Types Of Mixer In Pharmaceutical Industry

Are you planning to take an initiative of pharmaceutical manufacturing? What kind of dosage do you want to work on? Is it solid dosage form like capsules, tablets, and pills, or liquid dosage form such as syrups, injection water and vaccines? Well, in any case you will surely need a mixer to get done with the inevitable step of the production which is mixing or blending. So, we are here to address your concerns regarding the Types Of Mixer In Pharmaceutical Industry.

There are wide range of mixer types which you will find in pharmaceutical industry, however, you may get confused when suddenly presented to these all at once. Thus, for your convenience and clear understanding, we have explained Types Of Mixer In Pharmaceutical Industry in this review. So, go through it and get all what you are waiting for!

1.What Is Meant By Pharmaceutical Mixer?

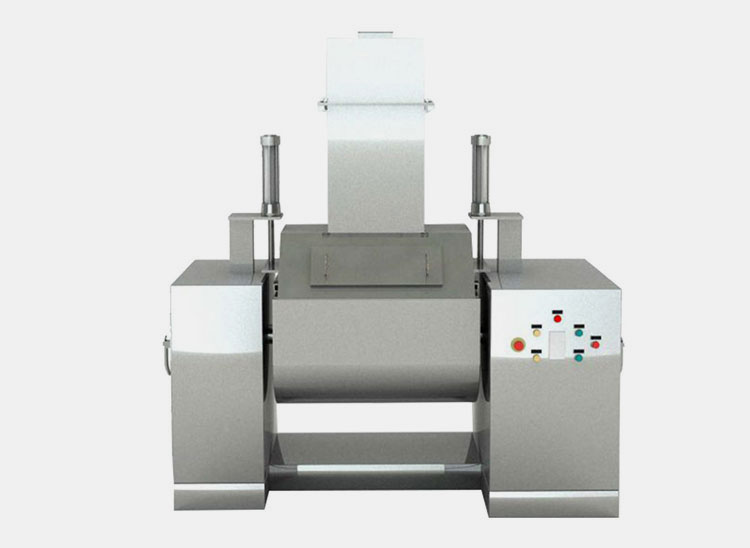

Allpack- CH Series Horizontal Tanker Typed Mixer

Pharmaceutical industry revolves around the manufacturing of drugs in all its forms encompassing solid dosage form, liquid dosage form and other therapeutic agents for external use like ointment. As we know that anything we use or consume on daily basis is made up of several components, so, how can pharmaceuticals skip these elements? Definitely they are made up of different ingredients.

Now, these ingredients vary from adhesive powder to free-flowing granules and viscous liquids. What here significant is to know that these materials need to be well mixed in order to create a uniform and homogeneous mixture for which pharmaceutical mixer is utilized.

Tablets and powder in spoons-Picture Courtesy: coherentmarketinsights.com

This equipment is designed keeping in view the sensitivity, flow, particle size, and other characteristics of various pharmaceutical materials. In addition to it, its automation and enhanced safety level has made it inevitable for production in pharmaceutical industry.

Before going into the detail of types of mixer in pharmaceutical industry, let's know some basic facts about it!

Functions of Pharmaceutical Mixer

Unlike conventional mixers, which we use in our homes to replace manual whisking and stirring for mixing few substances, pharmaceutical mixer performs diverse functions. These functions are the prerequisites for effective drug formation and delivery. Some of the important uses of pharmaceutical mixer include:

Mixing:Mixing simply refers to the uniform distribution of various solid particles such as powder, granules, or pellets.

Blending:It refers to the preparation of single mixture which is obtained by mixing solid and liquid substances. Thus, no particle can be identified being distinct from another rather the end solution is homogeneous.

Granulation:Pharmaceutical mixer can also perform the function of granulation by employing fluidization technique. It simply involves the supply of liquid in form of spray or gas to small particulates, which resultantly join together to form granules.

Emulsification:Emulsification is the formation of an emulsion by the dispersion of two immiscible liquids. This process is carried out by special pharmaceutical mixer which break down the structural properties of liquids in order to avoid their separation.

Homogenization:Pharmaceutical mixer may also be employed for the important task of making a homogeneous solution by mixing together miscible liquids under controlled temperature.

Deagglomeration:Apart from other uses, pharmaceutical mixer is also useful to discharge the duty of breaking down large agglomerates of powders or granules. It is easily done by tumbler mixers.

Common Mixing Combination

Various viscous formulation- Picture Courtesy: Fenty Beauty

Pharmaceutical mixers usually process the combination of two or more substances to get a uniform mixture such as active ingredients and excipients. In this way, three types of combinations are frequently employed by pharmaceutical industry through the use of mixers. These are as follows:

Solid-solid mixing:Such type of mixing combination only includes dry powders or granules which are thoroughly to processed. Tumbler mixers and convective mixers are the common pharmaceutical mixers utilized for free flowing and cohesive substances respectively.

Solid-liquid mixing:Solid-liquid is another mixing combination which is being practiced in pharmaceutical industry with the help of relevant mixers such as paddle mixer and plow mixer etc. For such formulation, fluidization method is used to modify the structural properties of powders by applying binders and other constituents.

Liquid-liquid mixing:Liquid-liquid mixing involves the homogenization and emulsification of various types of miscible and immiscible liquids. As most of the liquid formulation for making ointments, gels, and therapeutic creams are viscous, so, heavy-duty mixers with rotating impellers are used to deal with thick materials.

2.Types Of Mixer In Pharmaceutical Industry- For Solid-Solid Mixing?

It is quite interesting to know about the types of mixers in pharmaceutical industry especially for solid-solid mixing as it is the most commonly used method for drug delivery. For instance, tablets, capsules, pills, and instant water mixers are all made from powders or granules which require accurate mixing. Now, the type of mixer for solid-solid mixing depends upon their flow properties such as:

Free Flowing Particles

Various medicine powders & granules

Free flowing particles are those dry constituents which flows easily without sticking to each other. They are also prone to quick mixing when exposed to shaking. Thus, tumbler mixers are designed to mix substances with easy flowability.

Tumbler Mixers

Tumbler mixers are the most popular mixers being employed to deal with free flowing powders and granules. These equipment follow the principal of tumbling where the vessel, in which material is loaded, continuously rotate or move in order to segregate and combine the inside content. Simultaneously, uniform mixture is achieved without any use of heat, liquid, or agitators.

Benefits:

By avoiding use of heat and moisture, tumbler mixers provide safe way of mixing for sensitive ingredients.

The absence of agitators enables them to maintain the original structure of particles throughout mixing by reducing the chances of size minimization.

Tumbler mixers are extremely effective in uniform particle distribution.

Limitations:

Such type of mixers cannot process fine and cohesive substances.

They have limitation of difficult way of material feeding which is frequently done manually.

Application

Tumbler mixers are suitable to deal with all kinds of non-adhesive powders, granules, and pellets in pharmaceutical preparations of solid dosage form and other sectors such as food, detergent industry, and chemical industry etc.

Types:

There are multiple types of tumbler mixers, each with unique features, which can be employed for solid-solid mixing. These are described below:

V Mixer

Allpack- Model CH-V Series High Efficiency Mixer

V mixer is one of the popular types of tumbler mixers which is characterized by its V shape body. The vessel depicts twin shell being joined at a single point, making a V shape. With precise structure and unique design, V mixer follows convenient way for mixing powders. Its revolution causes the material to move away and toward the center, resulting in segregation and unification of the content. Moreover, it provides a hygienic way for ingredients mixing by eliminating the chances of cross-contamination.

Double Cone Mixer

Allpack- Model W Series Double Taper-shaped Mixer

Double cone mixer is an astonishing equipment with vessel resembling double cone; one at the top and other at the bottom. It provides large room for material and support gentle mixing so as to maintain the delicacy of ingredients. The content gets easily mixed when continuously face falling through vessel rotation. Similarly, it consume less energy and is ideal for fragile products such as baby food mixing, protein powder, and pharmaceutical granules.

Stirring Mixer

Allpack- CW series stirring type Mixer

Stirring mixer is designed with distinct structure which facilitate the stirring of materials having different composition. During the process, content is kept tumbling due to the rotation and structure of stirring vessel. The consequent gravitational force keep moving the material which results in formation of homogeneous mixture. This feature of the mixer make it suitable for the processing of fine particulates with minimal sticky properties.

Octagonal Mixer

Another significant type of tumbler mixer is octagonal mixer which has special features of large capacity, steady tumbling, and octagon shape shell. Similarly, during rotation, the content laying inside undergo complex patterns, ensuring that all the particles are uniformly mixed. In this way, the octagonal mixer is considered as stronger than other sibling mixers.

Bin Blender

Allpack- DTH Series Post Bin Blender

Bin Blender is a special form of free-fall blender. It is has mechanically driven detachable bin inside with material is loaded for uniform mixing. The shape of the bin vary according to the user choice and it is easily movable. Moreover, bin blender is effective in mixing which in turn reduce time spent. It also eliminates the content segregation and provide protection against air-borne cross-contamination.

2D Mixer

Allpack- Model EYH Series 2D Movement Mixer

2D mixer is two dimensional mixer which is available in multiple capacities. The mixer can be easily distinguished by all the other tumbling mixer on its working basis which is regulated by a blending cylinder and swing frame. When the cylinder rotates, 2D mixer drum swing in right and left direction. This movement cause the material to get mixed in a quite effective way.

3D Mixer

Allpack- SBH-10 three-dimensional swing mixer

3D mixer has more complex specifications due to its three dimensional mixing and specialized structure. The material for mixing face simultaneous rolling, horizontal movement, and vibration as the bin start rotating. Thus, in a very short time span, extremely uniform and homogeneous mixture is prepared.

Cohesive Particles

Cohesive & fine powder flowing from bottle pores- Picture Courtesy: vogue.com

Cohesive particles simply means all the dry powder ingredients which are either too fine to flow easily or they are sticky in nature. As a result, they are often affected by the creation of lumps. In pharmaceutical industry, it is one of the critical tasks to make sure concerned dosage is prepared from accurate volume of uniform particulates. Thus, non free flowing particles are mixed by using convective mixers.

Convective Mixers

Unlike tumbler mixers, which follow the principal of tumbling or vessel rotation for material mixing, convective mixers are equipment with stationary shells. These shells can be horizontal or vertical and the mixing process is carried out by the blades or screws attached inside the mixers. Convective mixers are durable equipment made from quality stainless steel with often large size shells to accommodate material.

Benefits:

- Offers high mixing speed with sharp rotating impellers and short cycle time.

- Convective mixers are useful for size minimization of particles.

- They are multipurpose mixers as can be used for deagglomeration and removal of solid lumps.

Limitations:

- Not suitable for fragile, heat sensitive, and standard size particles.

- Occupy more space due to large body.

Application

Convective mixer is a good choice for hard and cohesive substances with poor flowability. These mixers are ideal for enhancing the efficiency of mixing in medium to large scale nutraceutical, veterinary, healthcare and food industry.

Types:

Convective mixers can be further categorized into two types according to their structure and mixing specifications. These include:

Ribbon Mixer

Allpack- WLDH horizontal bin mixer

Ribbon mixer is a machine designed to mix diverse powders uniformly. It has U-shaped horizontal shell inside which dual, sharp stainless steel ribbons are located. These ribbons play instrumental role in the precise mixing during operation. The cross mixing of outer and inner mixing towards the edges and center results in the formation of perfect mixture. Hence, it gives you smoothly finished mixture with less time and energy consumption. Moreover, it is suitable for pharmaceutical, condiments, and agrochemical products.

Conical Screw Mixer

Allpack- DLH Series Cone Mixer

Conical screw mixer is another equipment that belongs to the class of convective mixers. It has vertical cone-shaped structure inside which a screw agitator is fixed. Although, the shell of the conical screw mixer has small capacity of material holding, however, it is fast in mixing different types of ingredients by rotating screw in the center and orbiting around the periphery. It is safe for friable and heat-sensitive constituents.

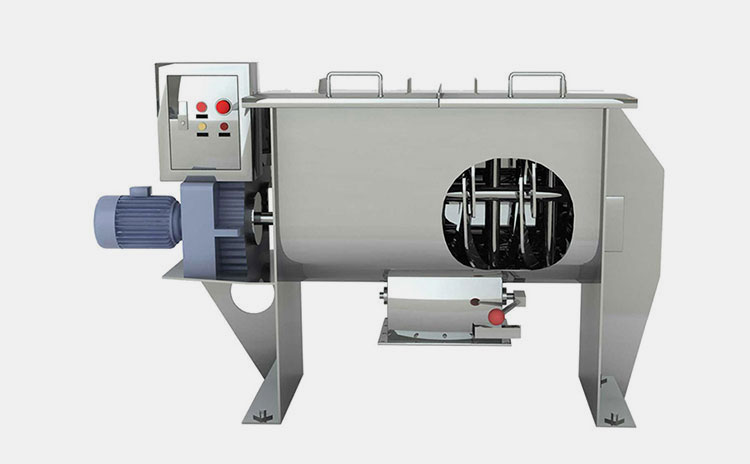

Paddle Mixer

Horizontal paddle blender powder mixer-Picture Courtesy: permix-mixer.com

Paddle mixer is another form of convective mixer which is employed to accomplish the task of solid-solid mixing. The mixer come in various shapes and sizes such as cylinder or horizontal. It features paddles which helps in the mixing of products by continuous rotation. The design of paddle is simple and it is cost-effective. In addition to it, the speed of the mixer ranges from 20 to 200 revolutions per minute.

3.Types Of Mixer In Pharmaceutical Industry- For Solid-liquid Mixing?

Apart from solid-solid mixing, pharmaceutical processing also involves the preparation of solutions which are obtained by using both the solids and liquids collectively. This phenomenon is referred to as blending in which solid material is diffused into liquids or small amount of liquid is added into solid for compact particles formation.

Similarly, the mixers employed for carrying out this function are also different from that of solid-solid mixers. They are of different types depending upon the level each substance is taken. So, let's understand these mixers!

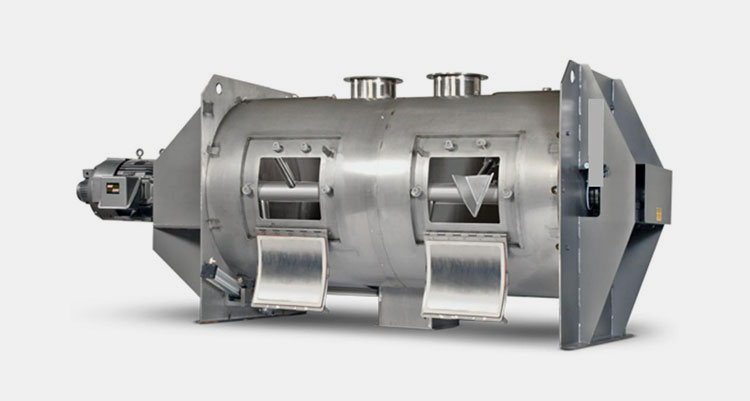

Plow Mixer

Ploughshare mixer- Picture Courtesy: tiermax.ca

Plow mixer is an innovative machine developed to deal with solid-liquid mixing. It can perform multiple tasks of granulation, fine mixing, emulsification, and suspension etc. Plow mixer generate high mixing accuracy by fluidizing the solid particles and producing desired results. It is often desirable for chopping hard and heavy ingredients. Similarly, by using its advanced machinery, plow mixer can work with great efficiency and excellence that it can be used in pharmaceutical, construction, and cosmetic industries.

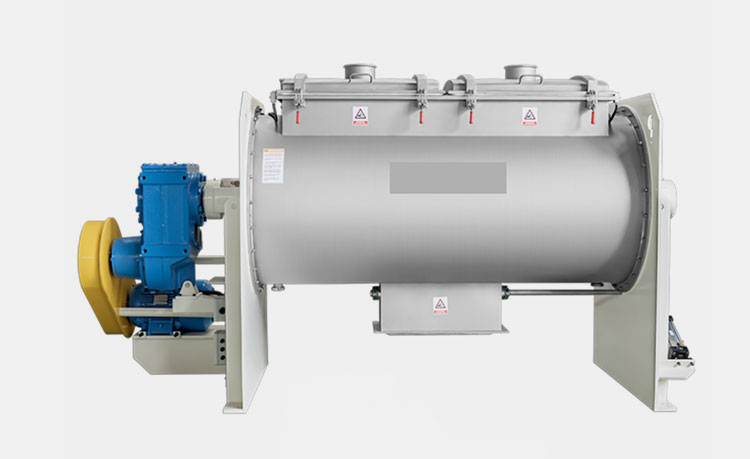

Double Shaft Mixer

WZL Double Shaft Mixer- Picture Courtesy: Shengli

Double shaft mixer is also a type of fluidized mixer which is capable to process solid-liquid combinations. It can better deal with the production of granules as well as slurry of solid particles in fluids. As the name indicates, this type of mixer has double shafts on opposite direction which increase the mixing process during operation. The rapid movement of shafts also result in heat generation that helps in producing a uniform mixture.

4.Types Of Mixer In Pharmaceutical Industry- For Liquid-Liquid Mixing?

After discussing in detail about mixers for solid-solid and solid-liquid combinations, now it is time to shed some light on liquid-liquid mixing. As we are familiar with the products like essential oil, syrups, and surgical spirit, these liquids are produced in pharmaceutical industry after thorough processing. It involves the major step of mixing different liquids for which two types of mixers are used:

Axial Flow Impeller Mixer

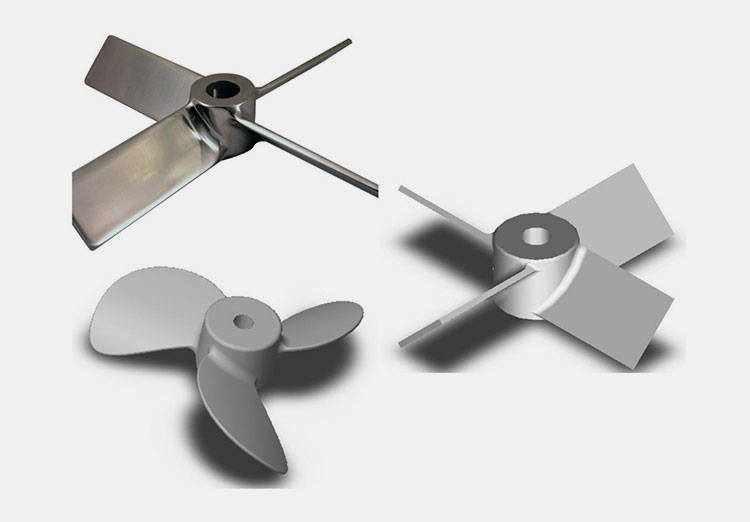

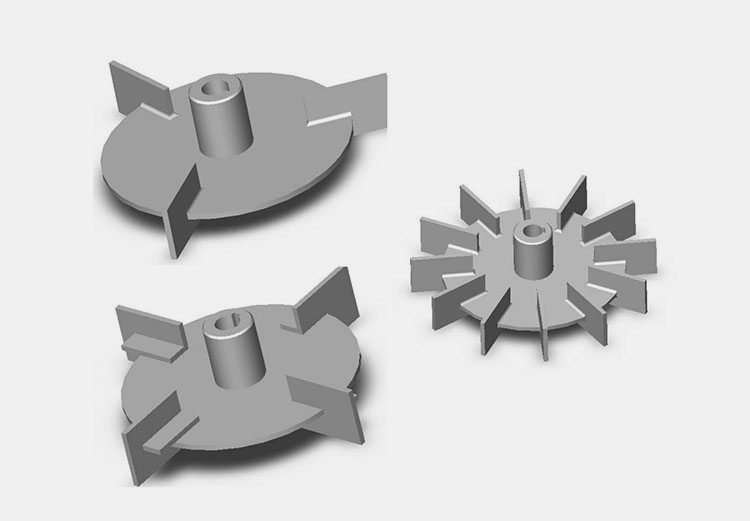

Axial Flow Impellers- Picture Courtesy: postmixing.com

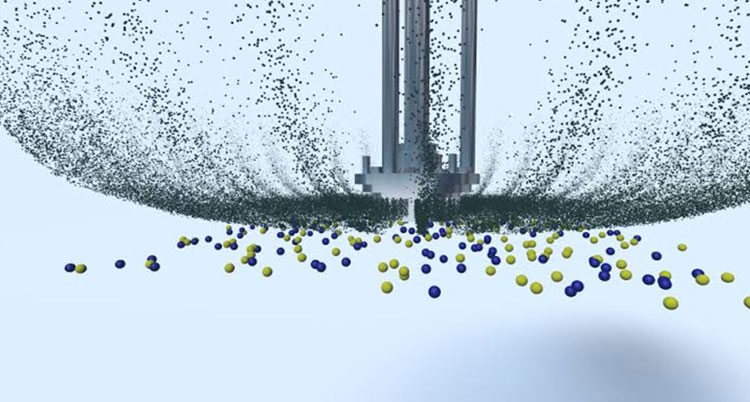

Axial flow impeller mixer is a kind of liquid-liquid mixing equipment. It uses axial flow impellers to create top to bottom motion in the tank. In this way, the pressure is generated by the mixing of water and solid particles are uniformly mixed as the impeller do not allow them to settle at the bottom. Axial flow impeller mixer is suitable for solid-liquid suspension with low energy consumption and simple working procedure.

Radial Flow Impeller Mixer

Various radial impellers- Picture Courtesy: postmixing.com

Radial flow impeller mixer is used for single or multi-phase applications. In such mixers, impeller is designed in 4-6 blades. It produces radial flow pattern, as a a result of which the fluids move perpendicular to the impeller. Radial flow impeller mixer is suitable for gas-liquid mass transfer.

5.Types Of Mixer In Pharmaceutical Industry- For Viscous Material?

There are some types of mixers in pharmaceutical industry which are specifically designed to deal with highly viscous materials because mixing these substances with normal mixers can ruin the formulation as well as may cause serious damage to the machine. Thus, special mixers such as planetary mixer, rotary stator motor, and emulsifying mixer are brought into the field. These are described below:

Cream dispensing over finger- Picture Courtesy: NutraGlow

Planetary Mixer

Planetary mixer- Picture Courtesy: empiresuppliesonline.co.uk

Planetary mixer is named after its mixing action which greatly resemble the way planets move in solar system. It has heavy-duty machinery with a mixing bowl, scrapper, and rotating beaters, and a base for material loading. The rotating agitators move in a planetary motion to create a uniform emulsion. It is ideal for viscous and sticky emulsion such as creams, ointments, gels, and shampoo etc.

Rotary Stator Mixer

The VRS Rotor Stator Mixer- Picture Courtesy: schold.com

Rotary stator mixer is a multipurpose mixer designed for efficient dispersing, emulsify, homogenize, and mixing of thick fluids and solid particles. The mixer constitute a durable rotary stator blade with integrated stand and power system. While mixing, the rotary stator blade reduce the size of granules and particles, if any, and form a homogeneous solution. Such type of mixer is good for pharmaceutical pastes, coatings, and liquid medication.

Emulsifying Mixer

Allpack- APKZRJ Up Homogenizer Vacuum Emulsifying Mixer

Emulsifying mixer is yet another type of mixer created for high matrix viscosity. It is made up of stainless steel with a vacuum pot for material mixing above which heavy-duty impeller with multiple blades is located. In emulsifying mixer, other pots are also attached for holding liquids such as oil and water. These mixers are ideal for preparing thick slurries and homogenizers in pharmaceutical, nutraceutical, cosmetic, and food industries.

6.Types Of Mixer In Pharmaceutical Industry- How To Pick The Best One?

In order to choose the best compatible pharmaceutical mixer, it is significant to consider some of the important factors which are enumerated below:

Mixing Combination

Liquid slurry mixing- Picture Courtesy: fluidhandlingpro.com

First, you should figure out what kind of mixing combination you are running or about to work on in future. Once you have determined this, it will be easy for you to draw a line among range of mixers and choose for you the desirable one. For instance, you need to determine whether you want to deal with solid-solid mixing, solid-liquid mixing, liquid-liquid mixing, or viscous material mixing.

Material Properties

After determining mixing combination, just deep delve into the material flow properties, viscosity, and sensitivity. It will further broaden your knowledge about the products at hand and selecting the most compatible equipment.

Production Efficiency

Liquid-solid mixing

Another significant thing to look for is to consider your current production volume. It will help you in choosing the right mixer because each type of mixer come in different speed ratio. So, you can opt for efficient one if dealing with large production volume.

Mixer Capacity

Pharmaceutical mixers are available in different capacities especially those use for powder and granules mixing. Thus, you should be very careful in selecting the mixer with vessel of desired capacity or else the overloading will cause mixer failure.

7.Types Of Mixer In Pharmaceutical Industry- What Are The Future Prospects?

Operator standing along pharmaceutical mixer- Picture Courtesy: amixon.com

The use of mixers is becoming undeniable not only in pharmaceutical industry but other fields as well such as food sector, beauty care industry, and chemical industry etc. Similarly, the material used for mixing has also seen variety and the growing customer demand for effective products is pushing manufacturers to automate their production lines.

In such a scenario, the importance of different types of mixers in pharmaceutical industry is growing. These mixers are going to dominate the market as a result of which it is expected that further improvement in the automation level, efficiency, and quality performance of the mixers will be enhanced.

Conclusion

To conclude, Types Of Mixer In Pharmaceutical Industry are numerous and they are of prime importance in mixing range of solid, liquid, and viscous materials. Knowing about each mixer is crucial to understand the purpose and working process. It is also helpful in making a vigilant choice during your selection. We hope you have understood the above explanation in a well manner. Still, if you have any query or you want to purchase a mixer. Then feel free to contact us. We will address your concerns and make sure to provide you with cutting edge solution!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide