1.What Is A Vacuum Sealing Machine?

Vacuum sealing machines are an invaluable tool for anyone looking to maximize the efficiency and longevity of their food storage practices. This process is typically used to preserve food and other items for long periods by preventing oxidation, mold growth, and pest infestations.

Vacuum sealing machines are commonly used in industrial settings and home kitchens. They can be used to package items for storage or sale, vacuum-seal perishable items, and protect delicate materials from harm.

Also, vacuum sealing machines can help reduce food waste by preserving food for longer than other methods of storing perishable items. The vacuum seal created by these machines helps maintain freshness and flavor while extending the food’s shelf life.

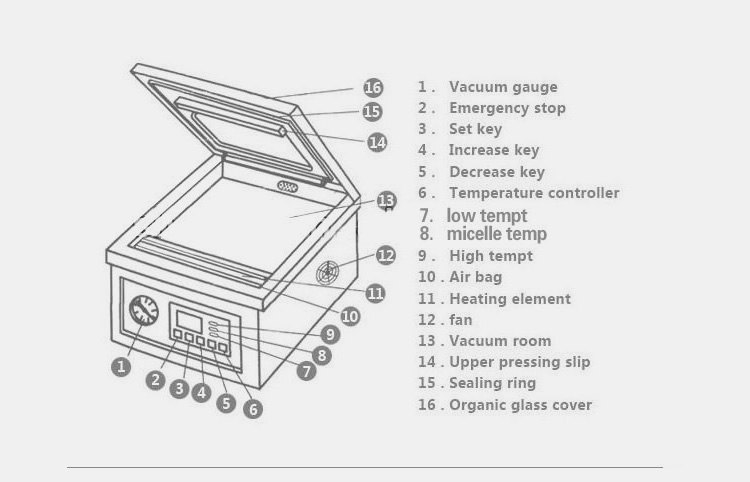

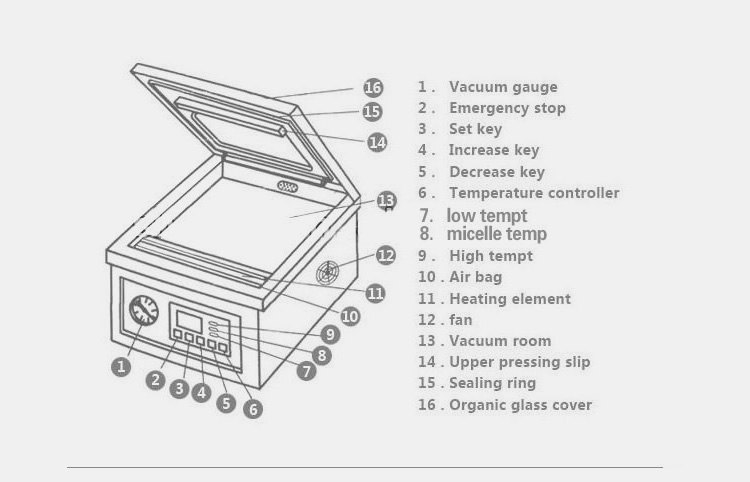

2.What Are The Components Of A Vacuum Sealing Machine?

Several components make up vacuum sealing machines. These include:

Vacuum Chamber

This chamber is where the food or product is placed to be sealed. It is typically made of stainless steel and features a lid that seals to create a vacuum inside the chamber.

Sealing Bar

This heated metal bar seals the vacuum pouch while removing the air inside.

Vacuum Pump

This creates a vacuum inside the chamber by extracting air from it.

Pressure Gauge

This indicates the pressure inside the vacuum chamber and serves as a guide to know when enough of the air has been extracted.

Timer

This lets the user control how long the vacuum sealing process should last.

Temperature Controller

This allows the temperature of the vacuum chamber and sealing bar to be adjusted to be at optimal levels for sealing.

Safety Interlock

This safety feature will prevent the vacuum chamber from opening until the vacuum has been released.

3.What Are The Benefits Of A Vacuum Sealing Machine?

Improved Food Freshness

Using vacuum sealed bags, food can stay fresher for longer periods of time depending on the vacuum level and other storage conditions. Vacuum sealing keeps out bacteria, oxygen and moisture which are the main contributors to food decay.

Preserves Both Flavour And Nutrition:

Vacuum sealing not only seals in unwanted air, but also locks-in flavours and nutrients that would otherwise be lost through oxidation.

Maintains Quality

Vacuum sealing helps to preserve the quality, color, and texture of food for longer periods of time.

Extends Shelf Life

vacuum sealed food can last up to four times longer than non-vacuum sealed food.

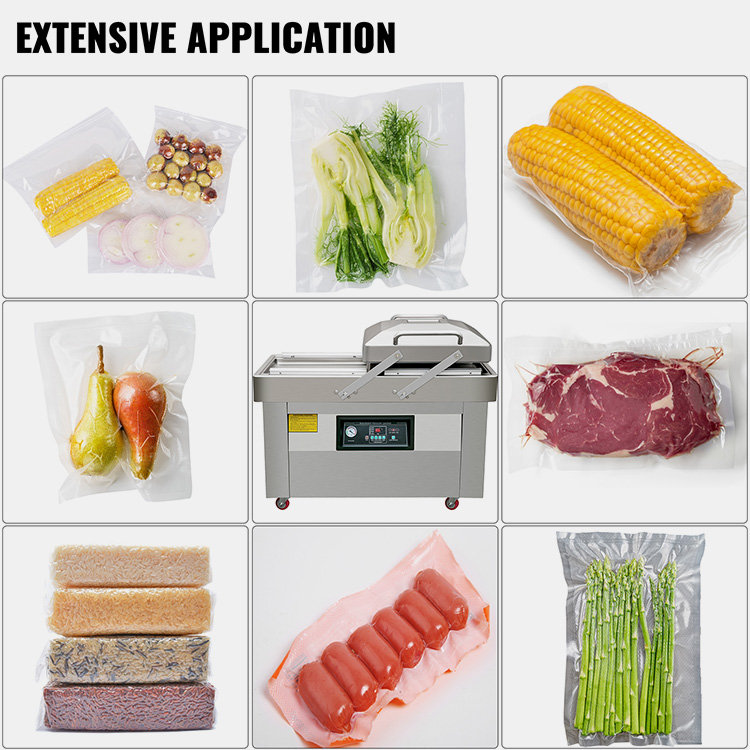

4.What Are The Applications Of A Vacuum Sealing Machine?

Food Industries

Vacuum sealing machines are widely used for preserving food, as it helps to preserve the freshness of the food. Vacuum sealing can be used to store food in a vacuum-sealed bag or container, which prevents spoilage due to oxygen and moisture. It also extends the shelf life of many foods such as vegetables, meat, cheese, grains and fruits.

Medical Industry

Vacuum sealing is often used for medical products like implants and prosthetics as well as pharmaceuticals that require an airtight environment for safe storage and transport. Vacuum-sealing also helps to preserve medical equipment such as surgical instruments and needles.

Kitchen Use

Vacuum sealing machines are widely used in the kitchen for food storage, vacuum-packaging, and vacuum marinating. Vacuuming food locks in flavor and preserves freshness longer than conventional methods of packaging such as zip lock bags, plastic wrap or aluminum foil.

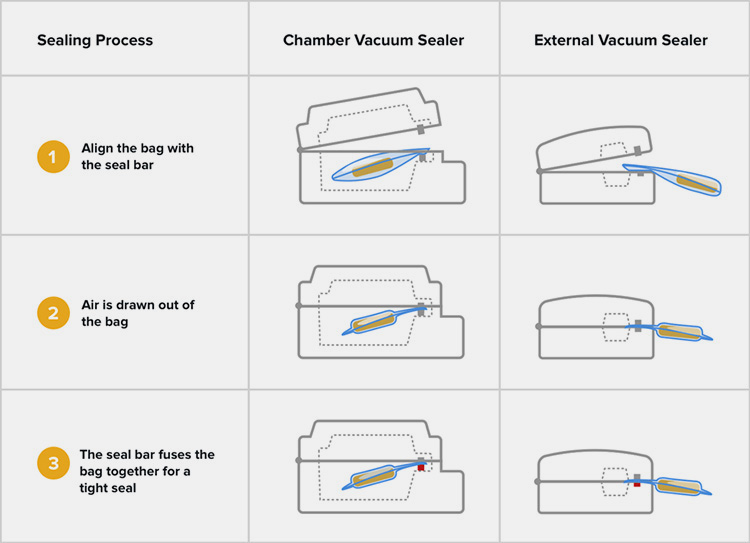

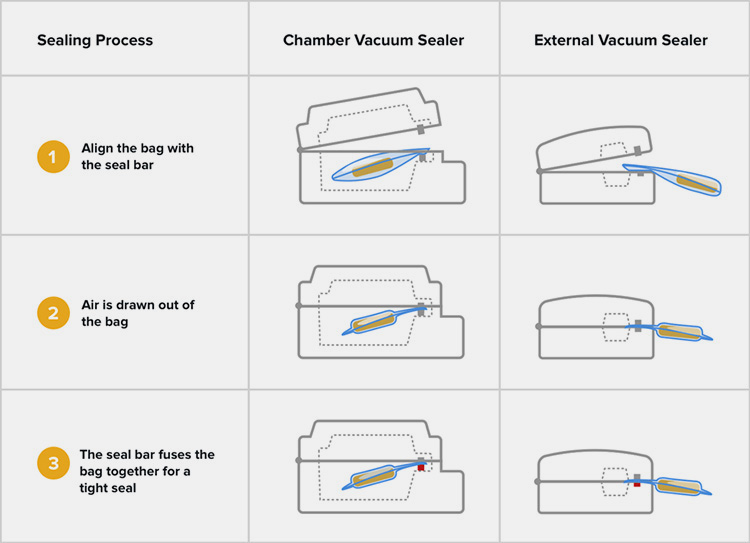

5.What Are The Working Principles Of A Vacuum Sealing Machine?

The working principles of vacuum sealing machines are quite simple. The device seals the package by drawing air out of the bag or container with a vacuum pump. This creates a vacuum inside the package that is then sealed shut with heat-sealing technology.

The vacuum pressure within the sealed package prevents oxygen from entering and spoiling food and protects against freezer burn. The vacuum also helps maintain the freshness of foods, preventing moisture from escaping.

6.What Are The Different Types Of Vacuum Sealing Machine Available In The Market?

a) Automatic Vacuum Sealing Machine

Automatic vacuum sealing machines are used in commercial settings and are among the most popular types. They are equipped with sensors that detect when a bag has been inserted and automatically apply the necessary pressure to create a tight seal. This makes them suitable for high-volume packaging operations, as it reduces labor costs and increases efficiency.

Components

An automatic vacuum sealing machine typically consists of the following components:

Vacuum Chamber

This is an airtight container used to create a vacuum environment for food storage. It is usually made of stainless steel or other durable materials and has a lid that securely seals during operation.

Vacuum Pumps

Pumps are necessary to create and maintain a vacuum within the chamber. Vacuum pumps are usually oil lubricated or dry and can be either single-stage or multiple-stage, depending on the model of the automatic vacuum sealing machine.

Sealing Bars/Jaws

These are used to heat seal plastic bags, containers, and other materials after they have been evacuated. The bar comprises a heating element and pressure applicator that seal two surfaces together.

Vacuum Valves

This component regulates the airflow into and out of the vacuum chamber during operation. Once the sealing is complete, they can release any remaining air from within the chamber.

Air Filters

These filters help keep particles from entering the vacuum chamber and affecting the quality of the seal.

Control Panel

The control panel is used to set the parameters for operation, including time, pressure, and temperature settings. It will also display any errors or alerts during operation.

Compressors/Secondary Pumps

These are sometimes necessary to quickly move air out of the system, allowing for faster sealing.

Working Principles

An automatic vacuum sealing machine uses a combination of heat and pressure to seal food items in airtight plastic bags or containers. To begin the process, the desired item (such as fruits, vegetables, meats, etc.) is placed into the automatic vacuum sealing machine.

A lid is then lowered to lock in the item, allowing for a tight seal. The automatic vacuum sealing machine then begins to heat and pressurize the air inside the container, resulting in a vacuum-tight seal.

Applications

Automatic vacuum sealing machines have a wide range of applications. These include food, medical device, and general product packaging, such as electronics and household items.

b) Semi-Automatic Vacuum Sealing Machine

Semi-automatic vacuum sealing machines are used in medium- to low-volume applications. They require manual bag insertion but still offer a consistent quality seal with minimal user input.

Components

A semi-automatic vacuum packaging machine is composed of the following components:

Vacuum Chamber

The vacuum chamber serves as an enclosure for the bag and product that needs to be sealed during the packing process. It keeps the air environment stable, providing an oxygen-free area to pack items.

Sealing Bar

The sealing bar, or sealer, creates a heat-sealed closure on the package. It uses hot wire technology to create an airtight hermetic seal and is moisture-proof.

Vacuum Pump

The vacuum pump removes all the air inside the chamber, decreasing atmospheric pressure and creating a vacuum. This allows for better product preservation, as it is sealed in an oxygen-free environment.

Control Panel

The control panel of semi-automatic vacuum packaging machines usually comprises a series of buttons and switches to manage settings that include sealing time and temperature, pumping speed, etc.

Vent Valve

This valve helps to evacuate air from the chamber faster and maintains a pressure differential between the inside and outside of the chamber.

Cut-Off Switch

The cut-off switch is used to stop the machine during operations in case of emergencies or errors. It helps to ensure the safety of personnel also.

Pressure Gauge

This display shows the pressure inside the chamber, which helps ensure the vacuum process is done correctly.

Heat Control System

This system maintains a consistent temperature on the sealing bar for an efficient and effective airtight seal.

Working Principles

The semi-automatic vacuum packaging machine creates a vacuum in the package or bag, typically via suction. This suction removes all the air inside the package and seals it shut. This device then applies either an adhesive film or heat seal to ensure the package stays secure, sealed, and airtight.

Applications

The semi-automatic vacuum packaging machine has many uses, from food preservation and transportation to medical applications. In the food industry, semi-automatic vacuum packaging machines help maintain the quality and freshness of food products such as dairy, meat, fruits and vegetables, nuts, snacks, and confectionery.

These machines can also be used in the pharmaceutical industry to seal medicinal tablets or capsules. Moreover, these devices are used in the medical industry to seal medical devices, instruments, and implants.

In addition to food and medical applications, semi-automatic vacuum packaging machines are used for packaging industrial products such as electrical components, machine parts, auto components, and more.

c) Manual Vacuum Sealing Machine

Manual vacuum sealing machines are used in small-scale applications or for occasional use. They require the user to manually insert the bag, apply pressure, and wait for a tight seal. This is an excellent option for those looking to save money as they are often less expensive than other machines.

Components

Vacuum Chamber

The vacuum chamber is a sealed area within the manual sealing machine where the product or package is placed before being sealed.

This chamber is typically made from stainless steel or plastic and has a manual pump or valve on one end that allows air to be removed from the chamber, creating a vacuum.

Heating Element

The heating element is responsible for melting the plastic material used in manual sealing machines. It is usually electric-powered and uses pressurized air to raise the element’s temperature.

Sealing Bar

The manual sealing machine uses a manual sealing bar to create a physical seal on the product or package being sealed. It is typically made from steel or aluminum and may have several different shapes and sizes depending on the size and shape of the product being sealed.

Vacuum Pump

The manual sealing machine also has a manual vacuum pump that removes air from the chamber and creates a vacuum to seal the product or package correctly. This pump typically uses pressurized air to remove all air from the chamber before the manual sealing bar is used.

Pressure Sensor

The manual sealing machine also has a manual pressure sensor used to measure the amount of air pressure in the chamber and ensure that the correct vacuum level is maintained for an effective seal.

Timer

There is typically a manual timer on manual sealing machines that allow users to control how long the manual sealing bar is pressed down, ensuring that the correct amount of time is used for a proper seal.

Working Principles

Manual vacuum sealing machines consist of two heated jaws that melt the edges of a plastic bag or pouch when clamped together, meaning any surrounding air is removed from the package, protecting its contents from oxygen and moisture.

The manual impulse sealer is operated by a manual switch, which activates the heating elements on both jaws to generate enough heat to achieve a tight seal. After sealing, the manual impulse sealer must cool down before it can be used again.

Applications

Manual vacuum sealing machines have a variety of applications. They are commonly used in food processing and preservation, laboratory testing, medical device manufacturing and packaging, electronics packaging, and more.

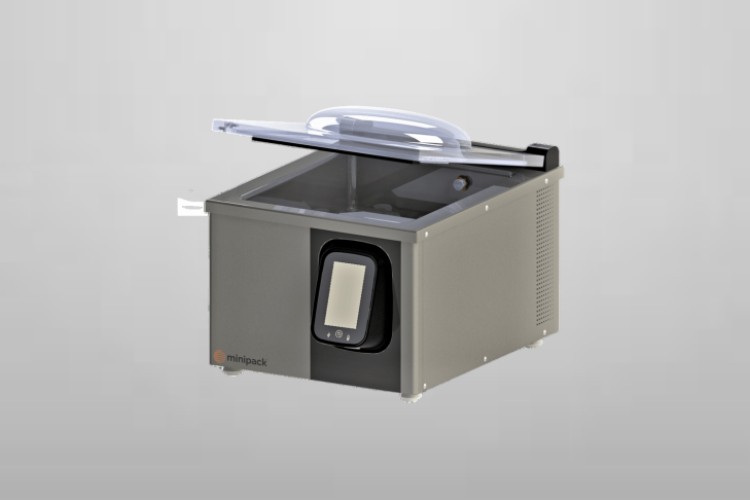

d) Chamber vacuum packaging machines

This type of vacuum sealer is designed specifically for industrial or commercial use. It features heavy-duty construction and can vacuum seal various items, including liquids and powders.

Components

Chamber

Chamber vacuum packaging machines are composed of an airtight chamber. This creates a sealed environment that can remove oxygen and other gases, allowing for the preservation of food products.

Vacuum Pump

Chamber vacuum packaging machines require a powerful vacuum pump to remove air from the chamber. The vacuum pump is typically driven by an electric motor and is connected to the chamber via a vacuum hose.

Heat Sealer

Chamber machines also include a heat sealer, which uses heated plates or wires to create an airtight seal on the packaging material. This helps to ensure that no oxygen can penetrate the package and spoil its contents.

Controls

Chamber vacuum packaging machines come with various controls which allow you to customize the operation of the machine. These include timers, pressure sensors, and other safety features that protect against over-packing or incorrect sealing.

Accessories

Chamber vacuum packaging machines often have various optional accessories, such as a loading table, feeding system, and vacuum bagger. These accessories help to streamline the packaging process and make it easier for operators.

Working Principles

These machines utilize a chamber with two distinct sections: an upper section and a lower section. The upper section is where the product is placed, while the lower section houses a vacuum pump that creates suction within the chamber. Once the product is placed inside the chamber, a lid is closed and sealed, creating an airtight seal.

At this point, the vacuum pump begins to draw out air from within the chamber. With each cycle of suction and release, more air is removed until the desired vacuum level has been achieved. Once this process is complete, an indicator light will turn green, indicating that the packaging process has been completed.

Applications

Chamber vacuum packaging machines are commonly used in the food processing industry, providing an airtight seal that preserves food products for extended periods.

Also, these devices can be used in the pharmaceutical industry to protect sensitive drugs and other products from damage.

Moreover, chamber vacuum packaging machines can even be used in the electronics industry, as they provide superior protection against air, moisture, and dust.

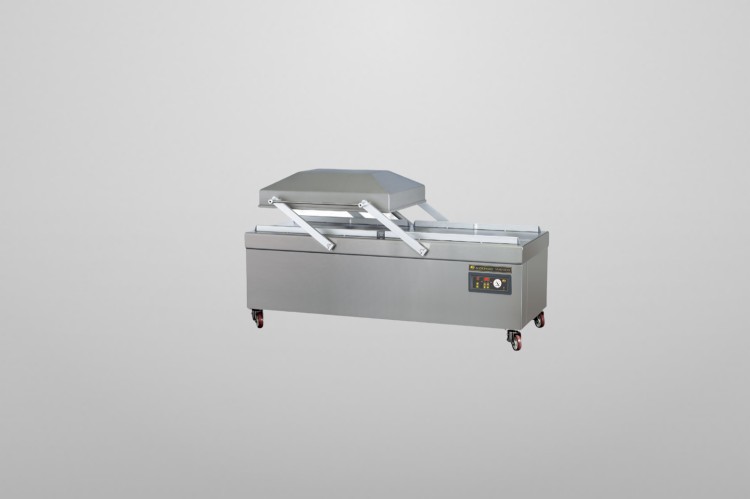

e) Double chamber vacuum packaging machines

This type of vacuum sealer is also designed for industrial use and can seal multiple items simultaneously. It has two chambers that allow an item to be vacuum sealed in one chamber and then vacuum sealed in the other.

Components

Double Chambers

Double chambers create a tight seal that prevents air from entering the package, creating an oxygen-free environment inside the package, which is ideal for keeping food fresh for extended periods.

Sealing Bar

The sealing bar provides a strong seal between the two chambers so that air cannot enter.

Vacuum Pump

The vacuum pump removes all of the air inside the package, creating an oxygen-free environment.

Film Roll Holder

The film roll holder holds the plastic film in place while the machine seals the package.

Temperature Controller

The temperature controller is used to regulate the temperature of the sealing bar, ensuring that it does not get too hot or cold when sealing packages.

Cooling System

The cooling system helps maintain a consistent temperature for optimal seal quality and prevents overheating of machine parts.

Control Panel

The control panel sets the machine’s settings, including sealing temperature and vacuum level.

Rollers

Double-chamber vacuum packaging machines are equipped with rollers to move the film in and out of the machine for efficient sealing.

Working Principles

The machine creates a vacuum inside the sealed chamber, which removes all of the air from the product. This helps preserve freshness, taste, and nutritional value for longer than traditional packaging methods.

The double-chamber vacuum packaging machines have two chambers: the main chamber, where the product is placed, and a secondary chamber, which contains an atmospheric vacuum used to evacuate air from the first chamber. The machine will typically come with an integrated pump system, which creates a vacuum in both chambers and then seals off each one separately. This allows for precise control over the amount of air removed from each chamber, allowing optimal product preservation.

Applications

Double-chamber vacuum packaging machines are widely used in various industries and applications. They are most commonly used in the food industry to preserve, store, and transport food products. These machines also package items such as medical products and electronics, allowing them to be transported safely and securely.

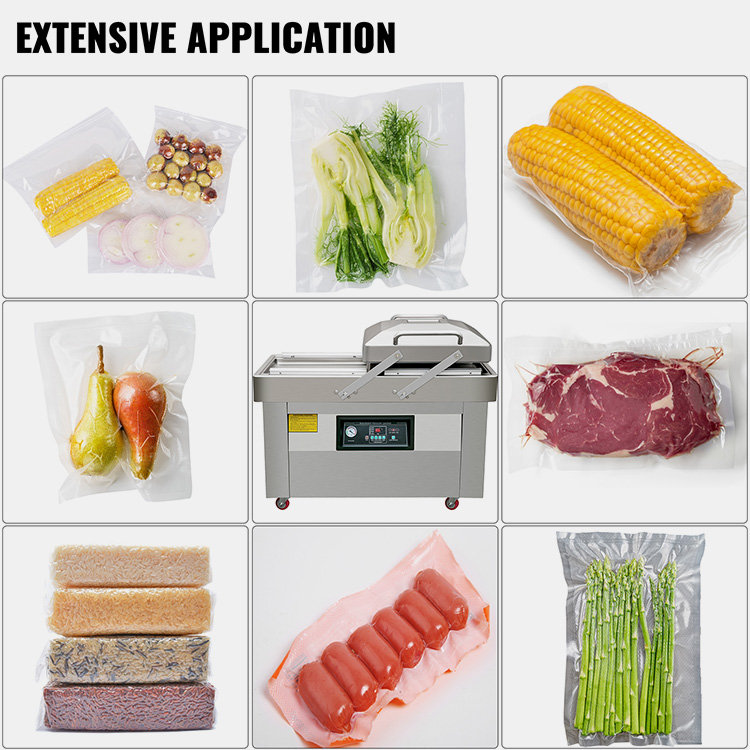

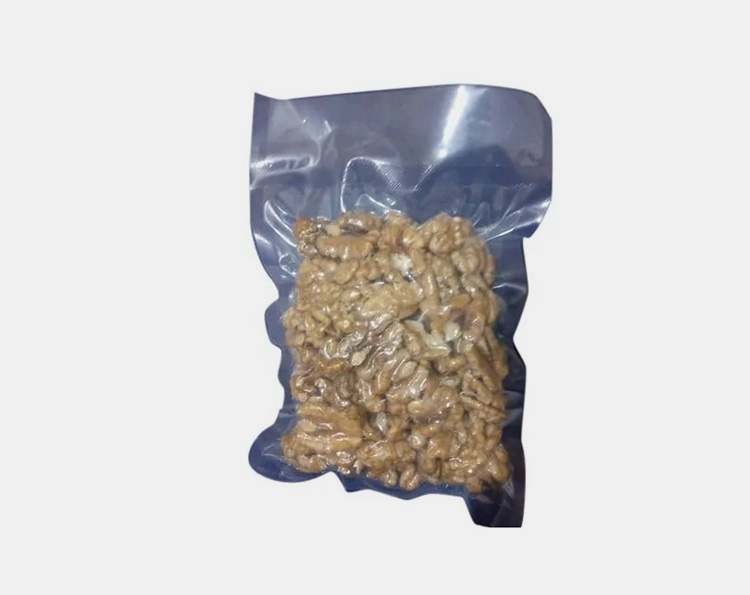

7.Which Kind Of Foodstuff Can Be Packed By A Vacuum Sealing Machine?

Fresh Fruits and Vegetables

Vacuum sealing preserves fresh fruits and vegetables, allowing them to stay fresher for extended periods. This helps reduce waste due to spoilage.

Dried Herbs and Spices

Vacuum sealing helps to keep herbs and spices fresh by preventing them from losing their aroma and flavor due to oxidation.

Meats and Seafood

Vacuum sealing locks in moisture, helping to keep the meats’ flavor intact while extending its shelf life. It also helps vacuum-sealed meats last longer in the freezer.

Grains

Vacuum sealing preserves the freshness of grains, such as rice, oats, and cornmeal, by preventing oxidation. This helps vacuum-packed grains last longer and stay fresher.

8.What Type Of Food Should Not Be Vacuum Packed And Why?

Soft Cheese

Vacuum sealing soft cheese can cause the texture to change, making it too firm.

Fresh banana

Vacuum sealing bananas can cause them to become too mushy and lose their flavor.

Whole apple

Vacuum sealing apples can cause them to become soft and mealy.

Raw Onions and Garlic

Vacuum sealing raw onions and garlic can cause them to become slimy and lose their flavor.

9.What Type Of Materials Does A Vacuum Sealing Machine Use For Packing Products?

Pouches

Vacuum bags are used in vacuum sealing machines to store and protect food and other items from spoilage. Vacuum bags are typically made of plastic or foil, and may be vacuum sealed by hand or with the help of a vacuum sealing machine.

Canisters

Vacuum sealing machines can also be used to vacuum seal food products in canisters, which is typically done for vacuum-packed items like canned fish and vacuum-sealed sausages.

Jars

Vacuum sealing machines can be used to vacuum seal products in jars, providing an airtight seal that will keep the contents fresh.

This is particularly beneficial for items like spices and condiments, which need to be kept in vacuum-sealed containers to prevent spoilage and flavor loss.

Trays

Vacuum sealing machines are designed to vacuum seal products in trays for storage and preservation. These trays are made of plastic or metal, depending on the machine’s design.

10.What Is The Shelf Life Of Goods Packed Using A Vacuum Sealing Machine?

The shelf life of products vacuum sealed with a vacuum sealing machine can vary depending on the food itself and the environment in which it is stored. Generally, vacuum sealed foods will last for weeks to months without degrading or spoiling.

vacuum sealing machines remove most of the oxygen from the packaging, slowing down oxidation and preventing bacteria growth. Vacuum-sealed fruits and vegetables, for example, can last up to three times longer than non-vacuum-sealed products. Vacuum sealed meats can last up to 8 times longer.

11.What Are The Safety Measures One Should Take While Using A Vacuum Sealing Machine?

- Wear gloves when handling vacuum sealing machines and vacuum bags: Wearing gloves reduces the risk of coming into contact with hazardous materials that may be in the vacuum bag, as well as protecting your hands from being burned by hot surfaces on the machine.

- Ensure vacuum sealer is properly grounded: Grounding the vacuum sealer is essential to avoid electric shocks that could occur if the vacuum sealer makes contact with water.

- Read and follow manufacturer’s instructions: Before use, make sure you read the manufacturer’s instructions carefully and understand all safety warnings associated with the vacuum sealing machine.

- Use vacuum bags that are compatible with vacuum sealer: Vacuum bags come in different sizes and materials, so make sure you use vacuum bags that are compatible with the vacuum sealing machine in order to avoid any damage.

- Keep vacuum sealer away from heat sources: Vacuum sealers should be kept away from heat sources such as open flames or hot surfaces, as this could cause a fire or even an explosion.

- Keep vacuum sealer away from children: Vacuum sealers should be kept away from children as they may not understand how to properly use the machine and its associated risks.

- Do not vacuum seal flammable items: Vacuuming sealing machines must not be used to vacuum seal items that are flammable, as this poses a serious fire hazard.

- Do not vacuum seal hazardous materials: Vacuum sealing machines must not be used to vacuum seal hazardous materials, such as caustic liquids or explosives, as this could result in an explosion or injury.

12.What Are The Common Problems Associated With Using A Vacuum Sealing Machine And Their Possible Solutions?

Faulty Vacuum Sealing

Faulty vacuum sealing can be caused by the vacuum sealer not closing securely, a damaged or worn vacuum sealer bag, or clogged valves.

Possible Solutions

Ensuring that the vacuum sealer is properly closed before engaging the vacuum mechanism, using new bags for each vacuum cycle, and cleaning the valves regularly.

Leaks

Leaks can occur when the vacuum sealer does not make a proper vacuum seal or if there is an air leak in the vacuum bag.

Possible Solutions

Double-checking that the vacuum sealer is closing correctly, using multiple vacuum seals for more difficult items, and ensuring that the vacuum bag has no punctures or holes.

No vacuum

No vacuum can occur if the vacuum sealer’s motor is not working properly, a clog in the valve, or a leaky vacuum bag.

Possible Solutions

Checking the power to make sure it is on, cleaning the valves regularly, and ensuring that all vacuum bags are intact with no punctures or holes.

Excessive Vacuum

Excessive vacuum can occur when the vacuum sealer is set to a higher vacuum setting than necessary for the vacuum bag being used.

Possible Solutions

Adjusting the vacuum settings according to the type of bag being used and using multiple vacuum seals for more difficult items.

Heat Damage

Heat damage can occur when the vacuum sealer’s heating element is too hot, resulting in the bag shrinking or melting.

Possible Solutions

Adjusting the temperature of the vacuum sealer according to the type of vacuum bag being used and using lower vacuum settings for delicate items.

13.What Are The Maintenance Procedures Of A Vacuum Sealing Machine?

- Check the vacuum chamber for any cracks or damage, and replace broken parts if necessary.

- Inspect all seals regularly to ensure they are in good condition and not leaking vacuum. Replace worn or damaged seals as needed.

- Clean the vacuum chamber and vacuum seals with a vacuum cleaner or compressed air to remove any dust and debris.

- Lubricate all moving parts and vacuum seals periodically, as specified by the vacuum sealing machine manufacturer’s instructions.

- Check vacuum levels regularly and adjust if necessary to ensure maximum efficiency of the vacuum sealing process.

- Test the vacuum sealing machine frequently to ensure that vacuum levels and sealing processes are working properly.

- Check for any loose screws, nuts, or bolts and tighten them if necessary.

- Monitor the vacuum chamber temperature regularly as it can affect vacuum seal performance.

- Clean the vacuum pump filter periodically according to the manufacturer’s instructions.

- Schedule regular maintenance and repairs as needed. This can help to prevent future breakdowns and ensure your vacuum sealing machine remains in good working order.

14.What Factors Should Be Considered Before Purchasing A Vacuum Sealer Machine?

Price

Before purchasing a vacuum sealing machine, it is important to consider the price of the machine. Consider researching vacuum sealers in different price ranges and determine which one fits your budget best.

Size

Vacuum sealer machines come in various sizes, so it is important to take into account how much space you have available to accommodate the vacuum sealer.

Features

Different vacuum sealing machines come with different features, such as built-in storage for vacuum bags, an adjustable vacuum speed and technology that prevents air leaks. Consider which features are most important to you before making your purchase.

Durability

It is also important to consider the durability of the vacuum sealer. Look for vacuum sealers with a durable construction that is designed to last.

Warranty

Before making a purchase, make sure to check if the vacuum sealing machine has a warranty and what it covers. This can help provide peace of mind in case anything goes wrong with the machine.

CONCLUSION

If you are planning to buy a vacuum sealing machine for your business or home, Allpack is the best place for you. We offer a wide range of machines with different features and specifications. You can also get custom made machines according to your specific requirements. So, what are you waiting for? Contact Allpack today and get the best deals on vacuum sealing machines.

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours