Vacuum Packaging VS Nitrogen Packaging

In nowadays, vacuum packaging and nitrogen packaging plays a vital role in packaging industries and they are the mainstream packaging methods now. Here you will learn about their similarities and differences in some ways. Let’s figure it out together!

1.What Is Vacuum Packaging and Nitrogen Packaging?

Have you ever noticed any vacuum-packaged product or nitrogen-packaged product in your daily life?

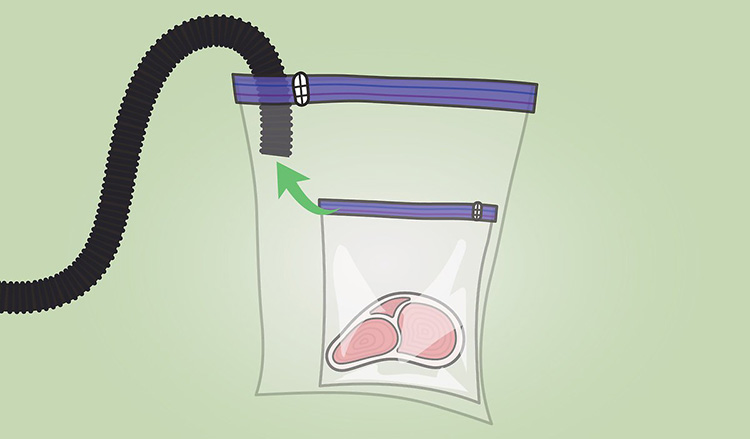

Vacuum packaging also called decompression packaging. By extracting all the air in the packaging container and sealing it, the bag is kept in a highly decompressed state. This method is called vacuum packaging. By maintaining low levels of oxygen inside the packaging, there is no chance for microorganisms to survive. This keeps food fresh and resistant to spoilage.

Nitrogen packaging pumps out all the air in the packaging container to make the air in the packaging bag reach a predetermined vacuum degree, and then fills it with nitrogen, carbon dioxide, oxygen, ethylene and other gases. Finally, the sealing process is completed. Nitrogen packaging can well make up for the packaging of some fragile items that cannot be vacuum-packed, such as puffed food.

2.In What Industries Are Vacuum Packaging and Nitrogen Packaging Mostly Applied?

Vacuum packaging and nitrogen packaging are mostly applied in food industry, pharmaceutical industry, chemical industry. In different industry, the application of them are different.

Food Industry

Vacuum packaging and nitrogen packaging are mostly applied in food industry.

Vacuum packaging is often used to package pickled products, such as sausage, ham, bacon, salted duck, etc., pickled vegetable products, such as pickled mustard, dried radish, kohlrabi, kimchi, etc., soy products, such as dried tofu, vegetarian chicken, red bean paste, etc.

Nitrogen packaging is often used to package puffed, fragile and squeezed foods, such as potato chips and biscuits. When the packaging bag is filled with inert gas, it can also keep the food crisp and fresh without any harm to the body.

Pharmaceutical Industry

Vacuum packaging uses special pharmaceutical vacuum bags to package drugs. Some special medicines, or tools such as surgical forceps that need to be used during the operation, will be sterilized and vacuum-packed to ensure the sterility of the equipment.

Nitrogen packaging is used in pharmaceutical packaging, pharmaceutical replacement gas, pharmaceutical nitrogen-filled packaging, transportation, and Chinese herbal medicine moth prevention, anti-corrosion protection, scientific research and medical deep low temperature and cryotherapy, etc.

Chemical Industry

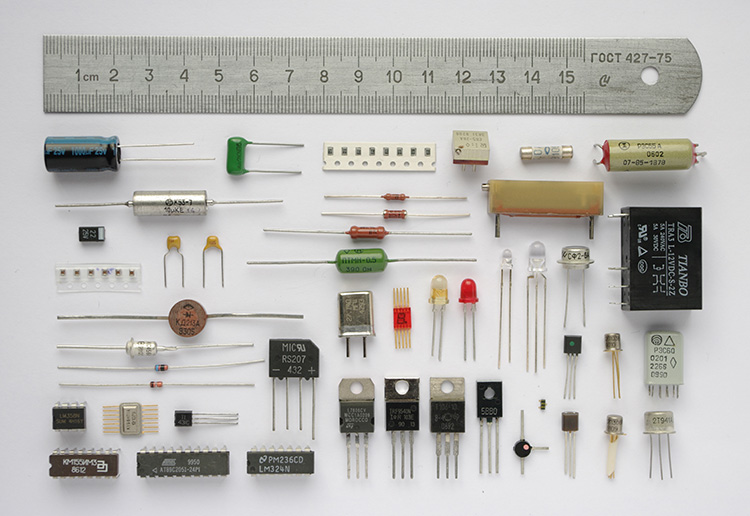

Vacuum packaging and nitrogen packaging can also be applied in chemical industry. Vacuum packaging can be applied in sealing the solid and semi-solid chemicals and chemical reagents. Nitrogen packaging is often used to encapsulate electronic components and contact lenses, etc.

In different industries and fields, both vacuum packaging and nitrogen packaging have different uses. But their biggest use is still in the food industry.

3.What Are The Packaging Principles For Vacuum Packaging and Nitrogen Packaging?

The vacuum packaging and the nitrogen packaging are the same working principle in the first step which is taking out the oxygen from the packaging bags and containers. Then the second step of the vacuum packaging is sealing the bag or the container. And the second step for the nitrogen packaging is to inject inert gases like nitrogen or carbon dioxide, etc.

Packaging Principles For Vacuum Packaging

The principle of vacuum packaging is to extract all the air in the package, and cooperate with the packaging material with extremely low oxygen transmission rate, so that the outside oxygen cannot penetrate into the inside. Reduce the rate of oxidation and rancidity of food to ensure the freshness of food.

Vacuum-packed food can be stored for about 14 to 20 days at 0±1°C. The shelf life of vacuum packaging itself is about 5 to 7 days longer than that of pallet packaging.

However, vacuum packaging cannot inhibit the growth of anaerobic bacteria and the deterioration and discoloration of food caused by enzyme reactions. Therefore, food preservation also needs to be combined with other auxiliary methods, such as refrigeration, quick freezing, dehydration, high temperature sterilization, radiation sterilization, microwave sterilization, etc.

Packaging Principles For Nitrogen Packaging

The working principle of Nitrogen packaging includes the process of vacuum packaging, that is, the food is packed into the bag, and then the air in the bag is extracted. When the food bag reaches the predetermined vacuum degree, nitrogen, carbon dioxide, and other gases are filled in the packaging bag, and then the sealing process is completed.

The working principle of Nitrogen packaging is relatively simple, that is, the oxygen that microorganisms depend on for survival is taken out, which makes the growth and reproduction speed of microorganisms drop sharply.

Some people may confuse vacuum packaging with nitrogen packaging. In fact, nitrogen packaging includes the part of vacuum packaging, but nitrogen packaging has one more part that injects other inert gases than vacuum packaging. Nitrogen packaging procedures are a little more complicated than vacuum packaging procedures.

4.Why Food Need To Be Vacuumed Packaged Or Nitrogen Packaged?

Have you noticed that why most of the raw meat in the supermarket are in vacuum-packaged but some are not. That is because the vacuum-packaged meat is suitable for you to place in the refrigerator for your convenience after purchase. Other meats that are not vacuum-preserved are for you to eat fresh.

Benefits For Both Vacuum Packaging and Nitrogen Packaging

Improve Appeal

The nitrogen-filled packaging of the items has a beautiful and generous appearance, and you can directly see the true shape of the items, which is convenient for you to choose.

Keep Fresh

Vacuum nitrogen-filled packaging is suitable for some fried foods or fruit and vegetable chips, which can not only maintain the crispness of the food. At the same time, it can effectively prevent food rancidity or extrusion. This preserves the freshness of the food.

Prolonged Storage Time

Vacuum nitrogen-filled packaging can choose hot-melt packaging materials at will. This kind of packaging material is low in cost, and after being filled with nitrogen, it can prevent the intrusion of external gas and moisture, and can effectively prolong the storage period of food.

Food Safety

The survival of microorganisms is very dependent on the concentration of oxygen. After oxygen is extracted from vacuum packaging and nitrogen-filled packaging, the reproduction of anaerobic bacteria will be inhibited. In an oxygen-depleted environment, anaerobic bacteria can thrive, potentially causing food safety issues. Vacuum packaging and nitrogen-filled packaging can maintain food safety.

Benefits of Vacuum Packaging

Preventing Freezer Burn

Freezer burn can occur when food is frozen without preparation. This happens when the surface of food dehydrates, which results in a dry and tough appearance. Freezer burn can also change the taste and texture of food. Vacuum bags reduce freezer burn by preventing food from being exposed to cold, dry air.

Benefits of Nitrogen Packaging

Anti-extrusion

Vacuum nitrogen-filled packaging is most suitable for packaging of fragile materials that are not easy to squeeze, such as flowers, puffed food, snack food, etc. This just makes up for the shortcomings of vacuum packaging.

By understanding the advantages of vacuum packaging and nitrogen packaging, you can choose the packaging way that suits you most according to your own products.

5.What Are The Differences Between Vacuum Packaging and Nitrogen Packaging?

Vacuum packaging and nitrogen packaging have many similarities but also have many differences. The difference between vacuum packaging and nitrogen packaging is mainly in these aspects, including packaging principles, product appearance, quality check.

Packaging Principles

Vacuum packaging is mainly used to extract all the gas in the product packaging. The main machine is vacuum packaging machine. And it includes various types like single chamber vacuum packaging machine, double chamber vacuum packaging machine, etc.

Nitrogen-filled packaging is mainly to extract all the gas in the product packaging and fill it with other inert gases, including nitrogen, carbon dioxide, etc. The main machine is nitrogen packaging machine. And it includes various types like vacuum nitrogen flushing sealing machine.

Product Appearance

For products that are vacuum-packed, the outer packaging material of the product will collapse, making its own shape appear around the product. The appearance of vacuum-packed products will be distorted, deformed, and may cause the product to lose its physical characteristics.

Nitrogen-filled packaging uses nitrogen or other inert gases instead of oxygen, so that the shape of the outer packaging does not change. It can well maintain the original shape of the product. Therefore, nitrogen-filled packaging is very suitable for packaging fragile products, such as puffed products.

Quality Check

There is no gas in the sealed package of vacuum-packed products, which makes the leak test impossible and needs to be tested manually. Makes quality control difficult.

Nitrogen packaging can continuously monitor the gas content in the packaging during the packaging process of the product. After the sealing of the product is complete, any leaks can be detected to ensure the integrity of the seal.

There may be some way more differences in the vacuum packaging and nitrogen packaging, like cost, packaging materials, packaging rolls, etc. If you want to know more, then you are free to come to us.

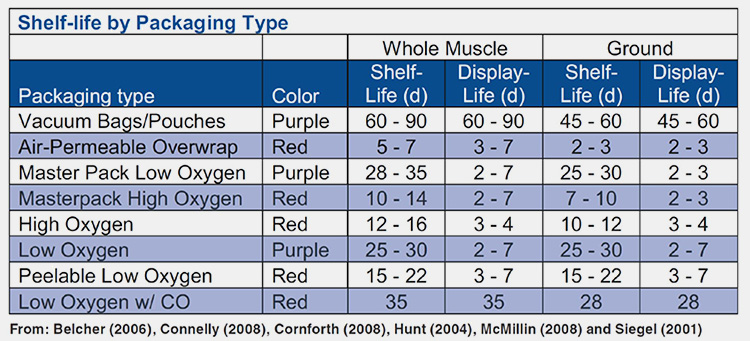

6.What Are The Product Shelf Life By Vacuum Packaging and Nitrogen Packaging?

The shelf life of different products is different. Here we focus on food. Because the shelf life of food is shorter than that of anything else. At the same time, the shelf life of the same kind of food is different when vacuum packaging and nitrogen packaging are used respectively.

Product Shelf Life By Vacuum Packaging

The main function of product vacuum packaging is to remove the oxygen inside the product. This can prevent food from spoiling and also prolong the shelf life of food. The shelf life of different foods is different. Among them, we mainly discuss meat, fruits, vegetables, dry food, powdery food.

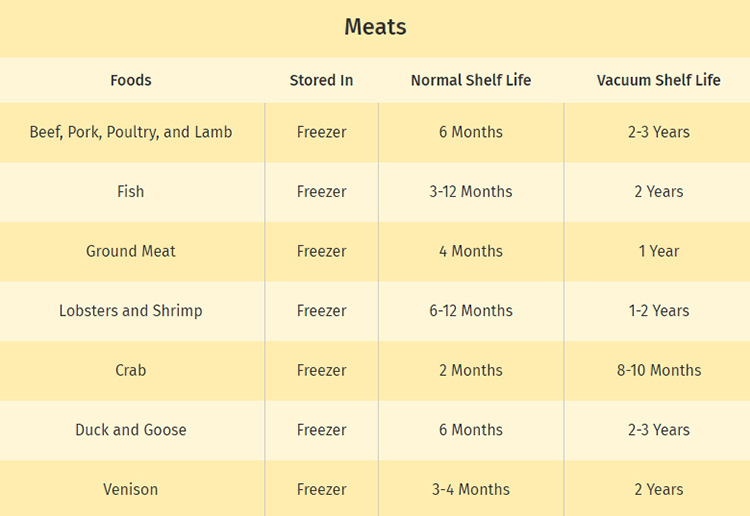

Meat Vacuum Shelf Life

Meat is one of the most commonly vacuum-packed foods. Because meat is very important in your life and meat is very perishable. To keep meat fresh, meat should be vacuum-packed and stored in the refrigerator. This will maximize the freshness of the meat.

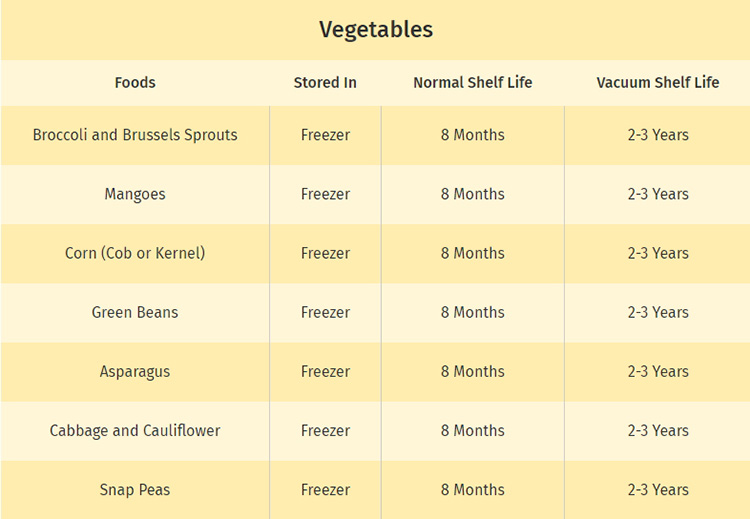

Vegetables Vacuum Shelf Life

Vegetables have a slightly shorter shelf life because they contain too much water inside. And the vegetables will continue to respire in the vacuum packaging, resulting in loose sealing. Therefore, vacuum-packed vegetables should be eaten as soon as possible.

Fruits Vacuum Shelf Life

Fruits have an even shorter vacuum shelf life than vegetables. Because fruits contain more water than vegetables. And if the fruit is left for too long, the water in the body will evaporate, causing the loss of nutrients in the fruit. It will also damage the taste of the fruit. Fruit that has been vacuum-preserved should therefore be consumed as soon as possible.

Dry Food Vacuum Shelf Life

Dry food including rice, beans, nut, etc. have a longer vacuum shelf life. Because this type of food contains less water in the body. And this kind of food is more suitable to be preserved in vacuum.

Powdery Food Vacuum Shelf Life

Vacuum packaging can effectively prevent powdery food from hardening and deterioration due to air absorption during storage. The vacuum shelf life of Powdery food can be extended by 2 to 3 times.

Product Shelf Life By Nitrogen Packaging

Oxygen is a substance that microorganisms depend on for survival. By using nitrogen, like carbon dioxide and other inert gases to replace the oxygen in the packaging bag. This delays the growth and development of microorganisms very well, and prolonged the shelf life of food

The extension of the shelf life of food by Nitrogen packaging is longer for foods with lower moisture content, such as snack foods, coffee, dry goods, etc. For fresh fruits and vegetables with higher moisture content, etc., the extended period of shelf life is shorter. For meat products, the preservation effect of cooked food is far better than that of ready-to-eat meat.

In addition to vacuum packaging and nitrogen packaging, there are other packaging ways. These packaging ways have completely different effects on the shelf life of food. These methods include air-permeable over-wrap, master pack low oxygen, master pack high oxygen, etc. These methods have completely different effects on the shelf life of food.

Different products have different storage and packaging methods. But you can choose the best or most suitable packaging way for your product. However, how to choose the most suitable packaging way according to your product? The following questions are perfect for your deep thinking.

7.How To Choose Vacuum Packaging and Nitrogen Packaging?

How to decide whether you should adopt vacuum packaging or nitrogen packaging according to your products? With this in mind, you need to think about it from several point views of the packaging costs, the packaging materials, packaging machines.

Packaging Costs

During the packaging process of nitrogen packaging, additional inert gas, such as nitrogen, carbon dioxide, oxygen, ethylene, etc., needs to be filled. Some of these noble gases are very expensive to manufacture. Will increase your production costs. Therefore, if you can use vacuum packaging products, try not to choose nitrogen packaging.

Packaging Materials

Especially for fragile snack foods or puffed foods, nitrogen packaging must be used. Because of the use of nitrogen packaging products, the extrusion, breaking and sticking of food can be well avoided. It is more convenient for food storage and transportation. At the same time, it can ensure the crispness of puffed food.

Packaging Machines

If you have many series of products that need to be packaged. Then you need to consider vacuum packaging machine or nitrogen gas flushing machine. Among them, there are many product lines of vacuum packaging machine. There are more options. You can choose whether to consider vacuum packaging or nitrogen packaging from the perspective of the machine.

If you have more want to know you can come to us anytime and welcome to discuss with us.

8.What Products Can Not Be Vacuum Packaged or Nitrogen Packaged?

Though vacuum packaging and nitrogen packaging are goods ways fr packaging different things and products, there are also a lot things that you can not pack with these packaging ways.

Products Can Not Be Vacuum Packaged

Quilt or Clothing

Some quilts or clothes will have a lot of wrinkles after being vacuum-packed. Even if these folds are taken out or re-watered, there is no way to restore them to their original shape. Therefore, such quilts and clothing are not recommended to be vacuum packed.

Sharp Product

Vacuum packaging mainly uses transparent film outer packaging bags to vacuum seal things that need to be vacuumed. Therefore, if the outer surface is very sharp, it is easy to scratch the outer packaging bag. Such items are not suitable for vacuum packaging. For example, among the fruits are durian and so on. Knives, forks and the like are included in the kitchen utensils.

Liquid Supplies

When liquid supplies are vacuum packaged, they need to be completed in a sealed vacuum working chamber or studio. When the liquid in Liquid products is placed in a sealed vacuum working chamber or studio, it is prone to overflow and other phenomena. Therefore, Liquid products are not suitable for vacuum packaging.

Products Can Not Be Nitrogen Packaged

Non-food Product

First of all, most liquid, semi-fluid, solid granular, powdery, pasty foods, fresh fruits, vegetables, rice, flowers, chemicals, precious medicinal materials, valuable calligraphy and paintings, electronic components, etc. are suitable for nitrogen packaging. However, nitrogen packaging is a method with a higher cost than vacuum packaging. Therefore, non-food or low-cost products are not suitable for nitrogen packaging.

When you are choosing related machines for vacuum packaging and nitrogen packaging, you should also pay attention to these points.

Conclusion

When you are applying the vacuum packaging and nitrogen packaging to your business, it will do a great job and bring good prospect to your business. If you have any need or any question about this type packaging ways or packaging machines, you are welcome to come to us anytime, and we will do our best to fulfill your quests.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide