Ideal Vacuum Gas Flushing Packaging Machine

- Microcomputer Control System

- Perfect Pneumatic Sealing Effect

- Fast Pumping Speed

Vacuum Gas Flushing Packaging

Allpack vacuum gas flushing packaging machine is to extract the air inside the containers and then files maintain them into other gases, for the purpose of storing products for a longer time. It is widely used in various types of food, hardware, pharmaceuticals, chemicals, aquatic products, electronic components industries, and various forms of products (solid, liquid, powder, paste) in vacuum-packed. It can prevent the product due to oxidation or spoilage caused by bacterial growth to achieve the extension of product shelf-life and storage time purpose. With the simple structure in linear type, easy to install and maintain. The products after packing can be prevented from oxidation, going mold, insects, or getting damp, thus can be kept fresh for a longer time. This machine can finish the whole program of vacuum extraction, gas flushing (optional), and sealing, it is ideal for industries.

Vacuum Gas Flushing Packaging

DZ-800W Multi-functional Vacuum Gas Flushing Packaging Machine

Allpack DZ-800W multi-functional vacuum gas flushing packaging machine has no vacuum chamber, it can be used not only for sealing, but also for vacuum or inert gas flushing after vacuum. This machine has double nozzles thus it has faster gas flushing speed, which increase its production efficiency. It is more suitable for packing products which has less requirements for vacuum but high requirements for purity of gas flushing. The vacuum gas flushing packaging machine is available for sealing products whose length is 800 or 1000 mm.

Double Nozzle Design

Wide Scope Of Application

Clear&Smart Control Panel

DZQ-60OLD(VS) Vertical Double Nozzle Vacuum Gas Flushing Packaging Machine

The DZQ-60OLD(VS) vertical double nozzle vacuum gas flushing packaging machine is many types of products, especially food products, it is a multifunctional equipment which can be used for both sealing and gas flushing. This double nozzle of this vacuum gas flushing packaging machine let it has a wide application, and the double heating design let the machine be suitable for bags which are made of thick films and compound films. The sealing length of it is customized, there are two options: 800 mm or 1000 mm.

Adjustable Sealing Head Height

Chamber-less Design

Automatic Packaging Procedure

DZQ-60OL(/S) Vertical Double Nozzle Vacuum Gas Flushing Packaging Machine

Allpack DZQ-60OL(/S) vertical double nozzle vacuum gas flushing packaging machine has high requirements for the purity of inserting gas but has low requirements for vacuum index, it can vacuum, seal and insert gas into products, for the purpose to keep them fresh for a longer time. This vacuum gas flushing packaging machine adopts double nozzle and no chamber design, it means that it is suitable for more applications, it is widely used in food & beverage industries, medical industry, hotels, restaurants, farms, etc.

Easy&Safe To Operate

Perfect Packaging Effect

Instant Gas Flushing Operation

The Buyer's Guide

Gas Flush Packaging Machine: The Complete Buying Guide in 2025

Advance level packaging consists on multiple sorts of tasking such as removing extra gases from the packet and after that sealing is made.

For achieving advance level packaging gas flush packaging is a handy tool that can assist you in many ways and you will get highly effective packaging.

To know everything about gas flush packaging machine you need to look into this healthy article that explains all about gas flush packaging machine and its different technical abilities.

1.What is gas flush packaging machine?

Gas flush packaging machine is an efficient packaging and sealing machine that is used for packaging the products through gas flush.

The unique ability of Gas flush involves injecting and removing an inert gas (carbon dioxide, nitrogen, helium etc) repeatedly in order to remove all the oxygen present inside the package.

After that process gas flush packaging machine then seals pack your package to save your products from contamination.

2.Do you know about the different advantages of gas flush packaging machine?

The gas flush packaging machine has been gaining popularity because of its efficiency and versatility. Some of the advantages of the gas flush packaging machine are discussed below.

High Efficiency

The gas flush packaging machine has a very high efficiency. It is capable of removing almost all the oxygen present in the package.

Efficient removal of oxygen or any other unwanted compound present inside the packaging material is very important because if they are not removed efficiently, your product has chances of getting expired or contaminated.

The packaging and sealing efficiency of the gas flush packaging machine is also very high that adds to the value of this machine.

Maintains Quality of Products

In industries such as food and pharmaceutical industry, maintenance of quality of the products in the intended shelf life is very important.

The gas flush packaging machine, through proper flushing and sealing makes sure that there is no unwanted gas present inside the package and no chance of contamination from the outside is present.

In this way, your products remain fresh and in good state of quality in their intended shelf life.

Highly Productive

The gas flush packaging machine is a very productive machine and can do a lot of work on its own in a very short interval of time.

This saves you time and increases your production and sales. In this way, the gas flush packaging machine increases your income.

Easy to Use

The gas flush packaging machine is a very easy to use machine. It does not require any professional training to operate the gas flush packaging machine.

You do not need to spend money to hire any professionals. In this way, the gas flush packaging machine saves your precious money.

Versatile Machine

The gas flush packaging machine is a very versatile device. It finds its application extensively in the food and pharmaceutical industries.

The role of gas flush packaging machine in various industries is discussed later in this article.

Easy Maintenance

The gas flush packaging machine is very easy to maintain. You have to make sure that the machine is cleaned regularly, the old and worn out parts are changed timely and the electrical supply to the machine is proper.

3.What are the different types of gas flush packaging machines?

Gas flush packaging machines come in different shapes and sizes, depending on the type of product being packaged. There are three main types of gas-flush packaging machines:

Heat gas flush sealer

A heat sealer is a different sort of gas flush packaging machine which works mainly through heat to provide efficient sealing.

Working

Heat sealers are used to create a hermetic seal on flexible packaging material. Heat is applied to the plastic, which melts together and forms an airtight seal that prevents oxygen and other contaminants from entering the package. Heat sealers often include adjustable settings so they can be used on a variety of packaging materials.

Advantages:

- The main advantage of using heat sealers is that the process is relatively fast and easy to use.

- It can also provide a strong and reliable seal that prevents air from entering the package.

- Heat sealers are also relatively inexpensive and require minimal setup time.

Disadvantages:

- The main disadvantage of using heat sealers is that they can only be used on flexible packaging materials.

- In addition, heat sealers typically require a pre-made pouch or bag in order to be used effectively.

Components

Heat gas flush sealer is made up of different parts here are some of important ones.

Conveyor system

They are composed of heating elements, a conveyor system to move the packaging material through the machine, and a controller.

Heating element

The heating elements are typically made from a copper wire wrapped around a ceramic core, which is then covered with insulation material.

The conveyor system moves the packaging material through the machine and can be adjusted for different types of packaging materials.

Controller

The controller is responsible for controlling the speed and temperature of the heating element, as well as other machine functions such as pressure, timing, and safety.

Form-fill gas flush packaging machine

In most of the food industries a form fill gas flushing packaging machine is used for variety of products packaging.

This machine uses a filled form of gas in a plastic valve and then the food packet is filled with that gas.

Working

Form-fill seal machines are used to create packages with a combination of gas flushing and vacuum sealing. This is done by filling the product into the package and then sealing it with heat. The machine is then pressurized with the desired gas, such as nitrogen or carbon dioxide, to flush out oxygen and other impurities. Finally, the product is vacuum sealed using a vacuum pump.

Advantages

- Greater efficiency and speed in packaging.

- More precise gas flushing with controlled settings.

- Easy product changeover and versatility.

Disadvantages

- More expensive upfront cost.

- Higher energy consumption.

- Possibility of product contamination from improper sealing and flushing.

Components

Gas flush Nozzle

This nozzle is used to inject the selected gas into the package.

Heat Sealing Bar

Used to seal the package after it has been filled and flushed with gas.

Vacuum Pump

This pump is used to remove air from the package before sealing.

Safety Devices

The machine should be equipped with safety devices such as pressure sensors, temperature regulators, and emergency shutoff switches.

The diverse range of gas flush packaging machines can provide a variety of benefits to producers and consumers, depending on the type of product being packaged.

Vacuum free gas flush packaging machine

A vacuum packaging machine is used for packing products that need to be airtight and oxygen-free.

Working

This type of machine works by using a sealed chamber and a vacuum pump to remove all the air from inside the package.

The product is placed in the chamber, and then gas is injected into the chamber to flush out any oxygen and other impurities. The gas is then evacuated, leaving a vacuum-sealed package with the product inside.

Advantages:

- High-speed and efficient packaging process.

- Minimal product damage from lack of oxygen.

- Can be used for a variety of products.

Disadvantages:

- Higher upfront cost.

- High energy consumption.

- Possible contamination if not properly sealed and flushed.

Components

The main components of a vacuum packaging machine are, pump, fan, gas injector, and control panel.

The chamber

The chamber is an airtight enclosure where the product is placed and sealed.

Pump

It helps to create a vacuum inside the chamber, while the fan helps move air out of the chamber.

Gas injector

The gas injector is used to flush out oxygen and other impurities, while the control panel allows the user to adjust settings such as temperature and pressure.

The components work together to create a reliable and effective vacuum packaging process.

4.Which types of industries or businesses use gas flush packaging machine?

The gas flush packaging machine is widely and extensively used in different industries. Some of these industries are discussed below.

The Food Industry

Gas Flush Packed Food

The gas flush packaging machine finds its most common and wide application in the food industry. The reason behind this lies in the fact that the gas flush packaging machine preserves the quality of food during the intended time period.

As already discussed, the gas flush packaging machine eliminates all the oxygen or any other foreign particle present inside the packaging.

The oxygen present in the atmosphere actually play a significant role in food spoiling. It can do it in various ways such as oxidation reactions and provision of suitable conditions for microbial growth and contamination.

These reactions or processes lead to a very off flavor and a foul order of food. The gas flush packaging machine actually saves the food from all this because of its efficient operation.

Many different kinds of food products such as sea food, poultry items, meat and cheese are packed using the gas flush packaging machine.

The Pharmaceutical Industry

The gas flush packaging machine is also used in the pharmaceutical industry for packaging the drug products that are prone to damage due to atmospheric oxygen, moisture or microbial contamination.

The environmental damage to the drug can reduce its efficacy to such a low level that it fails to achieve minimum effective concentration in the blood. The contaminated drug also has an increased toxicity which can lead to severe side effects.

The gas flush packaging machine saves the drug product from any damage during the intended shelf life. In this way, the efficacy and effectiveness of the drug product is conserved throughout the shelf life.

5.How the gas flush packaging machine works?

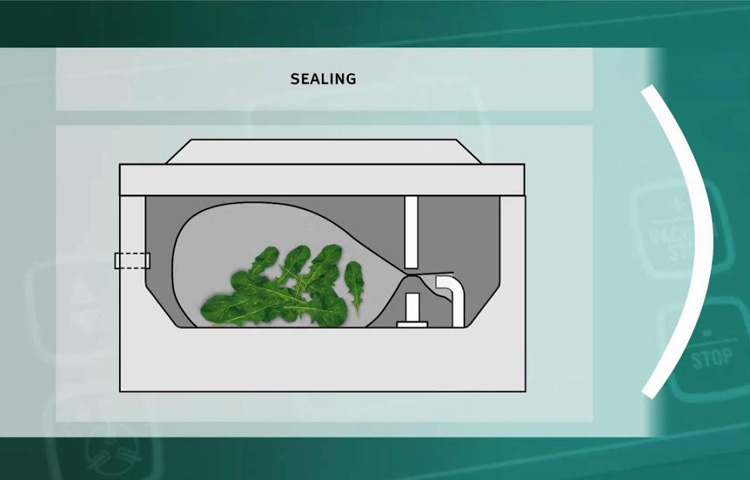

The gas flush packaging machine is a very simple machine and its working is not too complicated. It does an amazing job by following just a few simple steps.

First step in the working of the gas flush packaging machine is flushing off the gases (especially oxygen) present inside the package. For this purpose, of gas such as nitrogen or carbon dioxide is frequently injected in and evacuated out of the package many times.

The density of the gas used for flushing is usually greater than oxygen. This causes the forceful elimination of oxygen from the package. This step reduces the oxygen concentration inside the package to a significantly low level.

The second step involves the vacuum packaging. The gas flush packaging machine creates a vacuum inside the package and then the package is sealed.

Vacuum sealing ensures prolonged quality preservation of the products by reducing the chances of microbial growth.

These two steps briefly explain the working of the gas flush packaging machine.

6.Which kinds of gases are used in gas flush packaging machine?

The working of the gas flush packaging machine greatly depends upon the type of gas you are using for flushing purpose. Choosing the right gas for your intended purpose is a very crucial step. Different types of gases used in the gas flush packaging machine are discussed below.

Nitrogen

Being a non-reactive and an inert gas, nitrogen is used in the gas flush packaging machine for eliminating the air from the package. Oxygen is the main target of nitrogen.

Nitrogen also finds its application as a filler gas for prevention of the collapse that may be caused in the packaging of the products which tends to absorb carbon dioxide.

Nitrogen (100%) is also used for preventing the oxidative rancidity in the packaging of the dry snacks.

Carbon dioxide

Carbon dioxide is the most efficient gas for inhibiting the microbial growth. Therefore, using carbon dioxide for flushing purpose can be very beneficial.

Generally, the greater the concentration of carbon dioxide used, the greater is the preservation of products inside the package. But the level of carbon dioxide must not exceed limit because it can lead to package collapse, tainting of flavor and drip loss.

The lower limit of the concentration must also be considered. For example, minimum concentration of carbon dioxide for controlling the growth of molds and bacteria must be greater than 20%. Any concentration below 20% will not do the job effectively.

Argon

Visual look of Aragon gas

The properties of argon are same as nitrogen. Argon is non-reactive, odorless, tasteless and an inert gas. The molecular weight of argon is greater than that of nitrogen.

Argon can replace nitrogen in the controlled atmosphere in various applications because of its similarity with nitrogen but a greater weight.

The solubility of argon is twice as compared to that of nitrogen. These factors make argon a preferred gas for usage with the plant products.

It is believed that argon inhibits microbial growth, harmful chemical reactions and enzymatic activities.

Oxygen

Surprisingly, oxygen is also sometimes used as a MAP gas. Although oxygen has destructive reactions with food that cause its spoiling but in some cases, oxygen may prove to be beneficial.

For example, oxygen can inhibit microbial growth in some vegetables and fruits. It can also maintain respiration in plant products and freshness in meat.

Carbon Monoxide

Carbon monoxide is harmful, flammable, colorless, odorless and a toxic gas. Carbon monoxide is also used in gas flushing along with carbon dioxide for increased shelf life and preservation of red meat.

The properties of carbon monoxide that make it a worthy candidate for its use in gas flushing include its stability at higher temperature and its ability to inhibit the growth of many harmful bacteria

7.Which factors you should consider while purchasing gas flush packaging machine?

The gas flushing machine can prove to be a great addition to your business but choosing the right machine is a crucial step. Following are some factors that you should consider when buying a gas flushing machine.

Best Quality

While buying a gas flushing machine, always go for the best quality. A good quality machine will give you great efficiency and productivity.

Make sure that the gas flushing machine you are planning to purchase has the approvals of quality compliance such as cGMP, EN and CE.

Compatibility

Compatibility is the second most important factor you should consider while purchasing the gas flushing machine. Make sure that the variant you are going to buy meets the requirement of your business and has the capacity to serve your business well.

Best Price

When choosing the gas flushing machine, keep browsing for the best price. Make sure that you get the right value for your money.

Make sure that you check prices from all the sellers and choose the one who gives you the best price. This will save you from getting overcharged.

Beware of Scam

While purchasing anything online, there are always chances of scam because there are a lot of scammers online.

They receive money from you and send you sub quality products. Always check online reviews before making any transaction. This will save you from getting scammed.

Availability of Mechanics and Spare Parts

Always make sure that you can easily find trained technician or mechanic for repairing the gas flushing machine in your area. Also make sure that the spare parts are easily available so that in future, when you have to change any part, you can easily find it.

8.How gas flush packaging machine is different from other packaging machines?

Gas Flush Packaging Machines are specifically designed to provide a hermetically sealed package that requires a precise amount of gas inside. These machines have a number of features that set them apart from other types of packaging machines. These include:

Features

- Highly precise and adjustable control over time, pressure, and gas flow.

- The ability to adjust the atmosphere inside the package for different products.

- The ability to detect leaks and prevent them with a special sealing agent.

- The ability to accurately measure the amount of gas that is introduced into the package, so that it is not too much or too little.

- The ability to work with various types of gas, including nitrogen and carbon dioxide, for different product requirements.

- The ability to fully vacuum the package before sealing, so that the product is not damaged during transportation or storage.

- A high-precision mechanism that ensures a consistent and reliable seal.

- The capability to quickly adjust the pressure of the gas in order to maintain an optimal atmosphere inside the package.

- The ability to offer a variety of customized solutions, from individual machines to fully automated systems.

These features make gas flush packaging machines an ideal choice for businesses that need to protect their products from environmental conditions during transportation and storage. By providing a precise and consistent seal, these machines offer superior protection and peace of mind.

9.Which gas is suitable to use in a gas flush packaging machine to keep the food fresh?

The best gas to use in a gas flush packaging machine to keep food fresh is carbon dioxide (CO2). Carbon dioxide is an inert, non-toxic gas that helps prevent the growth of bacteria and microorganisms, as well as slowing down spoilage.

Carbon dioxide is also used in modified atmosphere packaging (MAP) systems, where it is combined with other gases like nitrogen or oxygen to create an optimum environment for preserving food. Additionally, CO2 is also used for carbonation and freezing applications.

It has a low vapor pressure, which helps it penetrate deep into the package, thereby creating a tight seal. It is also easy to transport and handle, making it an ideal choice for gas-flushing packaging systems.

Aside from CO2, other gases that can be used for gas flush packaging include nitrogen (N2), oxygen (O2), argon (Ar), and hydrogen (H2). However, these gases may be less effective than CO2 in preserving food quality and shelf life.

Conclusion

In conclusion, the ALLPACK gas flush packaging machine is very useful and effective to help your business grow in a rich manner such as the packaging of food and pharmaceutical products that are prone to damage due to atmospheric gases or moisture. To clear all your confusion and hesitation we are always available for our customers so, if you want any guidance related to your business you can contact us at any time because we are always ready for a chat to clear customers' confusion & help them in any regard during their shopping.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586