1.What Is Food Vacuum Packaging Machine?

Food Vacuum Packaging Machine

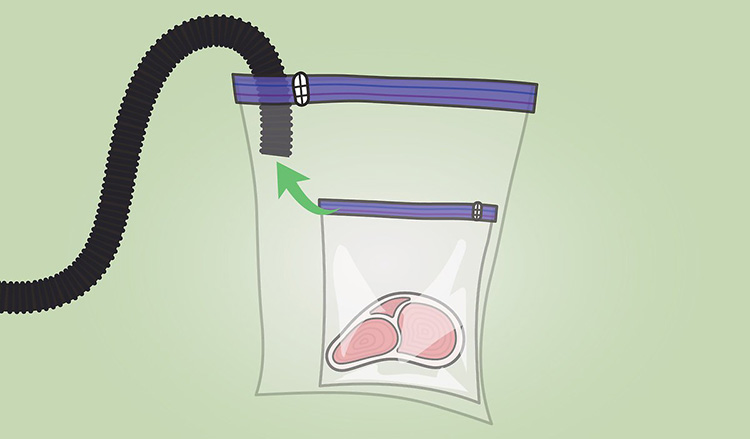

Food Vacuum Packaging Machine is a special machine that can put food into packaging bags. The machine will first extract the air from the bag. When the packaging bag reaches the vacuum level set by the machine, the sealing process is completed. In this way, the food will be completely and safely packaged.

Have you ever seen this machine in your life before? If you have not seen a machine in your life before, it is okay, because you must have seen the vacuum-packed food in your life every day, especially in a convenience store, shopping mall, airplane or even in Pharmacy.

Vacuum-packed Food

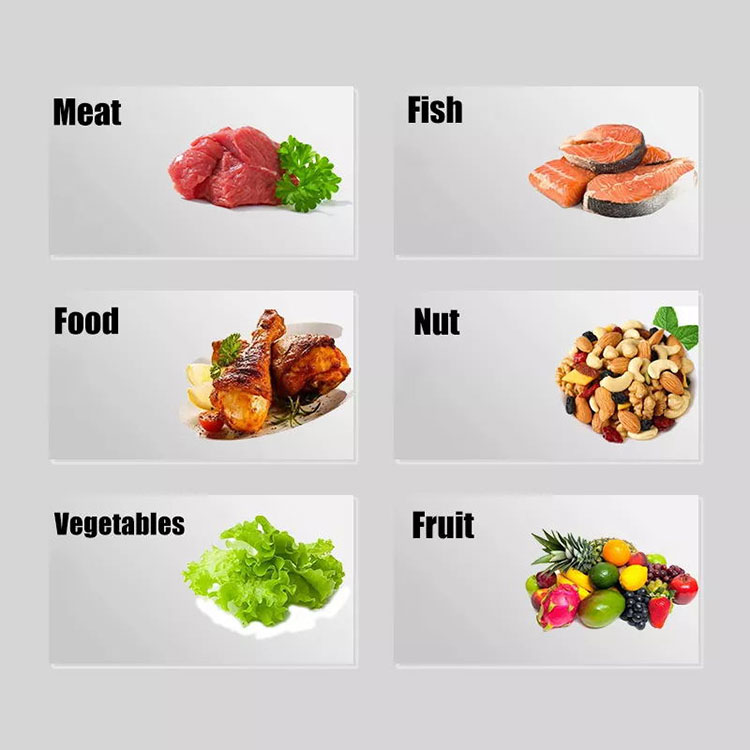

In the food industry, vacuum packaging applications are very common. Such as various cooked products such as chicken legs, ham, sausages, grilled fish fillets, beef jerky, etc.; pickled products such as pickles; and soy products, preserved fruits, etc.

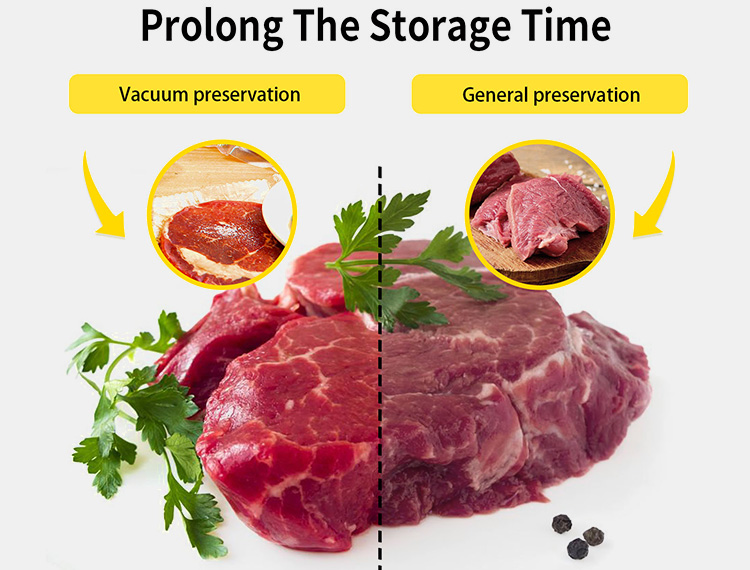

A variety of food products that require freshness are increasingly being vacuum-packed. Foods that have been vacuum-packed have a longer refreshing time and shelf life.

Nitrogen-filled Packaging on the Shelf

2. What Is the Characteristic of the Food Vacuum Packaging Machine?

There are two types of food vacuum packaging machines for you to choose from, including household types and commercial types.

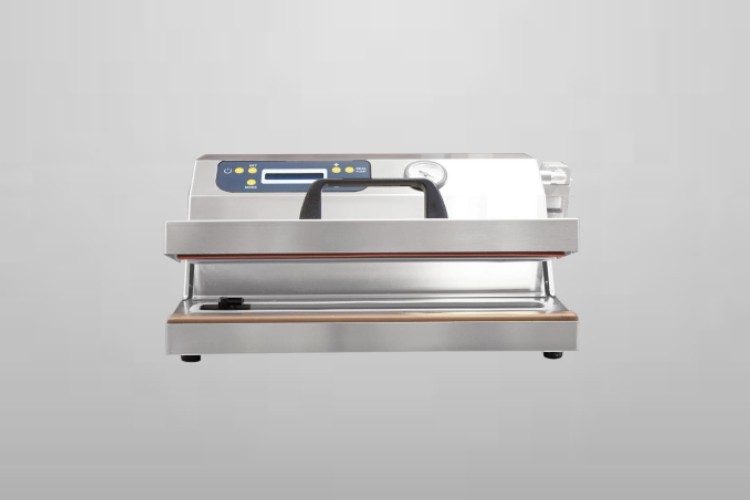

Household Food Vacuum Packaging Machine

The characteristics of household Food Vacuum Packaging Machine:

Household Food Vacuum Packaging Machine has great vacuuming performance. This machine is suitable for vacuum packing many kinds of plastic bags and compound bags. The food that has been sealed by the packaging machine can be kept fresh at room temperature for an extended period of time. This can effectively prevent the food in the refrigerator from being smelled, spoiled, dehydrated and cracked.

Household Food Vacuum Packaging Machine

Household Food Vacuum Packaging Machine has a super vacuum function. This machine is designed with digital control of heat sealing time and overheating automatic protection alarm device that can seal all kinds of plastic bags with a high degree of automation.

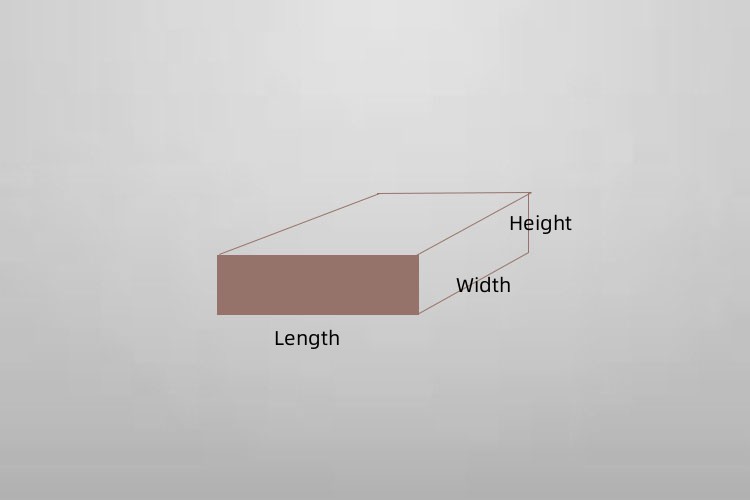

Size

Household Food Vacuum Packaging Machine saves electricity with small size and light weight. They are highly portable with simple structure and it is convenient for you to use.

Household Food Vacuum Packaging Machine is widely used in your daily life, and now is more and more popular.

The characteristics of commercial Food Vacuum Packaging Machines:

Commercial Food Vacuum Packaging Machine

After the food is put into the vacuum bag, the air in the bag is evacuated through the vacuum packaging machine.

When a certain degree of vacuum is reached in the packaging bag, the sealing process will be completed. Of course, the characteristics of vacuum packaging machines with different structures are also different.

Mechanical extrusion vacuum packaging machine: It uses sponge-like items from both sides of the packaging bag to remove the air in the bag, and then uses heat to seal the bag mouth to complete the vacuum operation.

Now in business, the most mainstream food vacuum packaging machines are the Chamber Vacuum Packaging Machine and Thermoforming Vacuum Packaging Machine. If you are in a small business then I highly recommend you the Chamber Vacuum Packaging Machine. If you have a long industry chain, a large business, and need efficient machines, then I highly recommend the Thermoforming Vacuum Packaging Machine.

3.What Is the Operation Method of Food Vacuum Packaging Machine?

The operation method of household Food Vacuum Packaging Machine:

- Open the sealer.

- Place the package opening in the black sealing ring.

- Close the sealer.

- Turn on the switch.

- The green light is on to pump air, and the red light is on to seal.

- The air extraction effect is shown in the following figure, without any bubbles.

If you are a housewife, and often need to use a food vacuum packaging machine. Well, I highly recommend you this small-style household food vacuum packaging machine. Simple and convenient to use.

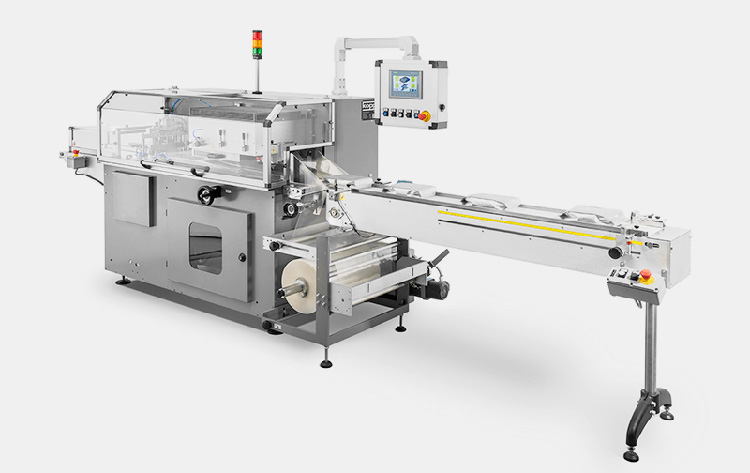

The operation method of Commercial Food Vacuum Packaging Machine:

Each commercial food vacuum packaging machine is used differently, but these machines are fully automatic. And the operation method is very simple, as long as you follow the instructions of the machine to operate, you don’t have to worry about making mistakes. But just in case, when the staff is operating, please assign a supervisor to supervise on the side.

Double Chambers Vacuum Packaging Machine

Next, we will take Double Chambers Vacuum Packaging Machine as an example to teach you how to operate this kind of machine.

Preparation before operation:

You need to check whether the oil level of the vacuum pump is correct, and check whether the vacuum pump oil is lacking.

When packaging products, you should pay special attention to the fact that when vacuuming salt-containing liquid products such as pickling liquid. The liquid will enter the vacuum pump oil and cause vacuum pump oil pollution. In this case, you need to replace the vacuum pump oil.

Vacuum Pump

Then you need to make a power connection and start preparing to operate the machine.

At first, you need to turn on the vacuum pump start switch, and the vacuum pump starts to run.

Then you should turn on the heating switch to preheat.

Then you have to confirm the vacuum and heat sealing time, and choose the vacuum and heat sealing time according to the packaged product. Because the time setting is according to the product size or the thickness of the bag to be adjusted.

Finally, you have to turn on the main switch of the machine, and the machine starts.

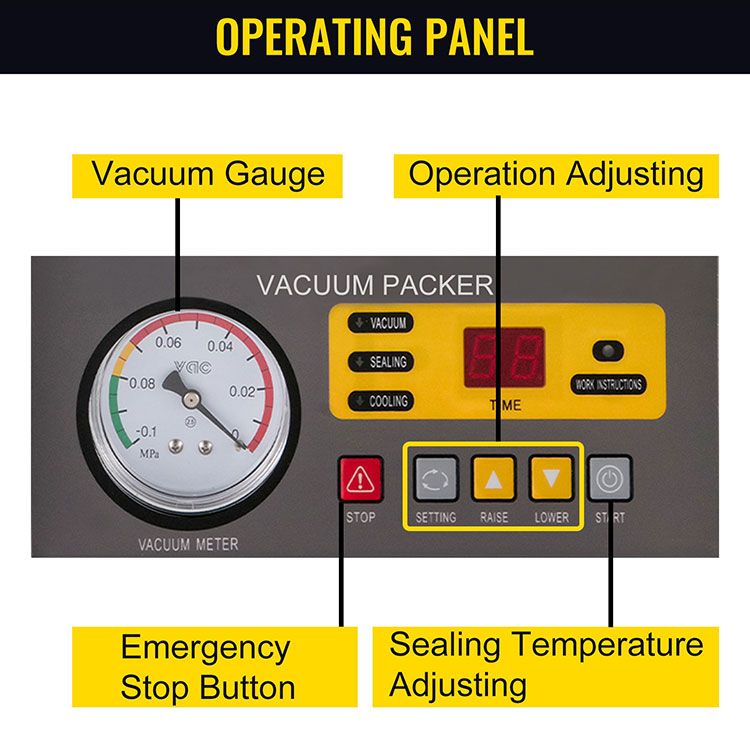

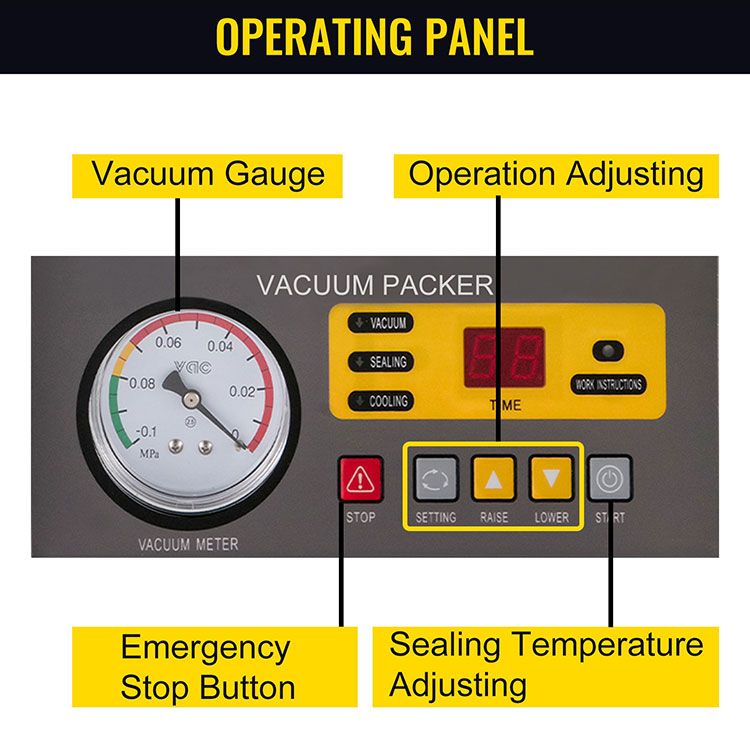

Operation Panel

Operation of the Machine:

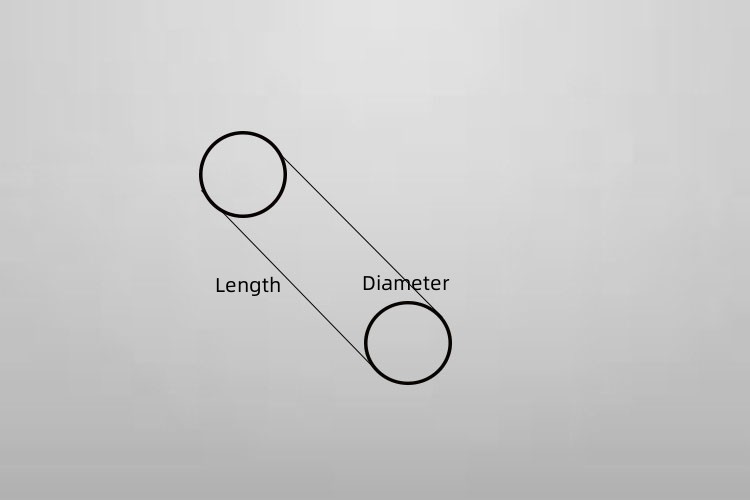

When you place the product, you need to place it according to the length of your own product. Because the belt runs continuously, you can continue to place the product.

The machine will work continuously, and you can turn off the start switch so that once the machine cycles, it will stop at the beginning, so when you click, you can move on to the next job.

Length of the Product

Your machines will be equipped with emergency stop devices. If something goes wrong while the machine is running, you can push the emergency stop button so that your machine can stop working immediately and the studio will go up.

The operation method of the automatic food vacuum packaging machine is very simple, have you learned it? If you still do not understand, you are welcomed to consult us. In your life, have you observed which foods can be vacuum-packed and which foods cannot be vacuum-packed?

4.What Can be Packed by the Food Vacuum Packaging Machine?

Pickled Products: Sausage, ham, bacon, duck, etc.;

Pickled Vegetables: Mustard, dried radish, kohlrabi, kimchi, etc.;

Soy Products: Dried tofu, vegetarian chicken, bean paste, etc.;

Cooked Food Products: Roast chicken, roast duck, sauce beef, etc. ;

Convenient Food: Rice, instant wet noodles, cooked vegetables, etc.;

Soft Canned Food: Bamboo shoots in water, fruits in sugar water, eight-treasure porridge, etc.

5. What Kind of Foods Are not Suitable for Vacuum Packaging?

Fresh plant seeds, corn kernels, whole grains, and so on are not suitable for storage in vacuum bags. Because the living seeds will carry out respiration, even if the air inside is exhausted, it will also carry out anaerobic respiration by itself.

If the seeds are vacuum-packed, the bag will bulge. A lot of gas will bulge the bag, so the seeds need to be dried before being vacuum-packed.

Fresh Seeds

Plant rhizomes, ginseng, radish, ginger, and so on are not suitable for storage in vacuum bags. For example, for some pickled vegetables, there may be shredded ginger and minced ginger in the vegetables.

If the cells are still alive if they are not pickled, they will also undergo respiration and will swell.

Ginger Root

Fresh vegetables and fruits. Here refers to green leafy vegetables. The leaves need to undergo photosynthesis, if there is no oxygen, it will accelerate its corruption, and the fruit needs to breathe, so it is recommended to use a fresh-keeping box at this time.

The vacuum degree should not be too high, and appropriate you need to leave some air for them.

Fresh Lettuce

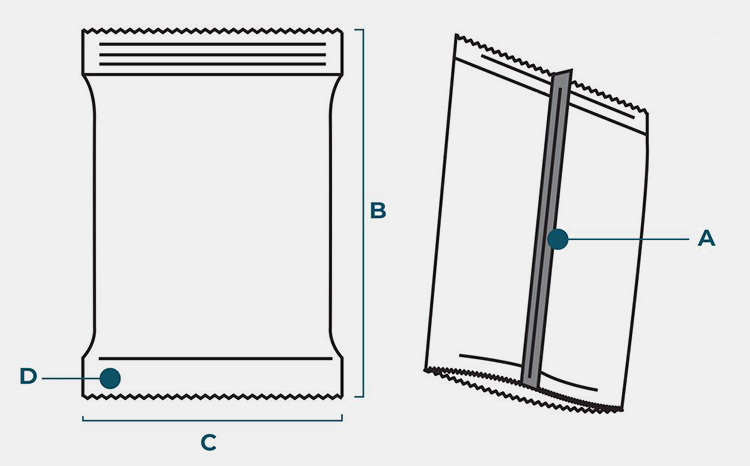

Food vacuum bags should be selected from safe and healthy materials, such as three-sided sealing bags made of double-layer composite films or three-layer aluminum thin composite films.

Vegetables have a relatively short shelf life and should be eaten as soon as possible.

6. How Many Types of Food Vacuum Packaging Machines Are There?

Household Food Vacuum Packaging Machine:

Household Food Vacuum Packaging Machine

Commercial large-scale packaging machines mainly include: suction-type vacuum packaging machines, chamber-type vacuum packaging machines, thermoforming vacuum packaging machines, tray-style vacuum packaging machines and table-style vacuum packaging machines, etc.

Here, you will learn about chamber vacuum packaging machines, tray-style vacuum packaging machines and table-style vacuum packaging machines. Because this is the mainstream Food Vacuum Packaging Machine now.

Suction Type Vacuum Packaging Machine: This type of machine inserts an exhaust pipe from the opening of the packaging bag, which is evacuated by a vacuum pump and then sealing the bag.

Suction Type Vacuum Packaging Machine

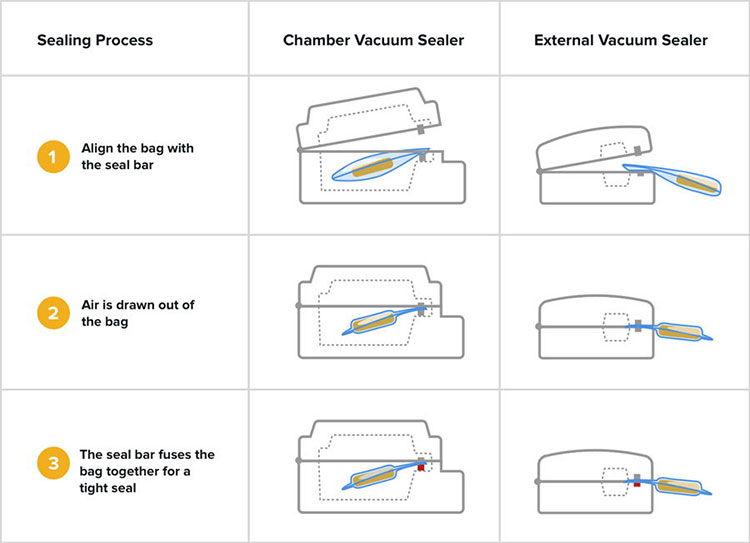

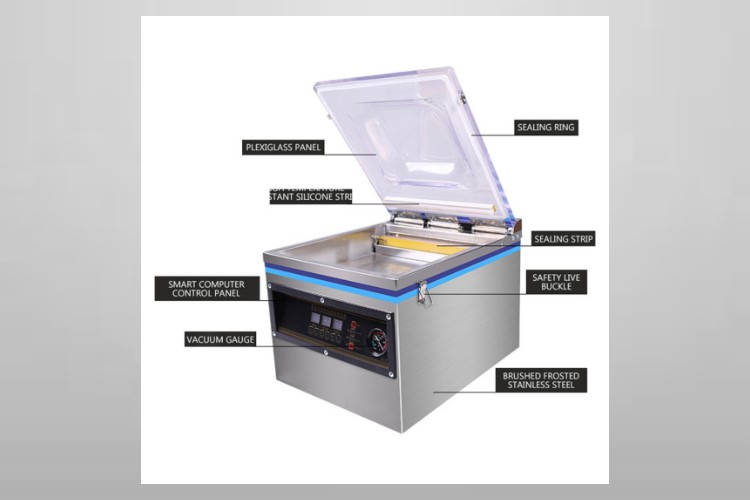

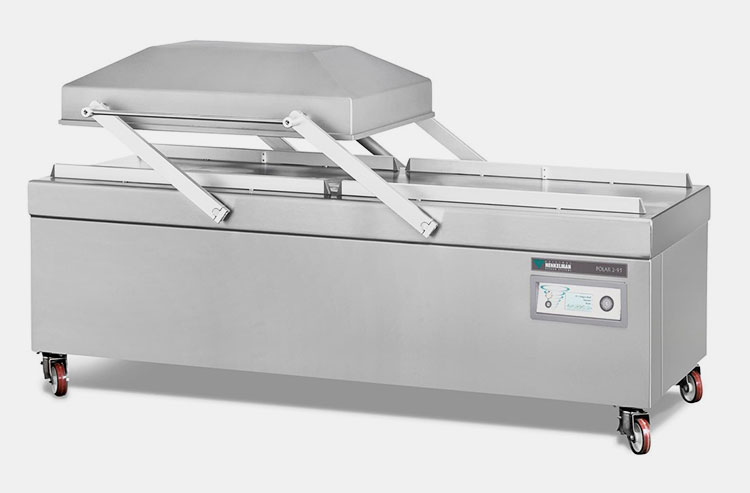

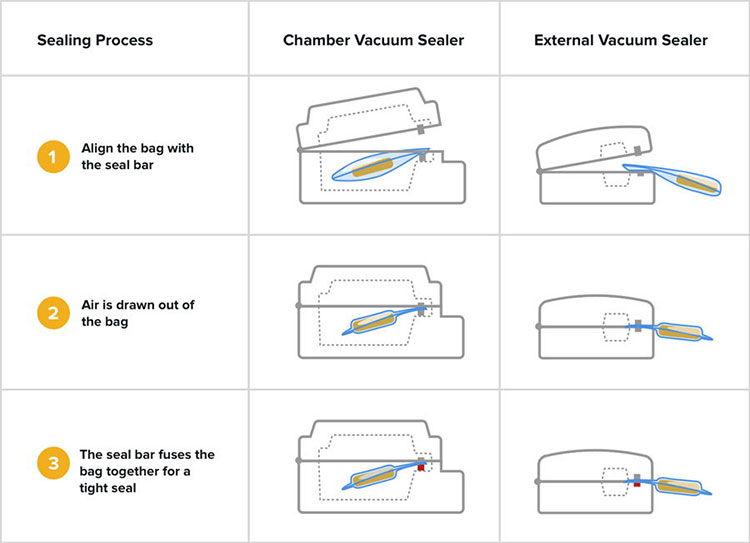

Chamber Vacuum Packaging Machine: This type of machine will put the plastic bag containing the food into the vacuum chamber, then close the lid and extract the air. When the predetermined vacuum degree is reached, the heat sealing device is on to seal the mouth of the packaging bag. This kind of vacuum packaging machine is now a mainstream vacuum packaging machine.

Chamber Vacuum Packaging Machine

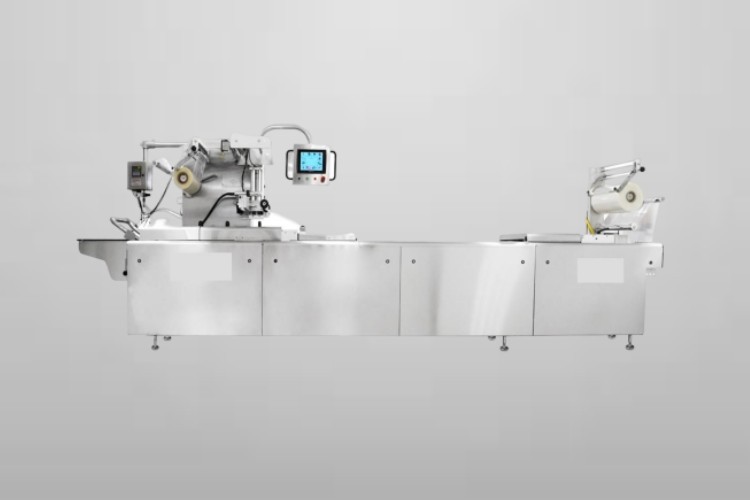

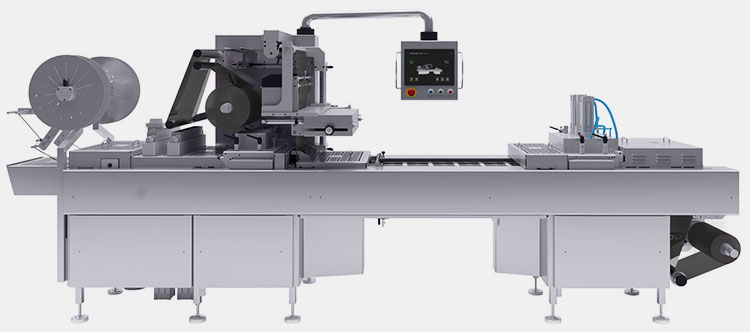

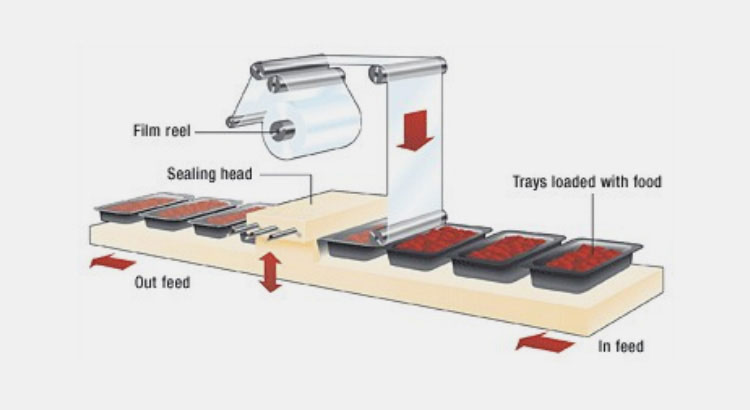

Thermoforming Vacuum Packaging Machine: This machine is also known as a continuous vacuum packaging machine. Using the method of sheet thermoforming in the model, making the packaging container directly on the packaging bag, and then the processes such as filling, capping, vacuuming, inflation, cross-cutting and longitudinal cutting are completed.

Thermoforming Vacuum Packaging Machine

Chamber vacuum packaging machine also includes a single chamber vacuum packaging machine and double chambers vacuum packaging machine.

Single Chamber Vacuum Packaging Machine

Single Chamber Vacuum Packaging Machine

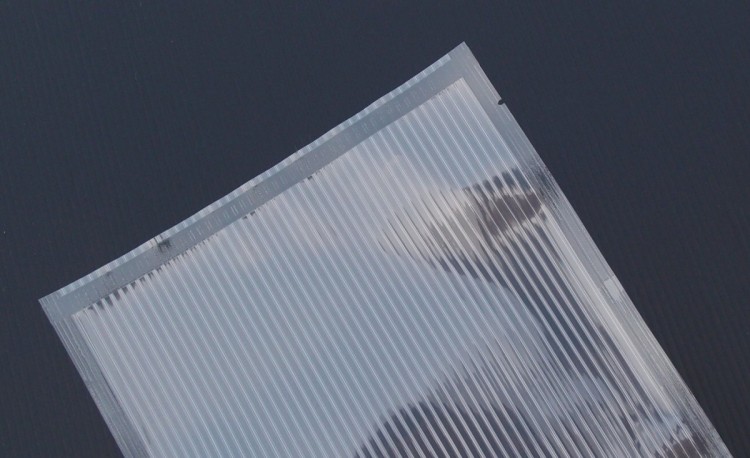

The materials that are vacuum-packed by this equipment can avoid oxidation, mildew, moth-eaten, and moisture, and prolong the storage period of the product.

The working chamber of this equipment is deep, and suitable for vacuum packing tall materials.

Its sealing strip is arranged in an “L” shape, which can meet the needs of different sizes of packaging bags.

By using transparent plexiglass, it is convenient for you to monitor the entire vacuuming process.

This device is equipped with a computer board to facilitate your control.

You can freely choose to configure the stainless steel inclined table, which is convenient for packaging items with liquids.

You can freely choose to configure the filling pad, which can meet the needs of different height packages and improve packaging efficiency.

You can freely choose to configure a dust filter to pack powder products.

Double Chambers Vacuum Packaging Machine

Double Chambers Vacuum Packaging Machine

Double Chambers Vacuum Packaging Machine

The materials that are vacuum-packed by this equipment can avoid oxidation, mildew, moth-eaten, and moisture, and prolong the storage period of the product.

This equipment can pack multiple products at the same time, suitable for small-scale continuous work with high work efficiency.

You can control it through a computer board or a relay.

You can freely choose to configure filling pads to meet the needs of different height packages and improve packaging efficiency.

You can freely choose to configure a dust filter for vacuum packaging of powder products.

The body material and studio depth of this device can be customized according to your needs.

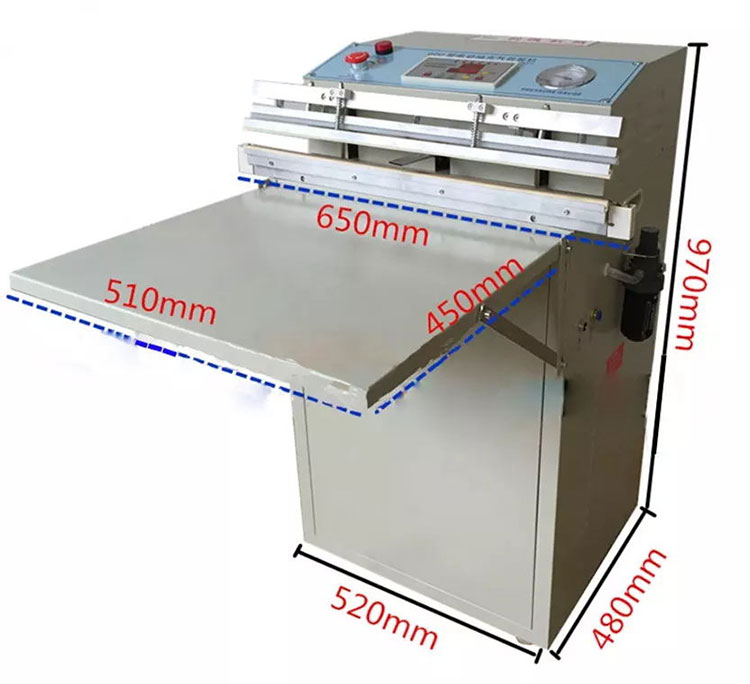

Table-style Vacuum Packaging Machine

Table-style Vacuum Packaging Machine

The materials that are vacuum-packed by this equipment can avoid oxidation, mildew, moth-eaten, and moisture, and prolong the storage period of the product.

By using the computer board control, you can store 5 setting programs to ensure that you can achieve the reliable packaging effect you want.

By using transparent plexiglass, it is convenient for you to monitor the entire vacuuming process.

You can freely choose to configure the stainless steel inclined plate, which is convenient for you to pack liquid food.

You can freely choose to configure filling pads to meet the needs of different heights of packaging, thereby improving packaging efficiency.

Please note that this machine cannot be inflated.

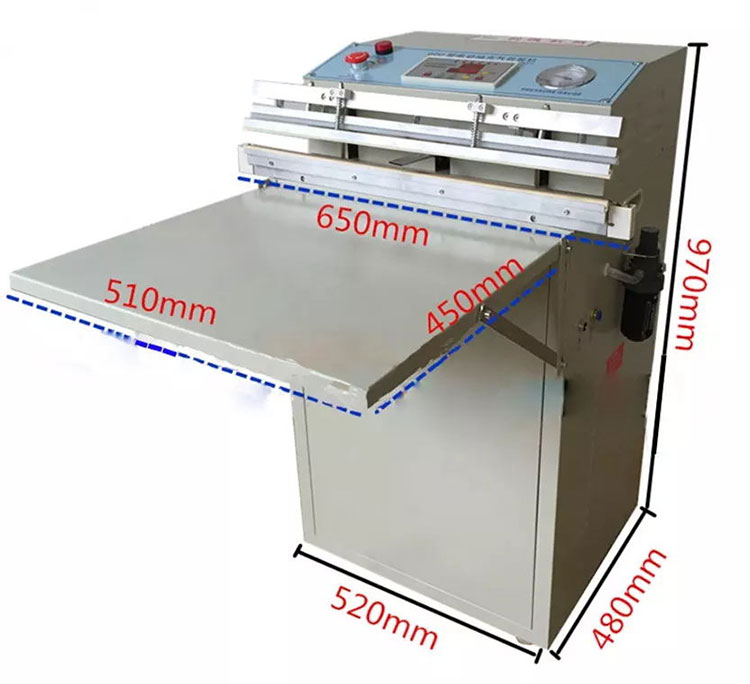

Vertical Vacuum Packaging Machine

Vertical Vacuum Packaging Machine

The materials that are vacuum-packed by this equipment can avoid oxidation, mildew, moth-eaten, and moisture, and prolong the storage period of the product.

By using the computer board control, you can store 5 setting programs to ensure that you can achieve the reliable packaging effect you want.

By using transparent plexiglass, it is convenient for you to monitor the entire vacuuming process.

You can freely choose to configure the stainless steel inclined plate, which is convenient for you to pack liquid food.

You can freely choose to configure filling pads to meet the needs of different heights of packaging, thereby improving packaging efficiency.

These are some types that I recommend, and if you have any other types of questions, I will be pleased to help you.

7. How Will You Benefit From Food Vacuum Packaging Machine?

The benefits of household Food Vacuum Packaging Machine:

The machine adopts noise reduction processing, which can provide you with a quiet environment when using it. It can greatly reduce the three noises of wind, machinery and vibration.

The machine is small and does not take up a lot of space. When you buy this device, you can store it in various corners of the kitchen. Making your storage more convenient and the kitchen tidier.

This machine is designed with multiple security protections. The heating process is provided with a protection function, which provides you with multiple protection functions for safer use.

Simple and fast to use, suitable for all ages.

The benefits of commercial Food Vacuum Packaging Machines:

The food vacuum packaging machine can effectively remove part of the air (oxygen) in the packaging container, and can effectively prevent the food from spoiling;

The food vacuum packaging machine adopts packaging materials with an excellent barrier (air tightness) and strict sealing technology and requirements, which can effectively prevent the exchange of packaging materials, which can not only avoid food weight loss,and loss of taste, but also prevent the secondary food pollution;

The removal of gas in the vacuum packaging container will accelerate the conduction of heat, which can not only improve the efficiency of thermal sterilization, but also avoid the rupture of the packaging container due to the expansion of the gas during thermal sterilization;

So there is no need to worry about that Food Vacuum Packaging Machine will not be helpful in your life.

8. What Fields Are Food Vacuum Packaging Machines Mainly Used In?

Food vacuum packaging machine uses plastic or plastic aluminum foil film as the packaging material, which can be used for packing liquid, solid, powdery paste food, grain, fruit, pickles, preserved fruit, chemicals, medicinal materials, electronic components, precision instruments, rare metals, etc.

Vacuum-packed food can avoid oxidation, mildew, moth-eaten, rot, moisture and other influences. And it can prolong the freshness and shelf life of food.

This equipment is especially suitable for industries such as tea, food, medicine, shops, research institutes, etc. And this machine has the advantages of beautiful appearance, compact structure, high efficiency, and easy operation.

You may also pay attention to the food vacuum packaging in other ways or industries.

9. What Is the Working Principle of a Food Vacuum Packaging Machine?

Sealing Process Table

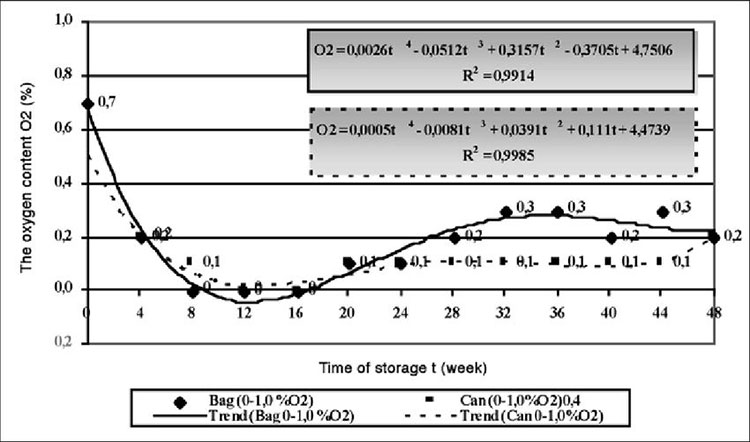

The main function of the food vacuum packaging machine is to remove oxygen, which is beneficial to prevent the food from spoiling.

The working principle of the food vacuum packaging machine is relatively simple.

Because food spoilage is mainly caused by the activity of microorganisms, and most microorganisms (such as molds and yeasts) require oxygen to survive.

Food Vacuum Packaging Line Chain

Vacuum packaging uses this principle to remove the oxygen in the food in the packaging bag, so that the microorganisms lose the environment for survival.

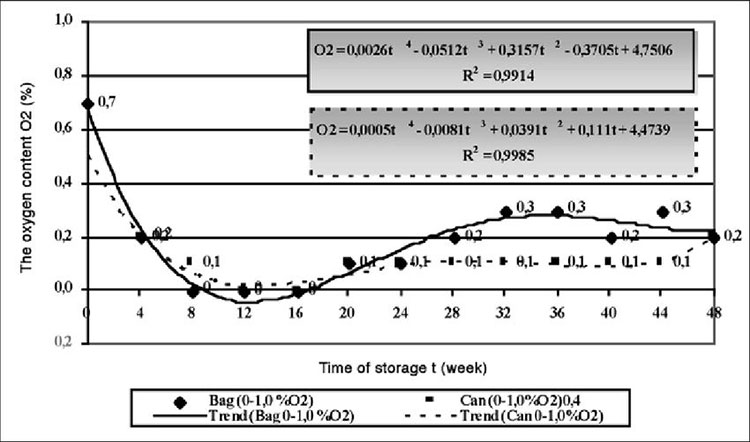

Experiments have shown that when the oxygen concentration in the packaging bag is less than 1%, the growth and reproduction speed of microorganisms will drop sharply. When the oxygen concentration is lower than 0.5%, most microorganisms will be inhibited and stop multiplying.

Oxygen Content Table

(Note: Vacuum packaging cannot inhibit the reproduction of anaerobic bacteria and the deterioration and discoloration of food caused by enzymatic reactions, so it needs to be combined with other auxiliary methods, such as refrigeration, quick freezing, dehydration, high-temperature sterilization, irradiation sterilization, microwave sterilization, salt pickled etc.)

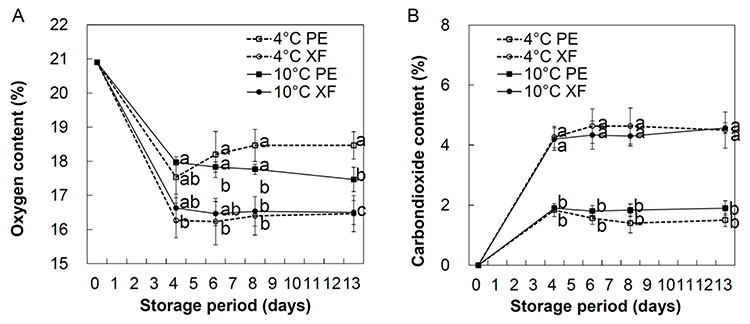

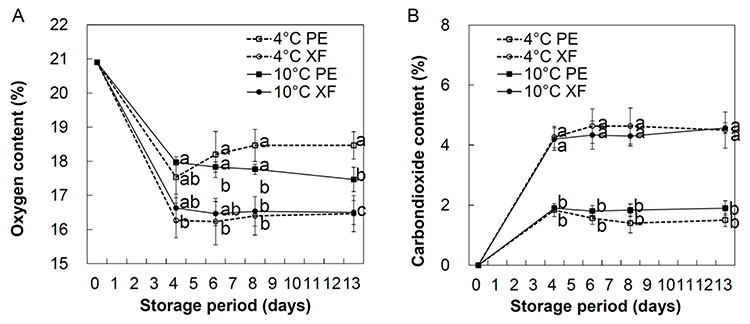

In addition to inhibiting the growth and reproduction of microorganisms, another important function of vacuum oxygenation is to prevent food oxidation.

Because oily foods contain a lot of unsaturated fatty acids. Unsaturated fatty acids are easily oxidized by the action of oxygen, thus making the food taste bad and spoiled.

Carbon dioxide Content Table

In addition, oxidation can easily cause the loss of vitamin A and vitamin C. The unstable substances in food coloring are exposed to the action of oxygen, darkening the color.

Therefore, oxygenation can effectively prevent food spoilage.

In addition to the function of oxygenation and quality preservation, vacuum packaging mainly has the functions of anti-pressure, gas resistance, and preservation. This can more effectively keep the original color, aroma, taste, shape and nutritional value of the food for a long time.

In addition, there are many foods that cannot be vacuum-packed, but must be vacuum-inflatable packaged. Such as crunchy and brittle food, and food that is easy to agglomerate and easy to deform and lose oil; food with sharp edges and corners or high hardness that will pierce the packaging bag, etc.

Potato Chips Vacuum Packaging Machine

After the food is vacuum inflated, the inflation pressure in the packaging bag is stronger than the atmospheric pressure outside the packaging bag. This can effectively prevent the food from being crushed and deformed under pressure, making the appearance of the packaging bag more beautiful.

The vacuum inflatable packaging is filled with a single gas such as nitrogen, carbon dioxide, oxygen, or a mixture of two or three gases after vacuum.

Among them, nitrogen is an inert gas, which plays a filling role to maintain a positive pressure in the bag. In this way, the air outside the packaging bag can be prevented from entering the bag, which has a protective effect on the food.

Nitrogen Vacuum Packaging

Carbon dioxide can be dissolved in various fats or water to form carbonic acid that is less acidic. This carbonic acid can effectively inhibit the activity of microorganisms such as mold and spoilage bacteria.

Oxygen can inhibit the growth and reproduction of anaerobic bacteria, and can maintain the freshness and color of fruits and vegetables. High concentrations of oxygen keep fresh meats bright red.

10. What Are the Components of a Food Vacuum Packaging Machine?

There are 6 parts of a household Food Vacuum Packaging Machine:

Size

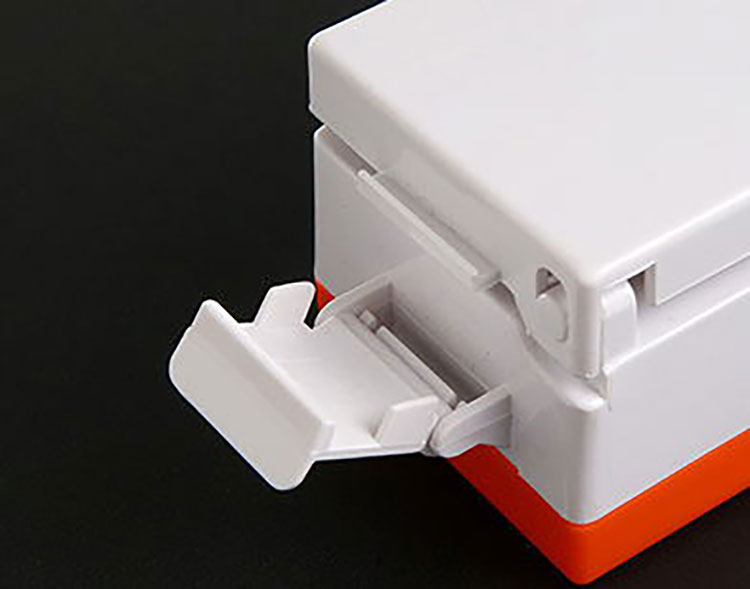

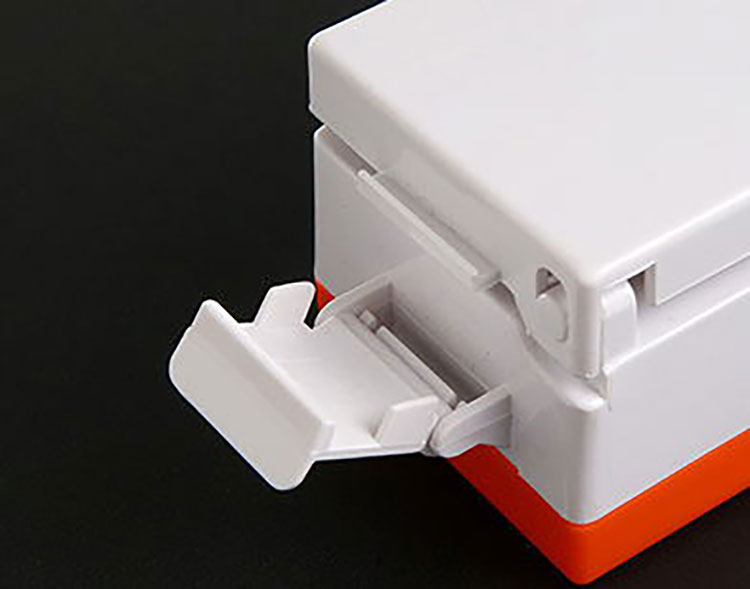

Both sides of the device are designed with sturdy snaps. Airtight to prevent air leaks during your operation.

Sturdy Snap

There are two pairs of air vents on the bottom of the device. Reasonable exhaust and heat dissipation design can effectively reduce the temperature inside the equipment, thereby prolonging the operating life of the motor.

Air Vents

The inside of the device is provided with a high-density EVA sealing strip. Ensure airtightness, help the vacuum chamber to achieve a fully closed environment, and achieve a vacuum of -0.4 BAP.

Sealing Strip

There is a high-quality heating wire inside the device. The heating wire matched with the fuselage is 29cm long, and the sealing width reaches 1.5cm, which makes the sealing more firm.

Heating Wire

The exterior of the device is made of high-quality ABS material. The use of high-quality ABS material can prevent riots and falls, not fading and not scratching.

ABS Material

The bottom is provided with a vacuum outlet valve. After the food is sealed, if the sealing machine cannot be opened, you should lift the air release valve.

Vacuum Outlet Valve

There are 5 parts of the commercial food vacuum packaging machine:

Whole steel structure: The shell of food vacuum packaging machine is usually made of stainless steel or carbon steel.

Stainless steel material is not easy to corrode and rust, and it can be used for a long time. It is more suitable for a relatively humid working environment; the vacuum chamber is made of glass.

Stainless Steel Shell

Vacuum pump: The vacuum pump is the main component of the food vacuum packaging machine, and it is the heart of the food vacuum packaging machine. Generally, the bigger the vacuum pump is and better the food vacuum packaging machine will be, and of course the more expensive it is.

Therefore, considering the cost-effectiveness factor, the configuration of the vacuum pump is configured according to the size of the vacuum chamber.

Vacuum Pump

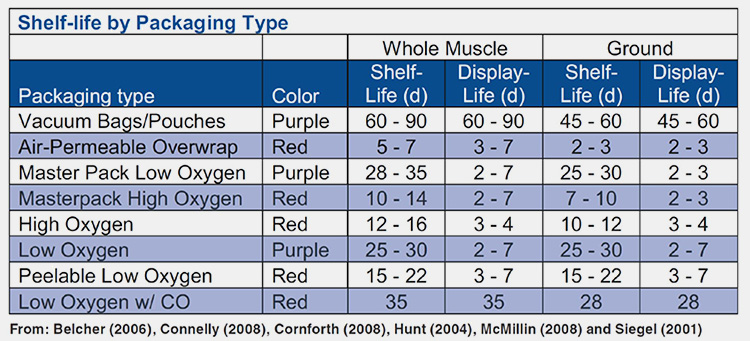

Electronic components: The electronic components of general food vacuum packaging machines are mainly composed of solenoid valves, frequency converters, relays and computer control panels.

Sealing Ring

Wearing parts: The main wearing parts of the food vacuum packaging machine include heating strips, insulation cloth, etc. Usually these wearing parts need to be replaced regularly.

Sealing ring: The vacuum chamber is equipped with upper and lower sealing rings. If the machine doesn’t have seals, then the vacuum can’t be finished.

11. What Should You Consider Before Buying a Food Vacuum Packaging Machine?

Food Vacuum Packaging Machines are divided into commercial and household use. You can judge from the following differences: machine size, price, power, energy consumption, vacuum weight, vacuum times, efficiency, etc.

If you need a common household small food vacuum packaging machine, then the price does not need to be expensive. But you’ll need to choose a textured bag so you can vacuum it. You can easily buy it online, TV shopping and offline or contact us.

Size

If you need a commercial food vacuum packaging machine, the price is generally higher. And the vacuum bag for packaging needs to be thicker, but does not need a textured bag.

Packaging Bags Without Texture

And you need to consider the following principles:

Packing speed: In order to improve production efficiency, a double-chamber or multi-chamber vacuum packaging machine can be selected to improve the progress of the entire production.

Whether the packaged items need to be filled with other protective gases: Optional multifunctional vacuum packaging machine with inflation device. For example, potato chips need to be filled with nitrogen during vacuum packaging to maintain good freshness and taste.

Nitrogen-filled Vacuum Packaging Snacks

Requirements for the vacuum degree of the packaged items: If the packaged items need to be well preserved under the condition of high vacuum degree, you need to choose a Chamber Vacuum Packaging Machine.

Chamber Vacuum Packaging Machine

The requirements of the state of the components of the packaged items for the vacuum packaging machine. Such as solids, granules, cooked food, liquids, etc.

When you are buying food vacuum packaging machine, when packing solids, granules and other dry and non-corrosive materials, you should choose a vacuum packaging machine made of aluminum alloy.

When packaging with soup, materials with high salt and acid content, you should choose a vacuum packaging machine made of stainless steel or aluminum-magnesium alloy.

Milk Vacuum Packaging

The sealing ring of a food vacuum packaging machine is generally made of silicone rubber or black rubber. A few low-grade products use foam rubber. Silicone rubber has high-temperature resistance, corrosion resistance, good sealing performance, and long service life, while foam rubber has poor sealing performance, is easy to fall off and short service life.

Silicone Rubber

12. Why Does the Vacuum Packaging Machine Leak Air During Packaging?

Air Leaking of Bad Sealed Packaging Bag

There are many reasons why the vacuum packaging machine cannot be vacuumed cleanly. The main reasons are: the vacuuming time is too short. The vacuum pump is aging or not properly maintained.

The vacuum studio is not well sealed, and there is air leakage when vacuuming. The power of the vacuum pump is too small and the actual pumping speed ratio does not match, and the vacuum cannot be fully pumped.

The solution is as follows:

You should prolong the vacuuming time.

You should replace the vacuum pump, and pay attention to maintaining and replacing the vacuum pump oil timely.

If the vacuum pump has not been maintained for a long time, you should first clean up the waste oil in the vacuum pump before replacing it.

(Generally, the first maintenance is after the vacuum packaging machine has been working continuously for 300 hours.

After that, the maintenance will be carried out after the vacuum packaging machine has been working continuously for 500 hours.)

Proper Operation

You should check the vacuum chamber for leaks. If there is an air leak, you must replace the sealing strip in time.

If the vacuum pump is too small to achieve the desired vacuum effect, you need to replace it with a higher-power vacuum pump.

After the mechanical equipment is bought and used for a period of time, you must pay attention to its maintenance.

Just like a car, it needs regular maintenance. If maintenance is not in place, no matter how good the equipment is, it cannot be used for a long time.

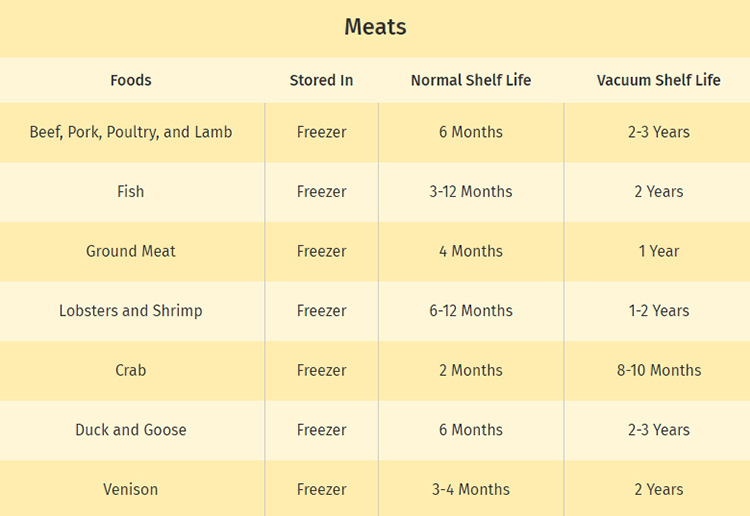

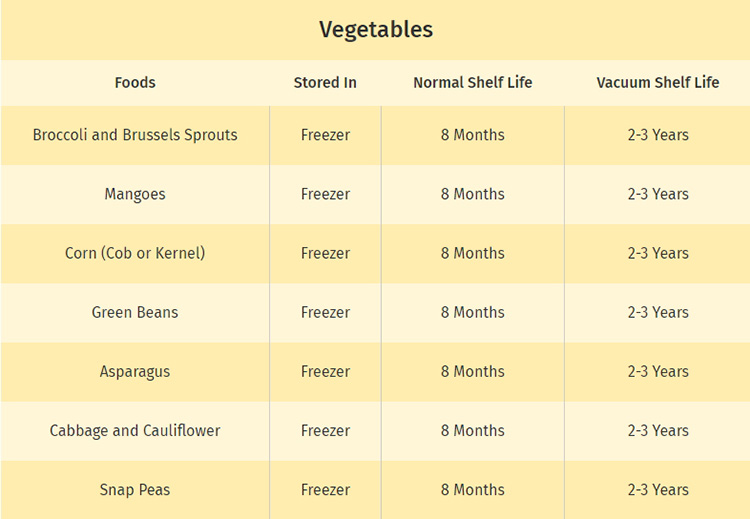

13. How Long Can Vacuum-packed Food Generally be Stored?

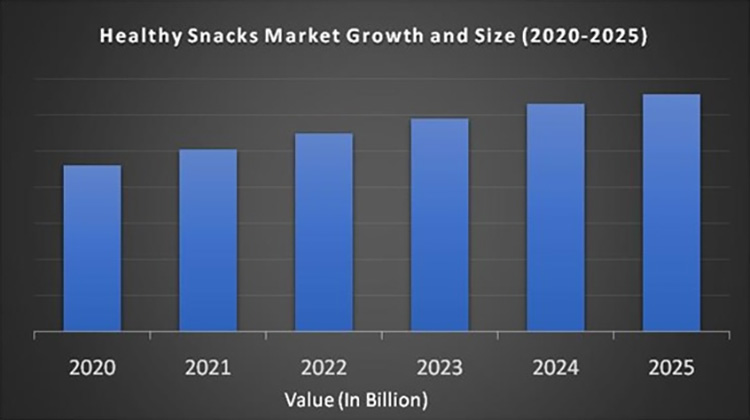

Vacuum-packed food can generally be stored for about 1 to 12 months. The storage time varies depending on factors such as the type of food and the processing before packaging.

Different types of food after vacuum packaging have different storage times at room temperature.

In general, fresh agricultural products or lightly processed meat products can be kept at room temperature for 2 days. But after vacuum packaging, it can be extended to 6 days, and some can be extended to 18 days.

Vacuum Packed Fresh Agricultural

Dried fruit vacuum-packed food can be stored for a long time, even more than twelve months.

Storage Time Table

Storage Time Table

Cooked vacuum-packed food will keep for a shorter period of time. Typically, it stays fresh for around 15 days in winter and spring. And in summer and fall, it will only keep for about 4 days to about a week, but preferably needs to be refrigerated.

14. How to Vacuum Pack Food With Liquid?

At present, the most common vacuum packaging of pure liquids on the market is Tetra Fino Aseptic, which is what we see as boxed milk. This is the vacuum packaging of pure liquids.

Tetra Fino Aseptic

When the food with soup is vacuum packed, you can choose a liquid vacuum packing machine. This machine is provided with a groove. This allows the liquid to sink without spilling during vacuum packaging.

There is a double-chamber concave liquid vacuum packaging machine and a rolling vacuum packaging machine. By adjusting the angle of the machine, a certain angle of inclination can be created to prevent the soup from spilling.

15. Can You Eat the Leaking Vacuum-packed Food?

You would better not eat food that is leaking air.

It is best for you not to eat food that leaks air, because the vacuum packaging is for the purpose of preventing air from entering, preventing oxidation, and preventing corrosion.

If the vacuum packaging leaks, it proves that the air enters, so the items may deteriorate.

Inflatable packaging is generally filled with nitrogen and carbon dioxide, which can protect fragile food and prevent corrosion.

Once air leaks, the food will be oxidized with the air, and it is likely to deteriorate.

If the air leaks for a long time, it is impossible to judge whether the food is edible or not. It is likely to cause symptoms of abdominal pain, bloating, and diarrhea.

Similarly, food that has no air leakage but has expired is also inedible.

16. What Should You Do When Choosing Food Vacuum Packaging Bags?

Food Vacuum Packaging Bags

The outer packaging of food vacuum packaging bags needs to be marked with text. Label the factory name, factory address, and product name. And the words “for food” should be clearly marked.

Products are accompanied by a product inspection certificate after leaving the factory. This food vacuum packaging bag is relatively safe.

Colored vacuum bags (dark red or black, etc. currently on the market) cannot be used for food packaging. Because these vacuum bags are often made of recycled plastic.

Food Vacuum Packaging Bags

Food vacuum packaging bags are odorless when they leave the factory. Vacuum bags with special odors cannot be used as food vacuum bags.

Try to use food vacuum packaging bags that are not coated or plated.

In the current packaging design, in order to make the packaging bag more beautiful and corrosion-resistant, many manufacturers have used a large number of materials with coating.

This not only brings difficulties to the recovery and reuse of materials after the products are scrapped. And most of the coating material itself is toxic, if you use these food packaging bags, it will bring great harm to your health.

Coated Food Vacuum Packaging Bags

After knowing all this knowledge about Food Vacuum Packaging Machines, how do you feel about it? I feel it is a kind of amazing machine in daily life.

Conclusion

Food Vacuum Packaging Machines can bring great convenience to your life. Whether it is put into production in daily life or in business, it is very promising. Why not have a try of this kind of machine? If you have anything else that you don’t understand, you are welcome to consult.

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Double Chambers Vacuum Packaging Machine

Double Chambers Vacuum Packaging Machine

Storage Time Table

Storage Time Table