Tapped Density Tester:The Complete Buying Guide In 2025

Do you know what is tap density tester? If you don’t know it, you may still served by it. Metal powder, nonmetal powder, dyes, pharmaceuticals, pesticides, abrasives, paints, food additives and so many kinds of powder products may be tested by tapped density tester.

But do you know what is tapped density? What is the difference between apparent density and tapped density? Why you need this and what can the tapped density tester benefit you? After reading of the complete buying guide of tapped density tester in 2024, you may become the professor of this machine! Come on and have a reading!

1.What Is Density Tester And Tapped Density Tester?

Tapped Density Tester-Sourced:bettersizeinstruments

To know density tester and tapped density tester, you may first have a clear understanding of density. Density is the ratio of mass to volume. It can converted density ratio into other units and concentrations for specific applications, like alcohol, gravity, API and so on which are widely used in chemical, pharmaceutical and other industries.

Tapped density is the important support for compress and flow of powder, granule, pellet, flakes and so on. Tapped density tester gives the precise result efficiently which is rather helpful in pharmaceutical, chemical, medical and many other fields. It can test the natural product like silver powder, nickel powder and artificial one like dyes, pesticides.

2.What Can Tapped Density Tester Do?

Many industries cannot refuse the contact with tapped density tester. Do you know the reasons?

Raw material quality test

Raw Material Quality-Sourced:nutu

Tapped density tester can test the purity and concentration of powder products. With tapped density tester, you may have your raw material a clear and distinct look. You may also makes better products with deeper examination on raw material quality.

Raw material composition test

Raw Material Composition-Sourced:ujimatchatea

Tapped density tester can test the raw powder purity as well as the composition. For pharmaceutical powder, food powder, metal powder and so on, you may have a better look on its composition.

Powder flow behavior predict

Powder Flow Behavior-Sourced:granutools

The flow behavior of powder is also an important part for many product. The knowing of powder flow behavior can help deal with many problems. For example, the powder flow behavior of raw material is an important element in making tablets.

3.Which Field MayTapped Density Tester Be Applied?

Powder is the raw material form which is frequently applied in many fields and industries. Here are the industries which tapped density tester frequently applied.

Oil industry

Oil Industry-Sourced:netzero-events

In oil industry, there is the essential use of silver, iron, aluminum, zirconium powder and many other kinds of powders in it. The tapped density tester can test the right composition, flow and many other features of the powder.

Chemical industry

Chemical Industry-Sourced:gtai

Chemical products are varied and the raw powder applied in it are also varied. Titanium dioxide, zeolite, boron carbide, graphite, quartz, gypsum and such essential chemical products have the powder form and can be tested by tapped density tester.

Food industry

Food Industry-Sourced:foodmanufacture

For food industry, you cannot miss the food additives which are so important in modern world. For the diverse food additives and food powder in food industry, you can have a better prove in the powders added in food industry.

Pharmaceutical industry

Pharmaceutical Industry-Sourced:markrhodes

Powder can make tablet, pill and many other medical form in pharmaceutical industries. The nice qualified raw powder can make medicine give better effect and make more qualified products.

4.What Is The Use Of Tapped Density Tester In Pharmaceutical Field?

Powder is the important medical form in pharmaceutical field and the tapped density tester which makes the deep test of this form is thus rather important in pharmaceutical field.

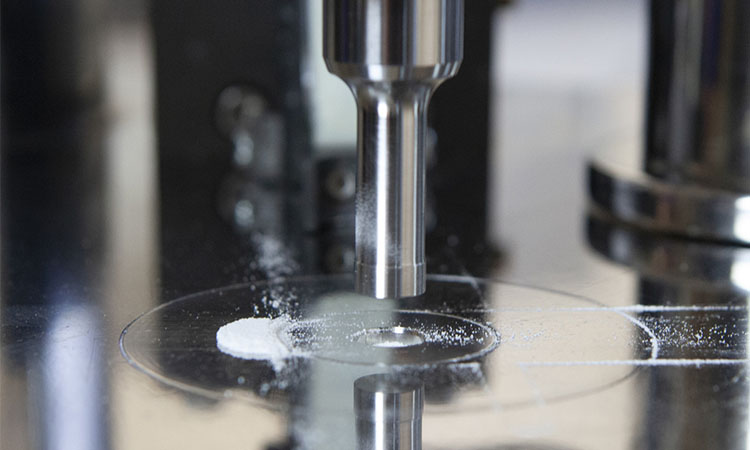

Test the compression

Test The Compression-Sourced:merlin-pc

Pharmaceutical powder are usually composed by pharmaceutical ingredients and excipients. To make the real nice and qualified tablet and pill, the pharmaceutical powder should be with great compress features.

Test the flow property

Test The Flow Property-Sourced:icheme

The successful making of some medicine like capsule or medicine with suspend form, one should make the medical powder with great flow property. The tapped density tester can make the precise testing and share you the reliable results.

5.What Benefit Can Tapped Density Tester Take You?

Tapped density tester can be widely used in many field and takes much benefits to these fields. Here are the benefits which tapped density tester can take you.

High precision

High Precision-Sourced: Pngtree

Tapped density tester makes precise test and gets every number precise as the missing of a small number may lead the mistake in later work. The test is thus high precise and rather reliable.

Easy operation

Easy Operation-Sourced:anton-paar

The operation of the tapped density tester isn’t that difficult though it is highly intelligent and precise. It is equipped with the automatic calculation features and is tend to equipped with touch screen. The operation is easy and will become easier.

High Flexibility

High Flexibility-Sourced:labulk

Tapped density tester is high flexible. You may test powder with one or two test station configurations or combine the two to make the test.

Great intelligence

Great Intelligence-Sourced:aimsizer

Tapped density tester is intelligent enough to make the intelligent judges of the coming number. It keeps its high accuracy with great intelligence and may save much energy and time of operator.

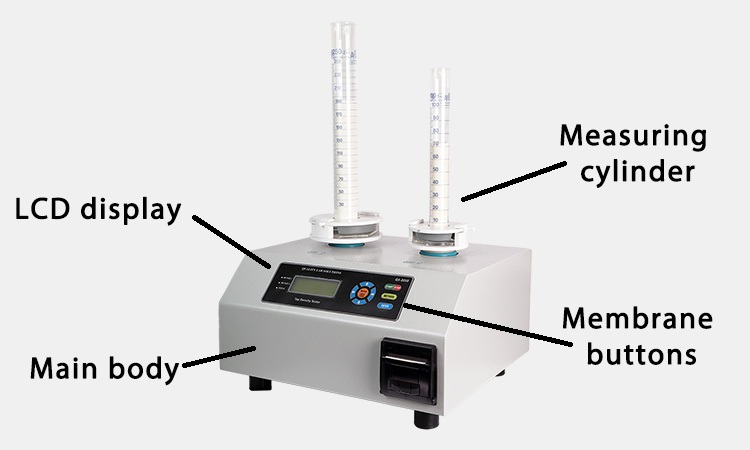

6.What Are The Main Components Of Tapped Density Tester?

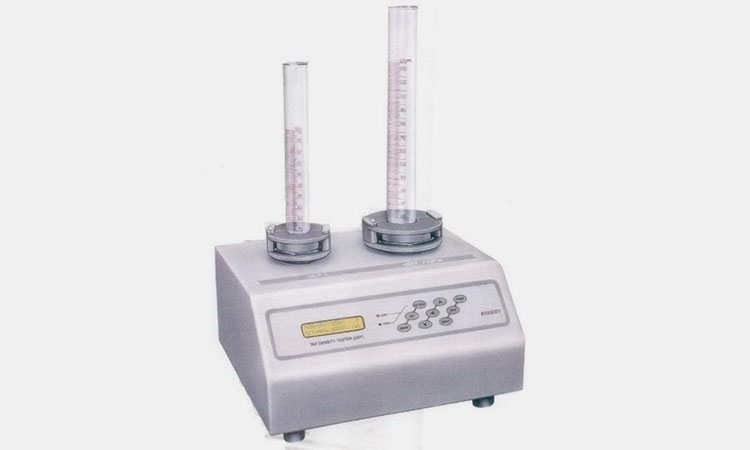

Tapped density tester is small but fragile. Here are the new tapped density tester type and let us explore its main components.

Main Components Of Tapped Density Tester-Souced:qlsindia

| Components | Usage |

| Main body

|

The main body of tapped density tester is a regular rectangle box. It has printer and calculator set in it which play the job of making the precise calculating and essential printing for the test. |

| LCD display

|

LCD display is the place which shows the operating process and testing process of tapped density tester. The size of it may varied but you may always have a clear knowing of machine operating from it. |

| Membrane buttons

|

Membrane buttons are the tools which may help the operating of machine and import of number. It is like the brain of the testing machine and the only difference lies in the work is initiated by you. |

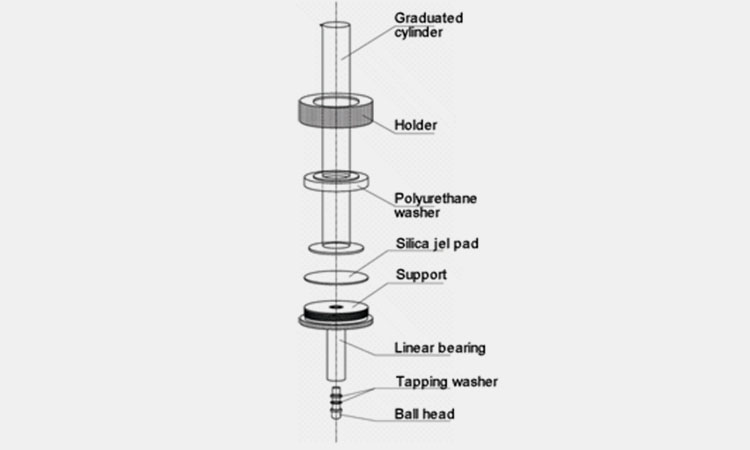

| Measuring cylinder

|

Measuring cylinder is the place where place the powder sample and you may find two or three test station configurations work the same time. The cylinder looked simple but not with simple structure. You may find the graduated cylinder, holder, polyurethane washer and so on combined in order to make effect. |

7.What Is The Working Principle Of Tapped Density Tester?

Tapped density is a complex and deep knowledge, but the tapped density tester can give you precise and accurate result with simple operation.

Make the preparation

Make The Preparation-Sourced:learnloft

You should clean machine and check the machine state for the later smooth operation. And for raw material, You’d better dry it. For powder with volatile substance, you should not dry it. And for powder which is oxidized easily, you should dry it in vacuum state. For the powder which cannot be dried, you may test it in real state.

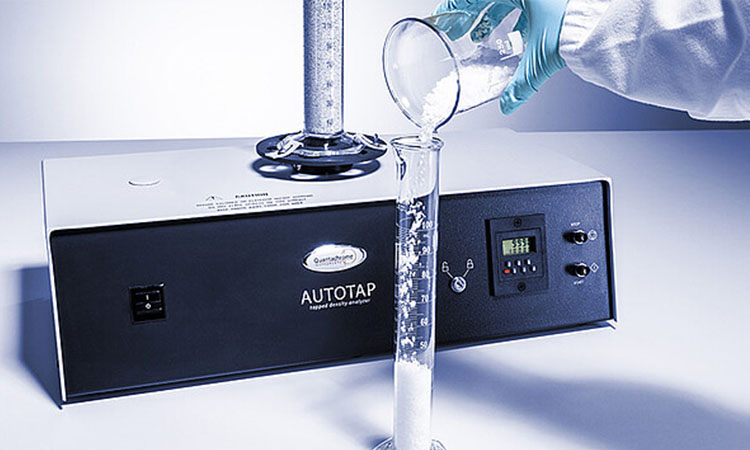

Weighing and adding

Weighing And Adding-Sourced:lab-label

Weighing the powder you need and adding the weight of powder in machine. While in adding powder in cylinder, you should make the powder in surface level and then place cylinder in vibration platform.

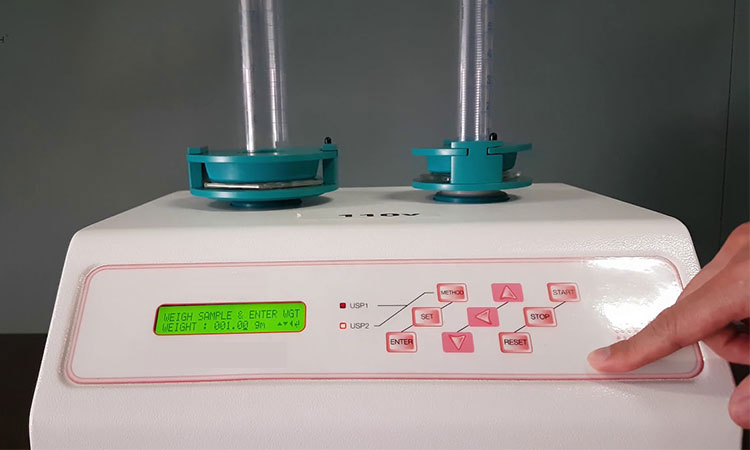

Enter tapping number

Enter Tapping Number-Sourced:labtroninstrument

You may set the tapping number in machine and then let machine start the tapping. The tapping number of different powder all varied, for metal powders, it should be about 3000 times.

Adjust vibrating frequency

Adjust Vibrating Frequency-Sourced:shutterstock

The vibrating and tapping frequency can be adjusted. The normal vibrating frequency is 100-300 rounds per minutes. And you may adjust it according to your powder feature.

Imputing volume

Imputing Volume-Sourced:torontech

For the volume of powder, you may get it clearly if the powder surface is level after tapping. And for the one not level, you should check it several more times and input the average number.

Calculating and printing

Calculating And Printing-Sourced:hmk-test

With all data needed get in, you may then get the calculating process and get the results which are completed by machine. You may then get the results printed.

8.How To Install Tapped Density Tester?

The tapped density tester is a fragile machine, but the installation doesn’t need you much hard work. The machine has the body part complete and most you need to do is to install cylinder part.

Choose cylinder size

Choose Cylinder Size-Sourced:anton-paar

A tapped density tester is usually equipped with different size of cylinder. To make the precise and efficient testing, you may get the one based on the powder weight and artificial density.

Install cylinder

Install Cylinder-Sourced:labulk

Cylinder is the straight container. The internal structure is not that simple. You should first lace screw cap and polyurethane washer from the upper side of it. Then you should put the silica jel pad from the bottom of the cylinder. After the screwing of cap, you may then place the tapping apparatus in the guide bearing.

Adjust tester and make test

Adjust Tester-Sourced:lpp-equipment

For later smooth operation, you should adjust your tapped density tester. Is the initial value right? Does the amplitude adjust? Do you choose the right cylinder size? You would better give the new machine a powder test to see the right installation.

9.How To MaintainTapped Density Tester?

Tapped density tester should be maintained carefully to prolong the life span and help it to make better performance.

Make the regular cleaning

Regular Cleaning-Sourced:istockphoto

You should make the regular cleaning of the machine to prove its great state. You should clean the cylinder with tissue paper and cotton cloth for the soft and clean cleaning. Remember to turn off the machine while cleaning.

Check the condition regularly

Check The Condition-Sourced:clickmaint

You should check your tapped density tester regularly. Do you install printing paper? Do you lubricate the bearing? Is the ground cable in the right condition. All in all, you should observe machine state carefully.

Place and move carefully

Place And Move Carefully-Sourced:labulk

Tapped density tester should be placed in a stable and firm place. The accidental slip may cause the forever damage of machine. While moving it, you should also take concern to not punch or hurt it.

Use with great care

Use With Great Care-Sourced:medicalexpo

In the work of tapped density tester, you would pay attention to the powder or suspend liquid. Do not let liquid flow into or slip into the tapped density tester. The leaking of liquid is hurt to machine.

10.What Other Machine Can Be Used For The Density Testing?

Tapped density tester is a type of density tester for testing density. And here are other way you may want to know for other density testing.

Hydrometer

Hydrometer-Sourced:indiamart

Hydrometer is a density tester which test the density of liquid. It is made of blown glass and has a steel shot in its bottom. You may get the density by immersing it in sample liquid. It is easy to operate and save time.

Pycnometer

Pycnometer-Sourced:masiyelabs

Pycnometer is also the glass made density meter. It can test the density of liquid, solid and even gas. With right measuring and operating, it can give the result with high accuracy.

Digital Density Meter

Digital Density Meter-Sourced:anton-paar

Digital density meter has portable and bench top type. The two type can both give the precise density measuring. The U-shaped glass tube is the secret of its high accuracy. It can handle various types of sample.

Coriolis density meter

Coriolis Density Meter-Sourced:emerson

Coriolis density meter adopts the principle of vibration to get out the density data with high precision. It measures the mass flow not the volumetric flow. One its drawback is that it cannot calibrated while using.

Nuclear density meter

Nuclear Density Meter-Sourced:humboldtmfg

Nuclear density meter gets the density of project from the measuring of gamma radiation. It can only measure the products which are seen in the gamma radiation beam. You need certificate and license for the operating.

Microwave density meter

Microwave Density Meter-Sourced:global.toshiba

Microwave density meter is suitable for the testing of dissolved solids. This type of tester is suitable in the use of consistent solution. It has various way to test the solid density and can prove great accuracy.

Ultrasonic density meter

Ultrasonic Density Meter-Sourced:roycewater

Ultrasonic density meter calculate the density of material with various principle. But the accuracy and efficiency of data from this way can be great proved. For some type pf this kind, it can only work with the solids with less than 10% concentration.

11.What Are The ProblemIn Tapped Density Tester Working And How To Solve Them?

The operating of tapped density tester cannot always be smooth and easy. Here are the problem you may meet in tapped density tester and the ways to solve it.

Unlit panel

Unlit Panel-Sourced:nbchao

Your tapped density tester may be powered with no reaction on panel. You may check the unit and fuse. Do you forget to turn on the unit? Does fuse burned out? After the careful check and relative solution, you may have panel lightened.

Obstructed tapping

Obstructed Tapping-Sourced:indmkt

If your tapping can’t go on smoothly, you may check the bearing and ensure the lubricated. For the machine with no tapping work, you may check the speed adjuster and check the related sections.

Unclear report

Unclear Report-Sourced:aimsizer

The unclear report may caused by the thermo paper problem. Do you have the paper installed in right direction? Do you have the paper with good quality? The checking of paper quality and right place of it can prove the report quality.

No printing

No Printing-Sourced:geneq

For the printer which is failed to make the smooth printing, it may ran out of the printing paper. Fill the new printing paper and you may have the tapped density tester printed report.

12.What Factors May Cause The ErrorsOf Results in Tapped Density Testing?

What factors may cause the errors if results in tapped density testing? If you wanna the precise and accurate testing result, here are the factors you should notice.

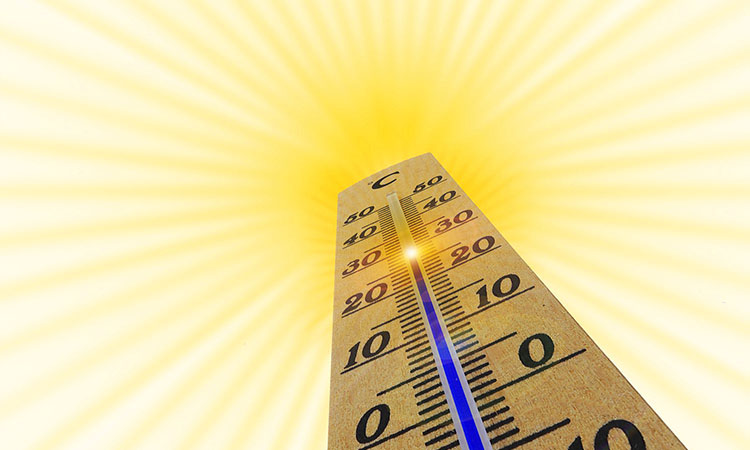

Temperature

Temperature-Sourced:thoughtco

Temperature will affect the machine and the material sample. The rising of temperature may cause the decrease of density. And some density tester may also be affected at different temperature.

Pressure

Pressure-Sourced:esmagazine

Pressure may affect the rigidity of mass flow tube and gravimetric meters. The setting of barometer in density meter can help measure the air pressure.

Damage

Damage-Sourced:thenounproject

The damage of tapped density tester like pitting, cracking, erosion and so on may cause the errors in density testing.

Air Bubbles or impurities

Air Bubbles Or Impurities-Sourced:stockfood

The air bubble and impurities in sample may cause the density results big difference. The deep cleaning of cylinder may avoid the appearance of this condition.

Viscosity

Viscosity-Sourced:wiki.anton-paar

Viscosity has little connection with density, but it may affect the density testing. It is tested that the increasing of sample viscosity may lead the density errors.

Conclusion

What is tapped density tester and what are the use of it? You may have a clear answers. The complete buying guide of tapped density tester shows you the comprehensive knowledge about this type of machine. If you have any problem about this post or this machine, you may contact us now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide