Twelve Lanes Powder Cartoning Production Line: The Complete Buying Guide In 2025

Whether its pharmaceutical, foodstuff, chemical or cosmetic industry, manufacturing and processing of powders is inevitable. Similarly, dealing with huge level of production and packaging require efficient, sophisticated, and advanced equipment which can bring ease in your work. Therefore, Twelve Lanes Powder Cartoning Production Line is created to transform the industry's efficiency level.

It is an outstanding powder packaging tool which cover both the primary and secondary packaging of every kind of powder. Not only that, but it also preserves the sensitivity, quality, and essence of your powders. You can customize it as per your preferences and get the desired output. All it requires is to discover in depth about A Twelve Lanes Powder Cartoning Production Line. So, be ready to give this buying guide a thorough read!

1.What Is Twelve Lanes Powder Cartoning Production Line?

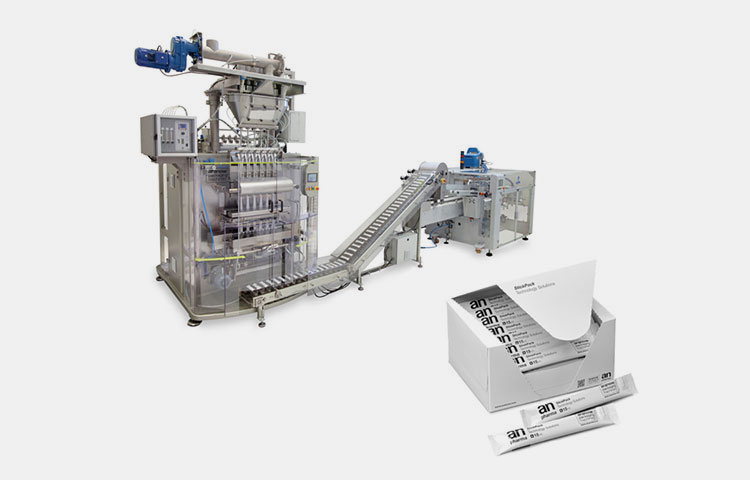

Multi-lane stick bag counting & cartoning machine- Picture Courtesy: samfull.net

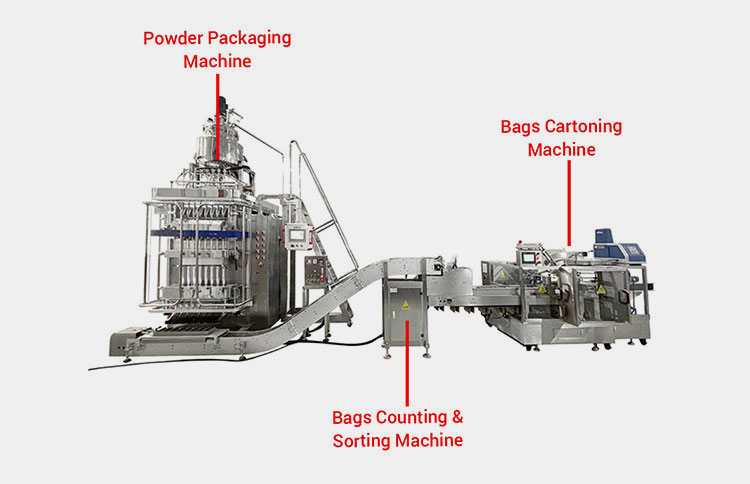

Twelve lanes powder cartoning production line is an assembly of several equipment which together form a production line to carry out the full powder packaging. It mainly consists of a twelve lanes powder packaging machine, bag sorting or counting machine, and a cartoning machine.

This production line is extremely fast in its performance by first encasing precise amount of powder into twelve individual packages and then passing these finished powder packages through cartoning phase where the secondary packaging of powder bags is accomplished. It follows an automatic way for doing this task, therefore, you can get extremely high output ratio in terms of production.

2.Explain The Benefits Of Twelve Lanes Powder Cartoning Production Line?

Twelve lanes powder cartoning production line is the name of advanced technology composition. That's why, you can gain a lot by using this packaging solution. Let's know some of its most prominent features and associated benefits:

Working Continuity

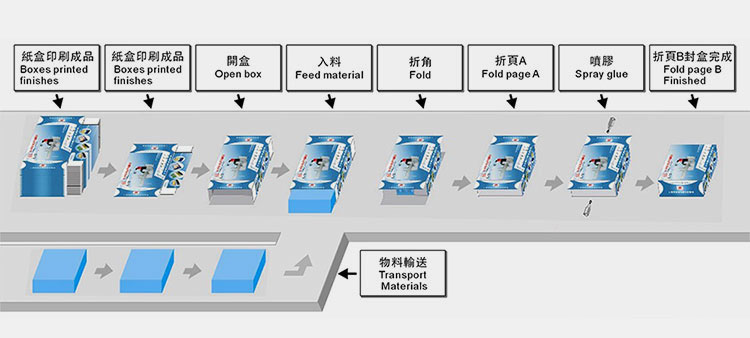

Working process of cartoning machine

The interconnected assembly of a twelve lanes powder cartoning production line is a perfect display of fully automatic equipment. It thus reduces the interruptions caused by manual interference and ensure the smooth working which definitely enhance your packaging efficiency.

Compact

Compact multi-lane powder cartoning production line- Picture Courtesy: Viking Masek

Although, this production line is composed of several units, yet it occupies less space due to its compact and durable body which is made up of fully secured quality material. Hence, you can locate it wherever you want and mobilize it easily.

One-Step Solution

Various stick packs along with cartons- Picture Courtesy: KenHigh

Twelve lanes powder cartoning production line is one-step solution, and it offers both the primary and secondary packaging services for your powder packaging. For instance, its multi functioning capability can outstandingly finish powder measuring, bag making, filling, sealing, cutting, sorting, cartoning, and discharging etc.

High Protection

Powder cartoning under protected environment

Another most crucial attributes of this twelve lanes powder cartoning production line is its safety for material as well as operator. In addition, all its movable and heating parts are covered in protected glass to avoid pollution and the contact parts of material and boxes are made from food grade stainless steel.

Easy Handling

Operator setting machine- Picture Courtesy: Optima Packaging

Despite having large body, a twelve lanes powder cartoning production line require little maintenance and is extremely handy to operate. The user is only required to set the machine parameters by using intuitive control panel and power the machine on. The rest of operation is done automatically by machine.

3.Enlist The Various Types Of Powders Which Can Be Processed By A Twelve Lanes Powder Cartoning Production Line?

A twelve lanes powder cartoning production line can be employed to pack all kinds of powders whether free flowing or cohesive. So, below is a brief list to shed light on some of the notable ones which we use in our daily life. These include:

Coffee Powder

Coffee powder presentation idea

Coffee is the most favored drink worldwide which is derived from coffee beans. It also carries certain health benefits. That's why, its use is common in houses, workplace and outdoor. Thus, to aid consumers, a twelve lanes powder cartoning production line can be simply employed for packing large volume of coffee powder into single serving stick packs or sachets.

Milk Powder

Milk powder in bowl

Milk powder is also delivered in individual packages to ensure instant use. Therefore, this machine is capable of doing this task with great efficiency and safety to retain the quality of your milk powders.

Pharmaceutical Powder

Pharmaceutical capsule powder- Picture Courtesy: harpersbazar.com

Wide range of pharmaceutical powders are now used for treating certain illnesses instead of using high dose and oversized pills. However, these medicated powders are in need of hygienic environment for packaging. In this way, a twelve lanes powder cartoning production line is the best suitable to maintain the quality and sterility of pharmaceutical powders.

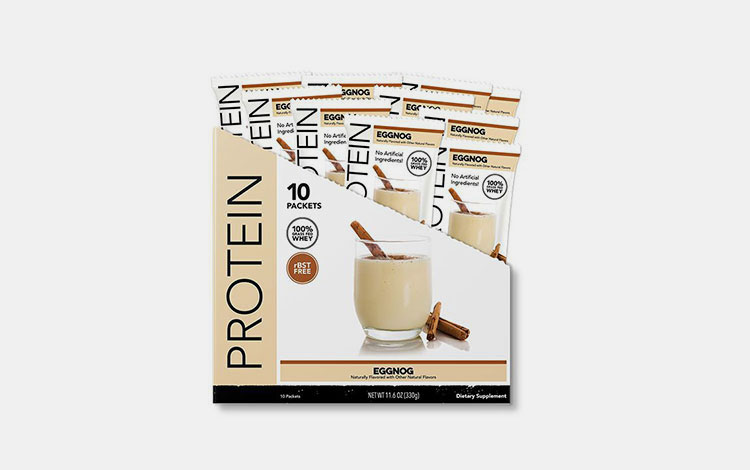

Protein Powder

Protein powder carton packaging- Picture Courtesy: cleansimpleeats.com

Protein powders are obtained from plants, eggs, and milk etc. They are rich in protein and often taken as meal replacement powder. Some of the popular examples include whey protein, pea protein, hemp protein, and milk protein powder etc. All these protein powders are suitable to be processed by this sophisticated production line.

Seasoning Powder

Powder seasoning in bowl- Picture Courtesy: poshjournal.com

Seasoning powders are edible powders which are produced by crushing spices, herbs, along with flavorings. They are used for adding color, taste, and aroma to food like noodle, curry, and other cuisines. As, seasoning powders are often spicy, so, a twelve lanes powder cartoning production line is a good choice to deal with their packaging.

Dye Powder

Natural dye kit

The production line can also process various types of dyes like hair dye, pigment dyes, synthetic dyes, and natural dyes into beautiful single use bags for primary packaging and cardboard boxes for secondary packaging.

4.What Are The Working Principles Of Twelve Lanes Powder Cartoning Production Line?

A twelve lanes powder cartoning production line follows predetermined process for carrying out powder packaging. Therefore, it is based on few working principles whose understanding will help you operate it on the right way. They are as follows:

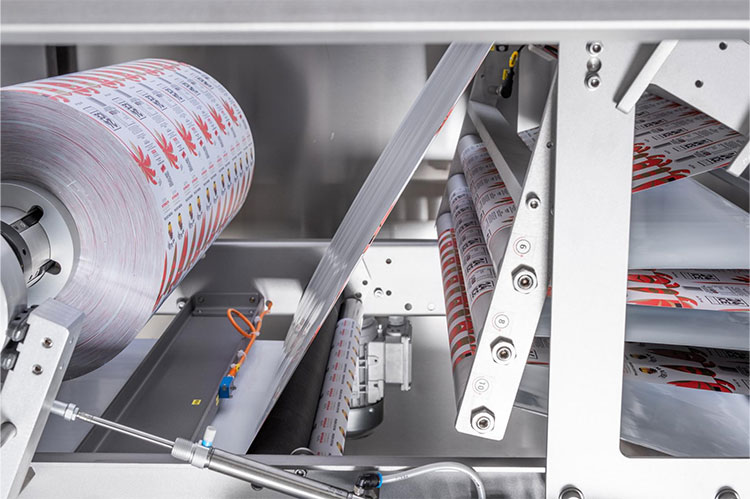

Loading Phase

Film loading into machine

The initial phase includes the loading of different materials into the respective sections of the twelve lanes powder cartoning production line. For this, operator will supply the material hopper with enough volume of powder or connect a feed station for continuous automatic feeding. Moreover, the film roll will be fitted into a film holder, and the magazine of cartoning unit will be loaded with the stock of unformed flat boxes.

Operational Setting

Operator setting machine parameters through touch screen interface- Picture Courtesy: Viking Masek

After loading, the second most essential step to be carried out for operating the production line involves the setting of basic parameters. It takes place when user communicate to the PLC touch screen and fix the data regarding bags length, width, sealing temperature, and cutting style. Similarly, the bag sorting unit has separate control board through which the number of bags to be assembled for each box is settled.

As far as the cartoning machine is concerned, so, it has a separate small computer where operator makes the setting for picking and forming boxes, their filling, coding data, and sealing.

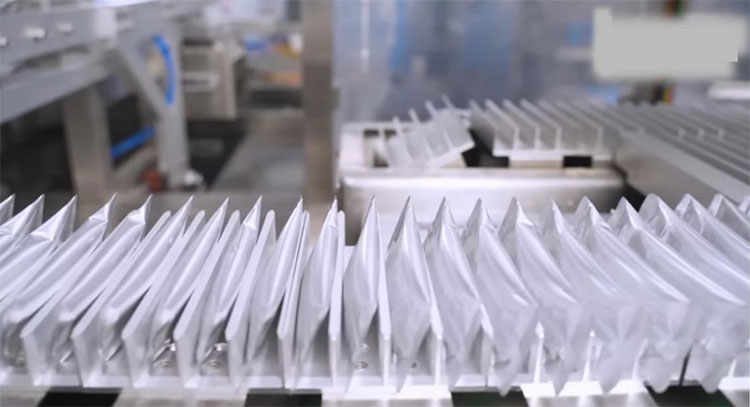

Bags Formation

Bags formation- Picture Courtesy: Viking Masek

Now, the machine is powered on which begin the step of bag formation. As the machine starts, multiple film tension rods also start moving and the film on moving wheel is unwinded. The rollers guide the direction of film and moved it ahead where the film is divided into twelve pieces and each piece of film is wrapped around a cylindrical bag former. Afterward longitudinal and bottom seal is added to these film layers which result into creation of bags.

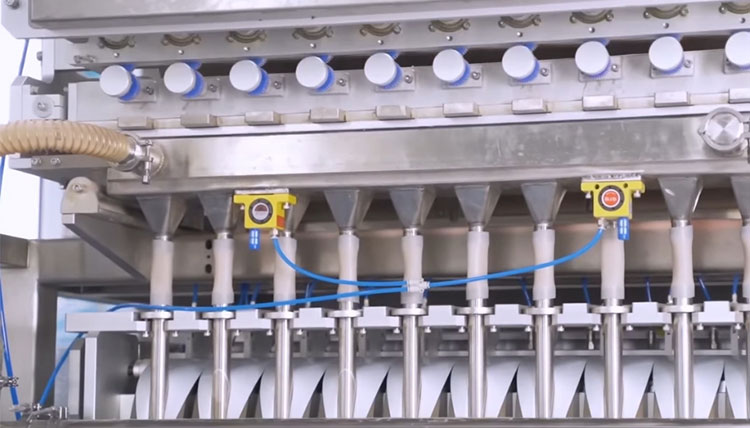

Powder Weighing & Filling

Powder filling into bags- Picture Courtesy: KenHigh

As soon as the bag formation takes place, metering device initiate measuring the amount of powder to be filled in each bag. Similarly, the weighed powder is poured into individual bags through upper feeding tubes in a safe tidy manner.

Bags Sealing & Cutting

Bags cutting and conveying from powder packaging machine- Picture Courtesy: diagraph.com

After filling, the next step is sealing and cutting. Here, the heated pair of sealing jaws come in contact which leads to the creation of stringent sealing on opening of powder filled bags, while forming the bottom seal of next batch. In addition to sealing, cutting is also introduced to the bags for their separation and designing.

Bags Sorting

Bags sorting- Picture Courtesy: KenHigh

At this point, the finished powder packages are ready for entering into another unit for sorting, that's why instead of discharging these bags are mobilized towards sorting machine through a conveyor belt. During sorting, these packages are accurately counted and assembled for next round.

Carton Formation

Carton Formation- Picture Courtesy: WinnTech Pack

Moving forward, the cartoning machine comes into action and start forming carton by picking premade flat box from magazine and undergoing it through intermittently located robotic arms which form carton through opening and bottom flat folding.

Bags Cartoning

Bags cartoning- Picture Courtesy: WinnTech Pack

Now, the most crucial step of bags cartoning is carried out. For this, the sorted group of finished powder packages is supplied to the machine through conveyor belt on one side while cartons on the other. Similarly, each group of packages is inserted into the passing carton through robotic arm and these cartons are sealed one by one.

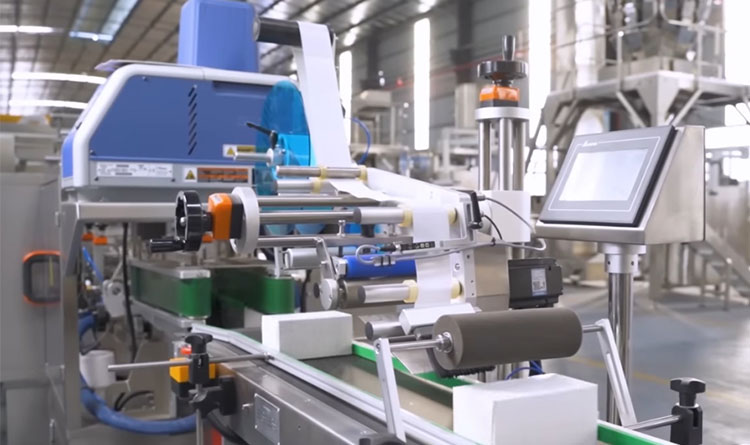

Carton Printing

Carton printing- Picture Courtesy: KenHigh

Upon bags cartoning, the finished bags cartons are passed by the printing unit umahere necessary data such as batch no, manufacturing date, and expiration date are printed over the cartons.

Finished Carton Discharging

Finished carton discharging- Picture Courtesy: WinnTech Pack

At last, the finished powder cartons are discharged from the machine through conveyor belt and collected in a container or processed for further packaging.

5.What Parts Constitute A Twelve Lanes Powder Cartoning Production Line?

A twelve lanes powder cartoning production line is the creation of several machines which are too made from small to large components. That's why, we have come up with this question to provide you a valuable insight regarding all these components and the function each play. So, consider the underlying explanation:

Structure of Multi-lane stick bag counting & cartoning machine- Picture Courtesy: samfull.net

Powder Packaging Machine

Powder packaging machine constitute the very first section of a twelve lanes powder cartoning production line. It plays a significant role in forming bags and undergoing these bags through powder filling, sealing, and cutting etc. It consists of several components including:

Hopper:Hopper is the feeding tank of a powder packaging machine situated on its top. It is in direct contact with bulk powder; therefore, it is made from food grade 316 stainless steel. The function of hopper is to hold powder and supply it to machine during operation.

Weighing System:it is another part of the machine which is responsible for accurately weighing the amount of powder for filling in each bag. The type of weighing system depends upon the nature and flow of powders like free flowing or adhesive powders.

Film Roll:Film roll is a stock of plastic, aluminum, or laminated paper available in form of reel. It is fitted in the machine for bags formation.

Bag Former:Bag former is a cylindrical shape device which is also made from corrosion resistant and antibacterial stainless steel as it is in contact with packaging material. It is useful for bag formation.

Filling Heads:There are twelve filling heads in the machine through which the weighed powder is discharged into individual bags.

Bag Sealer:A pair of bag sealers is available in the machine naming horizontal seal and vertical seal. The former is responsible for making top and bottom seal on bags, while as, the latter make longitudinal back sealing on bags.

Electric Cabinet:There is a heavy-duty machinery fixed into the machine which encases all the electrical components of machine in form of circuits, power boards, and fuses etc. It is known as electric cabinet which ensures safety of machine.

Control Panel:Control panel is a computer like device with touch screen display. It is extremely beneficial for communicating commands to machine. It comes up with latest features of offering multiple languages and can store different settings.

Bag Cutter:Bag cutter is a sharp blade like tool which may come in style shape like zigzag, round, or flat. It is employed for adding cut to finished powder packages for their separation and beautification.

Protection Window:The powder packaging unit of twelve lanes powder cartoning production line have a transparent glass window over its working area. The purpose of this protection window is to enable user for clear observation of machine working as well as restricting environmental pollution to ensure safety.

Bags Counting and Sorting Machine

Bag counting and sorting machine is the second section of a twelve lanes powder cartoning production line. It is pivotal for arranging the finished powder packages into groups by counting. Different parts together help the machine to carry out its function among which the major ones are:

Multi Channel Sorter:It refers of a device having number of compartments which hold inside them individual packages.

Conveying System:The machine has a conveying system which is solely responsible for taking the finished powder packages from powder packaging machine and transporting it towards counting and cartoning unit.

Bags Counting Unit:This part of machine has a detection system which helps in the exact counting of packages as set by the operator.

Bags Assembler:Bags assembler is a device where counted bags are kept until they are inserted into a carton.

Bags Cartoning Machine

The final unit of a twelve lanes powder cartoning production line is bags cartoning machine. Its purpose is to enclose the group of powder packages into a single box. For this, it uses multiple tools which are as follows:

Magazine:It is a station where initial cartons are stacked in flat form.

Robotic Arm:It refers to the device which picks up preformed flat cartons from magazine and place them over conveyor for formation.

Folding Flappers:The machine has folding flappers which are responsible for folding the bottom and top side of cartons.

Guide Rail:It is a type of transmission device which helps in the mobilization of cartons.

Data Coder:Data coder is another important part of the machine which is used for printing variable data the cartons.

Exit Station:It refers to a device which finally discharge the finished bag cartons from machine.

6.Highlight The Uses Of A Twelve Lanes Powder Cartoning Production Line?

Twelve lanes powder cartoning production line has numerous applications due to its adaptability and flexibility that it can process every type of powder. Some of its prominent uses are as under:

Pharmaceutical Industry

Herbal powder for medication

This comprehensive solution is perfectly applicable in pharmaceutical industry where processing of drugs is a routine practice. That's why, it is admired for the effective performance to carry out the primary and secondary packaging of pharmaceutical powders.

Beverage Industry

Instant coffee stick packs cartoning

Beverage industry is also involved in the manufacturing and processing of solid beverage in form of powder. Therefore, to pack such a large amount of juice powder, meal replacement powder, milk mixers, coffee, and energy drink powder in cartons, a twelve lanes powder cartoning production line is ideally suitable.

Food Industry

Various powdered spices

Food industry is a large sector where the use of a twelve lanes powder cartoning production line is inevitable. It is because, products like condiments, milk powder, tea, coca powder, and food additives are often delivered in powdered form. Thus, the packaging requirement is high which can be only fulfilled by using this advanced solution.

Nutraceutical Industry

Nutraceucal powder carton packaging- Picture Courtesy: nutribullet.com

Another notable application of the production line is nutraceutical industry where protein, calcium and vitamins are obtained from fruits, nuts, and seafood etc., and delivered in form of powder for instant use. Therefore, the best way for their preservation is to give them highly secure packaging which is only possible by employing this equipment.

Cosmetic Industry

Cosmetic powder carton presentation idea

Cosmetic industry is also growing rapidly so as its packaging needs for which a twelve lanes powder cartoning production line is always recommended. Hence, the common examples of products we see being packed it include hair dye, black powder, facial powder, and facial clay etc.

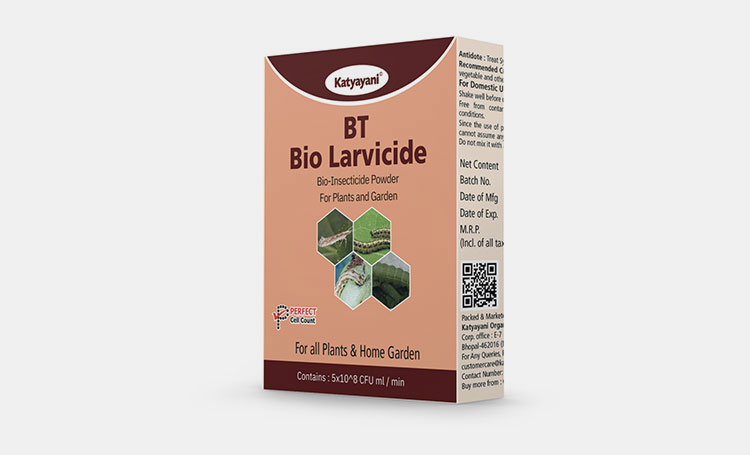

Chemical Industry

Pesticide powder carton- Picture Courtesy: plantlane.com

Like other fields, the spectrum of chemical industry is also very extensive. Products like pesticides, herbicides, organic chemicals, and pigments etc., are all can be defined as chemicals. That's why, they require safe environment for packaging to avoid damage to users and surrounding and this is outstandingly accomplished by the enclosed body of a twelve lanes powder cartoning production line.

7.How To Maintain A Twelve Lanes Powder Cartoning Production Line?

Regular maintenance is crucial for keeping your twelve lanes powder cartoning production line at good working condition. Therefore, you should be ready to take relevant measures for drafting a schedule and conducting a proper maintenance system for your solution. In this way, underlying guidelines will be useful:

Maintenance icon- Picture Courtesy: gesrepair.com

Cleaning:Cleaning is very important for ensuring the efficiency and safety of your twelve lanes powder cartoning production line. For this, it is necessary to only use the cleaning products as recommended by the producer to avoid damage to any part.

Moreover, during cleaning, make sure to accurately remove out the dust, dirt, and residues left or accumulated in machine. Parts like hopper, filling nozzles, and sealing jaws should be given priority.

Lubrication:Lubricating your production line with recommended oil or grease greatly helps in reducing the friction and possibility of wear and tear also disappear. It is also very useful for enabling every movable part to work freely.

Setting:It refers to both the parameters setting and structural setting. So, be careful when operating your twelve lanes powder cartoning production line. Make sure to check each unit is well-connected through wires and other devices. Along with that, each time when you begin operation, keep checking the parameters setting and adjust accordingly.

Parts Changeover:At any point, your twelve lanes powder cartoning production line may start malfunctioning due to parts breakdown or failure. In such case, it is obligatory to take notice of the part and replace it timely to avoid further damage.

8.What Quality Standards Should A Twelve Lanes Powder Cartoning Production Line Meet With?

As twelve lanes powder cartoning production line is meant for dealing with food and non-food powders, it must adhere certain quality standards in order to be safe and hygienic. In this way, international community has established few quality standards whose compliance guarantees the safety of machine being made. These include:

ISO standard logo- Picture Courtesy: arenasolutions.com

International Organization for Standardization (ISO)

ISO is an international organization established for developing standards which circulate around the globe. It has many bodies regulating in over 160 countries. Thus, your machine must be certified by ISO.

Food And Drugs Administration (FDA)

FDA is another important agency created for ensuring public health safety by keeping strict principles for all the goods and machines being associated with food and drugs.

Current Good Manufacturing Practices (cGMP)

Under the auspices of FDA, rules and regulations with the name current good manufacturing practices are employed to assure the quality, identity, and purity of drugs products and equipment. Similarly, a twelve lanes powder cartoning production line certified by cGMP validate its advanced technology with updated quality standards.

Conformate European (CE)

CE is yet another quality standard obligatory for all the goods and products which are produced in European Union countries or meant to be sold there.

9.Troubleshoot The Common Errors Of A Twelve Lanes Powder Cartoning Production Line?

There are always possibilities that your twelve lanes powder cartoning production line may show inconsistencies during operation in different forms and due to various reasons. However, regardless of whether the issue is small or large, it can have serious consequences on your packaging. Hence, it is better to understand what these problems are and how to solve them. For this, follow the upcoming explanation:

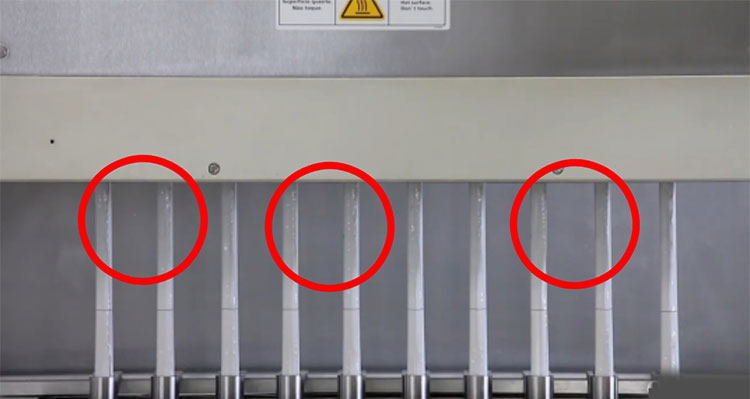

Improper film tracking

Displaying film tracking error- Picture Courtesy: KenHigh

Causes

Automatic film tracking system is not working.

Bags forming tubes are either damaged or installed improperly.

Film pulling rollers and belts are not set up properly.

Solutions

Check the setting in touch screen interface and reset it for proper functioning.

Check the forming tubes and install them properly. In case of damage, replace them with new ones.

Readjust the film pulling rollers and belts for accurate functioning.

Powder filling inconsistency

Highlighted powder filling mechanism- Picture Courtesy: Optima Packaging

Causes

The powder may be cohesive due to which it creates bridges inside hopper.

The powder is not well set, especially in case of cup fillers which results in weight variability.

Solutions

In case of cohesive powder, it is better to use agitators and small vibrators to break ratholes.

For this, adding the flowing agent into powders will be good. Apart from this, changing the design of hopper from conical to wedge will also resolve the issue.

Leakages of packs

Powder package leaking

Causes

The major reason is powder being trapped between two sides of the film due to dust.

The sealing jaws may generate inconsistent temperature which result into weak, partial, or burned resulting in powder spilling from pack.

Solutions

It can be tackled by reducing the level of dust generated by powder during filling and also the integration of dust aspiration system will restrict powder from dispersing.

It is a serious problem and should be quickly countered by adjusting the temperature of sealing jaws to suitable level.

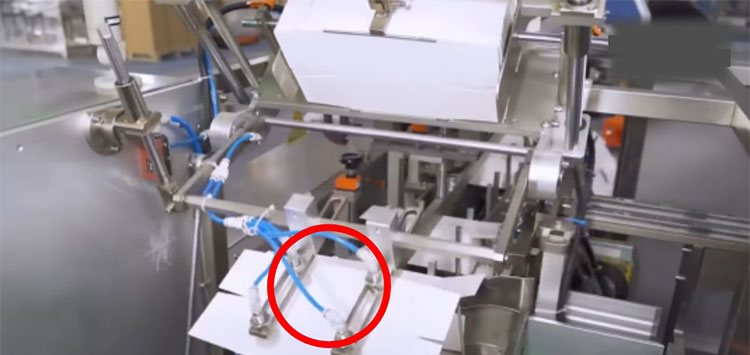

Problem in carton sucking

Carton suction process- Picture Courtesy: KenHigh

Causes

The air circuit might be leak causing air to escape and thus making the force unable to suck cartons.

The carton suction head may be aging.

Low vacuum pressure results in poor sucking.

Solutions

Check the air supply pipeline for possible leakage and replace if the leak is big.

Replace the suction head for effective gripping of cartons.

Increase the air pressure for proper functioning of suction cup.

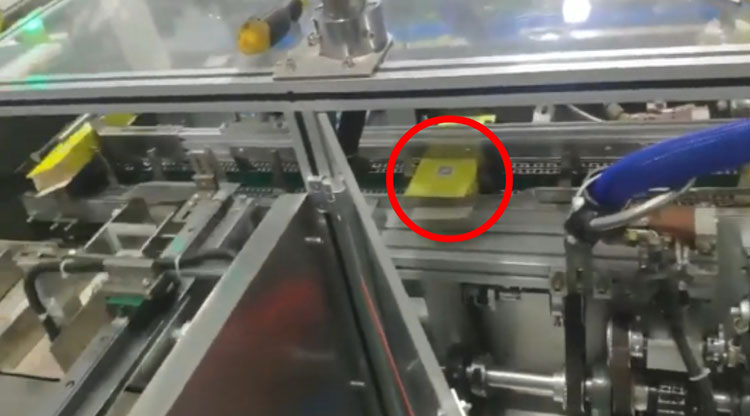

Carton formation issue

Encircled carton during formation- Picture Courtesy: WinnTech Pack

Causes

The carton is too hard due to weak indentation which causes difficulty in carton formation.

The position of carton placing guide rod and feeding template is not correct.

Solutions

You need to use cartons with proper indentation.

Adjust the position of guide rod and carton feeding template.

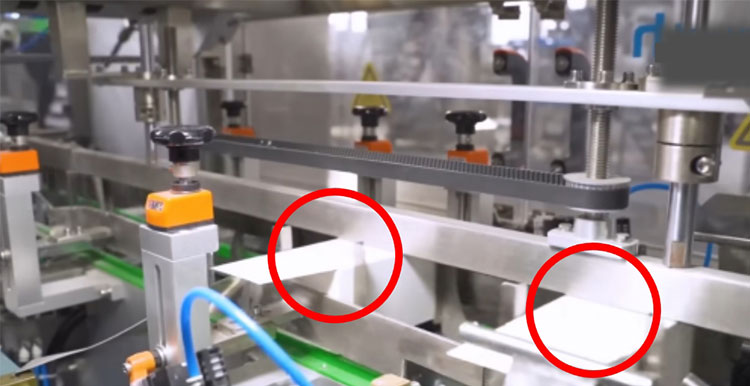

Intermittent stopping of conveyor

Carton conveying on transmission device- Picture Courtesy: KenHigh

Causes

There might be shortage of carton feeding material or cartons.

The machine may be shut down due to inadequate or poorly connected power supply.

The transmission gear is damaged or broken.

Solutions

Check and supply the machine with required material for functioning.

Supply adequate electricity to machine and connect it properly.

Replace the transmission gear along with adjoined chain.

10.How To Choose The Most Suitable Twelve Lanes Powder Cartoning Production Line?

When choosing a twelve lanes powder cartoning production line, you may feel haphazard to opt for which one. Therefore, we have tried to make this decision an easy for you by displaying some of the instrumental factors for consideration. These are as follows:

Speed

Multi-lane Powder Cartoning Production Line

It is important to check the speed of a production line which you intend to purchase. It is because there are multitude of solutions available in market, however, each equipment has different speed. The speed also depends upon the material being processed. For instance, large size packages with designed cutting may require more time. Hence, checking the speed of production line is important.

Cost

Another significant aspect to look for is the overall expenditure of buying a twelve lanes powder cartoning production line. It will include the exact price of equipment along with installation, maintenance, and operation cost. So, make sure to fully satisfy yourself by asking every possible question from vendor regarding the cost you will have to pay.

Flexibility

Applications of a twelve lanes powder cartoning production line Various powder stick packs along with cartons- Picture Courtesy: KenHigh

When choosing a twelve lanes powder cartoning production line, it is crucial to check the ability of equipment to deal with different types of materials. The more the equipment is adaptable the higher will be chances to deal with variety of products and packaging formats. Similarly, the flexible production line will be the best compatible to meet your packaging needs in the future.

Warranty & Assurance

Warranty icon- Picture Courtesy: ctcu.com

Buying a twelve lanes powder cartoning production line means transforming the fate of your business. In such a case, it is your prime responsibility to pay attention to all the formalities directly and indirectly associated with its quality. In this way, warranty policy is one of the eminent things to consider.

Conclusion

So, it's time to wrap up this piece of information about a Twelve Lanes Powder Cartoning Production Line with a reminder that no matter it's a food, medical, or beauty care industry, this production line is applicable. Where efficacy, quality, and hygiene are important, understanding the structure, working process, and maintenance methods are also very useful. So, make sure you have gone through all the data provided above. Still, if you have any query or want to know more about a Twelve lanes powder cartoning production line then leave us a message we will answer it shortly!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide