Vertical Bagging Machine: The Complete FAQ Guide In 2025

Have you ever heard vertical bagging machine? It is a practical equipment which is commonly used in food, pharmaceutical and cosmetic industry, etc. As the name implies, vertical bagging machine is to pack all kinds of materials into bags, and it works vertically. Besides the function, do you know anything else about this machine? Or, what do you want to know about a vertical bagging machine?

To meet your demand, here comes this FAQ guide, which will give a comprehensive introduction of vertical bagging machine. In this article, you can learn everything about this machine, including advantages, applications, main parts, working principle and so on. Are you ready to learn vertical bagging machine deeply? Let’s begin!

1.What is vertical bagging machine?

Vertical bagging machine is a multi-functional packaging equipment which can be used to pack powders, liquids, granules, flakes, pastes, etc. This machine can make packaging bags by itself, and fill raw materials into the bags, then seal them. The vertical bagging machine has a high degree of automation, can work smoothly and efficiently, as a result, it is popular in a lot of industries.

2.Why vertical bagging machine is popular among industries?

As is mentioned above that vertical bagging machine is popular among industries, but do you know why? To be honest, this machine has many advantages so that it can bring great convenience to industries, some of the advantages are as follows:

Easy Changeover

Vertical bagging machine provides easy and quick changeover, if you want to pack different products and need bags of different sizes, the machine can achieve the changeover in minutes, which will not affect the production efficiency, and you don’t need to use any tools.

Simple to Operate

The vertical bagging machine is fully automatic, it can complete various operations such as bag making, material filling, sealing, cutting and discharging by itself. Therefore, you can say this machine is simple to operate, what you should do is to set up all kinds of parameters on the touch screen and pour raw material into the hopper.

Easy Integration

Vertical bagging machine can be used alone, and it can also be integrated with other automatic equipment such as conveyors, multi-head weighers, cartoning machines

and so on. It is easy for vertical bagging machine to be integrated with these machines, which can improve the production efficiency of your business.

Modular Design

Vertical bagging machine adopts modular design, therefore, it is easy to deliver and install this equipment. In addition, it is also convenient to replace the worn parts of vertical bagging machine to make a upgrade to it, doesn’t require complicated procedures.

3. In which industries can vertical bagging machine play its role?

Since vertical bagging machine can pack a variety of products, it can be applied in a lot of industries, next let’s list them together!

Food Industry

Food Industry-Photo Credit: ECHO Machinery

Vertical bagging machine is widely applied in food industry, it can pack almost all food products, which include candies, popcorn, chips, spices, nuts, sauces, biscuits, coffee beans and coffee powder, milk powder and so on. You can say that vertical bagging machine is necessary to food industry.

Pharmaceutical Industry

Perhaps you often see medicines packaged in bottles or blisters, in fact, there are also medicines packaged in bags, packing medicines in small bags is convenient for patients to take medicines. So, vertical bagging machine is used to pack solid formed medicines such as capsules, softgel and tablets into bags.

Agriculture Industry

In agriculture industry, all kinds of agricultural products, such as rice, wheat, soybeans, corn kernels, seeds, etc, need to be packed in small bags for sale. Vertical bagging machine becomes a good choice, it can make different shaped bags and pack these products into them.

Cosmetic Industry

In general, cosmetic products are packed in cans, bottles and jars, however, the samples of many cosmetic and skin care product come in bags. Vertical bagging machine is used to pack cosmetic and skin care products such as liquid foundation, essence, lotion, shampoo, conditioner, etc.

4. How many types of vertical bagging machines are there in the market?

As a matter of fact, there are many different types of vertical bagging machines in the market, to classify them, you need to use different criteria.

- In terms of working

(1). Intermittent Vertical Bagging Machine

Intermittent Vertical Bagging Machine-Photo Credit: Multiko Packaging

Intermittent vertical bagging machine is a traditional type of packaging equipment, the material filling system of this machine is intermittent rotary operation, besides, there will be a short pause when the machine is pulling film and sealing bag, it will continue to pull the film after the sealing reaches a certain period of time. As a result, the speed of intermittent vertical bagging machine is relevantly slower.

(2) Continuous Vertical Bagging Machine

Continuous Vertical Bagging Machine-Photo Credit: Viking Masek

Different from intermittent vertical bagging machine, during the working process of continuous vertical bagging machine, there isn’t any pause. The machine adopts continuous rotary motion system so that it has fast packaging speed, in the recent years, continuous vertical bagging machine has gradually replaced the intermittent one.

- In terms of bag style

(1) Sachet Vertical Bagging Machine

Sachet Vertical Bagging Machine-Photo Credit: Lenis Machines

Sachet vertical bagging machine is used to pack powdered and granular products, this machine can provide various bag style such as 3-side sealing, 4-side sealing and back sealing. This machine can complete operations such as automatic sachet making, measuring, filling and sealing, date printing, cutting.

(2) Stick Vertical Bagging Machine

Stick vertical bagging machine is special, if you need to pack powders,granules, liquids and pastes in thin stick-shaped bag, this machine is suitable for your requirements. There are single lane stick vertical bagging machines and multi-lane one, which are applied in different fields such as food, pharmaceutical, chemical industries and so on.

(3). Triangle Bag Vertical Bagging Machine

Triangle Bag Vertical Bagging Machine-Photo Credit: Samfull Packing Machine

Triangle bag vertical bagging machine is specially designed to make pyramid shaped bags and fill all kinds of products into these three-dimensional bags. This kind of vertical bagging machine is suitable for packing a variety of products, including snacks, tea leaves, grains and so on.

- In terms of raw material

(1) Granule Vertical Bagging Machine

Granule vertical bagging machine is designed for packing powdered and granular products such as chips, popcorn, nuts, seeds, rice, coffee beans, tea and so on. This machine has high speed and flexibility, can pack products into bags accurately, is an ideal equipment for packaging industry.

(2). Liquid Paste Vertical Bagging Machine

This machine is used to pack liquids and semi-liquids, it is suitable for many liquid products such as shampoos, sauces, beverage, pastes, etc. Liquid paste vertical bagging machine can work smoothly, complete a series of operations such as measuring, bag making, filling, sealing and cutting by itself.

(3) Tea Bag Vertical Bagging Machine

Tea Bag Vertical Bagging Machine-Photo Credit: XHTEAPACK

Even though granule vertical bagging machine can package tea leaves, there is a professional tea bag vertical bagging machine on the market. This is a machine that automatically forms double chamber tea bags with tea bag paper, mainly used for packaging of loose tea, fermented tea and medicinal herbs.

5. How vertical bagging machine differs from horizontal bagging machine?

Both vertical bagging machine and horizontal bagging machine are popular packaging equipment, and they have similar applications, however, there are some differences between the two machines, which are as follows:

- Packaging Process

You can observe the appearances of the two machines, it is obvious that their working directions are different. The raw material enters the vertical bagging machine from the hopper on the top, while horizontal bagging machine uses a conveyor to deliver raw material. For all operations after that, one of the two machines works vertically and the other one works horizontally.

- Suitable Products

As you know that vertical bagging machine can deal with different forms products such as powders, granules, liquids and semi-liquids. But for horizontal bagging machine, it isn’t suitable for liquid products because of its working direction.

- Bag Style

Vertical bagging machine can provide a wide range of bag styles which are different in shapes and sizes, not only limit in sachet, therefore, it can meet more packaging demands. However, the horizontal bagging machine don’t has such a high flexibility, it can make sachets and pouches.

- Occupied Area

Vertical bagging machine has small occupied area, while horizontal bagging machine need a larger area because of its horizontal layout. Therefore, vertical bagging machine is suitable for factories which have limited spaces.

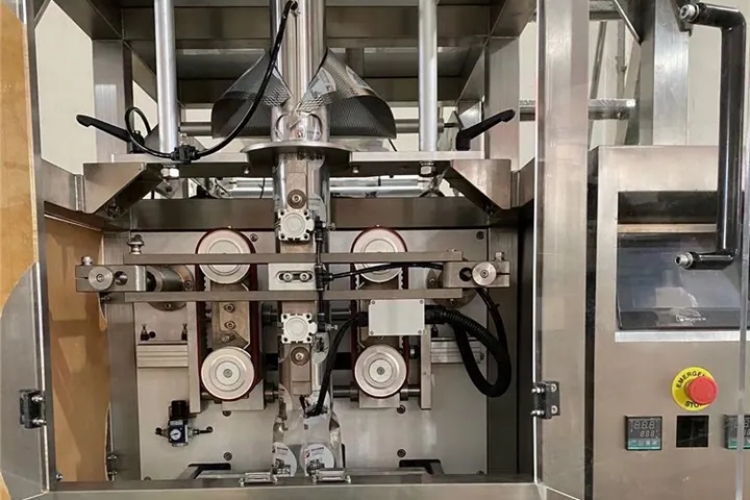

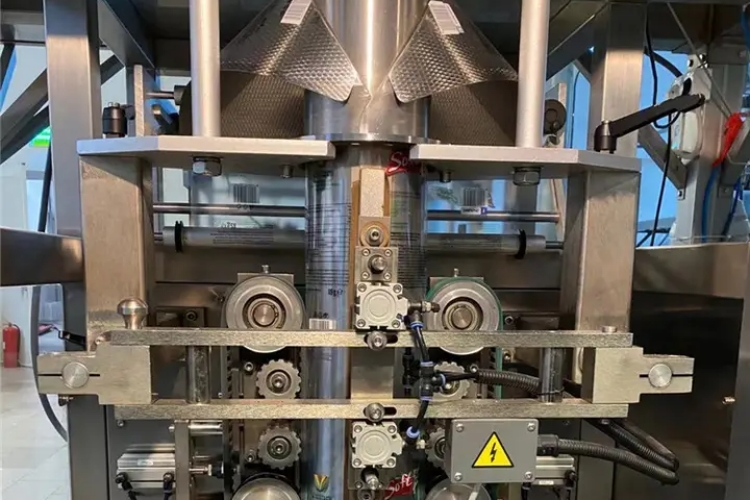

6. How many components consist of a vertical bagging machine?

Actually, vertical bagging machine doesn’t have a complex structure, it is easy for you to learn the components of this machine, just read the following content.

- Hopper: The hopper is at the top of vertical bagging machine, it is to store the raw materials before they are filled and packed.

- Roll Film Placement Device:You can also call this part as film holder, it is to place and fix packaging film.

- Measuring Cup:This part is used for material metering and unloading, in other word, it is to determine the dose of material, ensure the filling accuracy.

- Control Panel: You can regard this component as the brain of the vertical bagging machine, it controls all working steps of the machine.

- Coder: The function of coding is to print the production date and other information of the product on the packaging film.

- Bag Forming Machine: During the working process of vertical bagging machine, the film is pulled down and come into shape of bags in this part.

- Vertical Sealing Device: The vertical sealing device is to heat seal the two sides of the bag.

- Horizontal Sealing Device: The function of this part is similar to that of vertical sealing device, but the horizontal sealing device is to seal the top and bottom of the bag.

- Cutting Device: This part is to cut off the connection of each two bags so that the finished product can be discharged.

7. What is the working principle of vertical bagging machine?

Totally speaking , the whole working process of vertical bagging machine can be divided into 10 steps, including packaging film unwinding, coding, bag forming, vertical sealing, bottom sealing, metering, material filling, top sealing and cutting & discharging.

- Packaging Film Unwinding: When the vertical bagging machine begin working, the packaging film is pulled out and tensioned by rollers, this step is to make preparation for the bag forming step.

- Coding: Some vertical bagging machine has the coding function, the coder will print the production dates and other information on the packaging film.

- Bag Forming: When the packaging film pass through the bag forming device, it is twisted and folded, at this moment, the packaging bag is preliminary shaped.

- Vertical Sealing: This is the first sealing step, which is to seal the side of the bag. How to achieve this operation? The vertical sealing device is heated and then presses on the side of the bag so that it is perfectly sealed.

- Bottom Sealing: It is not enough that the sides of the bag are sealed, the bottom also need to be sealed, otherwise the material filled into the bag will leak out. Therefore, the next step of vertical sealing is bottom sealing, it is achieved by the horizontal sealing device.

- Metering: Vertical bagging machine is equipped with a measuring cup which is used to measure the dose of material, ensure the accurate filling.

- Material Filling: The bag is now sealed on three sides, which is ready to be filled, therefore, in this step, the measured raw material is fallen and filled into the bag.

- Top Sealing: When the filling process is finished, the horizontal sealing device will seal the top of the bag so that the raw material is packed in it, the packaging process is finished.

- Cutting & Discharging: Even though the raw material is filled and packed in the bag, this bag is still connected to the bag above it. Therefore, in the final step, the machine cut off the connection of the two bags and the finished product is discharged.

8. What raw materials can be packed by vertical bagging machine?

It is obvious that vertical bagging machine can pack many products of different industries, even though the categories of these products are various, in essential, they can be classified into certain forms, such as:

Powders

Vertical bagging machine is able to pack powdered products, such as milk powder, coffee powder, flour, wheat flour, drug powder, seasoning powder, chocolate powder, matcha powder, egg yolk powder, washing powder and so on. When the vertical bagging machine pack powders, it mainly uses the powder screw with the measuring cup for material feeding.

The powder screw is stirred in the hopper, so the powder product is more uniform during the stirring, and then falls into the measuring cup, which plays a role in metering, and next the measured powder product will be filled.

Granules

Also, vertical bagging machine can be used to fill and seal granular products, including but not limited to rice, nuts, beans, grains, seeds, plastic particles, gummy candies, fertilizer, desiccant, tea leaves, etc. The granule vertical bagging machine is specially designed to package these products.

To fill and pack granular products better, the vertical bagging machine is always equipped with a multi-head weigher, which plays a role in weighing and material feeding.

Liquids & Semi-liquids

Besides solid products, vertical bagging machine can pack liquid products, either. The machine can pack liquids and semi-liquids, which include beverages, shampoos, sauces, pastes, yogurts, body lotion, laundry detergent, face cream, various oral liquids, etc. For better packaging of liquid products, you can use a liquid paste vertical bagging machine.

Different from other vertical bagging machine, liquid paste vertical bagging machine adopts a liquid pump which is used for automatic quantitative packaging of liquid and sauce materials. And notice that, if you need to pack viscous liquid product, the liquid pump should be replaced by a rotor pump.

9. What shape bags can be made by vertical bagging machine?

Different products have different packaging requirements. Of course, it is impossible for a vertical bagging machine to provide only one kind of bag style, guess how many shape bags can be made by this machine? Come and learn then now.

3-side Seal Bag

3-side Seal Bag-Photo Credit: Pouch.eco

As the picture shows, 3-side sea bags are sealed on three sides, leaving only one side open to pack products. This kind of packaging bag is one of the most common ways of making bags in vertical bagging machine.

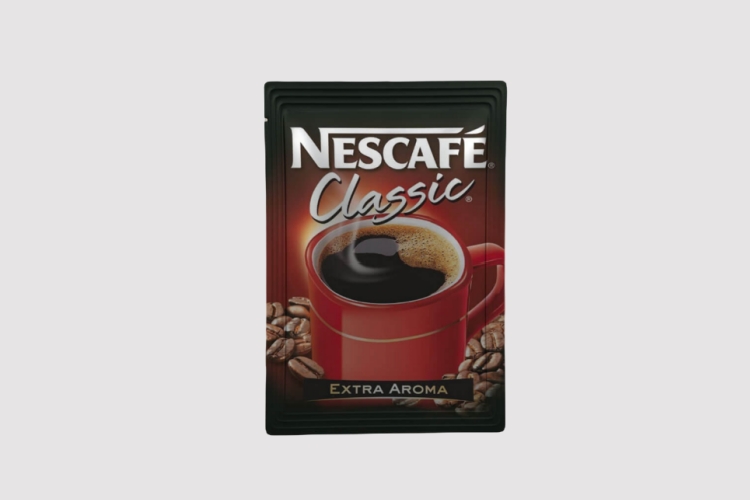

4-side Seal Bag

4-side Seal Bag-Photo Credit: Nescafe

Besides 3-side seal bag, 4-side seal bag is also a common bag style which is provided by vertical bagging machine. All four sides of the 4-side seal bag are sealed so that it have good air tightness. 4-side seal bags are mainly used for packing coffee, tea and food products, etc.

Pillow Bag

Pillow Bag-Photo Credit: BW Flexible Systems

Pillow bag, can also be called back seal bag, it is sealed on the center of its back, has beautiful and neat appearance, this bag style is commonly seen in food packaging, usually used to pack candies and snacks.

Gusseted Bag

Gusseted Bag-Photo Credit: Viking Masek

The gusseted bag has good stability, which is because of its shape, the top and bottom are sealed while the two sides are propped up. This kind bag is always used in PET food packaging and fertilizer packaging.

Triangle Bag

Triangle bag is three-dimensional, this bag is sealed on two sides and contains four triangle faces, the compact tetrahedral structure provides great stability. The triangle bag is applied in packaging coffee, tea and snacks.

Double-layer Bag

Double-layer bag contains an inner bag and a outer bag, generally speaking, the inner bag has filter function, this kind of bag is used to pack coffees and teas. Not every vertical bagging machine can provide this bag style, to make double-layer bag, you need to use special vertical bagging machines, which can produce the inner bag and the outer bag, and put the inner bag into the outer bag.

10. How to improve the operation efficiency of vertical bagging machine?

It is important for you to learn how to improve the operation efficiency of your vertical bagging machine, this is a vital skill.

Choose High Quality Parts

Firstly, you need to equip your vertical bagging machine with high quality parts, such as hopper, measuring cup, cutter and so on, as you know, excellent components can increase the production speed of the machine.

Set Up Routines

If you often use your vertical bagging machine to pack the same product, you can set up a common routine and store it well, which can reduce the setup time when switching between products or bag sizes, thus improving operation efficiency.

Regularly Clean and Lubricate the Machine

The vertical bagging machine needs good maintenance to play its best condition, so after each use, remember to wipe off the accumulated dust on the machine and lubricate the parts of the machine regularly, which can make it work smoothly and prolong its service life.

Train the Operators Regularly

To improve the operation efficiency of the vertical bagging machine, you can not ignore the operators, they need to be well-trained and totally master the operating knowledge. Only in this way can the vertical bagging machine exert the highest production efficiency under the operation of the operator.

11. What are the future trending technologies in vertical bagging machine?

To meet the growing packaging demands, the vertical bagging machines on the market are upgraded all the time, and there are some trending technologies which are applied on these machine, let’s learn them together.

- As the PLC technologies are growing, the improvement of machine automation and integration has become a trend, which can make your vertical bagging machine work faster and bring you higher economic benefits.

- Sometimes, the cleaning of vertical bagging machine may make you feel tired, don’t worry, now, more and more vertical bagging machines are made of easier-to-clean materials and designed for touchless operation.

- The biggest breakthrough is that many vertical bagging machines have advanced data analysis ability, which can provide the data of machine performance and product quality, helping you plan the production process better.

12.What are the factors to consider before purchasing a vertical bagging machine?

It is a common question that what kind of vertical bagging machine should you choose, if you want to know the answer, you need to figure out your requirements, consider different aspects and make a comprehensive evaluation.

Determine Your Products

At first, you need to make it clear that what kind of products will you pack by a vertical bagging machine, what form your product takes is important. If you need to pack powdered or granular products, you can choose a granule vertical bagging machine; if your products are liquids, liquid paste vertical bagging machine is a good choice.

Determine Bag Style

Next step, you need to determine which bag style do you want, to be honest, the vertical bagging machines on the market can meet almost all kinds of bag style, but for some special bag style, such as triangle bag and double-layer bag, you need to find specific vertical bagging machine.

Production Efficiency

In addition to the product itself, the performance of the machine is also very important, you should estimate the output you need, and then think about the production efficiency. If you need to pack a large amount of products, you’d better choose a vertical bagging machine with high production efficiency.

Conclusion

In a word, vertical bagging machine has a wide range of application, can help industries increase production efficiency and save labor cost, is an ideal packaging equipment. After reading this complete FAQ guide, do you think you understand vertical bagging machine well enough? If you still have something puzzled about this machine, welcome to consult us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide