Your Premier Transparency Tester Supplier

- Enhances Operation Traceability and Efficiency

- Enhances Proper Company Identity

- Reduces Risks Associated with Transparency

Transparency Tester

Allpack Transparency tester is applying to test the light transmittance, transmission haze, and reflection haze, reflectivity of transparent and semitransparent parallel level material and plastic films. Also it is suitable for liquid samples (water, beverage, pharmacy, colored liquid, grease) turbidity measurement. It is the basic instrument for plastic, glass products, all kinds of transparent packaging films, colored and colorless of organic glass and aerospace, automotive glass and photographic film.

Allpack Transparency Tester

Touch Screen Of Transparent Tester Light Transmittance Gelatin Testing Machine

Allpack Transparency tester adopt the parallel lighting, hemispherical scattering, and integral ball photoelectric receiving mode. The microcomputer automatic controls test system and data processing system, convenient operation, no knob, and a standard print output pull, automatically display the average value of transmittance /haze repeatedly measured. The transmittance results is up to 0.1%and the haze degree is up to 0.01%.No zero drift, confidence is strong, the specific structure- Open sample window is almost not limited to sample size, fast measurement speed.

Thoroughly eliminating the influence to results by environment.

Sample being conveniently taken out or put in by using standard test tube.

Airtight light source system.

The Buyer's Guide

Transparency Tester: The Complete Buying Guide In 2025

Do you want to check the transparency of softgel capsules? Or are you interested in making your quality control more strict for determining the objects transparency level? If yes! You are at the right place! Your concerns can be easily addressed by simply employing a transparency tester.

This innovative device can greatly help in examining the transparency of wide range of products. With simple structure, convenient operation, and maintenance schedule, you will get benefited by using this equipment. So, be ready to embark on this beautiful journey of exploring latest transparency tester!

1.What Do You Understand By Transparency?

Hand holding transparent round ball reflecting buildings- Picture Courtesy: myzeo.com

Sometimes, we get confused when hearing the term transparency and often substitute it with other terms. However, that's not the case! By transparency we simply mean the condition of being transparent. For instance, an object can be called transparent if it can pass lightening through it. Now, the level of transparency vary from one type of object to another for which a transparency tester is used.

To put it in simple words, transparent beakers are always used for testing liquids instead of opaque ones. The only reason is because transparency of the beaker allow to notice the changes made.

Similarly, a transparency tester is used for all the objects which are meant for transparency from plastic to glass and drugs like softgels.

2.What Is A Transparency Tester?

Transparency tester

Transparency tester is an automatic equipment tailored with astonishing features to examine the transparency of various objects. These include all the items which are clear and reflect light such as softgels, glass, and plastic etc.

As the transparency level is considered eminent during production, this device can greatly help in displaying accurate information by employing its sensors for detection. It consists of few components, thus, having small footprint and easy working procedure. Moreover, this transparency tester is applicable in different industries.

3.What Is The Role Of A Transparency Tester In Pharmaceutical Industry?

Laboratory testing of softgel capsule- Picture Courtesy: soft-gel.com

Pharmaceutical industry is an area with consistent demand for immense responsibility and hygiene throughout production. It demonstrates the value for accuracy and precision which is relevant in terms of drug manufacturing and associated tools. Similarly, transparency tester is considered a key instrument for various reasons.

Firstly, it helps in detecting the transparency of most sensitive dosage form that is softgel. Since, softgels are often opaque and holds essence and liquid mixture, this device can help in detecting even the minor irregularities that are existing.

Secondly, certain plastic and glass gadgets like sampling glass, tubes, and containers are continuously used in medical sector. Thus, it becomes obligatory to conduct a proper quality testing for them. Here, is where the importance of a transparency tester is realized to take the charge and provide essential data about object transparency.

4.Write Down The Benefits Of A Transparency Tester?

Transparency tester is a sophisticated machine that carries in it myriad of benefits both in terms of structure and performance. These advantages are enlisted below:

Simplicity

Simple softgel transparency tester- Picture Courtesy: es-france.com

The foremost attribute of a transparency tester is its simplicity that can be seen by looking into its precise structure. The design of the tester is quite simple with few components which make its operation easy to conduct without requiring special training. Moreover, it occupies less space and little maintenance so you can place it anywhere you want.

Improve Quality Control

Quality control inspection- Picture Courtesy: deskera.com

The prime purpose of using a transparency tester is basically to comply established standards and identify your product as a quality product in the market. In this way, a transparency tester help you to improve the quality control by tracing errors, so, they can be easily reduced.

Enhance Efficiency

Softgel processing on large scale- Picture Courtesy: pharmaceutical-technology.com

Particularly in pharmaceutical industry, you need to undergo the products through series of testing for quality production. Similarly, it becomes necessary for the desired testing equipment to be efficient and effective in performance. This quality you will easily fine in a transparency tester which facilitate quick testing of various objects and save your time.

Cost-effective

Cost-effective image- Picture Courtesy: Freepik

Most of the manufacturers worry about the labor intensity and operation complexity of machines, especially in pharmaceutical sector, as they lead to increase in overall production cost. In such a scenario, equipment like transparency tester proves to be an ideal instrument that helps you in cutting down extra cost by offering an economical way for testing.

High Accuracy

Red softgels- Picture Courtesy: stylecraze.com

Another most crucial benefit of a transparency tester is its high level accuracy during testing. By employing high resolution light and premium sensor, it can display you the minute change being recorded during testing. Thus, the overall testing accuracy is high.

5.What Things You Can Test By A Transparency Tester?

A transparency tester can test any type of object which is transparent. These include wide range of items encompassing drugs like softgels and other objects including bottles, vials, ampoules, and sampling glass object. You will know their explanation in upcoming paragraphs:

Softgel Capsules

Various softgel capsules- Picture Courtesy: Vitalfoods Insights

Softgel capsules refer to the liquid based capsules which are characterized by their gel like soft outer shell holding inside it a liquid dosage. Mostly, softgel capsules are having transparent shell through which the inside content can be easily seen. Similarly, during their production, the transparency level is checked for which a transparency tester is capable.

Glass

Glass sample set- Picture Courtesy: halbe-rahmen.de

Glass is among other objects which can be tested by using a transparency tester. As glass is considered more hygienic and safe against microbes and bacteria, medical industry is frequently using it for packaging of liquids as well as solid formulations in form of ampoules, vials, and bottles. Apart from this, glass is also used for sampling and in screens. Thus, its transparency is crucial to check.

Plastic

Plastic testing tubes- Picture Courtesy: vmandk.co.za

In addition to glass, plastic is also popularly used in various industries for being transparent such as eye lenses and illumination lights etc. Since, these uses of plastic is associated with its transparency, a transparency tester should be used to determine that desired level.

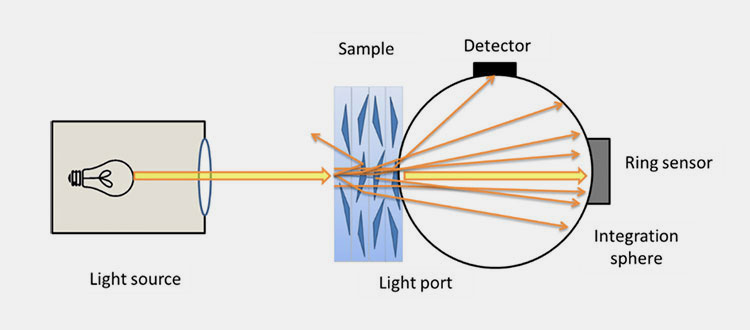

6.What Are The Working Principles Of A Transparency Tester?

Although, the working principles of a transparency tester is quite easy, you need to pay attention to few things which will definitely help you in conducting a successful operation. So, let's figure out these details in underlying steps!

Tester Setting

The very first thing you need to do is to set your transparency tester. For this, it is important for you to have a prior knowledge regarding the arrangement of tools inside the tester. So, take start from checking the location of light source if it is on right place then do check the detector arrangement for accurate working. In addition to it, set the batteries on exact place.

Object Placement

Once you are done with the setting, just pick up your object and place it inside the tester location in a right direction. Press the power button on front, and the testing process will get started.

Transparency Detection

Detection of transparency tester- Picture Courtesy: researchgate.net

As soon as the tester is powered on, the light source will initiate generating the illumination towards object. Now, this lightening is reflected on opposite side which in turn is detected by the powerful sensor. The sensor convey information about the smallest possible changes to the computer processor.

Final Results

The complete information about the transparency level of object is sent to computer processor and it will be displayed to you via display. Hence, the tested gets completed and you can simply remove out your object from the tester.

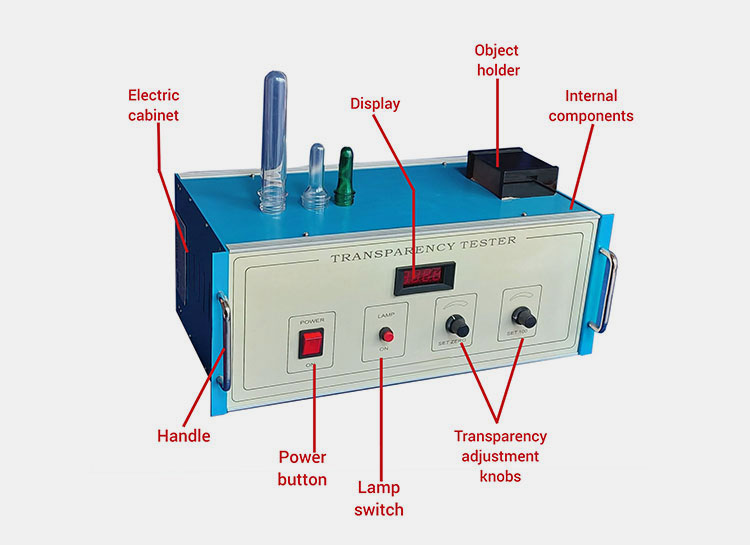

7.Describe The Components Of A Transparency Tester?

A transparency tester is made of different components each playing its distinct role to done with the testing. The major parts along with their functions are explained below:

Components of a transparency tester

Electric Cabinet

Electric cabinet is the enclosure where electrical system in form of wires is integrated into the transparency tester.

Handle

It refers to the durable stainless steel handles which are attached to the machine for carrying it.

Power Button

It is a red color button located on the front side of transparency tester with upper and lower marks for power on and off respectively. Pressing it on simply energize the tester to start and vise versa.

Lamp Switch

Lamp switch is another button on the control panel which is used to illuminate the lamp on display so you can see the digits over screen.

Transparency Adjustment Knobs

There are two scrollable knobs situated alongside the lamp switch with set zero and set 100 marks. The former is used to adjust the transparency level to zero, while as, the latter is used to fix the transparency level to 100.

Internal Components

There are some critical components of a transparency tester inside the machine which cannot be seen apparently, however, they play key role in testing. These include:

Light Source:It refers to the device from where light is derived. It is an important part that is used to test the object by putting intense light over it.

Sensor:Sensor is another important component which perform the function of detecting changes in the transparency level of particular object.

Computer Processor:It is the brain of a transparency tester which calculate final data and manifest it through digits on screen.

Object Holder

Object holder is a type of compartment where desired tool like glass bottle or other tool is placed for testing.

Display

It refers to the digital screen that display over it final results in form of illuminated digits from zero to 100.

8.What Are The Uses Of A Transparency Tester?

The applications of a transparency tester are so many that you will find its use in every second industry associated with any kind of pharmaceutical, cosmetic, plastic, and glass processing. However, we have made it easy for you by highlighting the prominent sectors. These include:

Pharmaceutical Industry

Omega-3 fish oil softgels bottle- Picture Courtesy: ubuy.com.pk

Pharmaceutical industry is an area where adherence to strict quality standards has made the use of testing instruments a necessity. In this way, the use of a transparency tester is also prevalent here for various items including softgels, ampoules, vials, and bottles etc.

Optical Industry

Various eye glasses- Picture Courtesy: allaboutvision.com

Eye lenses used for weak eyesight are made from plastic or glass. Similarly, sunglasses are also used for eyes which means they are associated with something really sensitive. Hence, opticians use transparency tester to determine the clarity of glasses to the level that is suitable for human use.

Plastic Industry

Plastic testing tubes

Plastic industry is huge enough to cover all the areas. However, in this particular subject of application for transparency tester, we can simply talk about those plastic items which are frequently tested by using this instrument. These include plastic bottles, plastic sheets, and clear packaging films etc.

Automotive Industry

Automotive industry- Picture Courtesy: bopwindscreens.com

Automotive industry is also among the notable users of a transparency tester where the production and processing of windscreens is common. For their proper transparency tester, this equipment is used, so, as to find how clear the windows can show outside picture especially for traffic purposes.

Electronic Industry

Various fluorescent bulbs- Picture Courtesy: stouchlighting.com

The use of a transparency tester is not only confined to pharmaceutical and optical industry, rather electronic industry is also included in the list. In fact, electrical bulbs, tube light, tv screens, computer screens, and mobile screens are all the objects which need a compulsory transparency testing during their processing.

9.What Quality Standards Are Necessary For A Transparency Tester?

As far as the necessary quality standards for a transparency tester are concerned, so, there are few notable ones which a quality tester should adhere. These are enlisted below:

Quality standards icon- Picture Courtesy: pdj-consulting.com

National Standard:A transparency tester should meet the National Quality Standards for food additive gelatin which is GB6783-94.

Vocation Standard:Vocation Standard is another important quality standard for a transparency tester that is specifically designed for medicine gelatin. Thus, the fix standard for it is QB2354-98.

International Organization for Standardization:ISO is the most popular regulatory body on international level which is an additional standard that must be complied by a transparency tester.

Good Manufacturing Practices:GMP and cGMP are other such standards whose principles adherence indicate the high quality of advanced equipment.

Conformate European:Transparency tester manufactured or imported by any one of the European Union countries must be certified by CE.

American Society for Testing and Materials:ASTM is the most important quality standards in terms of testing instruments. In this way, a transparency tester must have compliance to it.

10.What Is The Maintenance Requirements Of A Transparency Tester?

Although, a transparency tester require little maintenance, you still need to focus on its daily schedule for cleaning and maintenance. It will help you keep it on good pace while reducing the chances for damages. In this way, underlying tips can be helpful:

Maintenance requirements- Picture Courtesy: privatehomemanagement.co.za

- Clean the tester on daily basis to remove out impurities and debris that may obstruct the way for quality testing.

- Check for missing, broken, or damaged parts during operation and timely replace such parts before they affect other areas of the tester.

- Make sure to set the parameters each time before you start testing. It will help you conduct an error free operation.

- Keep checking the batteries for charging and charge them timely. In case of batteries depletion, make sure you have calculated the time properly before replacement.

11.Factors To Look For When Buying A Transparency Tester?

If you want to buy a cutting-edge transparency tester for your manufacturing facility, then try to avoid making blind decision. In this way, the only way that can help you is to consider some important factors such as:

Size & Thickness of Object

As we have mentioned above, transparency tester can deal with range of tools with varying sizes, weight, and thickness. So, what you need to do is to simply know these specifications of the specimen which you will be testing by using this instrument. Its purpose is to select a device that is offering same configurations which you require.

Dimensions of the Tester

Dimensions of a transparency tester- Picture Courtesy: perfectgroupindia.co.in

Transparency tester is available in different dimensions especially in terms of light source and sensor sensitivity which are two inevitably critical aspects. Thus, you should ask your vendor to show you the model as per the requirements of your items for effective testing.

Testing Range

Another significant factor to look for is the testing range. Definitely, transparency tester do come with various ranges. For instance, if you want to test gelatin then you should determine the testing range which is often between zero to 100 with a standard transparency tester.

Quality Compliance

Quality checking image- Picture Courtesy: centerwatch.com

Adherence to necessary quality standards is also very important as it ensures the safety of equipment for your concerned objects. Apart from this, it is also necessary for you as a manufacturer because being an entrepreneur ask you to have proper certification regarding quality of machines.

Conclusion

To put in a nutshell, Transparency Tester is becoming key instrument in areas such as pharmaceutical industry, optical industry, and other hardware industries. With growing technological advancements, quality control is becoming more more uplifted in order to ensure a safe life for consumers. In such case, dynamic and versatile testing equipment like transparency tester is becoming more important. So, if you are interested in purchasing it, then make sure to consider a reputable supplier like Allpack which offer you wonderful solutions withone year of complete warranty and quality certifications. For further information please contact us!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586