a variety of packaging materials depending on the application. Commonly used materials include:

Pouches

Pouch packages are ideal for liquids, powders, and pastes with low viscosity.

Bottles and jars

Suited to products including pharmaceuticals, sauces, and condiments.

Cartons

Generally used for large and heavy products such as pet food or grain fillers.

Canisters

Canisters are suitable for lightweight materials including sugar, salt, honey and coffee among others.

Drums

Drums are recommended for hazardous substances, especially in industrial environments.

Sacks

This package is commonly used with grains and flours.

12.What Are The Maintenance Procedures For A Net Weight Filling Machine?

The following are some of the general maintenance steps to follow when caring for a net weight filling machine:

Check for any signs of wear or damage to parts before use, and replace any worn or damaged parts as needed.

Test the accuracy of filling weights regularly, either manually or with a special system.

Monitor the performance of the machine and adjust it if necessary according to manufacturer instructions.

Clean the machine parts regularly to prevent contamination and ensure accurate filling weights.

Lubricate all the moving parts frequently with approved lubricants according to the instructions of the manufacturer.

Inspect the machine and its components on a regular basis to make sure they are working properly.

13.What Are The Common Problems Associated With Using A Net Weight Filling Machine And Their Possible Solutions?

Overfilling or Under Filling

The net weight filling machines can cause either over- or under-filling due to weighing inaccuracies, incorrect settings, and improper product consistency.

To prevent this from happening, you should always double-check the settings before beginning a batch of products and regularly check that the machine is calibrated properly.

Contamination Risk

The net weight filling machine includes many parts that come in contact with the product, increasing the risk of contamination.

To reduce this risk, you should regularly clean and disinfect all parts of the machine, paying special attention to those that come into direct contact with the product.

Jammed Hoppers

The hopper of a net weight filling machine can sometimes become jammed, preventing the product from being dispensed. This is often caused by clumps in the product or foreign objects that have been mixed into it.

To overcome jamming, you should always check incoming batches for any contaminants and also use strainers to minimize clumping.

Corrosion

If a net weight filling machine is exposed to moisture or to harsh chemicals, corrosion can occur and this can lead to malfunctions and product loss.

Possible solutions include regularly inspecting the machine for signs of corrosion and taking steps to prevent exposure to moisture or chemicals.

Clogging

Clogging can be an issue in a net weight filling machine if the material being filled is too dry or not mixed properly. This can lead to under fills and product loss.

In order to solve clogging, ensure that materials are adequately mixed before filling and use lubricants such as vegetable oil to help reduce clogs.

CONCLUSION

All in all, investing in a net weight filling machine may be just what your company needs to reach its goals efficiently and profitably. Companies of all types and sizes from food-based producers to industrial chemical makers can benefit from utilizing this advanced machinery. Compared to manual methods of production, machines like the net weight filling machine not only improve accuracy and speed but also relieve human fatigue in repetitive tasks. If you are looking for a reliable device that can meet your filling requirements with precision, then you should look no further - contact Allpack today!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Net Weight Filling Machine: The Complete Buying Guide In 2025 Read More »