Viscosity Tester:The Complete Buying Guide In 2025

As an important physical parameter measuring instrument, the application of viscosity tester is across multiple industries. It can provide you with more refined and highly stable viscosity measurement. Do you understand the application and effectiveness of viscosity tester? In which industries can it be applied? Is its safety and effectiveness limited?

If you want to choose a suitable viscosity tester, what aspects should you know about? After choosing a viscosity tester, how should you apply and maintain it? This complete guide of viscosity tester will give you a comprehensive answer. Let's make it clear now!

1.What Is Product Viscosity?

What Is Product Viscosity-sourced: vikingpump

Product viscosity is a measure of the resistance or internal friction of liquids and viscous bodies during flow. Liquids with low viscosity have higher fluidity, such as water. Liquids with high viscosity have lower fluidity, such as hand cream. The formula for testing product viscosity is: product viscosity = shear stress / shear rate. Its results are usually expressed in centipoise (cP).

2.What Products Need Viscosity Testing?

What products are used for viscosity testing? Products in most industries, as long as they are related to liquids and pastes, are basically used for viscosity testing.

Food Products

Food Products-sourced: food52

The food industry is widely used for viscosity testing. Its products include but are not limited to beverages, milk, coffee, seasonings, ketchup, mayonnaise, jam, syrup, etc. By measuring the viscosity of food, it can help the product choose packaging containers and packaging methods.

Pharmaceutical Products

Pharmaceutical Products-sourced: aphenapharma

Various antibiotic liquid products, saline and glucose, vitamins and electrolyte liquids, cold and cough syrups, etc., can all be tested for viscosity to verify the product's effectiveness and subsequent packaging applications.

Chemical Products

Chemical Products-sourced: cdhfinechemical

Various chemical products, such as adhesives, petroleum, concrete, etc., will be tested for viscosity. The viscosity test of adhesives can help consider whether the adhesive flows on the parts after application. The viscosity test of petroleum can help predict the effectiveness of lubricants and help with pipeline design, etc.

Cosmetics

Cosmetics-sourced: sensient-beauty

Through viscosity testing of various cosmetics and skin care products, it can help manufacturers get the product usage experience and absorption effect in advance. The viscosity of skin care products is very important to the user's experience. These products include but are not limited to toner, lotion, cream, shampoo, shower gel, body lotion, etc.

3.What Is Viscosity Tester?

What Is Viscosity Tester-sourced: mtixtl

Viscosity tester, also called as viscometer or rheometer, is a tool used to measure the viscosity or flow resistance of liquids or fluids. It can accurately measure the flow resistance and friction inside the fluid. Viscosity tester can be used to test a variety of materials, including paints, coatings, adhesives, waxes, oils, plastics, food, beverages, toothpaste, cosmetics and shampoo.

4.What Industry May Benefit From Viscosity Tester?

Now all walks of life are widely using viscosity testers to measure products in different fields. These include:

Petrochemical and Oil Industry

Petrochemical and Oil Industry-sourced: chem

The viscosity measurement of oil is related to the quality of the product and the design and laying of the subsequent oil pipeline. In order to reduce costs and improve the effect, it is necessary to conduct viscosity testing in advance.

Pharmaceutical, Biotechnology and Clinical Research Industries

Pharmaceutical, Biotechnology and Clinical Research Industries-sourced: thoughtco

Now various fluid drugs, biotechnology and clinical research industries need viscosity testers to detect the main conditions and quality of drugs. This facilitates the subsequent drug development.

Food and Beverage Industry

Food and Beverage Industry-sourced: drinkjapan

The viscosity measurement of food and beverages is mainly for the subsequent selection of corresponding packaging methods and packaging containers. Products with different viscosities require different packaging methods.

Beauty and Cosmetics Industry

Beauty and Cosmetics Industry-sourced: today

More beauty and cosmetics industries are beginning to rely on viscosity testers. They can help detect the viscosity of products and thus predict the user's use effect.

Chemistry Industry

Chemistry Industry-sourced: smcompany

Many chemicals, such as pesticides, fertilizers, coatings, pigments, etc., also require viscosity testing. This can facilitate subsequent quality monitoring.

5.Why Should You Test Product Viscosity With Viscosity Tester?

You may wonder, what is the use of measuring the viscosity of products for our industry? It has the following main functions:

Understand the Viscosity of Materials

Viscosity of Materials-sourced: anton-paar

Using a viscosity tester to test materials can give a good understanding of the viscosity of boring materials. Therefore, it is possible to predict in advance

the performance of materials in the real world and the effect and quality of use.

Predict the Design of Production and Transportation Processes In Advance

The viscosity of products can greatly affect the final production, packaging and transportation plans of subsequent products. Products with high viscosity generally try not to use packaging that is difficult to access. Products with low viscosity have a wider range of packaging options.

6.What Are The Benefits Of Viscosity Tester?

Using viscosity tester can bring you the following advantages:

Wide Range of Applications

Wide Range of Applications-sourced: rheologylab

The viscosity tester is able to handle various types of materials and measure the corresponding viscosity. In addition to this, it can handle products of various shapes.

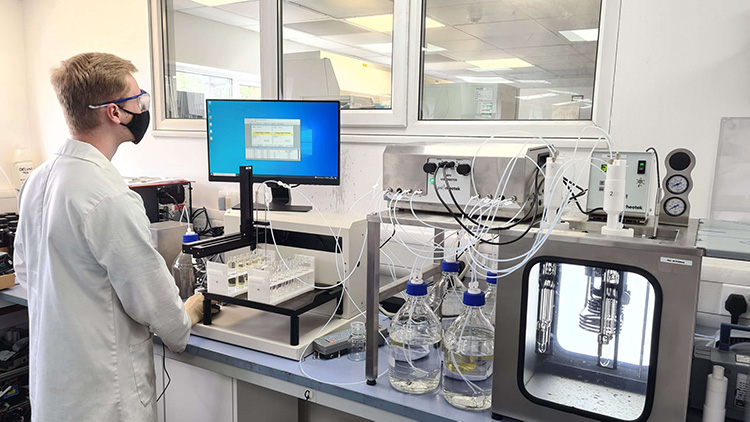

Improve Accuracy and Precision

Improve Accuracy and Precision-sourced: researchgate

There is a big difference in accuracy and precision between the viscosity measured by the naked eye or touch and the viscosity tester. The viscosity tester uses a built-in microprocessor to collect data, which can avoid data being affected by factors such as technology, temperature fluctuations and time changes.

Improve Efficiency and Speed

Improve Efficiency and Speed-sourced: labbulletin

Most viscosity testers are fully automatic models. In addition to providing the most accurate and precise results, it also simplifies the measurement process and avoids manual measurements and lengthy data analysis. Its application can significantly improve your measurements.

Enhance Data Collection and Management

Enhance Data Collection and Management-sourced: amsoil

Viscosity tester records all data electronically, eliminating the need for manual transcription. This avoids mistakes in manual transcription. You can easily access, view, export, etc. to enhance data collection and management.

Improve Safety and Reduce Waste

Improve Safety and Reduce Waste-sourced: psl-rheotek

Even with very few samples, the viscosity tester is able to make measurements and produce accurate results. This can reduce the dosage of test samples and reduce waste to a greater extent.

7.How Do You Measure Viscosity With The Viscosity Tester?

How Do You Measure Viscosity With The Viscosity Tester-sourced: fluidmatters

To measure the viscosity with the viscosity tester may need the following steps:

Wear Personal Protective Equipment

Before using the viscosity tester, you should wear personal protective equipment such as goggles and gloves. Avoid splashing and spilling of chemicals during operation.

Proper Setup

Check if the viscosity tester is properly placed. Make sure the digital rotational viscometer is mounted on a stable, level surface.

Sample Handling

Place the prepared sample safely under the spindle of the viscosity tester. Avoid spilling or splashing. Do not overfill the sample container, which will interfere with the rotating spindle.

Temperature Control

Regulate the temperature of the viscosity tester according to the user manual. Also pay attention to keeping the sample within the specified temperature range during the measurement.

Spindle Installation and Removal

When the device is tested and the data is output, disconnect the power supply. Safely remove the sample container and carefully remove the spindle or rotor accessories.

Data Reading and Recording

After the data is output and the spindle is removed, you can export and record the data for later comparison and processing.

8.How Many Types Of Viscosity Tester Are There?

There are several types of viscosity tester for your choice with good quality and stability. They are:

Capillary Viscometer

Capillary Viscometers-sourced: icllabs

Capillary viscometer, also called as U-tube or glass viscometer, is one type instrument used in the laboratory to measure the viscosity of materials. The viscosity of a material is measured by calculating the time it takes for a transparent or translucent fluid to flow through a glass tube. This type of capillary viscometer can also be divided into manual and automatic types.

Rotational Viscometer

Rotational Viscometers-sourced: dtc-webshop

Rotational viscometer, also called as Brookfield type viscometer. It mainly measures the viscosity of a material by the torque required by the rotating spindle in the torsion spring in the material. By changing the rotor speed and size, etc., it can help you measure different ranges of material viscosity. Rotational viscometer can use different spindle geometries to adapt to different types of materials.

Falling Ball Viscometer

Falling Ball Viscometers-sourced: cromocol

Falling ball viscometer is the viscometer that use the rolling ball principle. They measure the viscosity of a sample by rolling a ball in a closed, inclined capillary filled with a sample and calculating the time it takes to pass and the resistance it encounters under the action of gravity. An inductive sensor in the device can measure and record the time the ball rolls.

Vibrational Viscometer

Vibrational Viscometer-sourced: dscbalances

Vibrational viscometer mainly uses the resistance encountered by the vibrating blade when vibrating in the fluid to measure the viscosity of the fluid. Its shaft vibration and detection are both carried out through magnetism.

Cone and Plate Viscometer

Cone and Plate Viscometer-sourced: solvica

The cone and plate viscometer is a viscometer specifically used in laboratories. It is mainly used to measure the viscosity of non-Newtonian fluids. The sample is placed on a plate and the cone is rotated to apply pressure. This allows the shear rate applied to the fluid to be accurately controlled and measured.

9.What Are The Parts Of Viscosity Tester?

The parts of viscosity tester is simple. However, if there are more needs, you can also choose optional accessories like temperature probe, sample holder and protective cover to help you measure accurately and safely.

What Are The Parts Of Viscosity Tester-sourced: worldoftest

Rotating Spindle or Rotor

During the measurement process, it will be immersed in the sample. By applying shear stress to the spindle, it will cause the fluid to flow and deform, thereby measuring the viscosity of the fluid.

Torque Sensor

Torque sensor is mainly used to measure the resistance or torque experienced by the spindle during rotation, that is, the force it needs to overcome the sample. Its sensitivity is generally very high and the viscosity measurement is very accurate.

Drive System or Motor

The drive system or motor is mainly responsible for the speed of the spindle or rotor. It can keep the spindle running at a constant speed during the test.

Temperature Control

Temperature control is mainly responsible for keeping the sample at a constant temperature throughout the measurement process without being disturbed by the environment. Because viscosity usually changes with temperature.

Display and Interface

Display and interface can provide you with a friendly data viewing and monitoring platform. Generally, professional viscosity testers are equipped with LCD screens or touch screens to facilitate your data visualization.

Sample Chamber or Cup

The sample chamber or cup is used to hold the material to be measured. Its design and materials can reduce sample contamination and are suitable for most materials. It is also convenient for you to clean and maintain.

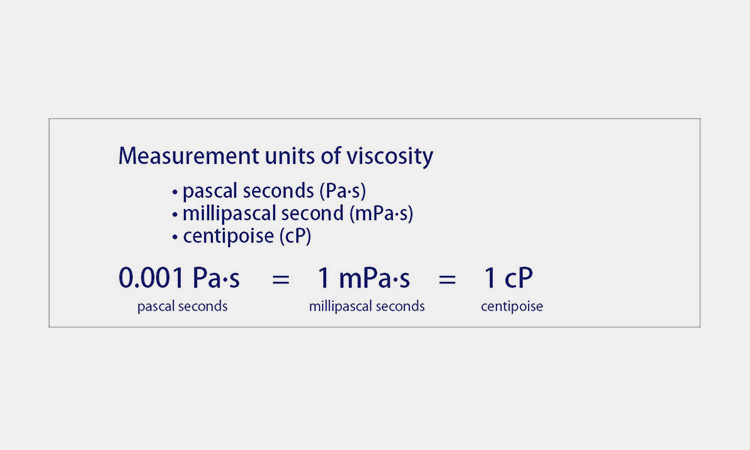

10.What Is The Unit And Rating Of Product Viscosity By Viscosity Tester?

In the process of understanding viscosity tester and product viscosity, it is inevitable to understand the unit of product viscosity.

The Unit Of Product Viscosity- Centipoise

The Unit Of Product Viscosity-sourced: thinkymixer

Centipoise is a common term for liquid viscosity. It is the smallest unit of dynamic viscosity. That is, the resistance and internal friction of a fluid when it flows under a certain shear stress. Its unit is: cP.

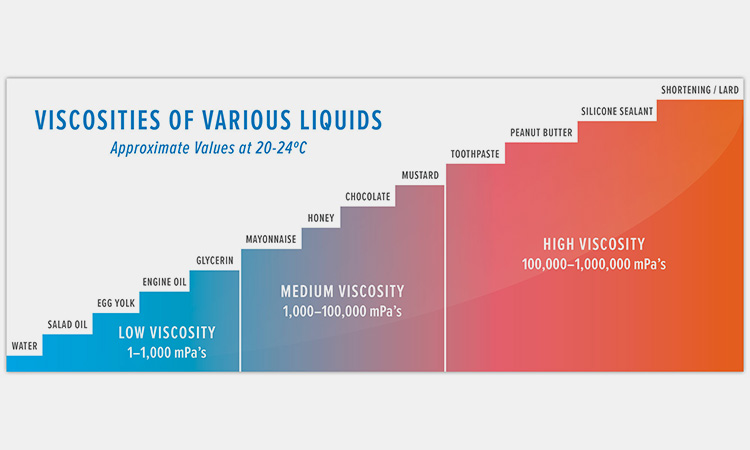

Rating Of Product Viscosity By Viscosity Tester

Rating Of Product Viscosity By Viscosity Tester-sourced: amazonaws

By using a viscosity tester, you can rate the viscosity of different materials. The higher the centipoise value, the higher the viscosity of the material. The lower the centipoise value, the lower the viscosity of the material.

Below are some examples of daily necessities and their corresponding viscosities:

| Items | Centipoise | Viscosity |

| Water | 1 | Non-viscous |

| Perfume | 1-7 | Non-viscous |

| Liquid ink | 25 | Non-viscous |

| Syrup | 44 | Semi-viscous |

| Oil | 160 | Semi-viscous |

| Varnish | 420 | Semi-viscous |

| Shampoo | 800 | Viscous |

| Ketchup | 190,000 | Viscous |

| Peanut butter | 250,000 | Viscous |

| Vaseline | 64,000 | Viscous |

11.What Are The Industry Standards For Viscosity Testing By Viscosity Tester?

There are several different, widely accepted standards for using a viscosity tester and doing viscosity testing. They include:

ASTM D4287

This standard refer to apply the cone or plate viscometer to determine the high shear viscosity of a sample. This method is suitable for testing the viscosity of paints, varnishes and related products at a shear rate of 12,000 s−1. However, it is not possible to measure the viscosity of very fast drying products.

BS 3900-A7

The BS 3900-A7 standard applies to the viscosity of most liquids or fluids. It is a widely accepted method and standard.

ISO 2884

ISO 2884 is an international standard on how to measure and evaluate the viscosity of materials. It specifies the use of a rotational viscometer to determine the viscosity of paints, varnishes and related products.

12.What Are The Factors To Consider When Choosing A Viscosity Tester?

By understanding the different types of viscosity testers and their characteristics. How do you consider and choose before using? There are several points for your reference:

Type and Properties of Test Materials

Type and Properties of Test Materials-sourced: hanchen

Different materials are suitable for different types of viscosity testers. Some specific materials are suitable for more professional instruments. For example, when you are considering measuring corrosive liquids, you must consider the corrosion resistance of the instrument.

Measuring Range and Accuracy

Measuring Range and Accuracy-sourced: sptthailand

If you do not have high requirements for the measurement range and accuracy, you can use a simple, home or laboratory type of viscosity tester. If you have high requirements for the measurement range and accuracy, then you should choose more professional rotational viscometers.

Temperature Control

Temperature Control-sourced: anton-paar

During the measurement process, temperature control of materials and viscosity testers is very important. Different rheometers and viscometers have different sensitivities. The influence of temperature will also affect the data collection and analysis of the equipment.

Ease of Use and Maintenance

Ease of Use and Maintenance-sourced: cscscientific

If the demand for ease of use and maintenance is high, you can choose rheometers and viscometers that are easier to use than others. You can also choose the type of laboratory instrument that operates efficiently.

Conclusion:

Choosing the right viscosity tester for your business and laboratory is a crucial decision. Through this complete buying guide of viscosity tester, you may learn about the different types of instruments and their related applications. If there are more types you want to know, please contact Allpack now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide