Tablet Machine: The Complete Buying Guide In 2025

How tablet machine significant?

In today’ blog post, you will be known about this robust and reliable machine which has wide and broad applications around the globe. Now you can enjoy making tablets of various shape, weights, sizes with professional results by using a tablet machine.

If you think, it will be an expensive machine or can not afford it. Then you might be wrong. Please read this blog and find out what’s more it offers you to with an astringent amount.

1.What is tablet machine?

Allpack Tablet Machine

So basically, tablet machine is used to compress the granular or powdered material into tablets of different shapes and sizes to ensure uniform distribution of drug. That is why it is called as tablet machine or pill press. This machine is operated by series of steps such a powdered material is placed in die cavity, high pressures are applied and finally formed tablet is ejected.

Such machines are commonly used in pharmaceutical and other related industries, where precise dosing, large production of batch with consistency and accuracy are required. These are important as they benefit the quality production with improved shelf life and stability. This minimal variation of dosage and sizes also improves the patient compliance because of familiar medication administration.

2.What are advantages of tablet machine? Why it is Important?

Precision

Every tablet has an active ingredient which plays a vital role in achieving maximum therapeutic effect, so tablet machines ensure the precise and accurate dosing with desired potency.

Efficiency

The production of large amount of quality product with minimal manufacturing time, this throughput is essential to meet the demands of manufacturer.

Quality control

Quality Control- picture courtesy: aaps.ca

Tablet machine ensures the overall quality of product. Variability within batches is strictly controlled in terms of size, shape weight variation to meet quality standards.

Convenience

Convenient equipment

Tablet machine is preferred over many other equipment just because of convenient presses, and safe formation,

3.What Industrial applications tablet machine offering its customers?

Pharmaceutical industry

Pharma tablets-- picture courtesy: alten.pt

Tablet machine is the vital part of this industry as it helps to manufacture a vast of array of medications with precise dosing and potency meeting all regulatory requirements.

Nutraceutical industry

Vitamin supplements

A supplement such as dietary vitamins, minerals, herbal extracts and bioactive compounds lies in such category. Tablet machines make sure precise dosing to meet consumer and market demands.

Cosmetic Industry

Pressed powder- picture courtesy: beautymag

Compressed eyeshades pallets, blushes, foundation cakes are also produced by such machines. These machines ensures the consistent texture and colors of cosmetic formulation to meet consumer demand.

Confectionary Industry

Candy tablets

In this industry, these machine enables the uniform size and weight of confectionary products such as candies , mint lozenges to appeal consumers.

Chemical Industry

Chemical Tablets

Tablet machine is used to compressed active chemicals to solid tablet formulation. These tablets are used as catalyst, disinfectants or agrochemicals.

4.What is classification of tablet machine?

Tablet Machine- picture courtesy: Ricardo

Tablet machines are of various kinds and types , commonly they could be classified on following factors , operating principle, feature design , production capacity and limitation and their automation level.

Classification of Tablet Machine

Operating principle

Single punch Tablet machine

Allpack Single Punch Tablet Machine

These machines are suitable for low scale production or for laboratory use, as it uses only single punch to compress the granulated or powdered material into tablets.

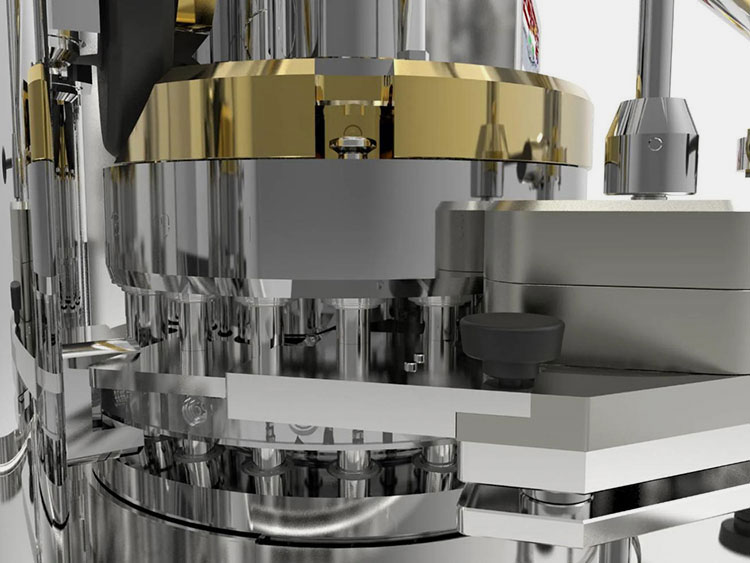

Rotary Tablet machine

Allpack Rotary Punch Tablet Machine

These machines are very efficient are highly recommended for large scale production as it as multiple die cavities and punches arranged on a rotating turret. High pressures are applied to compress the powder into tablet. It basically has a platform to hold dies and punches for tablet formation. Therefore, we can classify tablet machines according to turret type either rotary turrets or oscillating turrets.

Production capacity

Small scale Tablet machine

Allpack Single Punch Tablet Machine

These machines are used for small to moderate level of production volume used mainly in laboratories or small pharmaceutical facilities.

Medium scale Tablet machine

Flower Basket Tablet Machine- Picture Courtesy: Aipak

These machines are used for larger to moderate production volumes but not suitable for industrial scale.

High speed tablet Machine

Aipak High speed tablet press

These machines are capable of producing thousands of tablets per minute, ideal for large pharmaceutical industries where bulk amount of tablet formation is required. In this type, following sub-types of tablet machine are categorized.

Compressed Biscuit Tablet Machine

Allpack compressed Biscuit Tablet Machine

This type of tablet machine is specifically dedicated to manufacturing civilians' and military hard food that stays longer and fresh. This machine is based on rotary working those compresses biscuits and is considered as a key element behind its working.

Effervescent High Speed Tablet Machine

Allpack Effervescent High Speed Tablet Machine

This is kind of double tablet press giving you high production of effervescent tablets with special carving shapes firmly pressed into circular shapes. This machine is capable of producing single, bi-layer or multi-layer tablets which has high demand in medicinal sectors.

Automation level

Manual Tablet machine

Manual Tablet Machine

Such machines are operated manually that means it require manual filling of die cavity with material to form a tablet.

Semi-Automatic Tablet Machine

Semi automatic tablet machine- picture courtesy: aipak

These machines are not fully automatic means it requires human intervention in feeding the die and ejecting a tablet.

Fully automatic Tablet Machine

Fully automatic Tablet Machine- Picture Courtesy: Aipak

These types of machines are fully automated, means minimal to no human intervention required in tablet formation processes. All the steps are done by machine itself.

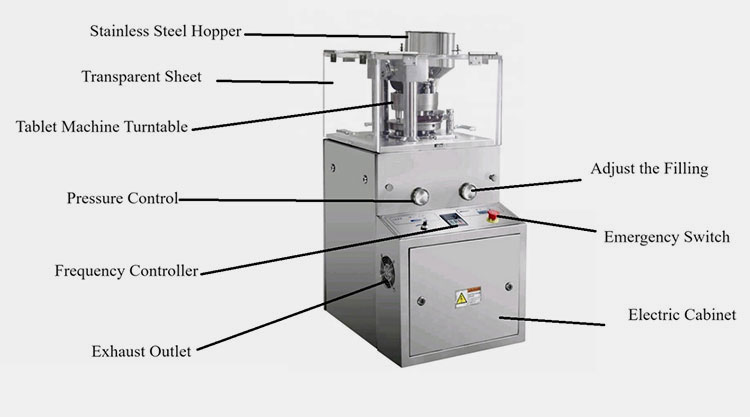

5.What is machine structure of tablet machine?

Allpack tablet machine

Tablet machines comprise of various parts and each part has different function to perform, following are the details.

Stainless steel hopper

Stainless steel hopper is made up of alloy which is composed of iron, chromium and nickel. This stainless steel is commonly used in pharmaceutical and food processing because of its anti-corrosive and hygienic properties.

Transparent sheet

The transparent sheet made up of polycarbonate or acrylic is used as a protective layer and also provides visibility of the interior of machine and technically prevent from potential hazards.

Tablet machine turntable

Tablet machines have a rotating platform for processing or assembling which comprises of compartments or stations where multiple tasks takes place like filling, compression, ejection in tablet formation.

Press control frequency controller

This part of tablet machine is responsible for regulating the speed and frequency of Tablet machine. It uses variable frequency drive to adjust motor speed for allowing the adjustments to particular production rates.

Exhaust outlet

Every machine has an opening to get rid of excess air , dust or fumes generated during process of tablet formation. This vent keeps the environment safe and clean from air borne particles which could lead to contamination.

Adjustable filling mechanisms

In tablet machine you can adjust the amount of material filled in a die mold or cavity by adjustable filling mechanism. With this mechanism we can control the amount of active ingredient dispensed, fill depth capacity, adjustable auger speed so that one could attain the uniformity in weight and accuracy.

Emergency switch

To avoid potential hazard or unwanted injuries, there is a prominent button clearly labeled so that one could press to stop the machine is a safety device that when pressed will halts the device in emergency.

Electric switch

Electric switch is responsible for power supply to the machine, it has several buttons to turn on or off, adjust specific setting of machines and to activate certain functions.

6.What is the working of tablet machine?

The working of the tablet machine involves several steps which are explained below:

Filling

Filling- Picture courtesy: ipharmachine

Filling is the first step in which powdered or granulated material is filled into hopper. Hopper led the powder to flow in the feeding unit called as feeding frame. Then feeding frame evenly distribute powder into the die cavity.

Metering

metering

Second working step is metering also called as weighing or dosage, in which precise amount of powder id weighed and then lower punch moves upward to remove excess material.

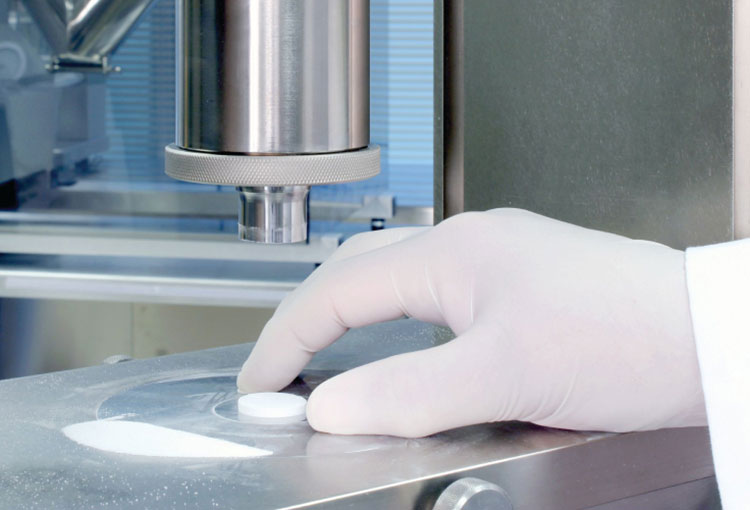

Compression

Compression- Picture Courtesy: Fluidpack

Compression is the third step; force is applied to compress powder into tablet. Furthermore, this process involves two steps known as pre compression and main compression.

In pre compression stage the upper punch descends downward to compress powder slightly and remove air pockets.

In main compression stage both the punches are brought together with much higher force to compress the powder so that it would attain the shape of tablet.

Ejection

Ejection of multi-layer tablets

Ejection is the last step in which the upper punch moves upward. Lower punch following the upper punch will raise the ejection and the tablets are ejected from the die bore to the scrapper, therefore scrapper will move the formed tablets into the container.

7.What is tooling of tablet machine?

To ensure the uniformity in shape sizes weight there are set of components in Tablet machine which are commonly referred as tooling. The primary components of the tooling tablet machines are:

Punches

Punches of tablet machine

Punches are the solid metal rod with specific sizes or imprint on it and it is used to compress the powder to form a tablet. There are two types of punches upper punch and lower punch. Upper punches descend from the turret or cam to compress the powder while lower punch rise to eject the formed tablet.

Dies

Dies of Tablet Machine

Dies are the solid metal mold which defines the size and shape of the tablets. Dies are arranged in a circular pattern on a turret or a rotary stand on a single punch machine. Each die consists of a punch cavity the upper die compresses the powder while the lower die ejects the formed tablet.

Die table

Die Table

It is a platform where all the dies a mounted. It rotates so that it could adjust the beneath die and adjust the indexes to carry out compression and ejection.

Die locks

Die Lock

Die locks are the phenomena to secure the dies in place during compression. They prevent dies from shifting under high pressure. They also ensure the uniformity in tablet thickness and prevent the damage of tooling.

Cam tracks

Cam Track

These are the channels or the grooves in the Tablet machine which ensure the correct placement and movement of the dies and punches during compression and ejection in tablet formation. It also ensures the precise alignment of upper and lower dies and punches.

8.How to maintain a tablet machine?

Maintaining a tablet machine- Picture courtesy: scientist live

Daily inspections and regular tunes ups are primarily required for the maintenance of the machine. Waiting for malfunction or unwanted incidents may halt the manufacturing processes which may cause a loss to economy in both ways like not meeting up the consumer requirement plus the wearing and tearing of machine parts.

Therefore, good preventive measures should be taken, and main principles must be followed,

- Excessive wear: when parts are not aligning correctly the will start to be wear off and damaged.

- Erratic compression and inconsistent weight control: it’s also an indicator to check whether machine is working promptly according to intended guidelines.

- Poor yield: utilization of damaged machine parts mostly results in extra unwanted loss.

- Migration of product outside zone: this is an indication of poorly adjusted part or utilization of damaged parts or seals.

- Weird noises: operators must be monitoring unwanted sound and noises or extra vibration which is sign of damaged parts or misaligned parts.

- Each and every part should be inspected regularly, informal or casual inspection may help to get rid of the problems or the problems are caught early.

9.What type of tablets can be produced from tablet machine?

Tablets are readily available in variety of ranges which differ in sizes or shapes. Variable tablet types are as follows.

Single layer tablet: Single layer tablets are those which have single active pharmaceutical ingredient. |

Bilayer tablets: bilayer tablets are made as the first layer with active ingredient is compressed and then other powdered material are kept on formed tablet and compressed together to form a bilayer tablet. |

Multilayer tablet: multilayer tablet is those which comprises of more than two active ingredient, the purpose of this tablet is to pave off the effective drug delivery system |

Effervescent tablet: effervescent tablets are carbon tablets normally larger than standard tablet and intended to dissolve in liquids. |

Chewable Tablets: are those ingested upon chewing and obtain active compounds. |

Laundry Tablets: are those used for laundry purposes that produce foaming effects when react with water and cleanse the sticky and hard stains. |

Medicine Tablet: which is entirely made up of medicinal active pressed firmly by a tablet machine that exerts therapeutic effect upon ingestion. |

|

10.What are the solutions and problems of tablet machines?

While working with tablet machine manufacturer must experiences some pitfalls but the expert is one who knows how to overcome the problem.

Capping of tablet after compression

Capping- Picture Courtesy: Sciendirect

This is because of the trapped air inside the die cavity and extra dry nature of the granulated or powdered material. This is overcome by increasing the dwell time of pre compression stage so the it will get extra time to come out. Make the use of enough lubricant for the compression of powder.

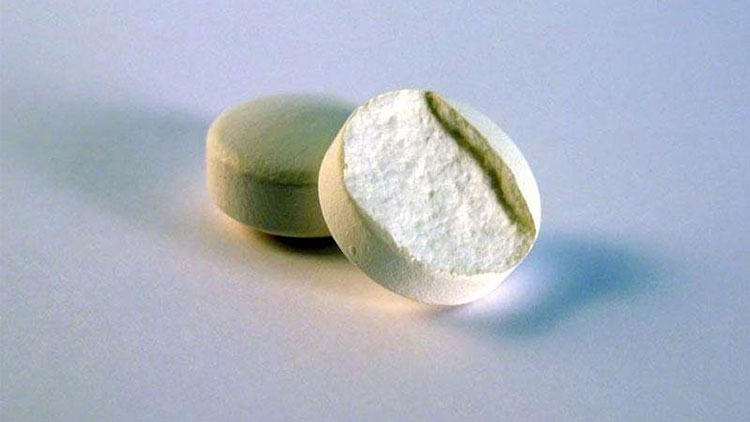

Lamination of tablets

Lamination- Picture Courtesy: Merlin Powder

Over compression or the inappropriate dies can cause the tablet to get cracked. So to avoid this one must enhance pre compression time to lead powders to stick together. To avoid lamination, tapered dies must be used.

Tablet particles stick to the punch or tip heads

Particles stick to the punch- Picture Courtesy: Pharm Tech

This is one of the major serious issues caused when particles from inside are wet , not dried completely tend to stick to punches. Sometime punching tools are also responsible for particles picking. Solution to such problem is increasing the pre compression dwell time for complete drying up of particles. After wet granulation particles must be given extra drying time. Regular polishing of pinches and dies will also reduce the tablets sticking to their heads.

Tablets binding happen inside the die restricting the way for tablet ejection

Tablet fails to ejects- Picture Courtesy: Tablet and capsule

When too much binding agent is used this leads the tablets to hold itself to die cavity and end result is a crumbled tablet when ejected. To avoid this problem binding and lubricating agent must be added carefully, and also makes sure that mixture is well dried.

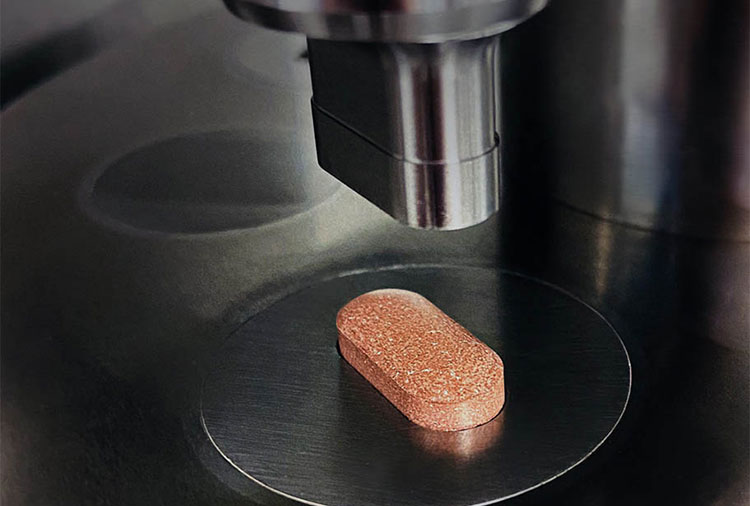

Tablets friability

Tablet Friability- Picture Courtesy: Biogrund

When the granule with no fine powder is used, less binders are used, high compression speed is set, these all may encompasses the various problems of tablets in packaging, delivery, and coating. Solution to this problem is simple and easy, just use correct number of binders and maintain a suitable compression speed. Furthermore, also reduce the size of granules.

Conclusion

A tablet machine is mandatory not only for pharmaceuticals company but also for various field of manufacturing. Machine is offering promising production with even weight and sizes of tablets using correct and refined configurations to meet your expectations. When choosing a tablet machine, consider Allpack to get programmable equipment in a pocket friendly manner. Please contact us for more information & support.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide