Top 8 Worldwide Blister Sealing Machine Manufacturers: The Ultimate Guide in 2025

Have you ever wondered how the Tables and Capsules are packed and sealed when you take them? Or have you learned about the blister sealing machine before?

This blog will tell you the answers about this kind of machine manufacturer’s details, products, and recommended reasons for the brands and products.

We have listed the top 8 worldwide blister sealing machine manufacturers that you may want to know, and let’s have a look!

Top 8 manufacturers of blister sealing machines in the world

The blister sealing machine uses the principle of heat sealing to seal the blister and paper card made of PVC, PE, PP, PET, and HIPS materials. It’s suitable for the packaging process such as toys, stationery, foods, commodity, cosmetics, hardware, medicine, etc.

Here is the top list of manufacturers:

| RANK | MANUFACTURES OF BLISTER SEALING MACHINE | HEADQUARTERS |

| 1 | HAMER | Swiss |

| 2 | GTE | Netherlands |

| 3 | ALGUS | Illinois, USA |

| 4 | ALLPACK | CHINA |

| 5 | VISUAL PACKAGING | Texas, USA |

| 6 | NEW TECH | Tennessee, USA |

| 7 | PIEDMONT NATIONAL | Indiana, USA |

| 8 | PYRAMID PACKAGING | Illinois, USA |

1.HAMER

Company Background & Information

HAMER is a European company founded in 1980 by the Schiess family of Swiss origin. It is currently run by the second generation together with a team of experienced professionals dedicated to providing solutions to your packaging needs. In their facilities, they design and manufacture equipment for the packaging market, especially thermoforming machines for the production of single-use plastic packaging, as well as automatic and semi-automatic lines for the production of blister packs.

Key Products

Blister Heat Sealing Machine HC63

Blister heat sealing machine HC63 is suitable for the manufacturing of face-seal blisters (blister to a single backing card) or trapped blisters (sealed between two cards).

Blister heat sealing machine HC63 integrates all the necessary operations for the sealing of a blister, from bubble feed, through loading of the product, sealing, and to the expulsion of the finished blister.

Recommend Reason

- With more than 40 years in the market, they can give you the experience that guarantees solutions.

- Their commitment is to solve your problems, which is why they offer tailor-made solutions, that suit your needs.

- Able to propose the design you need, and advise you on the selection of the most suitable solution.

- Will manufacture the mold that optimizes the performance and they will carry out the commissioning and starting up, guaranteeing control of the whole process.

- During the life of the equipment they will accompany you giving the necessary technical support at all times to ensure the correct operation.

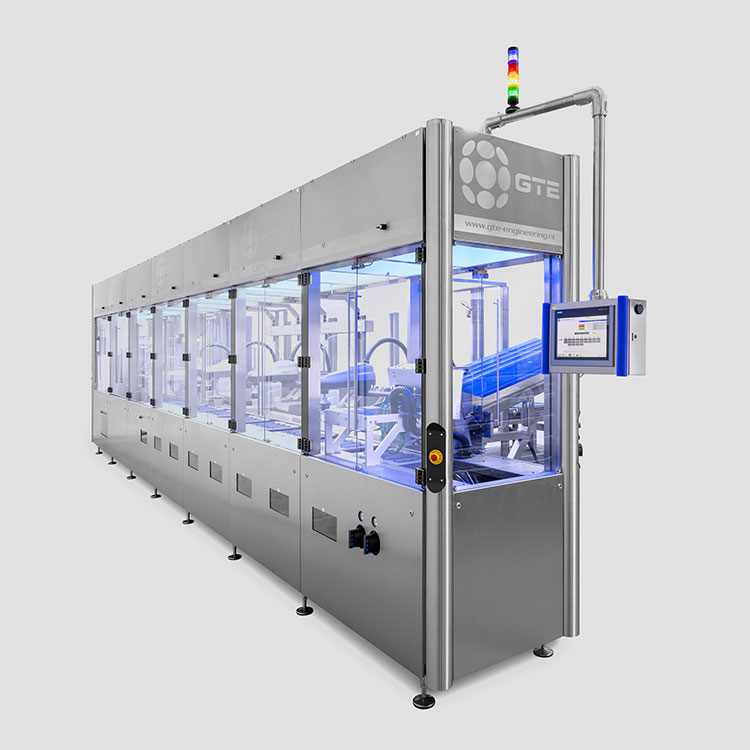

2. GTE

Company Background & Information

GTE-engineering is a supplier of assembly and packaging solutions for the healthcare industry. They design and create tailor-made machines for the assembly, packaging, and handling of drugs and medical devices. The first step in their process is analyzing your needs and wishes. Then they can provide both stand-alone and integrated solutions for your business.

Key Products

LAP-L Blister Fill and Seal Machine

GTE developed the LAP-L blister fill and seal machine for customers who automatically wanted to fill and seal two different blisters with each of their own configurations. The machines are flexible and quickly adjustable to various configurations. And the customer asked for the smallest possible footprint within the available space in a clean room.

Recommend Reason

- By acting as a full-service project manager, GTE is able to select the best production methods and develop multidisciplinary machines.

- GTE can realize inventive solutions that cut production time and costs, increase your competitive advantage, and tap into new markets.

- GTE can give your project a creative technological boost.

- GTE invent and develop new concepts that fit your needs so that you can continue your business operations fully prepared for the future.

3.ALGUS

Company Background & Information

Algus Packaging was established by Art Gustafson in 1995. This Algus Packaging property consists of a 115,260 SF Manufacturing/Distribution Warehouse and sits on approximately 15 acres. Algus Packaging encompasses over forty years of experience in the heat seal and thermoforming packaging industry. This company utilizes its 330,000-square-foot facility in DeKalb, Illinois to meet the unique needs of packaging customers. They are centrally located on two major interstate corridors, with rail access to Union Pacific.

Key Products

Algus Power Shuttle Sealing Machines

Algus Power Shuttle Sealing Machines are designed to meet the demanding seal specifications of difficult-to-seal multi-tray medical packages. The sealing process is completely validated using independent instrumentation which monitors sealing dwell time, temperature, and pressure variables. The compact design fits conveniently on 3.0*4.5 of floor space. The precise and repeatable operation guarantees maximum production results along with compliance with the most demanding quality specifications.

Universal 8 Medical Blister Seal Machine

Medical Blister Seal Machine is designed for a broad range of applications for medical devices, pharmaceuticals, and related industries. This machine can be used for carded pill packs, clinical trials, unit doses, foil lids, specialty films, conventional carded blister packs, and custom sealing.

It can provide flexibility that optimizes its performance and investment cost. This unique modular design allows for multiple machine configurations, alterations, and expansions based on your unique needs and growth. Servo-operated modules allow for “plug and run” reconfiguration without requiring any change to the other modular units.

Recommend Reason

- Algus Packaging property consists of a 115,260 SF Manufacturing/Distribution Warehouse and sits on approximately 15 acres.

- With a strategic Midwest location, Algus can provide a cost-effective solution to your business’s logistical needs by receiving products and distributing them to the entire nation economically.

- Products and services are within a day’s travel of 80% of the Midwest’s major population center.

- Machine technicians are available to assist with any packaging complication, as well as packaging systems development and design.

- CNC vertical machining centers perform blister form tooling, samples, and machine parts–supplying you with high-quality tooling with quick response times.

4. ALLPACK

Company Background & Information

Allpack is a professional packaging equipment manufacturer with 11 years of experience in packing machine labeling, and they focus on round bottles. The company covers a range of production areas like Carton Packaging, Sealing, Strapping, Vacuum Packaging, Capping Packaging, Labeling, Pharma Machinery, Coding, and Marking machines, and so on. They can solve & support your packaging equipment challenges, so you can grow your business.

Key Products

Blister Sealing Machine / XBF-500

Blister Sealing Machine XBF series blister sealing machine is widely used for blister packing of hardware, toys, small articles of daily use, and electronic components. The products after packing are visible and eye drawing, damp-proof, dustproof, secure, etc.

Blister Sealing Machine / XBF-750

Blister Sealing Machine XBF-750 automatic-high speed blister packing sealing machine is suitable for transparent PVC attracting models and reverted card seals together. It is transparent, artistic, moisture-proof, and dust-proof, guarding against disperses after the product seals packing. It is widely used in hardware, toy, stationery, eyeglasses, battery, handcraft, and so on.

Recommend Reason

- With service of free shipping and return service, a money-back guarantee, Online support 24/7, and secure payment.

- Provide massive and professional machinery and equipment. Various machines can provide different models to meet your different professional needs.

- With the complete shop and return policies to meet your unsuitable machine needs. Responsible for the entire shipping and delivery procedures and procedures, and deliver it to your home or company with peace of mind.

- Responsible for all after-sales problems. Provide you with a safe, secure, and trustworthy environment.

5.VISUAL

Company Background & Information

Visual Packaging is based in Dallas Texas and is known for developing enhanced equipment with superior automation and efficiency. The internal R&D and Product Development team has allowed the company to concentrate on matching machine designs to your needs. Visual Packaging is always to be a premier Packaging Machinery Manufacturing Company. Visual designs and manufactures a wide range of Packaging Machinery, Materials, Parts, Tooling, and Components expertly adapted to your requirements.

Key Products

Shuttle Type Heat Sealer Blister Sealing Machine

The Shuttle Type Heat Sealer Blister Sealing Machines are available in two different standard sealing areas of 14*18 inches and 18*24 inches. These high-quality sealers are ideal for startup companies, backup equipment, cellular production lines, or low-volume in-house packaging. The Shuttle Type Heat Sealer Blister Sealing Machines are available in one or two-station shuttle-type sealers utilizing quick-change ceiling fixtures.

Large Semi Automatic Rotary Blister Sealing Machine

The Large Semi Automatic Rotary Blister Sealing Machines are designed to include an optional automatic card feeding system and an automatic package discharge system. Their modular plug-and-play type design allows these units to be added to existing ESDSC Series machines at any time. These machines can be ordered without these options when lower production rates are needed.

Automatic Carousel Heat Sealer Blister Sealing Machine

Automatic Carousel Heat Sealer Blister Sealing Machines are ideal for high volume or JIT production. Given the proper conditions, these machines are capable of up to 18 cycles per minute in production. Automatic Carousel Heat Sealer Blister Sealing Machines are built with the capability to feed blisters, blister cards, and discharge finished packages when proper tooling is installed.

Recommend Reason

- Visual designs and manufactures a wide range of Packaging Machinery, Materials, Parts, Tooling, and Components expertly adapted to your requirements.

- Visual Packaging desires to be your partner in providing Packaging Machine Solutions to best suit all your packaging needs.

- Packaging Machine Solutions by Visual Packaging Manufacturer in Texas, USA for over 40 years.

- Most of the standard packaging machines are now available from stock or with short lead times.

- Visual Packaging has settled into its home in Texas and building inventory to meet the exacting demands of your packaging machinery clients.

6. NEW TECH

Company Background & Information

New-Tech packaging has stayed on the cutting edge of technology in the packaging industry since 1984. They leverage these ever-evolving technologies to build strong customer partnerships, to offer specialized and creative packaging, and to satisfy you by continuously meeting your needs. New-Tech approaches packaging differently by assessing the bigger picture of how your packaging materials and processes impact your revenues and expenses.

Key Products

Automatic Blister Sealing Machine

Automatic Blister Sealing Machines allow for a great deal of customization while increasing operational efficiency. This style of packaging is produced by this machine and cannot be created manually. Organizations that want to tap into the many benefits of blister packaging will need to have an automatic blister-sealing machine on-site.

Blister Sealing Machine

You can load packages into the Blister Sealing Machine and a custom fixture to keep the plastic clamshell or blister and the cards in place. The plastic blisters and cards are automatically inserted into the machine fixture, reducing the labor cost of manually placing them. As the machine advances, it will seal the clamshell and then seal the blister card. You can also seal one card to another with the blister sandwiched in between.

Recommend Reason

- At New-Tech, they understand the importance of your packaging design. They will help you get it right from the start, and then keep it the right season to season and year to year.

- At New-Tech Packaging, they refuse to treat packaging like a simple commodity product. They are a technology company, working in the commodity industry.

- If you’re an FDA-regulated company or a manufacturer that operates under an ISO quality system, then you know the importance of working with suppliers that have the same quality-focused mindset.

- At New-Tech, they take the time to analyze the details of your products and focus on the really massive cost savings that are hidden below the surface.

- They transform packaging from a commodity with our ability to design unique, problem-solving solutions.

7. PIEDMONT

Company Background & Information

Piedmont National was launched by Hugh Marx from his home with his wife’s help in 1950. Piedmont National provides quality products, prompt delivery, first-class service, and so on. They take great pride in being an accessible, family-run business with an unsurpassed record for customer retention and personalized service. Their executive team continues to provide a sincere commitment to your support and service.

Key Products

Semi-automatic Rotary Blister Sealing Machine

Semi-automatic Rotary Blister Sealing Machines are designed for medium to higher volume production requirements. These machines may be used for conventional carded blisters, full-face blisters, and half-clamshell styles as well as applications using Tyvek, foils, and other heat sealable lidstock.

General Purpose Shuttle Blister Sealing Machine

General Purpose Shuttle Blister Sealing Machines are designed and built for industrial applications. These machines are simply designed for ease of operator training and operation. An efficient heating system keeps power consumption low. This series of machines can adapt to seal blister packages for a wide range of products by simply changing the tooling.

Fully Automatic Carousel Plastic-to-plastic Clamshell and Blister Sealing Machines

Fully Automatic Carousel Plastic-to-plastic Clamshell and Blister Sealing Machines feature one heated sealing station, one cooling station, one bottom blister feed station, one insert card feed station, one top blister feed station and one finished package unload station, with the remaining stations used for operator product loading stations and customer furnished automation.

Recommend Reason

- Piemont National takes great pride in being an accessible, family-run business with an unsurpassed record for customer retention and personalized service.

- Thorough knowledge and industry experience are paramount to a standing reputation for excellence. Piemont National executive team continues to provide a sincere commitment to your support and service.

- At Piedmont National, solid values and unwavering commitment to you have created lasting relationships for over a half-century.

8.PYRAMID

Company Background & Information

Pyramid Packaging was officially incorporated in December of 1968 and created by proud US Army veteran James S. Ploen. His vision is to build a strong family company- brick by brick- that provided high-quality packaging machinery, materials, and service expertise under one roof. Pyramid’s position as a leader providing trusted and pragmatic packaging solutions became well established in the industry. Pyramid has won several awards in its 50 plus year history.

Key Products

Manual Rotary Blister Sealer

Manual Rotary Blister Sealers are designed and built for industrial applications. These machines are simply designed for ease of operator training and operation. An efficient heating system keeps power consumption low. This series of machines can adapt to seal blister packages for a wide range of products by simply changing the tooling. These systems are competitively priced making them ideal for contract packagers or low-volume equipment manufacturers.

Economical Semi-automatic Rotary Blister Sealer

Economical Semi-automatic Rotary Blister Sealers are designed for medium to higher volume production requirements where an economical but simple-to-operate machine is required. The machines may be used for conventional carded blisters, and full face blisters as well as applications using Tyvek, foils, and other heat-sealable lid stock. The standard machines feature one sealing station with the remaining stations used for load/unload stations.

Recommend Reason

- Throughout many years and continual evolution, the enduring principle focuses on building mutually beneficial long-term partnerships with customers, suppliers, employees, and our community.

- Pyramid’s unique relationship has enjoyed over five decades with its key supplier, auto-bag, exemplifying an enduring and successful strategic partnership between a value-add distributor, a manufacturer, and end-user customers.

- Pyramid has won several awards in its 50-plus-year history. In 2015, the company was named the Automated Packaging Distributor of the Year and has since continued representing APS for over 50 years in the Chicago market.

Conclusion

This top 8 blister sealing machine manufacturers are one of the best few manufacturers worldwide. If you are looking for a suitable brand or manufacturer of blister sealing machines, I hope this top list can give you some help and advice. If you have anything else to add or want to know more, you are welcome to consult us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide