Vacuum Packager: the Ultimate Buying Guide In 2025

Vacuum Packager: the Ultimate Buying Guide In 2025

Generally,when you go to the supermarkets,fruit shops and other food stores,you will find that a lot of food are packed by vacuum packager.Although you are not unfamiliar with vacuum packager,you still have little acknowledge of it.

Thus,this article will give a complete introduction of vacuum packager to you,the content of the text are as follows:

1.What is vacuum packaging?

Simply speaking,vacuum packaging is a packaging method which can keep the product fresh.How does it achieve such an effect?Vacuum packaging is to extract the air from the packaging pouch,then pouch is kept in a low oxygen condition ,so that the product can be kept fresh.

After realizing what is vacuum packaging,you need to know about the packaging pouches which can be used in the vacuum packaging industry.This question will be referred to below.

2.How many types of packaging pouches can be used in vacuum packaging?

In general,there are four types of packaging pouches can be used in vacuum packaging,which include:

PET Packaging Pouch

As is known,PET is the general term of the polymer which is obtained by condensation of polyols and polyacids,this type of packaging pouch is colorless and transparent,it is always used in vacuum packaging of cooked products.

PA Packaging Pouch

Basically,PA packaging pouch has good tenacity and tensile strength,so that it is suitable for vacuum packing of hard products, such as greasy food, meat products, fried food and so on.

PE Packaging Pouch

PE is a thermoplastic resin which is polymerized from ethylene,it is compared that the PE packaging pouch has a lower transparency than PA packaging pouch,alternatively,the sense of touch is harder.

But,PE packaging pouch isn’t suitable for the demands of high temperature and cold storage.

Aluminum Plastic Packaging Pouch

Aluminum plastic packaging pouch has a good isolation function for water and oxygen,therefore,it is widely applied in vacuum packaging of food, electronics, chemical industries,etc.Comparatively,the cost of aluminum packaging pouch is a little high,so the cost of vacuum packaging is relevantly high.

3.What is the vacuum packager?

Allpakchina DZ-4002E Single Chamber Vacuum Packaging Machine

Vacuum Packager is a machine which can extract the air from the packaging pouch and complete the sealing operation automatically.In another words,vacuum packager is a machine which provides vacuum packaging to products,to make them keep fresh and extend their storage time.

Because of its own function,the vacuum packager is widely used in food packaging industry,it provides many convenience to human’s daily life.

4.What are the development process and prospect of vacuum packager?

The development process of vacuum packager

Actually,the vacuum packaging technique origins from the 1940s,in this period,there is no existence of vacuum packager.The first development period of vacuum packager is from 1950s-1980s.At the beginning,the factories only create simple air pumps,which just adapt to low and medium level of vacuum packaging.

When it comes to 1990s,there is a boost of vacuum packaging industry,the number of the factories and workers is increasing rapidly,and the vacuum packaging devices are more advanced.Which means that vacuum packager enters a better stage.

Of course,until today,the development process of vacuum packager is never stop,instead,the whole industry is developing quickly.

The prospect of vacuum packager

As is mentioned above,the development process of vacuum packager is not stop,among with the development of new technology,the vacuum packaging technique is also growing faster and faster,the application range of vacuum packager is covered various economic fields.

What’s more,because the vacuum packager is applied all over the world,for the purpose of communicating and learning,many exhibitions of vacuum packager have been hold up.

5.What are the effects of the vacuum packager?

In many cases,vacuum packager is used for food such as meat,vegetables,fruits and so on.The reason why it is applied in many aspects is that there are some good effects of using vacuum packager.

Extend Food Shelf-life

When you use a vacuum packager to package food,the packaged food is sealed in a low-oxygen environment and it can be kept fresh.For instance,the meat which is vacuum packaged can be retained for longer time when compared to the meat without vacuum package.

Avoid Pollution

Besides,the vacuum packager can seal the packaging pouch,and isolate the environmental elements successfully,which makes the food protected from pollution.

Keep a Good Appearance of the Food

By using the vacuum packager,you can keep the original color of the food,so it looked as well as the original condition ,which can keep a good appearance of the food.

