Viscosity of Cream and Lotion: What Do You Know?

Viscosity of Cream and Lotion: What Do You Know?

What is viscosity? What is the difference of viscosity in cream and lotion? Why some liquids behave differently despite having same purpose or use? This is due to viscosity which makes them different on the basis of their texture and performance. Viscosity of cream and lotion play important role in maintaining consistency of product.

Viscosity of Cream and Lotion: What do you know? – Picture Courtesy: Freepik

Viscosity is defined as the resistance of fluid to flow or internal fraction. This article will help you understand the complex principle of viscosity and also answer some common question that comes up in your mind. Let’s start this topic with frequently asked questions and their expert’s answer.

1.What is viscosity of cream and lotion what do you know?

Viscosity of cream and lotion-Picture Courtesy: Block Party

Viscosity of cream and lotion is the measure of fluid to deform under sheer stress. It is perceived as flow behavior or resistance of pouring. Viscosity describes a fluid internal resistance to flow or also defined as measure of a fluid friction.

The basic principle of viscosity of cream and lotion is describes as: When a layer of liquid moves on the surface or another layer of the same liquid, the particles tend to oppose the movements resulting in developing a resisting force in liquid which is called Viscosity.

Viscosity of the cream and lotion is the effective factor to determine properties, consistency and stability.

Viscosity of cream and lotion will help you in selecting product or medium for medicinal purpose. Lotion are less viscous, more water content, easily spreadable and are preferable for hairy skin like scalp that’s why many scalp shampoo are lotion.

On the other hand, creams are more viscous, thick and suitable for dry skin because it create heavy barrier and keep skin hydrated and remain on skin for longer time.

2.How viscosity is measured using different apparatus in cream and lotion?

Measuring viscosity of cream and lotion Picture Courtesy: Byrdie

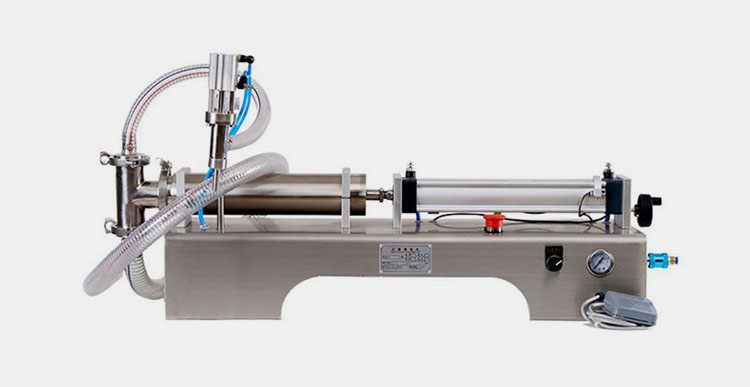

Viscosity is measured to quantify product flow behavior properties. It also effective in making decision for selecting mixing process and filling containers for the product as well as stability during storage, transportation till consumer use . In R&D labs specialized instruments are used to measure viscosity of cream and lotion are called “Rheometer” and “Viscometer”.

There are various method of measuring viscosity depending on the type of liquid and the circumstances. It involves different ways of measuring viscosity from simple ones involves counting each drop from thin tube or the complex one with specialized instrument with automatic recording.

Types of Viscometer

There are various methods used to measure viscosity of creams and liquids. These methods ensure consistency, stability and quality product. A viscometer is used to measure viscosity of cream and lotion. Let’s discuss in details each method and instrument used.

Capillary Viscometer

Capillary Viscometer- Picture Courtesy: Ubuy Jordan

This method of measurement, define as time required for fluid to pass through a thin tube (capillary tube) whose diameter and length is already known. Then the time taken by fluid is compared by standardize fluid (usually water) whose viscosity is already known.

There are two types capillary viscometer.

a- Ostwald’s Viscometer

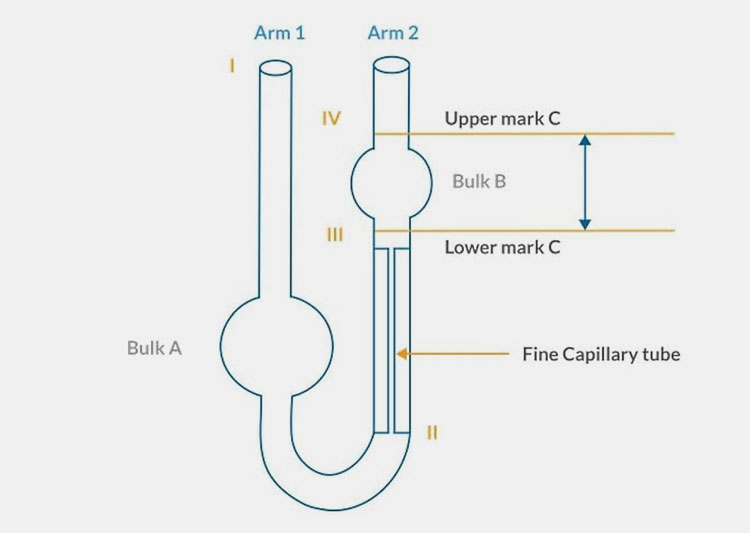

Ostwald’s Viscometer

Ostwald’s viscometer also known as U-tube viscometer. It measures the viscosity of liquid with known density.

Working Principle

The tube is filled with fluid through arm 1 up to bulk A, the liquid sucked through arm 2 till upper C mark and then allow fall from bulk B till lower mark C and time is noted and compared standard liquid which water.

b- Ubbelohde Suspended Level Viscometer

Ubbelohde Viscometer

It is the modified form of Ostwald’s Viscometer. It also works on same principle but with few differences.

Working Principle

There is a third vertical tube which is attached to the bulb below the capillary part. The liquid is filled through third arm in the quantity sufficient to fill the bulb in left arm. Rest the process is same U-shaped viscometer.

This viscometer is beneficial because it is simple in handling, inexpensive and portable.

Falling Ball Viscometer

Falling Ball Viscometer- Picture Courtesy: Helago-cz.com

Working Principle

It consists of a tube containing thick viscous liquid. A sphere is descend through the tube placed at specific angle, time taken by sphere to cross between two marks determine its viscosity. The time in which sphere is dropped is determined its viscosity.

It is a high speed device and gives precise result but requires high maintenance.

Rising Ball Viscometer

Rising Sphere Viscometer- Picture Courtesy: Direct industry

It is another falling ball viscometer and also known as Rheometer.

Working Principle

In this method, a stainless sphere or glass sphere is suspended in viscous liquid which is hung by a wire is lifted through the material at very low speed.

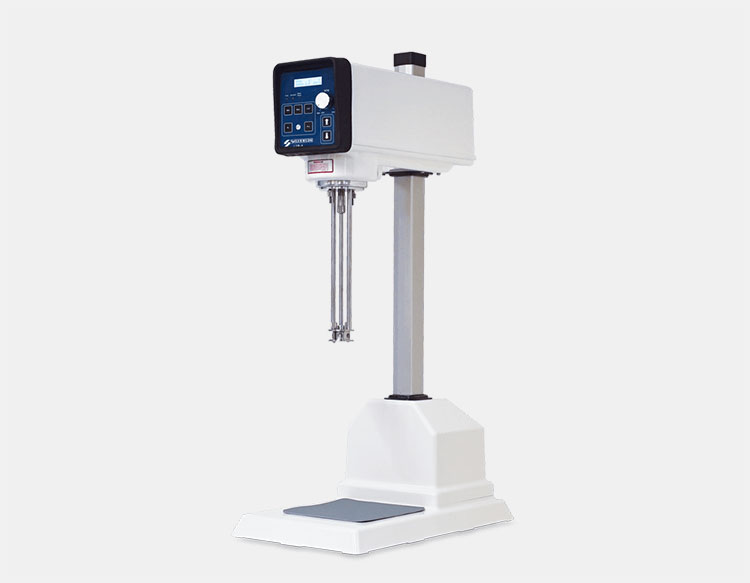

Rotational Viscometer

Rotational Viscometer – Picture Courtesy: DTC web shop

In this viscometer one surface is stationary and one part is rotating by an external drive.

Working Principle

A rotational viscometer works on the principle that the force required rotating an object submerged in viscous liquid, indicate viscosity of the fluid.

3.What are the different ranges of viscosities and ingredient used in cream and lotion?

Viscosity of Cream

Viscosity of cream depends upon the type of cream like either it is hand cream or body cream. But mostly viscosity of cream ranges from 36000 to 9500 cP (cp = Centipoise is the unit to measure viscosity). The basic ingredients used in formulation of cream are:

Humectant:They draw water and help to retain moisture in skin. Most commonly humectants are glycerin, lanolin and honey.

Liquid Oil:They are used as natural moisturizer and help to prevent water loss by creating protective barrier on skin.

Solid Oil (Butter):They are used for their specific benefit like keeping skin hydrated for longer period. Some of solid oils are used cocoa butter, Shea butter etc.

Thickener: Thickener is used to increase viscosity and to give desired consistency to cream. Like stearic acid and cetyl alcohol.

Emulsifier:They are added to make homogenous mixture of oil and water. Prevent separation of components.

Below table give you insight about percentage of each ingredient used in cream:

| Ratio | Ingredients |

| 60 % | Water |

| 3% | Humectant |

| 12% | Liquid Oil |

| 15% | Solid Oil ( Butter) |

| 3% | Thickener |

| 7% | Emulsifier |

Viscosity of Lotion

Viscosity of lotion depends on many factors but most important factor is ingredients used in lotion. Most of the ingredients are same as cream which we discuss above but they differ in percentages or quantity. Viscosity of lotion varies depending upon purpose and usage but mostly it lies between 2000 to 5000 cP. Let’s see table to get idea about quantity of ingredients.

| Ratio | Ingredients |

| 80% | Water |

| 4% | Humectant |

| 10% | Liquid Oil |

| 2% | Thickener |

| 4% | Emulsifier |

As you also notices that water content is more in lotion as compared to cream. On the other hand, butter and thickener is less in lotion that’s why lotion is less viscous than cream and more liquidy. These differences in viscosity make them different product unless they are used for same purpose.

4.What factors affect viscosity of cream and lotion?

There are a lot of factor which affect the viscosity of cream and lotion. It help user to decide how store product and which more suitable to use. I will describe you some basic factors which greatly impact the viscosity of cream and lotion.

Temperature Influencing Viscosity of Cream and Lotion

Watery Lotion due to inappropriate storage temperature- Picture Courtesy: Clare Henney

Temperature significantly impact viscosity of cream and lotion. As the temperature rises, viscosity of lotion and cream decreases because molecule gain kinetic energy and move more rapidly as a result in reducing intermolecular force which alter the viscosity.

You also observed cream and lotion in winter are thick in consistency while the same product loses its consistency in summer and become bit watery.

Composition of Cream and Lotion

Composition of Cream and Lotion- Picture Courtesy: Palmer’s

The component used in cream and lotion significantly alters viscosity of product. For example what kind of thickening agent is used because good choice of thickener increases viscosity? Like Carbomers and xanthan gum give desired consistency and maintain viscosity of cream and lotion. Balanced addition of humectant is also considered because excess solvent will decrease viscosity of cream and lotion. It will be helpful for different manufacturing industry while making cream and lotion.

Pressure influence on Viscosity of Cream and Lotion

Effect of Pressure on viscosity of cream and lotion- Picture courtesy: Happy Skin

Pressure also plays an important role in viscosity of cream but its effect is different from temperature. Increase in pressure cause slight rise in viscosity because molecules are pushed closer and leading to increase in intermolecular force. However this impact is quite small as compared to the impact of temperature.

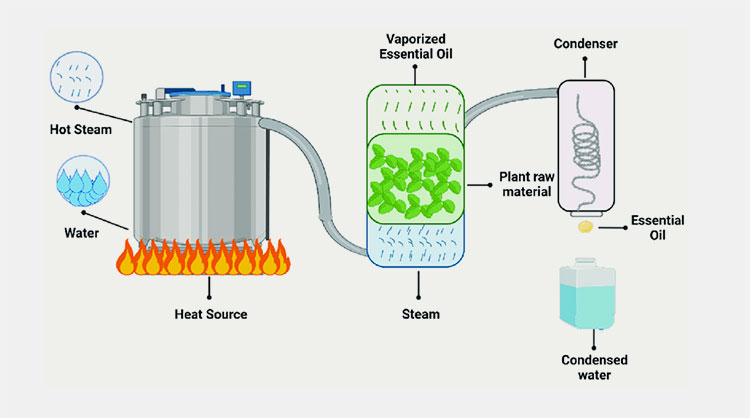

5.What equipment is induced to get desirable viscosity of cream and lotion?

There are various mixing equipment are used depending upon the viscosity of cream and lotion. Selecting right equipment is really important for desirable viscosity of cream and lotion. In this section I will tell you about some basic equipment which is really important.

For high to medium viscous cream helical-ribbon and high shear mixer are used. On the other hand, for low viscous lotion propeller mixer and impeller mixer are used.

Equipment for Mixing High Viscous Cream

Helical-Ribbon Mixer

Helical-Ribbon Mixer- Picture Courtesy: Unique Mixer

It consists of helical shaped ribbon construction which is ideal for homogenizing any kind of powder and suitable for homogenizing thick viscous creams.

Working Principle

Ribbon mixer work on the principle of shuffle movement that consists of two parts on central shaft. The mixing medium consists of inner or outer helical ribbon structure that designed to move inward or outward both. The outer helical pull the material from side to middle of cylinder and internal helical push back material on side. This back forth folding movement creates a mixing pattern.

High Shear Mixer:

High Shear Mixer for viscous cream – Picture Courtesy: Boss go

The high shear mixer balances mixing intensity for medium viscous creams without excessive consumption of energy. This mixer insures uniform viscosity by evenly mixing and distribution of ingredients in creams.

Working Principle

High shear mixer revolves around the concept of shear force. The mixer consists of a rotor that rotates at high speed within a stationary stator. The constantly moving rotor create centrifugal force while the stator remain stationary creating shear force resulting in reduced particle size and leading to evenly dispersed mixture.

Equipment for Mixing Low Viscous Lotion:

Propeller Mixer

Propeller Mixer – Picture Courtesy: SRT-Mischer.ce

Propeller mixer work on the principle of shearing force which facilitate blending low viscosity lotion by circulating fluid in both axial and radial direction.

Working Principle

Propeller mixer creates rotational thrust resulting in mixing of low viscosity lotion.

Turbine Mixer

Turbine Mixer – Picture Courtesy: Direct Industry

Turbine mixer is a mechanical device used to mix low viscosity fluids like lotion.

Working Principle

Turbine mixer creates turbulent movement of liquid due to combination of centrifugal and rotational force. These movement cause effective mixing of low viscosity lotion

6.What are the best packaging option in different viscosity of cream and lotion?

There are many options of packaging available for cream and lotion depending on the viscosity, consistency and ease of use. Some frequently used options are:

Wide Mouth Jars

Wide Mouth containers

Viscosity of cream and lotion greatly impact choice of container because thick viscous cream is easily scoops out from wide mouth jars. Its help in taking out last amount out jars so reducing waste of product. Better option for creams with chunks of fruit etc.

Pump Bottles

Pump bottles – Picture courtesy: Sanle plastic

These are suitable packaging for low or thin viscosity cream and lotion. It enable control over the amount dispensed, reducing waste and ensuring right amount is applied. It is also convenient to use and can easily be handled by one hand.

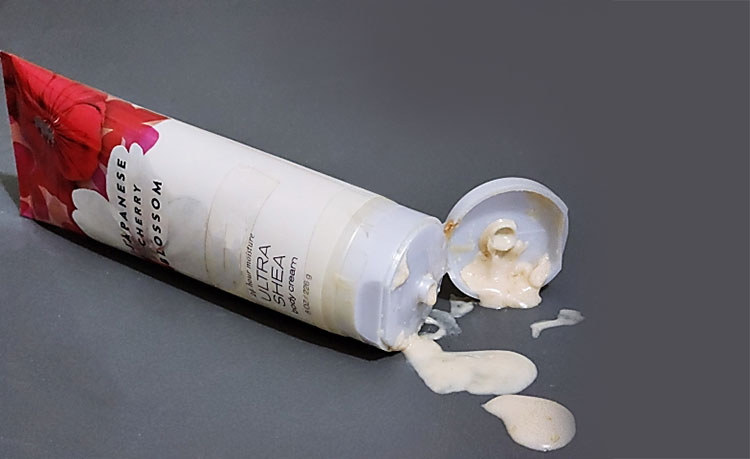

Collapsible Tube Container

Tubes Containers – Picture Courtesy: India Mart

Collapsible tube containers are preferred for lotion and medium viscous cream. It is portable to use even creams are easily squeezable from these tubes. It protects product from air and contamination therefore protecting product from degradation and contamination.

Conclusion

Viscosity of cream and lotion is an essential aspect in determining effectiveness and which product best suits you. In this article, we discuss about instrument and packaging container used depending on the viscosity of cream and lotion. We also understand the factors which need to be maintained for desirable viscosity of cream and lotion and the mixing equipment which are crucial for this step. However, if you need more information about viscosity of cream and lotion, then you are encouraged to contact our information service center at Allpack.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Viscosity of Cream and Lotion: What Do You Know? Read More »