Vacuum Powder Transfer System: The Ultimate Guide In 2025

Vacuum Powder Transfer System: The Ultimate Guide In 2025

Are you struggling to deal with powders? Why powder handling is so challenging? When thinking about the traditional way for powder filling methodology; indeed, it was very hard to handle. People might face so many complications. For instance, leakage, dust exposure, inaccurate dosage and so much more. Have ever heard about a vacuum powder transfer system?

This is the right place to explore the basic knowledge related to vacuum powder transfer systems. So, readers, I am sure that this article would be worth reading as it will help you in deciding the right machine and the basic points you must know when going to purchase the vacuum powder transfer system. Have a look at the below discussion.

1.What is a vacuum powder transfer system?

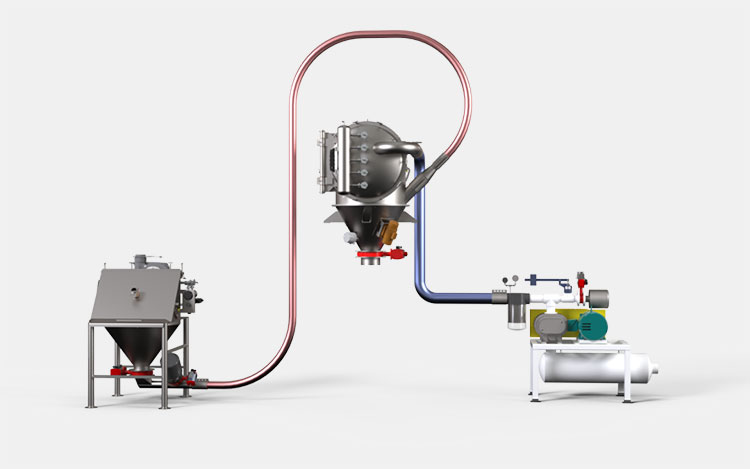

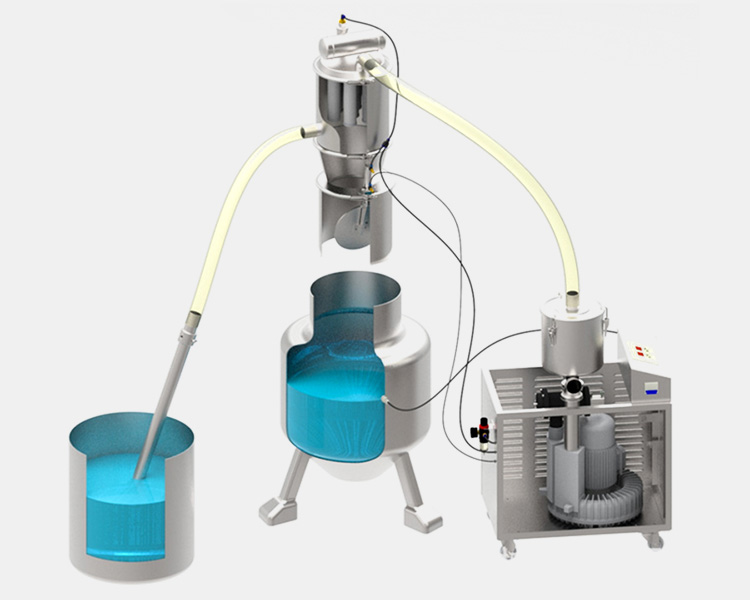

Vacuum powder transfer system- Picture Courtesy: HAF Equipment

A vacuum powder transfer system is an advanced solution offering you an enclosed framework for transporting powders from one point to another by utilization of vacuum suction criteria.

The machine is capable of rapid, accurate, and safe movement of your materials via circulatory pipes which is helpful in the integration of various units used in the process. Due to its simple framework with efficient output, it is therefore considered as a paramount tool in various production and packaging industries worldwide.

2.Why is there a need for a vacuum powder transfer system?

The vacuum powder transfer system is a promising machine required in manufacturing and packaging world due to certain described reasons:

Fast Mode of Transfer

Fast working- picture courtesy: Ganson

In the conventional practice, the powder transfer task was not only challenging but also confronting many hurdles that were making your time utilization and implementation of more labor. There’s always a need for such system that can help you with the fast transfer of powder with content and user safety. The machine is capable of accelerating processes with high speed and minimum human involvement.

As this process is hooked to more mechanical operation therefore you will face fewer problems as well as product loss.

Extremely Safe and Hygienic

Safe powder packaging- Picture Courtesy: Made Safe

When you belong to the manufacturing industry, along with producing a safe and hygienic product, you need to take care of your operators as well.

This is your prime responsibility and when you are installing a vacuum powder transfer system in your facility, it offers you containment especially when it comes to subjecting toxic, harsh, or volatile substances.

The machine is ideal and is designed with an enclosed structure that ensures reduced risk of material blowing, dust expulsion, and reduced dust suspension; so, it is keeping your environment and product safe.

Diverse Materials Handling

Vacuum Powder Transfer System- Picture Courtesy: T.H.E.M

The vacuum powder transfer system is capable of dealing with broad spectrum materials handling that range from free flowing to non-free flowing, granules, pellets, etc in a flexible way. Moreover, it is a promising unit that can pick up the material from multiple pick-up points without need for any extra resources. This is very beneficial to install when your production is based on picking up material from different locations.

Less Footprint

Less footprint- Picture Courtesy: CSIRO

When it comes to managing your space, the vacuum powder transfer system is absolutely an amazing solution as it is designed with a compact structure especially when you are addressing the filter receiver.

Moreover, it can allow you to integrate the machine with another system easily to facilitate work without requiring large spaces, as it is capable of accommodating other units in such a way as to manage the powder transfer without any obstacles.

Less wear and tear

Less wear tear- Picture Courtesy: NANJING SUNDGE

The vacuum powder transfer system often shows lesser wear and tear because machine velocity is ideal for carrying materials from one place to another in a subtle way. While it is easier to clean and requires lower maintenance. Therefore, the machine is generally considered as a useful option with an extended shelf life.

Energy efficient

Energy Efficient

This machine mainly focuses on the utilization of vacuum with the potentially higher outcome with the requirement for energy. Therefore, it is considered as a more energy-efficient equipment in your facility that can work in an optimized manner.

Easy to install

Flexible installation

The machine may look complex to you, but it gives an easy installation due to its modular structure. The machine is composed of the specific number of components making less intrusive installation process and test operation.

Gentle Handling

Gentle handling of ingredients- Picture Courtesy: News- Medical

Whether your material is fragile, free flowing, non- free flowing, abrasive, heat sensitive, or moisture sensitive, when it comes to dealing with a vacuum powder transfer system, it promises you that material integrity will be stable throughout the procedure.

3.What industry requires vacuum powder transfer system?

There are some special advantages of vacuum powder transfer systems- quick and dust-free powder transfer- due to which it is a go-to transferring system in industries. It is an incredible system immensely popular in various manufacturing sectors. Some fundamental industries that require this system include:

Pharmaceutical Industry

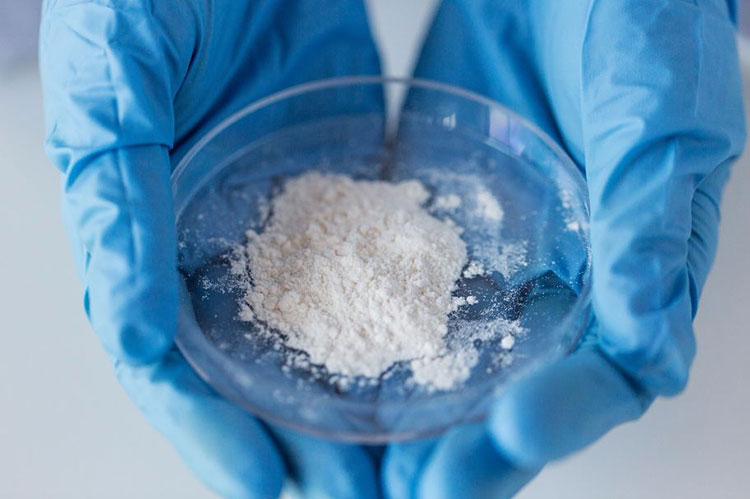

Pharmaceutical Powder

It is one of the most significant industries that require sterile processing, as otherwise, it causes severe problems of contamination in the formulation of medication, leading to serious health risks. Therefore, the vacuum powder transfer system is a major hit in this industry due to its transference of powders in a controlled sterile environment.

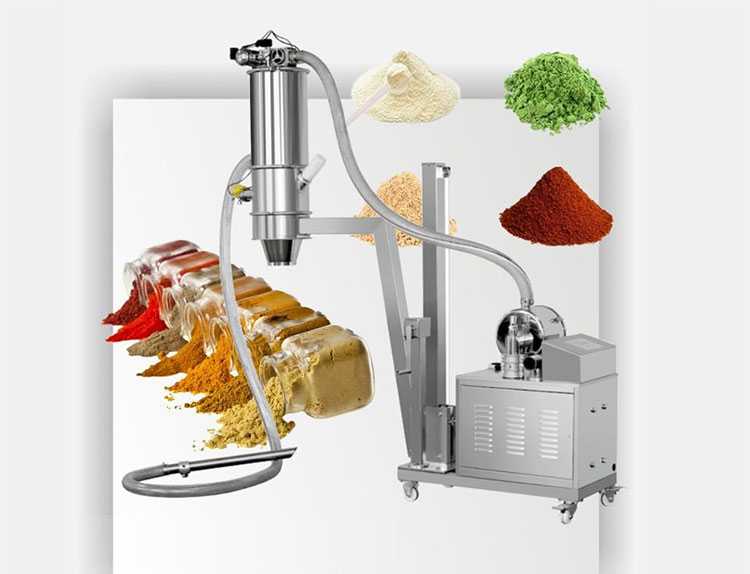

Food and Beverage Industry

Food Powder

The vacuum powder transfer system is extensively utilized in the food and beverage sector because it maintains hygienic quality standards and reduces dust production, keeping food and beverage powders- for instance, flour, sugar, salt, herbs, spices, and food flavoring- safe and pure for consumption.

Chemical Industry

Detergent Powder

This industry often processes and handles hazardous chemical powders and their exposure to working personnel could lead to health hazards. Hence, for safety and product integrity, the vacuum powder transfer system is utilized in the chemical industry for the transportation of different pigments, resins, detergents, acidic and basic salts, etc.

Cosmetic Industry

Cosmetic industry- Picture Courtesy: NCCS

Cosmetic and personal care powders require gentle handing that is accomplished with the vacuum powder transfer system. It delicately conveys cosmetic materials such as talcum, face powders, eye shades, makeup, and skincare powders. It is pivotal in maintaining the quality of cosmetic powders.

Additive Manufacturing Industry

Additive Powders- Picture Courtesy: SAM Sputter Targets

One of the significant contributions of the vacuum powder transfer system is in the additive manufacturing industry. It has a role in conveying metal, polymer, resins, additives, and other fillers powders and ensures accurate material feed for superior quality 3D printing,

Agriculture Industry

Agriculture Powders- Picture Courtesy: Gardening Mentor

It plays a vital part in the transference of different kinds of agricultural powders, like fertilizers, herbicides, pesticides, animal feed, and other agrochemicals. It is increasingly seen in the agriculture industry because of its clean and smooth handling of agricultural powders

Battery Manufacturing Industry

Battery Powder- Picture Courtesy: AZoM

The vacuum powder transfer system is an important part of the battery manufacturing industry because it transfers different metal powders, for example, lithium, cobalt, iron, and others for clean and efficient production of high-quality batteries.

Paint Industry

Paint Powder

This machine is utilized in the paint and coating industry for conveying various types of powdered pigments, dyes, tints, primers, sealers, varnishes, stains, etc to maintain uniform batch quality.

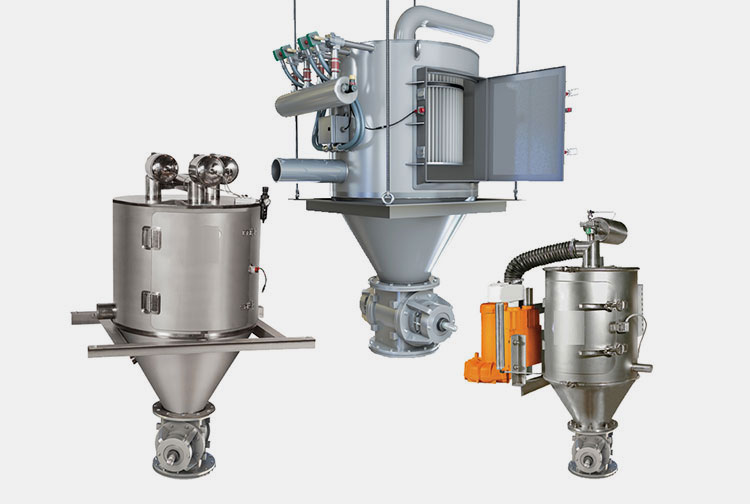

4.What are the types of vacuum powder transfer system?

Based on the powder characteristics, there are the two basic types of vacuum powder transfer system:

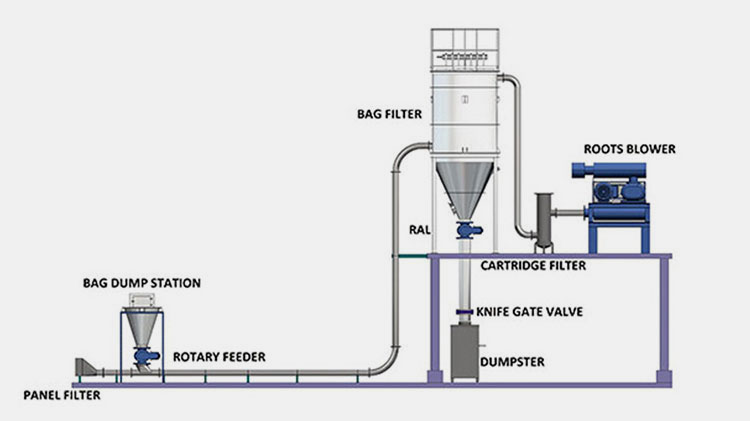

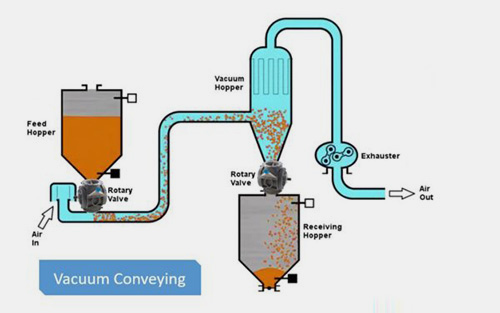

Dilute or Lean Phase Vacuum Powder Transfer System

Dilute or Lean Phase Vacuum Powder Transfer System- Picture Courtesy: REICO

The dilute or lean phase vacuum powder transfer system is used for those materials that require lesser pressure and high airflow speed to transfer them from one place to another place. Due to high velocities and a significant amount of force for the movement of powders, this is known as dilute phase.

The machine is capable to produce a high air velocity with a confined pressure that can leads to produce greater fluidisation of the product.

This kind of system is very useful in such industries where long-distance material is used to transfer, for example, medicines, agricultures, foods, or plastic or ceramic, etc. Also, this phase is mainly helpful when you have to subject material those are toxic in nature.

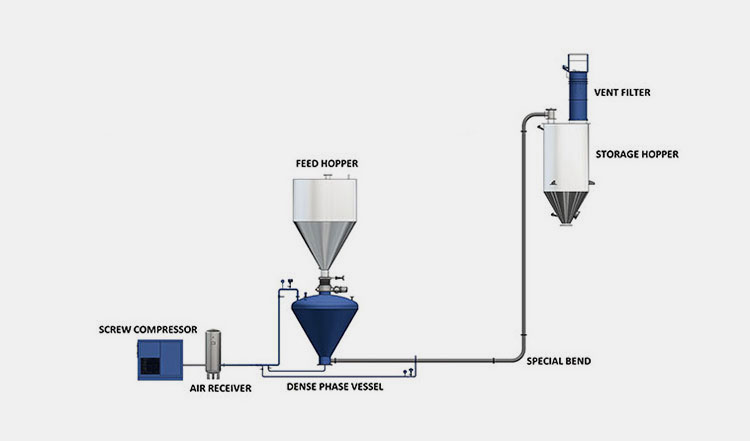

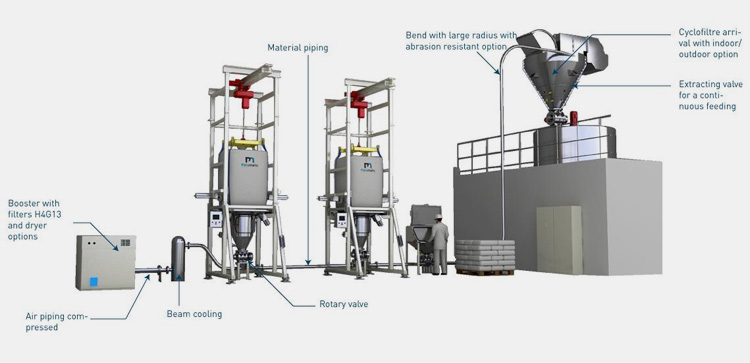

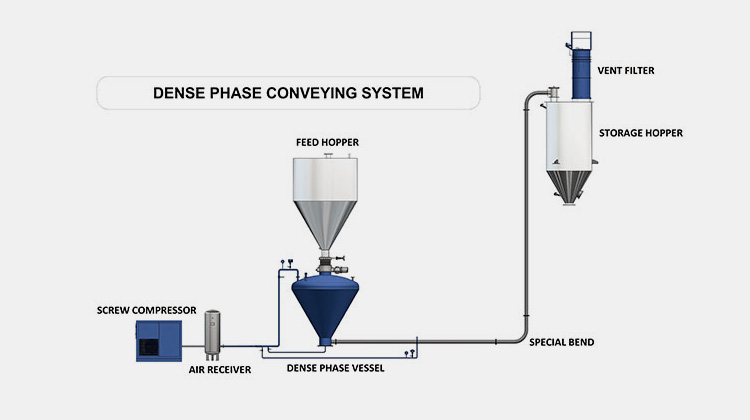

Dense Phase Vacuum Powder Transfer System

Dense Phase Vacuum Powder Transfer System- Picture Courtesy: REICO

This is kind of equipment following opposite working criteria than dilute phase vacuum powder transfer system. It utilises lesser speed and high pressure for materials transfer. The primary objective behind this concept is to deal products with fragile characteristics and can reduce the chances of wear tear of the circulatory system of the vacuum network especially when it comes to subjecting the abrasive materials.

When it comes to talking about pressure, it is composed of specified compressors that ensuring work under compressed air inside the network ranges from 1 bar g to more.

The benefit of this system is that it cannot results in piling up of the product inside the network, thus, giving you the safest working output.

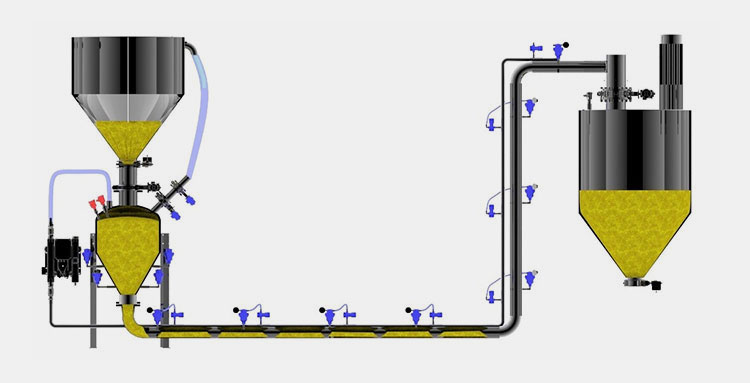

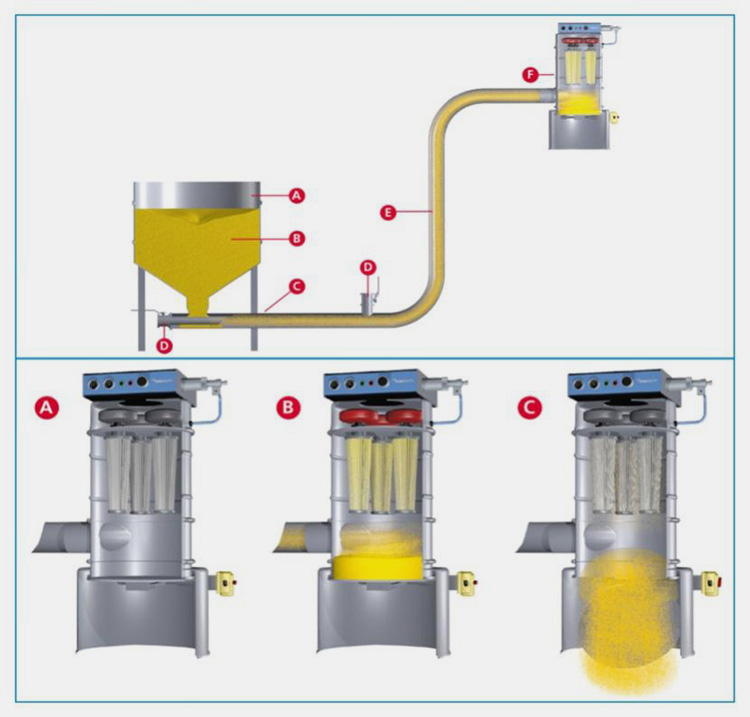

5.What is the operating principle of a vacuum powder transfer system? How does it work?

The vacuum powder transfer system is processes when it sucks materials with air elimination from the suction pipe. The atmospheric pressure forces the substances through the suction pipe. It is atmospheric pressure that is responsible for transferring the powders.

It uses the principle of negative pressure and airspeed to transfer powders through the pipeline network. Look at the working steps one by one below:

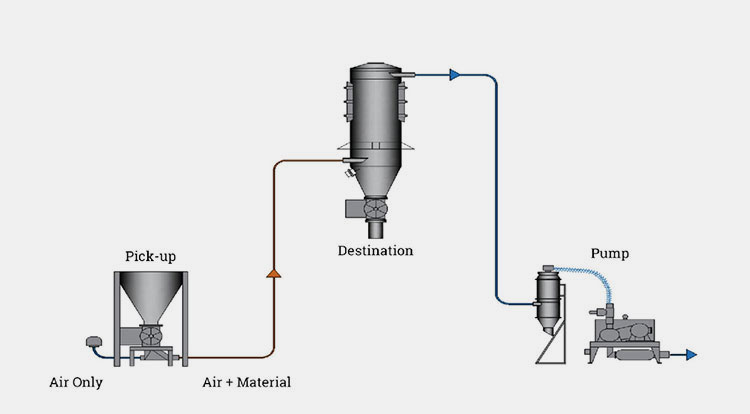

Principle of Vacuum Powder Transfer System- Picture Courtesy: Lutena Vakuum

Loading of Material

Loading of Material- Picture Courtesy: VOLKMANN GmbH

First, the powders are fed into a feed station. These stations are the material pick-up locations, consisting of hoppers, process machines, bins, bags, and other containers.

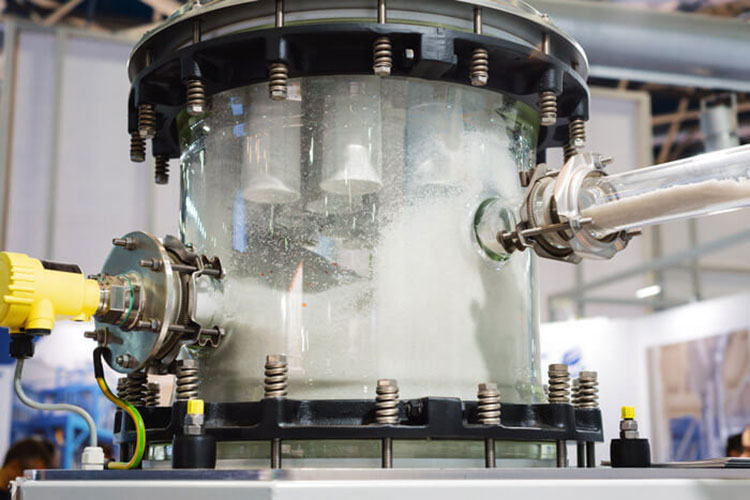

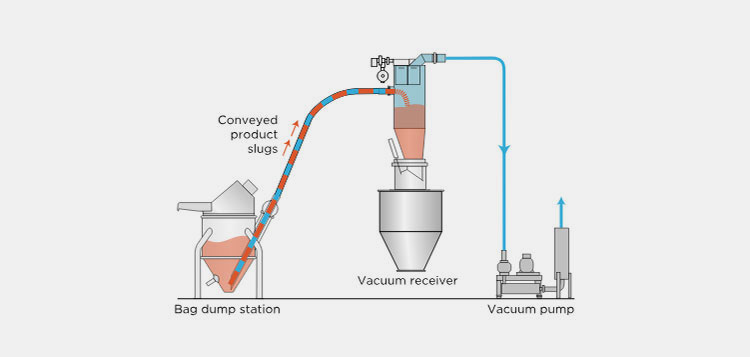

Vacuum Generation

Vacuum Generation- Picture Courtesy: BulkInside

The vacuum powder transfer system uses a vacuum pump or blower to generate the vacuum (low-pressure environment) in the transfer line or separator body. Air enters from the feeding point via a hose. This air draws powders together with it.

Powder Conveying

Powder Conveying- Picture Courtesy: Solberg Manufacturing

Because of the unique construction of the separator body, air velocity is decreased, and powders are held above the discharge valve of the vacuum conveyor. A filter unit is responsible for filtering airborne dust and powders from the transferring air inside the separator body.

Powder Discharge

Powder Discharge- Picture Courtesy: Join

As soon as the separator is completely loaded with the product, the vacuum pump is turned off then the air pressure in the vacuum powder transfer system equalizes with the surrounding environment within a few seconds.

Then the separated product is unloaded from the system via the discharge valve and dropped down directly into the destination location. After the discharge of the product, the filter units are automatically cleaned using an air shock system, and discharge valves are closed to start the whole powder transferring cycle again.

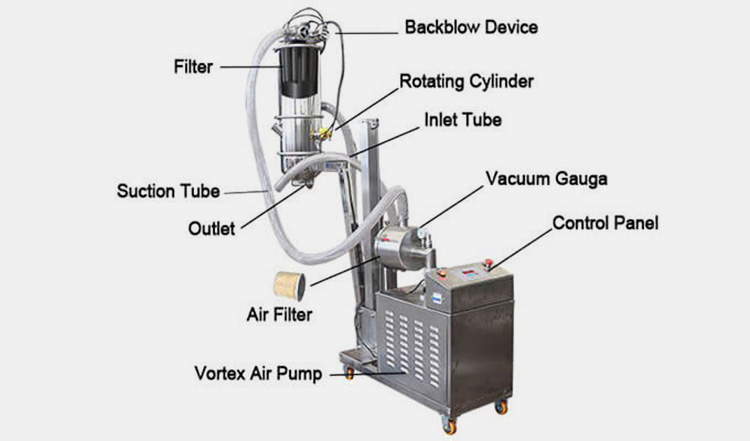

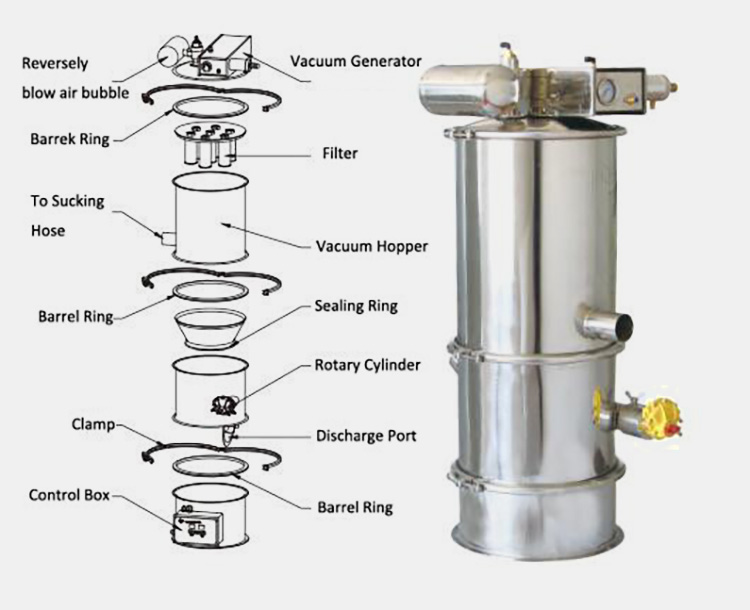

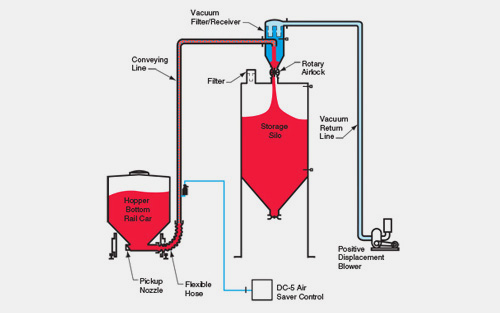

6.What are the components of vacuum powder transfer systems?

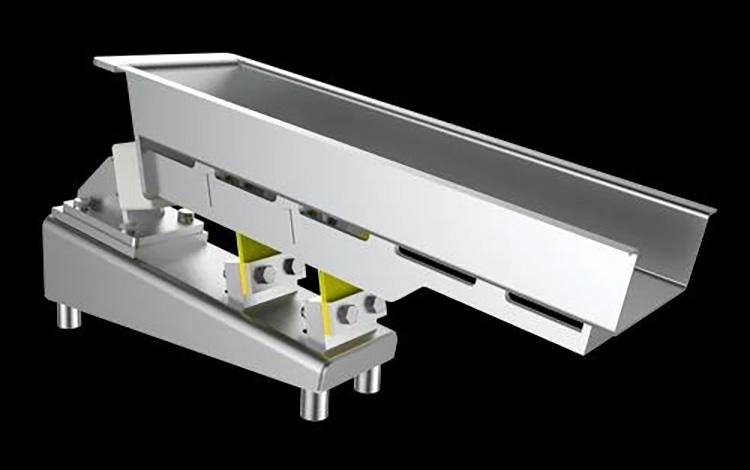

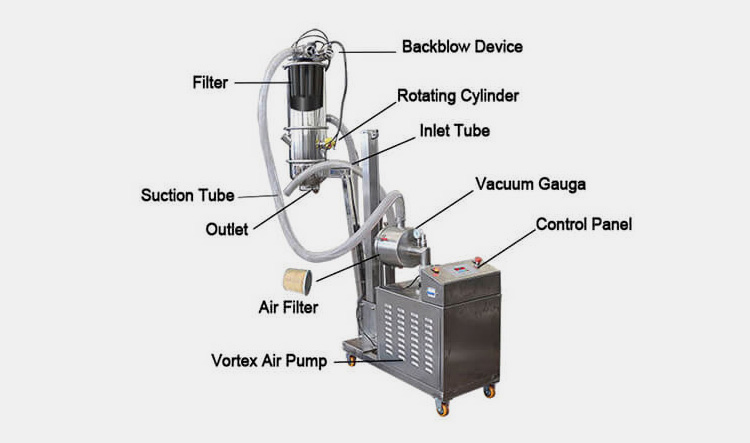

The vacuum powder transfer system is a simple unit with the composition of various parts. We have illustrated a figure for your understanding with specific functions. Have a look at below discussion.

The parts of vacuum powder transfer system- Picture Courtesy: pneumatic conveyor

Pick Up or a Loading Unit

The pickup point which is also known as the suction point which is responsible for picking up of the materials toward destination by the help of the negative pressure.

The purpose of sucking out the air is to provide a complete evacuation particles in this section. Moreover, fans and blowers make the controlled temperature and ensuring subtle blowing of materials.

Destination or Receiving Point

This is the middle point where the powder material has to stayed either for storage, mixing, filling or packaging purposes. It is facilitated by inlet which ensure subtle and airtight entry while discharge point which allows powder after treatment towards further units.

Pump

How is the negative pressure created? It is the pump which is responsible for the entire functionality of the vacuum powder transfer system. It is up to you what pump category you choose such as rotary, or diaphragmatic.

7.What materials require a vacuum powder transfer system?

Vacuum powder transfer system offers broad range materials dealsing, for instance:

Granular Powders

Granular Powders- Picture Courtesy: World Grain

These powders contain agglomerates of fine powders having a spherical shape. They have a coarse texture and better flowability than fine powders. Vacuum powder transfer system easily handles wide types of granular powders like pharmaceutical granules, sugar, salt, etc.

Fine Powders

Fine Powders- Picture Courtesy: The List

They constitute small particles with a size of less than 100 µm in diameter and handling of these powders requires caution because they can generate a lot of dust, leading to blockage of conveying systems. However, the vacuum powder transfer system is perfect for transferring fine powders with its vibratory feeders and fluidizing systems.

Pellets

Pellets- Picture Courtesy: Global Pharma Tek

They are often prone to chipping or breaking, so, a vacuum powder transfer system is used for delicately handling pellets, which preserves their structural composition during conveying.

Moisture or air Sensitive Materials

Moisture or air Sensitive Materials- Picture Courtesy: SGS

Since the vacuum powder transfer system is an enclosed design, therefore, it is commonly utilized for transferring moisture or oxygen-sensitive materials, because this system reduces the contact of water and air to materials, which can otherwise degrade them.

Hazardous Materials

Hazardous Materials- Picture Courtesy: Concrete Décor Magazine

This system is typically used for handling hazardous or toxic materials, as this device contains materials and keeps them enclosed, thus reducing the chances of explosions and inhalation of damaging particles.

8.How does a vacuum powder transfer system protect your ingredients from contamination?

A vacuum powder transfer system is incorporated with different features and mechanisms to maintain the integrity and sterility of powdered ingredients. Here are some significant safety features of the vacuum powder transfer system.

Closed Design

Closed Design- Picture Courtesy: Hapman

This system has enclosed and sealed construction that reduces exposure of powdered materials to the external environment, thereby averting the entry of airborne agents, dust, debris, and other foreign objects inside the device and keeping them from contaminating materials.

Filtration System

Filtration System- Picture Courtesy: Canadian Plastics

Different types of sophisticated filtration systems, like HEPA filters, are present at different locations in the vacuum powder transfer system to trap and remove airborne particles from the feed.

Leakage Prevention

Leakage Prevention- Picture Courtesy: Gericke

This machine has a strong vacuum seal and every connection and joint are designed prudently to prevent leakage, thus, this system prevents the entrance of external agents during the powder conveying and maintains the hygiene of the product.

Minimal Manual Handling

Minimal Manual Handling- Picture Courtesy: Volkmann GmBH

With this system, there is no need for a labor workforce, because it automatically handles and conveys the feed, consequently minimizing human contact with the powdery material, which is integral in preventing contamination from human mistakes or improper material handling.

9.What are the process tips of vacuum powder transfer systems?

Good practices can make your work life excellent. A vacuum powder transfer system is the safest method of transporting materials offering dilute or lean and dens phase process lines to convey in specialized pipelines. To have more efficient results, we have mentioned some straightforward process tips for you. If you follow them, we bet you will be approaching an extended shelf life of the unit.

Routinely Cleaning of the System

Routine cleaning of the unit

Remember guys! The filter is the main component of the vacuum powder transfer system. Therefore, never ignore their cleaning regularly to have a sharp suction operation. If the filter pores are blocked and restricting the airflow, it can affect the throughput, so you can apply a vacuum cleaner to pick the blockage and make the filter effective and clear.

Check Pumps and Gaskets

Checking parts of vacuum powder transfer system- Picture Courtesy: Filquip

As the system is entirely sealed and to assess the working status, you must check the pressure induced by the pumps and gasket. Any problem with these tools may result in a major drop in their performance due to air entrapment.

Good Internal State and Check Control Unit

Vacuum powder transfer system- Picture Courtesy: Nol-tec

Your machine’s internal wiring and state must be ideal to reduce the chances of static issues. Moreover, it is essential to have a calibrated machine to gain good and optimized processing.

10.What are the common problems and solutions of vacuum powder transfer system?

Nowadays, a vacuum powder transfer system is considered a hotline solution for powder conveying from its pickup point till final discharge. Along with several benefits, it is also facing some challenges that are easy to manage. Let’s see the basic issues and their solutions.

Pump pressure is jammed or stuck, the machine red indicator is ‘ON’ and shows you the delayed vacuum response.

Pump pressure failure

Solution

Such problems may occur due to low voltage and the pump mechanically doesn’t respond or produce optimized vacuum pressure. Side by side, check the lubricant level inside the pump that may result from the blockage response.

The machine doesn’t give a specified vacuum limit.

Vacuum powder transfer system

Solution

The pipeline of the system may leak or have air bubbles or air entrapment which keep emitting the pressure and may fail to attain the required vacuum, so the powder transferring is failed. To solve the problem, we would recommend replacing the leakage area with a new one to obtain the best possible pressure and vacuum.

How to deal with dust blowing during the powder transfer process?

Vacuum powder transfer system- picture courtesy: COSMEC

Solution

Although, the purpose of a vacuum powder transfer system is to maintain dust free working conditions sometimes you may encounter the presence of unwanted dust expulsion that might be controlled by utilizing of butterfly valve that must be installed with the system to give you a dust tight processing. Thus, the technician and work environment would be safer during the transfer of powders.

11.What are the critical considerations for vacuum powder transfer system?

When you’re planning to add the vacuum powder transfer system, we would suggest having a look at the below critical considerations to get the desirable unit and overall operation.

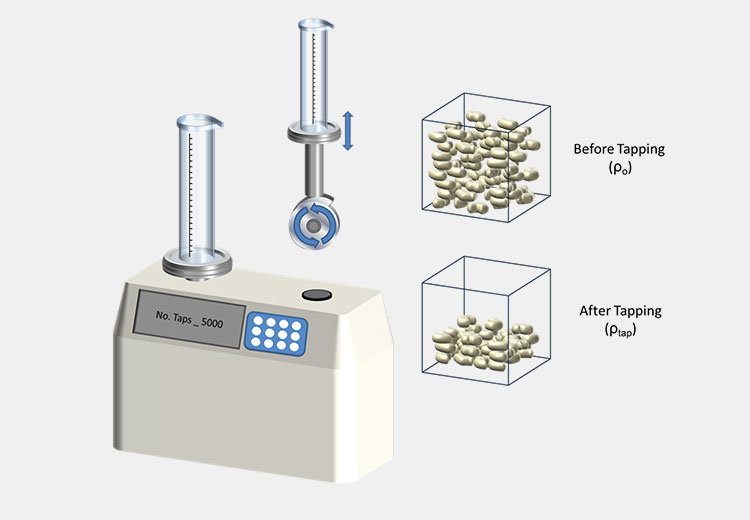

Bulk density

Measurement of bulk density

This is the important factor you must know, the reason behind estimating powder characteristics is only the great way to pick the vacuum transfer system. For example, if your powder bulk density is higher, you will need to select those units that are offering high velocities to suck the powder from the pickup point. Similarly, the powders with low bulk densities will require low vacuum velocities to pick powder from the pickup point.

Size of pickup point

Pickup point sizes- picture courtesy: GEA

The size of the pickup point is another significant factor you should consider when going to purchase the vacuum powder transfer system. This is because the right pick-up point will help you with flexible transportation of the powders. Also, it should be capable to configure various materials such as bag dump, bag unloaded, silo, etc.

Distance

Distance- Picture Courtesy: Coperion

You must know the distance between the pickup points of the vacuum powder transfer system, for example, the distance between loading and discharge into the container to get the most efficient supply and has capability to handle various types of blending materials perfectly.

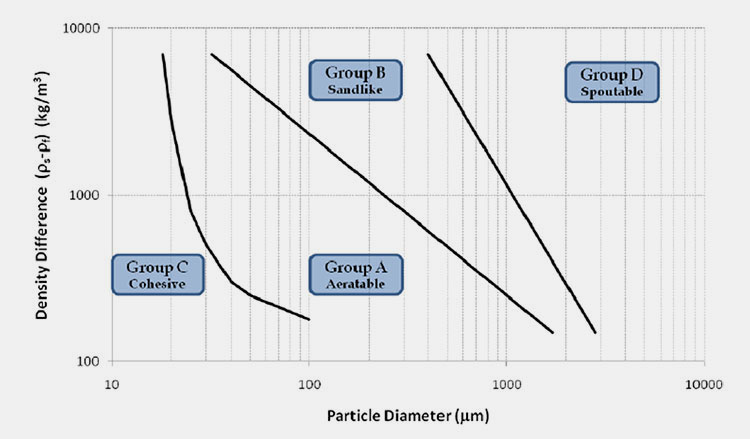

Flow Regimen

Gerald Classification of solid transfer- picture courtesy: Science direct

You must know that not all solids or powders are preferable to transfer by this technique rather you should estimate the fluidization characteristics to select dense or dilute phase systems, and it is simply mentioned in classes established by Geldart in 1973. For example:

| Class A | category particles exhibit the aeration with non-bubbles. |

| Class B | Powders begin with some bubbles upon fluidization. |

| Class C | here, the particles are characterized by cohesiveness and cannot fluidize rapidly. |

| Class D | particles are characterized by deep spouted layers. |

Cleaning

Easy to clean- Picture Courtesy: Bulkiinside

Your machine should be easy to clean and do not require too much time or effort for this task. Therefore, never ignore this point when looking for the machine and go for the machine which is pretty easy to clean and maintain to reduce time drainage and downtime.

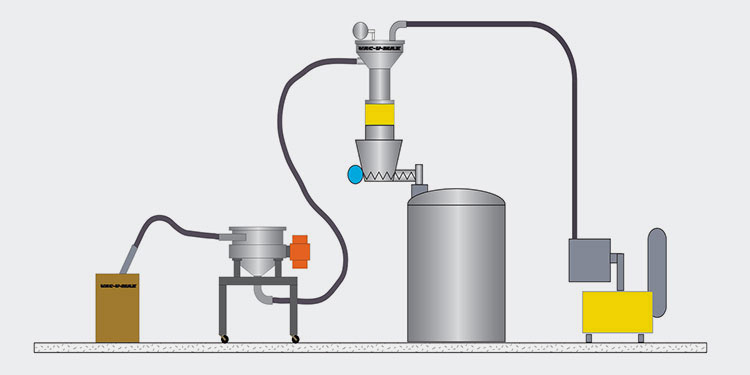

Piping and layout considerations

Piping and layout considerations- Picture Courtesy: VAC-U-MAX

This is very important to have the right vacuum piping and layout of the machine as it will help not only with transferring powders but with various ranges such as the finest dust particles to nanoparticles effectively. So, your system must be flexible with the running of materials with various characteristics and can be capable of withstanding powders belonging to different properties and densities.

Conclusion

The above discussion about the vacuum powder transfer system provides you with an ultimate gateway to choose the equipment for the material transfer in a controlled environment and maintain the safety of the product. The strictly enclosed circulatory system under a vacuum is undoubtedly the greatest approach to achieving benefits in your manufacturing and packaging sector. If you have any questions in your mind or want to speak to our technical experts for the machine’s purchase or guidance, we would like to send us a message or contact us via email now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Vacuum Powder Transfer System: The Ultimate Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours