Your Best Liquid&Granule & Powder Vertical Sachet Machine Supplier

- Worldwide branded components

- Easy and precise sealing pressure adjustment

- High accuracy for the smallest of dosing weight

Allpack Vertical Sachet Machine

Allpack vertical sachet machine is a mechanical device specially designed to automate the process of packing products into small sachets.The machine has been widely used for packaging small quantities of powder, liquid, or granules, such as sugar, salt, shampoo, or coffee into 3 side or 4 side sealing pouches.Allpack vertical sachet machine will ensure each package is of the same size and weight, providing a consistent and professional look.By automating the packaging process, these machines help businesses save on labor costs. Additionally, the precise filling mechanism reduces product wastage, further saving costs.With the ability to handle a variety of products and packaging materials, Allpack vertical sachet machines offer flexibility, allowing businesses to cater to different market needs.

Vertical Sachet Machine

APK-338-1 High-speed viscosity liquid vertical sachet machine energy gel cream lotion cheese honey paste packing machine

Allpack APK-338-1 high speed viscosity liquid vertical sachet machine is a roller type packaging machine designed for automatic forming, filling, and sealing of liquids, adhesives (creams, sauces, etc.), powders, granules, and other materials. This machine can achieve packaging with 3 or 4 sided sealing. It adopts an advanced industrial computer control system, which can conveniently and accurately adjust and change the bag size, length or reduction, and packaging speed.

Using high-reliability electrical and pneumatic components

Adopt squeeze exhaust method

automatic alarm and display the cause of the failure

APK-338-2 High-speed liquid vertical sachet machine ketchup honey oil jam jelly chocolate sachet bag liquid paste filling and packing packaging machine

Allpack APK-338-2 high-speed liquid vertical sachet machine can be used to pack liquids and semi-fluids such as sauces, soups, oils, etc.This liquid sachet filling machine can also run long hours without requiring any maintenance or repair. It is a sachet packaging machine with an external suction pump for light materials such as water or sauce.The machine will help you increase your efficiency by combining sachet filling and sealing processes into one single step.

Automatic fault alarm system ensures safe and reliable operation

Integrated control panel, man-machine interface touch screen

Easy operation and maintenance.

APK-338-3 High-speed sauce vertical sachet machine syrup jam honey juice sauce lotion packing

Allpack APK-338-3 High-speed sauce vertical sachet machine is designed to prepare sachet type packages and to place sauce products into the sachets. Such as jam, sauce, condiment, drink, oil, yogurt, shampoo, hand sanitizer, etc.It has been widely used in used in food, chemical, medicine, condiment, daily necessities. With stainless steel body, compact structure,the sachet machine has feature of stable performance, small footprint, easy maintenance.With touch screen operation,the machine is simple and east to understand.

Stable performance, small footprint, easy maintenance

Seal tightly to avoid moisture

High filling accuracy

APK-338-8 High-speed sauce vertical sachet machine peanut sauce pouch filling and sealing machine

APK-338-8 High-speed sauce vertical sachet machine,the difference with APK-338-3 is that its feed system adopts pneumatic rotor pump,that can fill up to 3600 bags per hour,quickly and accurately,and meet with GMP standards.The made pouch can be 3 side sealing or 4 side sealing .The parts that touch the material are stainless steel,it has been widely used in packing products in food,beverages,cosmetics,chemicals,and many other industries.

Famous brand components

Intelligent temperature controller

Easy adjustment and good application to various laminated film and paper

APK-338A2 High-speed granule vertical sachet machine chips rice dry fruits bag packing machine

Allpack APK-338A2 high-speed granule vertical sachet machine is operated by volumetric system for free-flowing products.You can use this machine to pack your sugar,salt,silica gel,sweeteners,granular coffee,black pepper etc.in the industries such as pharmacy,food,agricultural and chemical.There is reliable weight control during the packaging process and result in less product loss and the machine is easy to use and clean.This granule sachet machine could also offer you long-term,high-performance and compact solutions.

Packing type diversification

Automatically finish bag-making, weighing, packing, sealing, printing date and cutting

Quiet work circumstance quiet, low noise

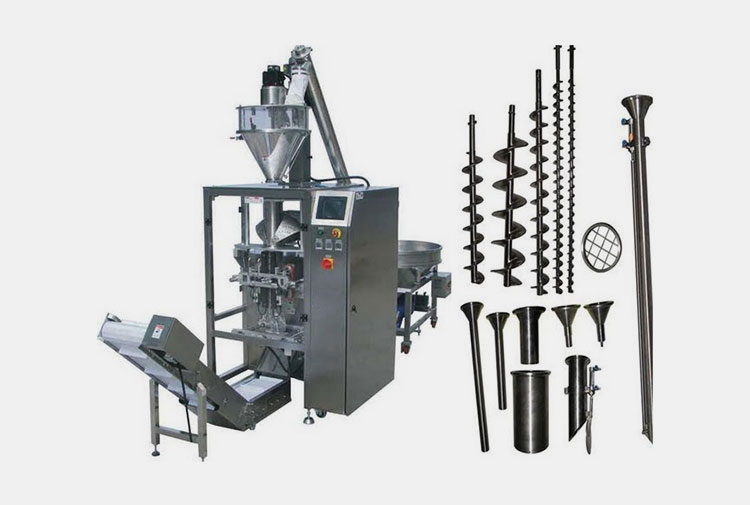

APK-338A3 High-speed powder vertical sachet machine milk wash powder chilli coffee powder filling and sealing machine

Allpack APK-338A3 High-speed powder vertical sachet machine is designed for filling semi -free flowing and non-free flowing powder products. For example cosmetics powder, 3in1 coffee, chemical powder, supplement powder, powdered coffee, spices products into four sides sealed sachet. Its advantage is it can be easily loaded with the sachet and you can easily adjust its parameters to meet your sachet packaging requirements.This sachet filling machine is made of stainless steel and can run long hours without wear and tear.

ntelligent PLC control system

Touch screen operation

Automatic slitting film system

Vertical Sachet Machine Videos

The Buyer's Guide

Vertical Sachet Machine: The Complete FAQ Guide In 2025

Why a vertical Sachet Machine is Popular?

There are several kinds of Form, Fill, and Seal Equipment ranging for various states of formulation and packaging applications. The leading usage among all is the Vertical Sachet Machine across the globe.

Picture Courtesy: GuardPack

There are significant factors behind its popularity. Out of which its simplest structure is paramount. In this blog, Vertical Sachet Machine: The Complete FAQ Guide In 2024, you will explore the basic details related to the equipment. Come and Explore!

1.What Is a Vertical Sachet Machine?

Allpack Vertical Sachet Machine

A vertical sachet machine is a multiline equipment that is capable of dealing with numerous packaging widths and formatting as well as different states of materials.

This is a flexible machine that is helpful in carrying packaging demands followed by advanced features.

This machine is user-friendly equipment with high elementary characteristics where it is responsible for the production of sachet following working pattern in a vertical fashion.

A Food-Grade and Stainless-Steel body made up of a vertical sachet machine is a promising piece of equipment that is compact in structure and cost-effective in price.

2.What Is the Function of a Vertical Sachet Machine?

There are various significant functions provided by a vertical sachet machine; some of its major functions are discussed below:

Versatile Sachet Types

Versatile- Picture Courtesy: Mock up Planet

A vertical sachet machine is a versatile machine that enables you to create unique packaging designs including 2-side seal, 3-side seal, or 4-side seal with diverse packaging features such as heat, ultrasonic, or magnetic sealing properties depending upon your need and machine manufacturer or models.

Quick Bag Former Changeover

Easy and Quick Changeover

This machine is user-friendly in nature, and it can manufacture sachet of different sizes which can hold materials with different weights ensuring ease of operation and seamless productivity.

PLC Control System

PLC Controlled Unit- Picture Courtesy: Dribbble

This machine has enhanced productivity as it is equipped with a PLC control unit where you can enjoy and operate the system by using touch touchscreen interface with easy-understanding options.

Greater Precision

High Precision- Picture Courtesy: Design Crowd

Due to the servo motor and advanced features of the vertical sachet machine, it provides accurate and fast working with maximum precision and high-quality packaging efficiency.

Auto Alarm Protection

Auto-Alarm Protection- Picture Courtesy: Kagome USA

Today, advanced vertical sachet machines are equipped with auto-alarm features that help you prompt notifications about downtime and make you alert about interruptions that are coming ahead. Therefore, let you know to protect the machine, production, and worker.

Food-Grade Stainless Steel Construction

Safe Machine- Picture Courtesy: Mockup den

The materials used in the vertical sachet machine are of high quality stainless steel that ensures high safety, minimum chances of cross-contamination, and an easy cleaning option therefore you can use it for packaging medicines, research-related products, or food items.

High Packing Speed

High Production Capacity- Picture Courtesy: Easy SnaP Technology

Due to high automation and fast production, this machine gives high productivity and delivers greater performance, now you can enjoy obtaining greater output in less work time.

3.What Are the Uses of Vertical Sachet Machine?

You can use a vertical sachet machine for various applications. In production companies, it is mainly used for packaging the mentioned below products. For example:

Food Industry

Food products

You have seen various food products presented in sachets. This particularly includes packaging items that are required for one-time or single-time usage. For example, sugars, salts, sauces, tea bags, etc. A confined portion of the product is perfectly packed by using none other than a vertical sachet machine with improved quality.

Medicinal, Medical & Healthcare Industry

Medicinal Sachet-Picture Courtesy: MedsGo

This is the most demanding fielding that keeps on growing leap and bound without affecting its market value.

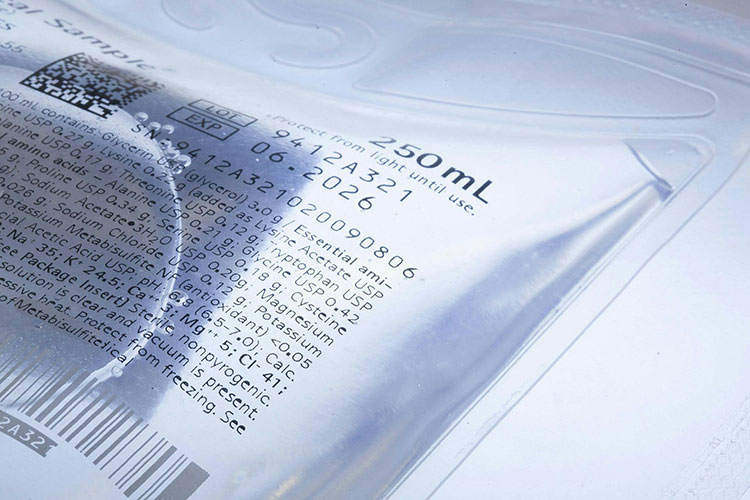

There are several products belonging to pharma and healthcare that need to be packed in single-dose sachets, such as vitamins, powdered unit dose medications, medical parts such as sutures, needless, and semi-solid products such as lotions, creams, and liquids, etc., the vertical sachet machine is important equipment that dealing with packaging and delivering an accurate dosage provided tamper evident sealing till its end-user safely.

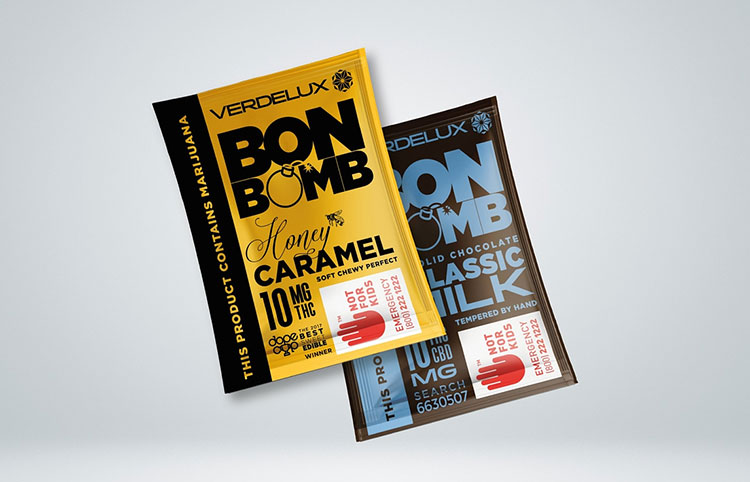

Cosmetics Industry

Cosmetic Sachet

What would be the cosmetics industry without a vertical sachet machine? Certain products are nicely packed in small aesthetic sachets such as shampoo, creams, masks, gels, primers cleansers, serums, and others by using a vertical sachet machine.

Household Industry

Holdhouse Item- Picture Courtesy: Homeporium Australia

You have seen fragrances, air fresheners, car fresheners, disinfectants, shiners, fabric softeners, and related products in sachets. This is facilitated by utilizing a vertical sachet machine that provides an accurate portion of the product to you.

Agricultural Industry

Agricultural Items-Picture Courtesy: Retail Koppert Canada

This field of production packaging is involved with products such as pesticides, seeds, crop boosters, plant supplements, and related items that are delivered in unit sachets by using reliable equipment known as a vertical sachet machine.

Chemical Industry

Chemical Items

Chemical products such as alkaline, acidic, organic, inorganic, neutral salts, and related formulations mostly come to you in a one-time usage sachet, which is mainly packed with a vertical sachet machine. Besides this, products such as sealants, lubricants, oils, and cleaners, are also safely packed by using the same source of machinery.

Beverage Industry

Beverages- Picture Courtesy: Bioplus

The Beverage Industry mainly relies on vertical sachet machines to pack products like coffee, tea, powdery or liquid energy drinks, and related formulations in sachets.

Pet Food Industry

Pet eatables and Healthacre Items-Picture Courtesy: Pet Chemist

Animal food products are usually available in sachet such as nutrients, food supplements, shampoos, and medicines. They are mostly portioned and dispensed by a vertical sachet machine.

4.Vertical Sachet Machine- How It Forms Sachet?

This is a kind of equipment that ensures the formation of a sachet following a vertical pattern. For that, you must have knowledge about the parts and their functionality. How it forms a sachet, we have discussed the steps for you below:

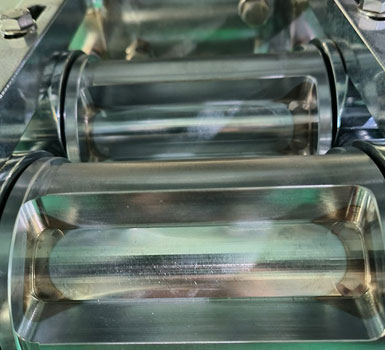

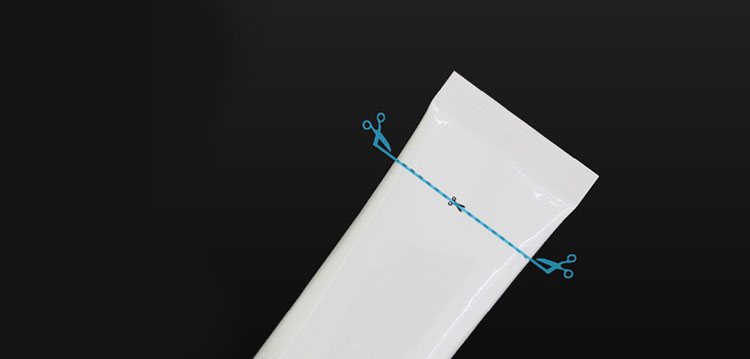

Sachet Film Pulling Mechanism

Vertical Sachet Machine

This system is involved with two basic units; an unwinding roller and a tensioner of the machine. When you adjust a roll stock over an unwinding roller or an unwinder, a tensioner ensures that it can be pulled easily without any interruption.

A roll is mostly based on materials that are Laminated PE, Aluminum, or PET. Similarly, in this case, a printer is equipped with the machine that is responsible for printing requirements when film is passed from these units.

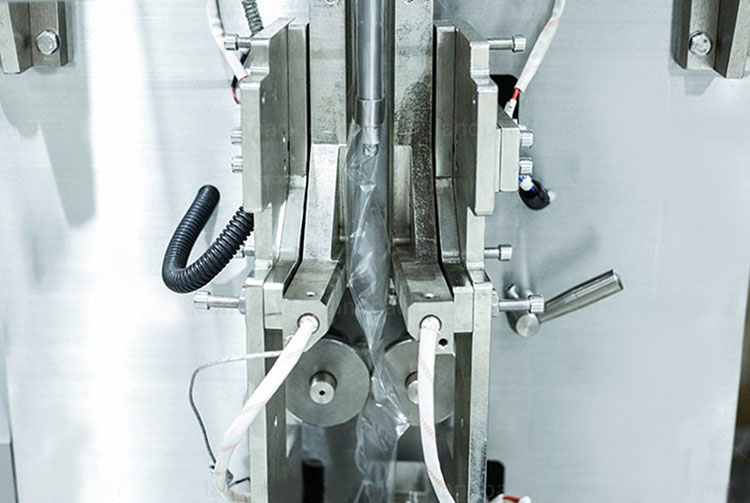

Sachet Formation, Filling & Sealing

Sachet Formation- Picture Courtesy: Packaging Machine

This is the main part of the work where the film is passed towards the sachet former. In this step, vertical and bottom sealers are involved to join the edges of the sachet to form a pack leaving the top side open.

Once the sachet is formed, an optimized quantity of the product is introduced into the bagging that is involved with the single-head or multi-head filling heads. The entire operation is synced electronically. Now sachet is ready for the final seal.

The top seal is done and the sachet is dropped down for the separation.

Sachet Cutting Unit

Cutting and Sealing- Picture Courtesy: Ocean Property

The filled and sealed sachet is separated by using fine cutters that punch a cut and bring the sachet toward the discharging unit.

5.How To Classify a Vertical Sachet Machine?

The basic classification of a vertical sachet machine is described below:

Small Size Vertical Sachet Machine

Small Vertical Sachet Machine

A compact and portable machine that is mostly used by you when dealing with small to medium capacities. This machine is available in semi-automatic and automatic features with the involvement and with no human intervention. This machine is easy to install, easy to operate, and easy to troubleshoot.

Large Vertical Sachet Machine

Large Vertical Sachet Machine- Picture Courtesy: Mateko

This is an extensive machine that is mostly applied to generate high production capacities. There’s one drawback associated with vertical sachet machines which is high floor space. However, you can enjoy the easy operating protocols, features, and advanced technologies when using a large vertical sachet machine.

According to the Filling Type

Auger Vertical Sachet Machine

Auger Vertical Sachet Machine

This is the popular equipment that is mostly recommended when you’re subjected to dealing with dry products. For instance, granules, powders, free-flowing as well as non-free-flowing, randomly shaped particles. Hence, a precise proportion of powder is taken and introduced into the sachet using an auger system without generating dust formation in your environment.

Piston Vertical Sachet Machine

Piston Vertical Sachet Machine- Picture Courtesy: PPI Tech

Dealing with liquid, semi-solid products, then a piston filler vertical sachet machine is ideal for you. This is particularly suggested for those customers or production businesses dealing with fluid formulations as the piston itself ensures the precise and correct amount of product and introduces them into each sachet respectively. Why piston? Because the piston is meant to narrow down the fluid flowing passaging and drop an accurate and exact amount of solution.

Pump Vertical Sachet Machine

Pump Vertical Sachet Machine- Picture Courtesy: Heyi-pack

A pump is responsible for forcing thick, highly viscous, or chunky materials directly into each sachet. A pump working depends on time-based or pulse-based. This means, that each time a specific amount is delivered, the amount is dropped down by each pulse.

Net-weigh Vertical Sachet Machine

Net-weigh Vertical Sachet Machine- Picture Courtesy: Wuhan Global

The working principle of a net weigh vertical sachet machine relies on measuring a net weight. Once it is estimated, the accurate amount of the product is filled into each sachet respectively.

According to the Number of Lanes

Single-lane Vertical Sachet Machine

Single-lane Vertical Sachet Machine

A simple structure vertical sachet machine where sachet formation, filling, and sealing are based on a single lane. This machine throughput rate is limited but is suitable for moderate productions.

Multi-lane Vertical Sachet Machine

Multi-lane Vertical Sachet Machine- Picture Courtesy: Packaging Machine

A highly advanced machine where fast and high output is generated. This is due to multi-lane features that can help in the production of high efficiency and generate a large capacity in a limited time.

According to the Products Type

Granule Vertical Sachet Machine

Granule Vertical Sachet Machine- Picture Courtesy: gd-Dachuan

This is the series of automatic formation of sachet using a vertical flow of working. this machine is specifically needed for products that are granular in nature. For instance, sugar, salts, coffee, spices, etc.,

Its advanced industrial control system makes an easy pathway to adjust the film, and sachet formation followed by its filling. This machine has a hopper allowing granules to vibrate which ensures an easy flow and filling into each sachet.

Sauce Vertical Sachet Machine

Sauce Vertical Sachet Machine- Picture Courtesy: gd-Dachuan

A sauce vertical sachet machine is mainly designed to dispense products that are viscous and thick states. Therefore, machines can tailor such materials with unique handling and ensure quality packaging output. The adjustment of film roll and sachet formation working is nearly too similar with other machines but the dealing with perishable sauces pattern is different as it acquires volumetric or piston fillers for consistent filling levels.

Liquid Vertical Sachet Machine

Liquid Vertical Sachet Machine- Picture Courtesy: gd-Dachuan

Effective and specialized equipment for dispensing or delivering liquid formulation into sachets by featuring volumetric, cup-filling, or piston-filling methods. This machine is commonly designed with non-drip features which helps in the prevention of leaking products and helps in handling liquid products efficiently.

6.What is the difference between Horizontal and Vertical Sachet Machine?

Both Horizontal Sachet Machine and Vertical Sachet Machine are known for their high-speed production output and greater capacity volumes. However, there are some distinct differences between these two machines. Understanding the difference would help you to make the right decision about your business needs.

Operation

Sachet Formation

A horizontal sachet machine operates following a horizontal format, a flat sheet is responsible for forming a sachet, and the sealing is basically done to create a holder or sachet pocket.

Compared to the vertical sachet machine, it is more visually appealing to consumers. In a vertical sachet machine, the entire working process takes place following a vertical flow.

Suitability for Type of Products

Types of products in sachet

A horizontal sachet machine is good at packaging solid products or fragile materials. This is because this machine is suitable for such products as it lowers the risk of damage during the procedure.

However, the vertical sachet is mostly suited for products that are of variable consistencies and nature. For example, you can pack products that are solids, liquids, semi-solids, powders granules, etc. The machine can ideally pack them as it can accurately pick and dispense them into the sachet.

Packaging Formats

Sachet Formats

Horizontal sachet machine provides you packaging formats in the form of sachets, and pouches. Whereas a vertical sachet machine is capable of producing a large range of packaging formats, including sachets, pouches, and stick packs, with various sizes and shapes.

Speed

Sachet Production

Well, both machines possess properties of high production speeds. But, horizontal sachet machine has somehow high edge over vertical sachet machines for speed and production capacity.

Space

Footprint

A horizontal sachet machine may need a greater surface for its installation. This is all because of its designs which are presented with a horizontal layout. Therefore, it is required to determine floor space when choosing the machine. However, a vertical sachet machine is ideal for small spaces as it has a compact footprint.

7.Vertical Sachet Machine: What Sealing Methods and Types Does it Offer?

Sachet are basically joined by none other than inducing various modes of sealing. Previously, sealing was only achieved by heat. With time, this process became more advanced, and various other sealing types emerged. The very common sealing types by vertical sachet machine are discussed below:

Methods of Sealing

Heat Sealing

Heat Sealing

A conventional way of sealing sachet where heat is mainly subjected for joining of the edges. There are two methods of heat sealing used for sealing sachet. For example:

Impulse Sealing

Impulse Sealing

As its name shows, an impulse of heat is radiated for sealing purposes. This is mostly used for packaging of those items that are very sensitive to high temperatures.

Continuous Heat Sealing

Continuous Heat Sealing

This is a common heating method used for high capacities production where continuous rays of heat are utilized for fast packaging production.

Ultrasonic Sealing

Ultrasonic Heat Sealing

This is the new technology for sealing sachet where an ultrasonic vibratory frequency is utilized for the sealing of the sachet. This is mostly used for those products that are liquids, or semi-solid in nature.

Mechanical Sealing

Mechanical Sealing

This type of sealing is involved with high-pressure exertion around the edges of the sachet. The greater pressure leads to the joining of the corners without generating unwanted heat hence can be suited for materials that are sensitive to heat.

Types of Sealing

3- Side Seal Vertical Sachet

3 side seal Sachet- Picture Courtesy: LLPAK

A vertical sachet machine that forms a pillow-shaped sachet with three sides sealing leaving one edge folded.

4- Side Seal Vertical Sachet Machine

4 Side Seal Sachet- Picture Courtesy: Pyramid

This is an excellent format where entire edges are closed by sealers.

8.What are cutting knives in a vertical sachet machine?

This is commonly known as a die-cut which fabricates a specialized cut shape at the edge of the sachet and creates a customized shape. This is a shape tool that is used to cut excess materials as well as a line for easy to tear to its customers. A die cutter or cutting knife comes in various shapes and sizes, it is up to you to figure out what type of cutter is good for you.

A vertical sachet machine provides the following cutting knife formats to its consumers:

Straight Cut

A straight cut sachet- Picture Courtesy: MARUTO

This is a robust method that offers a straight cut around the edge of the sachet to produce a professional presentation and easy opening to its customers.

Dash Line

Dotted Line Cut- Picture Courtesy: IMPAK

Dash lines or dotted lines are punched on the edges of the sachet and create tiny perforations. This perforation helps you in the easy separation of the sachet by just pulling it away from the other sachet. You can accurately and neatly cut the sachet and open it when required without worrying about product loss or accidental tearing.

Saw Tooth

Saw Tooth Cut Sachet

A zigzag cutting punched around the sachet edges maximizes the aesthetics and convenience to its customers with more tamper-proof properties as tearing can easily allow you to predict the originality of the product.

9.Vertical Sachet Machine- What Quality Testing Must be Performed after Sachet Formation?

After the fabrication of sachets (liquid or solid product), some quality tests should be performed to ensure the finished product's safety and avoid any potential incident.

Some typical tests that are performed to check the quality of packages are;

Visual Inspection

Visual Inspection – Picture Courtesy: Pharma’s Almanac

A visual inspection of the sachets produced is performed to check for any visible defects, such as appearance, print quality (crucial for branding and information regarding product), bar code visibility, package dimensions, or contamination.

Content Uniformity Test

Content Uniformity Testing

This test is crucial, particularly for medicinal products. It is done on multiple sachets to ensure the packages contain the correct amount of product.

Seal Integrity/Leak Test

Seal Integrity Test

This test is performed to check the integrity of the sachet sealing or to detect any invisible leakage in the sachet. It is usually performed using a vacuum leak test device.

The device functions by a negative pressure creation in a closed vacuum chamber.

The sachets with proper sealing will get inflated while the ones with defective sealing will remain flattened. The packages are immersed in a vacuum chamber filled with water (wet test) or a vacuum chamber without water (dry test) to detect bubbles, that confirm a leakage.

Stability Test

Accelerated Stability Testing – Picture Courtesy: Global Sources

This test is vital to check how the package reacts to different temperatures, particularly accelerated conditions, to ensure the product’s shelf-life.

Tear Test

Tear Test – Picture Courtesy: iStock

Multiple random sachets are checked to confirm that they open conveniently, as intended. A pre-determined pressure is applied to the sachet to evaluate the perforation strength of the sachet.

10.What are the basic Problems and Solutions related to the Vertical Sachet Machine?

Vertical sachet machine have become an indispensable instrument in many industries, providing rapid, efficient, and precise packaging of a range of products. However, just like any other industrial equipment, it can also encounter problems that lead to machine downtime and reduced productivity.

Here we will discuss some common issues related to the device and their solutions to maintain it in optimal condition.

Filling Inconsistency

Inconsistent Filled Sachets – Picture Courtesy: alumni.uod

The non-uniformity in the package filling is a common problem that arises in the vertical sachet machine resulting in variations in package weight.

It can be due to several reasons, such as a fault in the material flow, a faulty measuring sensor, or improper parameter settings.

Solutions: Validate the correct settings in the panel. Check the sensor for accurate measurements. Ensure the material flow is smooth.

Inaccuracy in Sachet Formation

Inaccuracy in Bag Lengths – Picture Courtesy: Dribbble

There can be a problem with the device resulting in the variability in the package formation.

The reasons could be; a fault in the film roller, improper film installation, jamming of film, or slipping of the film.

Solutions: Set the film roller perfectly and verify the pulling belts work well. Ensure the availability of film on time to avoid the shortage. Install the film appropriately.

Sealing Defects

Defective Sealing

The problem of improper or defective sealing.

The possible reasons may be; high or low track temperature, misaligned film running, disordered sealing jaws, or a dusty sealing station.

Solutions: Adjust the track temperature. Align the film to run with the edges. Clean the sealing platform properly. Align the sealing jaws.

Filled Sachet Trimming Issues

Trimming Defects – Picture Courtesy: Stluke

There could be a defect in the cutting of filled bags, leading to inconsistent bags or improper separation.

The reasons may be; worn or blunt trimming jaws or inaccurate cutting instructions.

Solutions: adjust the cutting settings. Replace or repair the trimming jaws, if necessary.

Conclusion

Various available vertical sachet machine manufacturing companies offer you a diverse spectrum of equipment with broad applications. Whether you’re filling powder, liquid, granules, or any product into a sachet- Allpack is your best solution. A huge experience in dealing with packaging equipment worldwide, today Allpack is known for its high state of art machines and tied with global manufacturing giants for its promising services. For your vertical sachet machine, please contact Allpack Team now.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586