6.What are the features of the vacuum packager?

Alpakchina HVC-210T1D Single Chamber Vacuum Packaging Machine

In general,vacuum packager is designed as a small size,so it doesn’t occupy too much space.

The second feature is that the vacuum packager is easy to operate,there are no complicated procedure of it,so that you can use a vacuum packager conveniently.

Because the working process of the vacuum packager is simple, the packaging speed is quite fast,it doesn’t take you much time to complete the whole operating process.

Moreover,the vacuum packager adopt a form of self-heating,which can save the energy sources.

And another feature is that vacuum packager can meet the different packaging requirements,for example,you can use it to package products in various shapes and sizes.

7.How will you benefit from using vacuum packager?

By the way,when you read about the effects and features of the vacuum packager,it is possible that you will come up with a question:how about the benefits?Then I’ll show you the benefits of using vacuum packager.

High Quality

According to the different packaging requirements,vacuum packager can provide different types of products,and ensure the finished products are in the same size and shape.It means that using a vacuum packager,you can guarantee that your products are high-quality.

Professional

In addition,there are some operations of vacuum packaging which you can’t do them by hand while vacuum packager can complete these operation quickly and professionally.It’s no doubt that ,in some cases,the machine is smarter than human’s hands.

Lower Cost

On the contrast to other packaging machine,the vacuum packager need a lower cost,because its working process is more simple,and the cost of the packaging material is also lower than others.

Avoid Damage

On the one hand,the products which is vacuum packaged can be kept in a fresh condition for longer time.On the other hand,after the vacuum packaging,the products are hard enough,so that they are not easily damaged by extrusion,which makes them easier to be transported.

Sanitary

Sometimes, there are some products need a strict hygiene environment in the packaging process,by using a vacuum packager,you can avoid the pollution,to ensure the products are sanitary.

8.What are the categories of vacuum packagers?

In terms of the different form,there are six main types of vacuum packagers:automatic continuous vacuum packager,automatic thermoforming vacuum packager,external pumping vacuum packager,internal pumping vacuum packager,vertical vacuum packager and feed bag vacuum packager.

Automatic Continuous Vacuum Packager

Automatic continuous vacuum packager is the most common vacuum packager in the market,this is an intelligent vacuum packer which is controlled by touch screen system.It is multifunctional and can operate automatically.

The automatic continuous vacuum packager is composed of transmission system, vacuum chamber, inflatable system, electrical system, water cooling and washing device, conveyor belt and fuselage, etc.

In terms of the operation,you just need to put the product on the conveyor belt,the machine will complete a series of operations automatically.

In a brief,the automatic continuous vacuum packager has a high degree of automation and high production efficiency. It is widely used in vacuum packing of powder or liquid products.

Automatic Thermoforming Vacuum Packager

Simply speaking,automatic thermoforming vacuum packager is a type of device which makes the packaging pouch be molded automatically by heating the film.It is the most modern and automatic vacuum packager.

The working process of this type packager is:heating and stretching the below film until it’s formed,then fill the products into the formed below film,after that,heat-sealing the upper film and the below film,finally the packaging pouch is created.The assembly line production of the machine improves efficiency.

As a result,automatic thermoforming vacuum packager is widely used in all kinds of food and non-food vacuum packaging, and it is suitable for large-scale vacuum packaging needs

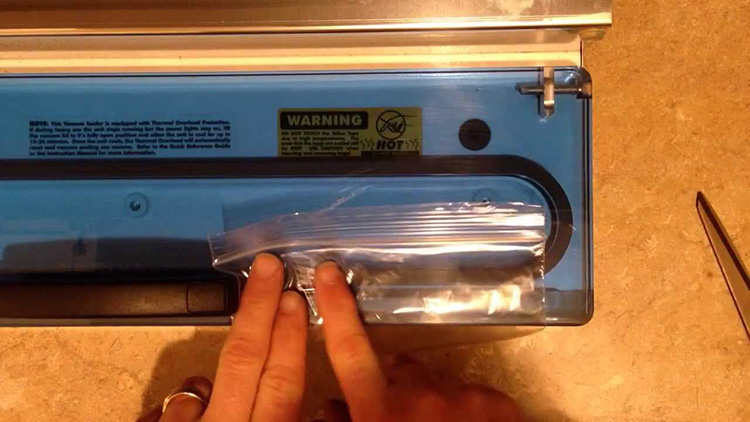

External Pumping Vacuum Packager

External pumping vacuum packager,as the name shows,is a device which put products on the outside of the machine during the vacuum packaging process.

On contrary to other vacuum packager,this type of machine is to put the pump into the packaging pouch,when the extraction process is finished,take out the pump and then seal the packaging pouch.

The external vacuum packing machine has high speed and is not limited by the size of the products, and it can ensure the beauty of the products to be packed

Internal Pumping Vacuum Packager

Comparatively,internal pumping vacuum packager complete the vacuum process inside the machine.The machine extracts the air of the packaging pouch in its own vacuum chamber and then completes the sealing operations immediately.

Conventionally,internal pumping vacuum packager can be divided into single chamber vacuum packager and double chamber vacuum packager.

Single Chamber Vacuum Packager

As you can see,single chamber vacuum packager is in small size,sometimes you can just put it on the tabletop.The working principle is simple,extracting the air in the packaging pouch,and then sealing automatically.

Generally,single chamber vacuum packager can be used for meat products, seasoning, soybean products, medicine, grain and other powder, solid, liquid vacuum packaging.

Double Chamber Vacuum Packager

Be similar to the single chamber vacuum packager,the double chamber vacuum packager uses its chamber to do the extraction operation,and fills inert gases into the packaging pouch,to achieve the purpose for anti-corrosion.

But the difference is that double chamber vacuum packager has two chambers,the two chambers can work alternately.

Vertical Vacuum Packager

The vertical vacuum packager is mainly provides vacuum packaging to powder and granule products.For instance,vertical vacuum packager should be applied when there are large packaging demands such as agricultural feed or chemical fertilizers.

Bag-type Vacuum Packager

As the picture shows,bag-type vacuum packager can complete the assembly line operation of packaging process automatically.Therefore,this type of vacuum packager improves the production speed and saves the cost of labor.

Generally,bag-type vacuum packager is applied in packaging casual snacks.

9.What are the application fields of vacuum packager?

After all,vacuum packager is applied in many aspects in your daily life,then this article will tell you some typical application fields of vacuum packager.

Food

To be honest,the most common application field you can see is the food packaging,vacuum packager provides vacuum packaging to food such as meat,fruit,vegetable,cookies,snacks and so on.

By using vacuum packaging,the color,taste and the mouthfeel of the products can be kept in a perfect condition,with such a advantage,vacuum packager is widely used in food packaging.

Medicine

Apart from the food industry,vacuum packager is also applied in medicine field,because of the particularity of medicine,the sanitary requirement is quite high.Vacuum packager can give a sterile package to the medicine product,then extend the storage time of the medicine and maintain the properties of drugs.

Electronic Component

Furthermore,vacuum packager can be used to package electronic components,but the material is a type of special plastic packaging pouch with shielding function,for the purpose to protect the electronic components from the damage of static electricity.

Metal

Even if metal is hard,it is easy to become oxidized,when the metal products oxidize,the appearance and the usage will both be affected.To resolve this problem,vacuum packager is also used in packaging metal.

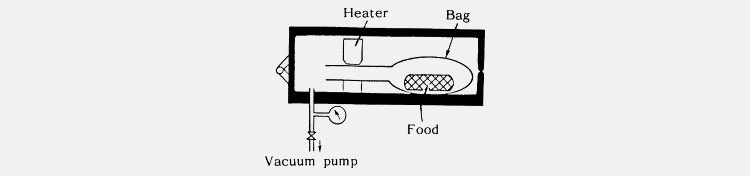

10.What is the structure of vacuum packager?

After reading the previous text,I guess you are more interested about the vacuum packager,the next part is to tell the structure of it.In the basic case,vacuum packager consists of the following components:

Upper and lower vacuum chamber and sealing ring

Generally,vacuum packager is a cavity structure,consists of the upper and lower vacuum chamber and the sealing ring which is between the two chamber.

Hot pressing sealing device

This device is installed in the vacuum chamber,it is composed of heat seal chamber frame,reset device,hot pressing frame and hot sealing chamber.

Vacuum pump,vacuum gauge and vacuum solenoid valve

Vacuum pump is equal to the heart of the vacuum packager because it’s the extraction air device of the machine.

Vacuum gauge is to monitor the vacuum index of the packaging products.

The vacuum solenoid valve is a special valve installed on the vacuum pump,it is connected to the same power supply with the vacuum pump, and the opening and stopping of the vacuum pump directly controls the opening and closing of the solenoid valve.

Time relays, transformers and contactors

There are always two time relays,one is to control the time of vacuum,the other one is to control the time of heat-sealing.

A transformer is a static electrical device. It is according to the principle of electromagnetic induction, a certain level of AC voltage and current into the same frequency of another level of voltage and current equipment.

Contactor is actually a kind of electromagnetic switch, can automatically break the high current circuit.

11.What is the working principle of vacuum packager?

Well,after understanding the structure of vacuum packager,next part is the working principle,in other words,what’s the technology support of vacuum packager.

To explain this question,we have to talk about microorganism,which results in the spoilage of the products.As well as known,the survival of microorganism is depended on oxygen of the air.How about making it lose the oxygen?

Now you can see the working principle of the vacuum packager is so simple,just extracts the air of the packaging pouch,then the microorganism loses its main living environment,the rate of their growth and reproduction are dramatically reduced, or even suppressed .So,the purpose of using vacuum packager is achieved.

12.What is the working process of vacuum packager?

In fact,there are four parts of the whole working process of vacuum packager:vacuum,heat-seal,gas returning and circulation.

Vacuum

At the first step,the cover of the vacuum chamber is closed,and then the vacuum pump begins working,at the same time,the vacuum process is started. As this operation goes on,the vacuum index is increased,when it reaches the rated vacuum degree,the vacuum pump stop working.

Heat-seal

The second step is the heat-seal,the outer air enters the heat seal chamber through the air inlet,at that moment,the gas in the heat seal chamber is expanding because of the pressure difference between the vacuum chamber and the heat seal chamber.

As a result,the upper thermopress frame begins to move down and press the mouth of packaging pouch,meanwhile,the heat seal transformer starts working and the seal operation is finished.

Gas returning

Next,the air enters the vacuum chamber,the vacuum index return to zero,the hot press frame is reset,then the cover of vacuum chamber is opened.

Circulation

If the vacuum packager is a double chamber vacuum packager,according to the procedure steps, the vacuum chamber is moved to another vacuum chamber, and the next working cycle is starts,the left and right chambers work alternately to achieve the cycle repeats.

13.How to use a vacuum packager?

Simply speaking,the operation steps of the vacuum packager is not complex,it is easy for you to use a vacuum packager.

Firstly,you should switch the power supply,choose the correct power switch according to your demand,after that,the power indicator is on.

Secondly,put the packaging pouch in the vacuum chamber,pay attention to the mouth,it should be put on the heat sealing strip neatly.

Then,you should close the cover of vacuum chamber,and adjust the knob of vacuum operation to control the vacuum degree according to the packaging requirement.

Next,when it is at the end of the extracting air process, the inflating operation begins, and you can control the length of time by adjust the knob of inflating operation.

After the above steps,the machine enters the heat-sealing part,you should adjust the time and temperature,a vital point is that you need to adjust the knob in a small range.

Finally,when the heat-sealing operation is finished,the cover of the vacuum packager will be opened,it means that the operation process is finished,you can prepare for the next cycle.

14.What are the operation key points of vacuum packager?

Although the operation step of vacuum packager is not difficult,there are still some key point you should pay attention to when you use the vacuum packager.

The first one is that you should keep the working area clean and tidy,which can

Effectively avoid the occurrence of the safety accidents.

Besides,please don’t use the vacuum packager in moist or high temperature environments,to prevent the machine from breaking down or blowing up.And you should also keep the good lighting condition of he working area.

What’s more,the vacuum packager has its own performance range,you can’t make it work overload,too much work may cause damage to the machine itself.

And please don’t maintain the vacuum packager while it is in operation,because when it is in operation,the machine is electric,it is not suggest to maintain it in such a condition.

The last but important,when you need to replace the accessories or reinstall the machine,you should turn off the power supply before the operation.

All above is the key points of operation,during the use of vacuum packager,you should memorize these points all the time,so that you can protect your machine and extend its service life.

15.How to maintain a vacuum packager?

It is interesting that the machine is similar to human,if you don’t maintain it,it also has a temper and then breaking down.For this reason,you need to maintain the vacuum packager regularly,the maintaining methods are as follows:

The most crucial one is that the vacuum packing machine should be used in the environment where the temperature is -10℃ -50 ℃, the relative humidity is no more than 85%, and there is no corrosive gas, no dust and no explosive danger in the surrounding air.

To ensure the vacuum pump can work normally,you should check the oil of it termly,if there’s moisture in the oil or the oil turns black,you should replace with new oil.

Don’t forget,the magazine filter should be removed and washed every one to two months.

When the vacuum packager has worked for continuous three months,you should add lube to the connecting parts of the machine.

In addition,the sealing strip should be kept clean,or the quality of sealing will be greatly compromised .

In order to avoid collision,don’t place the vacuum packager obliquely in the process of transport.And when install the vacuum packager,you should guarantee the machine can be put on floor stably.

In the operation process,you should ventilate the vacuum packager before turning on the power,on the contrary,at the end of operation,you need to turn off the power firstly.

16.How to deal with the malfunctions while using vacuum packager?

Whereas,it is inevitable that the machine may be out-of-order,what can you do when it’s broken-down?Just as the follow text:

The first situation is that the vacuum degree is low,there are several possible reasons.If the oil of vacuum pump is polluted,too little or too thin,you need to wash the vacuum pump,and add new oil.If the time of extraction is too short,you need to extend it;

If the exhaust filter is blocked,you need to wash or change it;If there is air leakage,you need to turn off the power,and then check whether the solenoid valve, pipe joint, vacuum pump suction valve or the surrounding gasket of the studio have air leakage.

The second situation is that the heating part occurs malfunctions.On the one hand,it doesn’t heat,you need to check the heater strip,time relay,heating wire and other heating device to find out which part is faulted,then change it.

On the other hand,when the heating device doesn’t stop,if the time relay is out of contact, adjust or replace it. If the AC contactor doesn’t reset, repair or replace it.

The third situation is that there is aloud noise. If the vacuum pump coupling is worn or broken,you need to replace it. If the exhaust filter is blocked or installed in an incorrect position,you need to clean or replace the exhaust filter and install it correctly.If there is oil leakage,check the solenoid valve.

And there are another situation is that the oil returning valve is blocked,you need to remove and wash it.

17.How to choose a proper vacuum packager?

Actually,you already have a relatively comprehensive understanding of vacuum packing machine,now you only need to learn how to choose a vacuum packager.Well,there are many types vacuum packager on the market,to find a proper one,you need to consider the follow factors:

To the beginning,if you want to improve the production efficiency,the first factor you need to think is the packaging speed,it is suggested that you can choose a double chamber vacuum packager.

Then,if the packaging products need to be fill other gases,you need to find a vacuum packager which has the air charging system.

According to the requirement of the vacuum degree,if the packaging products need to be storage in a high degree vacuum condition,you can choose a cavity vacuum packager.

But,after all,the demand of everyone is different,the most essential principle is that you need to choose vacuum packager based on your packaging demand.

Conclusion

In a word,vacuum packager is a device which is available in various fields,it brings many conveniences to your daily life.After reading about this article,you will have a general perception of vacuum packager.Welcome to contact us whenever you have other problems.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Vacuum Packager: the Ultimate Buying Guide In 2025 Read More »