Your Best Tablet Tester Supplier

- 100% USP/EP Compliant

- Constant Speed&Force

- Diameter&Hardness&Thickness&Control Testing

Tablet Tester

Allpack tablet tester t is to test the hardness, friability, dissolution and disintegration of pharmaceutical tablet. The machine is automated in hardness testing, whole structure with reasonable design, stable performance, easy to operate. Main technical indicators in line with the "Chinese Pharmacopoeia 2015 version" requirement, widely used in the pharmaceutical industry, scientific research, teaching, Institute for drug control and various pharmaceutical industry quality management department and laboratories.The technical indicators of each function are in full compliance with the "Chinese Pharmacopoeia 2015 Edition" and generic drug conformity evaluation standards.

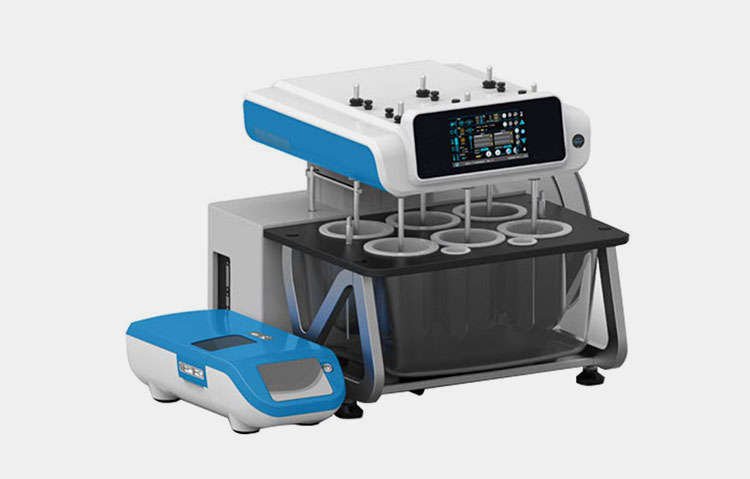

Allpack Tablet Tester

Multifunction Tablet Tester Test Hardness, Friability, Dissolution and Disintegration of Tablet

Allpack Tablet tester adopts with fault prompt function, the detection data can be exported and printed by USB.The hardness can be tested continuously for 1000 times, and the user can adjust the continuous test interval. The speed is more accurate, the operation is stable, the energy consumption is low, and the reliability is high.Adopts with convenient waterway system, this multifunctional tablet tester has high-precision and real-time constant temperature control, fast temperature rise, small temperature drift, over temperature protection and temperature calibration.

Higher precision integrated circuit design to ensure experimental accuracy

High-definition touch screen with simple interface and minimal operation mode

Smaller size, reducing the footprint of the lab bench.

The Buyer's Guide

Tablet Tester: The Complete Buying Guide In 2025

It seems like you are running a tablet compression business, right? Well, where tablet manufacturing is considered one of the profitable startups you will also find managing the quality control a difficult step. But this worry has been ended with the invention of new and innovative Tablet Tester.

Yes! You can easily carry out your tablet testing for determining their important parameters by simply employing a Tablet Tester. However, it is always important to have prior knowledge about the equipment you are intending to buy. That's why we have designed this buying guide to help you understand the tablet tester, its function, operation, troubleshooting and much more. So, be ready to explore it!

1.What Is A Tablet Tester?

Allpack- APK-6DN Tablet Tester

Tablet tester can be simply described as an advanced inspection equipment utilized for the testing of tablets. This multifunctional tablet tester is essential to determine the vary parameters of tablets including tablet hardness, friability, thickness, and disintegration.

As the quality control of produced tablets is considered important in pharmaceutical industry, a tablet tester play important role in achieving it by providing all the necessary information. It has safe structure along with simple operation thus enabling you to conduct a thorough testing without degradation of the tablets’ quality.

2.What Functions Are Performed By A Tablet Tester?

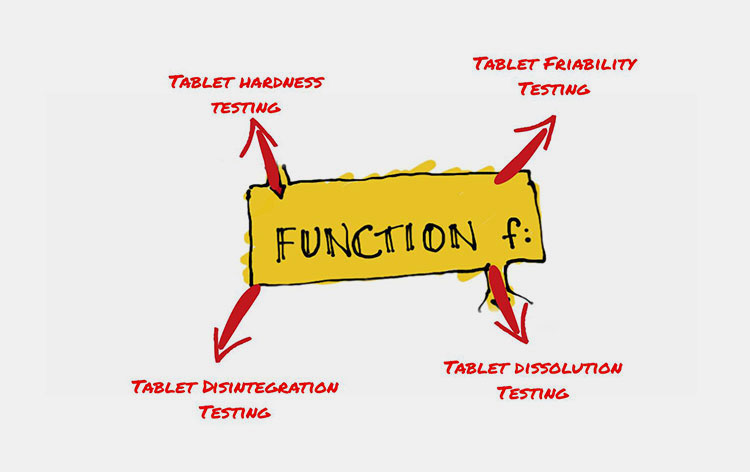

Functions of a tablet tester

Functions of a tablet tester- Picture Courtesy: seattlewebsitedevelopers.medium.com

In medical field, a single compresesed tablet is observed from various angles. Similarly, for the exploration of these eclectic parameters, individual tests are conducted. In this way, a tablet tester performs multiple functions such as:

- Examining the hardness of tablets.

- Determining the friability of tablets.

- Testing the thickness of tablets.

- Testing the dissolution of tablets.

- Checking the weight of tablets.

- Determining the diameter of tablets.

3.What Are The Advantages Of A Tablet Tester?

Tablet tester come with numerous features and specifications which ultimately become its advantages. Let's know few of its notable benefits in the underlying explanation!

Compact Structure

Compact structure of Allpack's APK-6DN Tablet Tester

The structure of a tablet tester is quite precise with small footprint and few components. Its overall compact design and low weight make it easily portable. Thus, unlike other tablets manufacturing machine it will not bother you to have extra room for placement.

Simple Operation

Operator turning the tablet tester on- Picture Courtesy: teledynelabs.com

Automatic tablet tester like electric and digital tablet tester have multiple options there for operation like LCD display, touch screen, and knobs etc. Collectively, these enable you to easily administer and monitor the tester functioning by controlling working parameters.

Testing Precision

Precise tablet friability testing- Picture Courtesy: pharmaceutical-networking.com

Tablet tester is designed with advanced technology of measuring and testing where it gives you information about minute changes. Thus, no ambiguity is left for inaccuracy, and you get precise results.

Product Safety

Ensuring the safety of tablets during testing is an important thing that must be considered. Due to this reason, a tablet tester is designed in such a way by using quality material that it does not degrade the quality of your produced tablets and conduct safe testing.

High Versatility

Various sizes & shapes of compressed tablets

Tablet tester is well known for its flexibility and adaptability to process any kind of tablet. For instance, you can test the tablets with varying sizes, shapes, and dosage by using the same tablet tester without changing any tools.

4.Enlist The Tablet Types Which Can Be Tested By A Tablet Tester?

Although, tablet itself is a category of solid dosage form along with capsules but it may also be divided into several types. These tablet types vary from one another on certain basis such as dissolution timing, ingredients used, and the way of taking. With tablet tester, you can test all these tablets forms which are explained below:

Immediate Release Tablets

Paracetamol tablet- Picture Courtesy: The Guardian

Tablets which are made to be released in body quickly after swallowing are known as immediate release tablets. They often dissolve in stomach and therefore you can test these tablets by using a tablet tester.

Extended-Release Tablets

Tablets in a hand- Picture Courtesy: lubrizol.com

These tablets are meant to be dissolved slowly in your body after the passing of fixed timespan. For such tablets, it is necessary to determine the release timing for which tablet tester is employed.

Effervescent Tablets

Effervescent tablets presentation idea- Picture Courtesy: rappler.com

Effervescent tablets are large size tablets with instant release properties. They are often used for doses which are meant for quick dissolution.

Coated Tablets

Various coated tablets- Picture Courtesy: pharmaexcipients.com

Most of the time, compressed tablets are added coating to mask the unpleasant taste, smell and enhance their release time. Therefore, these tablets are also checked for hardness, thickness as well as weight variation.

Uncoated Tablets

Uncoated tablets with bottle- Picture Courtesy: www.felixforyou.ca

Uncoated tablets are regular compressed tablets without any outer coating. They can be easily tested by using a tablet tester.

Chewable Tablets

Chewable tablets- Picture Courtesy: adobe.stock.com

Chewable tablets are large size flavorful tablets which are chewed instead of swallowing. Like other tablets, they are also tested to maintain drug quality.

Shaped Tablets

Heart shape tablets blister pack- Picture Courtesy: Freepik

Tablets are produced in various shapes encompassing regular round and oblong to more intricate shapes like triangle, heart, and pentagon. So, a tablet tester is simply able to test any tablet regardless of their distinct shapes.

Different Size Tablets

Small & large size tablets- Picture Courtesy: stock.adobe.com

Compressed tablets are not always the same in size due to variation in dosage quantity. Thus, you need not to worry about it when using a tablet tester.

5.How To Operate A Tablet Tester?

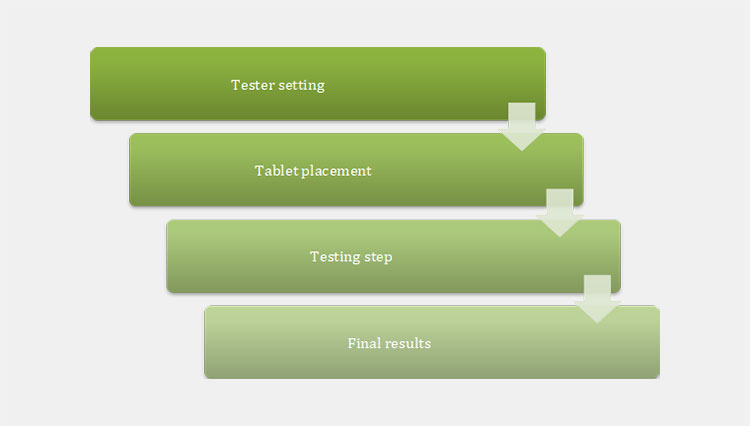

Operating a tablet tester is quite easy once you understand its structure and the working principles on which it works. It usually undertake few steps for operation which are explained below:

Tester Setting

Operator setting tablet tester- Picture Courtesy: merlin-pc.com

The process simply starts with the setting of machine where you need to check whether the parts of tester are properly located on their concerned locations. Similarly, you need to adjust the functional parameters of the tester by using a touch screen or knobs located on the tester panel.

Tablet Placement

Once setting is done, just pick up the desired tablet and place it in the testing unit of tablet tester. Press the power button and tester will be switched on for testing.

Testing Step

This the main step for testing of your tablets when a tablet tester begins its task. Now, depending upon your desired testing like hardness, dissolution, or friability, the tester will apply pressure to tablet until a fixed point is reached.

Final Results

At the end of testing, you will be shown the final results on a screen of tablet tester. Although it is optional, you can get the print of final information by attaching a USB.

6.Describe The Structure Of A Tablet Tester?

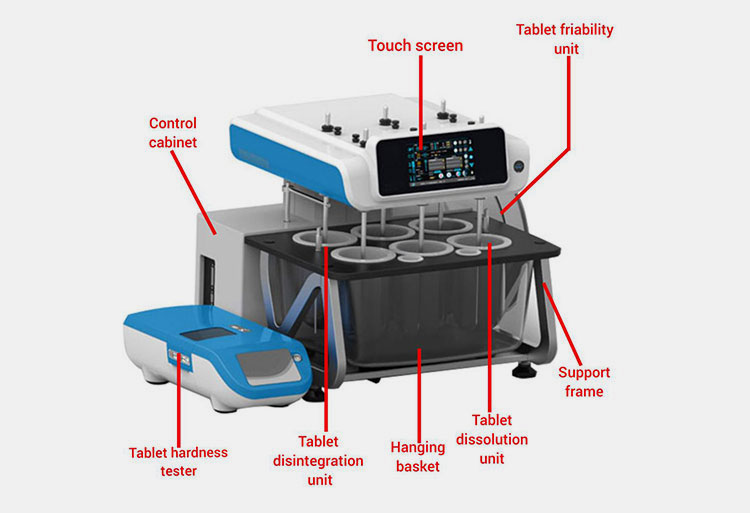

The structure of a tablet tester is compact with several units being interconnected together to make a single solution. It can be easily understood by looking into the underlying explanation:

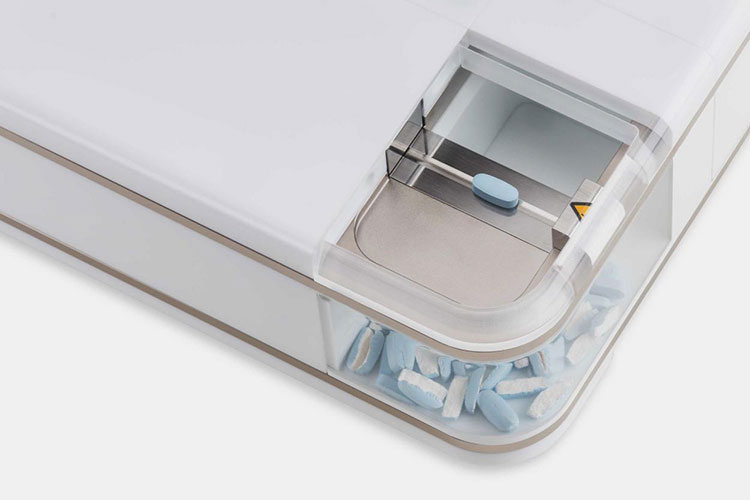

Structure of Allpack's APK-6DN Tablet Tester

Touch Screen

Touch screen is located on the top front of tablet tester. It is the controlling interface which display over it multiple data information about the tester. You can use it to set the parameters of machine like dissolution timing, controlling temperature, and the speed of friability testing drum.

Control Cabinet

It is the power house of tablet tester which supply power to each unit. It mainly consists of an enclosure and houses inside it the small wires, fuses, and circuits. Thus, the electric setting can be done through this part.

Tablet Hardness Tester

Tablet hardness tester is a precise device which is physically separated from the main tablet tester. It it mainly used to test the tablet hardness; therefore, you may find several components in its construction including:

LCD Display:It is a digital screen over which various options are there to show tablet hardness information like the diameter, quantity, and hardness of tablets. It is also used for setting the tester.

Testing Compartment:Testing compartment is the main chamber where tablet hardness testing is carried out. It has a visible protection cover inside which the jaws for tablet squeezing are placed, so, the testing can be safely done.

Power Button: Power button is situated on the front side of tester, so, the tester can be easily switched on and off.

Electric Board:This board is where electric supply to the tester is connected. It also has a place for USB.

Tablet Friability Unit

Tablet friability is another important unit if the tablet tester which is associated with the task of performing tablet friability testing. It is made up of few parts including:

Rotating Drum:Rotating drum is where tablets are loaded and tested for friability. It is made from Plexiglass for safe testing, and it consists of a drum and cover. Inside this drum, there is a tilted scoop which helps in the testing by intermittent holding and falling of tablets.

Central Wheel:The central wheel is attached to the rotating drum and helps in its rotation during testing.

Sealing Screw:Sealing screw is infused to the end of central wheel for attaching the cover to rotating drum.

Gear Motor:Tablet friability unit also has a silent DC gear motor which helps in rotating the drum at fixed speed.

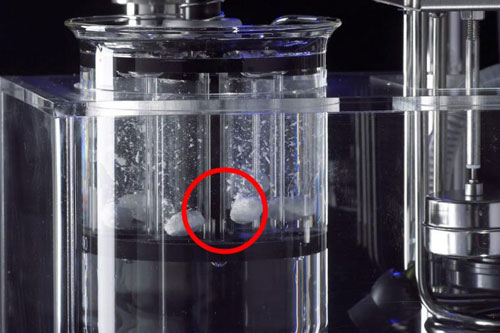

Tablet Disintegration Unit

It is the third unit of a tablet tester with primary purpose of testing the disintegration time of tablets. Similarly, it uses various parts to undertake the function which are as follows:

Disintegration Vessel:It refers to the beaker inside which tablet disintegration testing is conducted.

Rotating Rod:The rod is made from stainless steel and at its end, an enclosed perforated compartment is attached under which tablet is placed for testing.

Temperature Probe:Temperature probe is a type of sensor which used to measure the temperature of water.

Tablet Dissolution Unit

Tablet dissolution unit is the fourth unit of tablet tester which is integrated for examining the complete dissolution of tablets under standardized condition. It consists of:

Dissolution Vessel:It is the mixing vessel where tablet along with water is fed for testing.

Rotating Paddle:Rotating paddle is attached to the tester on upper side and its lower side is like an agitator which helps in the mixing of water during operation.

Disk Assembly:Disk assembly refers to the tool that is located at the bottom of dissolution vessel where tablet is placed.

Hanging Basket

Hanging basket is a large size tub inside which all the mixing vessels of tablet disintegration unit and tablet dissolution unit are placed collectively.

Support Frame

Support frame refers to the overall body of machine including main frame, stainless steel tools for holding various units and the feet.

7.Highlight The Applications Of A Tablet Tester?

The use of a multifunctional and advanced equipment like tablet tester can be found in every sector with some sort of engagement in tablets manufacturing. In this way, few notable areas can be explored in the upcoming paragraphs:

Pharmaceutical Industry

Various tablets & capsules- Picture Courtesy: pngtree.com

You will always find pharmaceutical industry as a field constantly engaged in producing existing formulas and discovering new medications for treating unconventional diseases. Among these medications, tablets are on top level which also require strict quality control to maintain structural integrity and therapeutic effects. Thus, a tablet tester become inevitable to enable you test your vary tablets by undergoing them various mechanical and structural testing.

Nutraceutical Industry

Various nutraceutical tablets & capsules- Picture Courtesy: nordic-nutraceuticals.co.uk

To help patients take care of themselves on regular basis, certain vitamins, minerals, and nutrients are beautifully encased in form of tablets. These tablets are then called nutraceutical tablets which you can consume without any fear for side effects. It must not be forgotten, that these tablets are also made under established quality standards, hence, tablet tester is also useful in nutraceucal industry.

Herbal Industry

Herbal tablets- Picture Courtesy: Freepik

Despite the developments made in pharmaceutical sector, most of the people around globe still prefer herbal medicine over any other treatment. Therefore, these herbal tablets and pills are made under hygienic condition to prolong their shelf life as well as drug quality. Ultimately, testing become essential to determine these factors for which a tablet tester is necessary.

Veterinary Industry

Veterinary tablets- Picture Courtesy: theparliamentmagazine.eu

The use of a tablet tester can also be seen in veterinary industry which has a growing market. It is greatly helpful to determine the tablets friability, hardness, and other properties which are used for pups and geriatric pets and animals.

Chemical Industry

Detergent tablets- Picture Courtesy: bosch-home.co.nz

Compresesed tablets are also produced in chemical industry for various purposes such as pesticides tablets, detergent tablets, and chlorine tablets etc. During their processing, testing is conducted to maintain the effective release time where a tablet tester is applicable.

8.What Quality Standards Should A Tablet Tester Comply To?

As a tablet tester is used for testing tablets in pharmaceutical and other sectors, it must be the product of quality material and advanced operating system. Now, it is often a conundrum for new buyers that how they can check whether the tablet tester is complying quality standards and if yes how they can find it.

So, the answer is pretty simple! You just need to check the certification of the vendor who is supplying the tablet tester. In this way, few important quality standards which are must for every tablet tester include:

GMP quality standard icons- Picture Courtesy: VectorStock

- International Organization for Standardization (ISO)

- Current Good Manufacturing Practices (cGMP)

- Food and Drugs Administration (FDA)

- Conformate European (CE)

- S. Pharmacopeia (USP)

- European Pharmacopeia (EP)

9.Can You Integrate Tablet Tester With Other Machines?

Definitely yes! You can use the modern tablet tester along with other tablet machines to enhance the efficiency of production. These machines are highlighted below:

Tablet Press

Allpack- ZP5/7/9 Top Quality of Single Punch Tablet Press Machine

Tablet compression is the core machine for making tablets. It turns the powder and granules into uniform and solid tablets through compression. The machine uses punches, dies, and pressure to carry out its function. Moreover, its structure is fully safe as made from corrosion resistant and quality stainless steel.

Tablet Coating Machine

Allpack- Tablet coating machine BYA-600

Tablet coating machine is a mechanical equipment which is used to coat compressed tablets with various types of liquid coating such as sugar coating, film coating, or enteric coating. It consists of a large rotating pan, tablet bed, spray nozzle, exhaust, and control system etc.

Tablet Deduster

Allpack- Top rotation type tablet deduster machine SZS230

Tablet deduster is a machine used to remove the dust or powder residues from tablets which are left during compression. It has a small portable structure comprising tablets inlet, plexiglass cover, stainless steel mesh, power switch and base etc. Before testing your tablets, you can use a tablet deduster to eliminate the possible dust accumulated over tablets.

Tablet Inspection Machine

Tablet inspection machine- Picture Courtesy: accurappl.net

Tablet inspection machine is another important equipment used for the inspection of tablets. Its main task is to examine broken and spotty tablets after compression. Thus, this machine help you in inspecting tablets before you take them for final testing with a tablet tester.

10.What Are The Cleaning And Maintenance Requirements Of A Tablet Tester?

Like other tablets processing equipment, tablet tester also require thorough cleaning and maintenance. So, you need to take care of these requirements for always keeping your tablet tester at good working condition. For this, underlying tips will be helpful:

Operator cleaning tablet tester by wiping cloth- Picture Courtesy: teledynelabs.com

Cleaning:Cleaning is a compulsory step that you should never skip. It helps you remove the debris and dirt from tablet tester. For this, you need to disassemble the removable parts of tablet tester including drum, mixing vessels, and rods etc. Wash down these tools with recommended detergent and use soft moist cloth for the rest parts. Once cleaning is done, properly dry all the components and assemble them correctly.

Adjustment:Undertake structural adjustment of the tools to avoid jamming and locate them on right place. For parameters setting, use touch screen each time before starting operation, so, there is will be least chance for errors.

Parts Changeover:Conduct regular servicing of the tester and in case of parts damage replace the defective parts with new one for smooth functioning.

11.How To Troubleshoot The Common Errors Of A Tablet Tester?

Although, tablet tester rarely show any serious problem, you may notice minor errors when operating a tablet tester. These are backed by some causes. Here is how you can easily solved these issues:

| i. LED on display is not illuminating | ||

Marked display of Allpack's APK-6DN Tablet Tester |

Cause:

The tablet tester may not be properly connected to electricity. There is power supply issue. The fuse may be blown. |

Solution:

Check the switch and accurately plug in to connect with electricity. Supply adequate power. Replace the fuse. |

| ii. Issue in tablet hardness testing | ||

Marked broken tablet during hardness testing- Picture Courtesy: teledynelabs.com |

Cause:

The jaws are not suitable for specific shape of tablets you are testing. Improper calibration has caused the measurement issue. |

Solution:

Change the jaws for different shapes of tablets. Calibrate the tester if system is out of calibration. |

| iii. Tablets disintegration issue | ||

Highlighting tablet disintegration issue- Picture Courtesy: pharmaceutical-networking.com |

Cause:

Inappropriate temperature often results in poor disintegration of tablets. The speed of rods is either too slow or too fast. |

Solution:

Check the temperature probe and set appropriate temperature. Adjust the speed of rods to suitable level. |

| iv. Tablet friability testing problem | ||

Displaying driving wheel of tablet friability tester- Picture Courtesy: merlin-pc.com |

Cause:

The program may not be started. The drive belt is broken causing drum to stop. The length of cycle is not correct. |

Solution:

Press the start button. Replace the drive belt. Set the cycle timing on touch screen interface. |

| v. Tablet dissolution error | ||

Tablet dissolution mixing vessels- Picture Courtesy: taawon.com |

Cause:

Uneven temperature often leads to inconsistent dissolution of tablets. Nonuniformity in the rotation of paddle is the root cause for inaccurate measurement of dissolution timing. |

Solution:

You need to use a reliable temperature system for uniform dissolution of tablets. It is important to keep checking the rotation speed and use special devices like tachometer for knowing the exact rotation speed. |

| vi. Printer is not working | ||

Showing tablet tester printing error- Picture Courtesy: copleyscientific.com |

Cause:

The printer may be disabled. You have not plugged the printer. There is power supply issue. |

Solution:

Check and enable the printer. Check and plug in the printer. Reconnect the printer with electricity. |

12.Factors To Consider Before Choosing A Tablet Tester?

The most valuable advice that fits on every manufacturer regardless of their background is not to rush! The same we have for you to not rush and take some time to consider important factors when buying a tablet tester. So, be ready to look into these factors!

Tester Specifications

Tablet hardness testing- Picture Courtesy: teledynelabs.com

First of all, try to know about the specifications of the tablet tester which includes its versatility to deal with different tablets, ability to conduct multiple tests, and capability to be attached with additional programs like printer etc. It is important to consider this factor, as you will find number of tablet testers out there in market but you need to look for your requirements only.

Cost

Cost presentation idea- Picture Courtesy: stock.adobe.com

It is significant to consider the cost of tablet tester as the price vary from one type of equipment to another. Similarly, estimate the overall cost by keeping in mind operation and maintenance expenditure.

Supplier Reputation

The supplier for purchasing tablet tester can make or break your profit margin. So, choose wisely! You just need to search about the company experience, warranty policy, customer service, and feedback of their previous customers.

Quality Compliance

Compliance icon- Picture Courtesy: financialcrimeacademy.org

Make sure to verify the quality compliance of a tablet tester. For this, simply check the certifications of the tester which are accredited by international quality standards including FDA, ISO, and GMP etc.

Conclusion

We are about to conclude this informative review about Tablet Tester: The Complete Buying Guide In 2024 with a reminder that tablet tester is inevitable in today's era where quality control is becoming strict everyday. Since, tablet is the most popular solid dosage form, demand for tablet tester is increasing. In such a scenario, it is very important to have adequate information regarding its structure, working, and maintenance which are all explained above. Similarly, finding an experienced vendor like Allpack can transform the fate of your business. So, don't forget to consider Allpack as your supplier for tablet tester! For further information contact us.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586