Your Super Tablet Friability Tester Supplier

- Meets current specifications of USP, IP and other Pharmacopoeias

- Intelligently control the rotating speed of cylinder and revolutions

- Auto stop at timing point

Tablet Friability Tester

Allpack tablet friability tester strictly follows the current Chinese Pharmacopoeia specification. It is suitable for testing the stability, abrasion resistance, rolling resistance and other physical strength (such as crushing strength, etc.) of drug tablets by tablet manufacturers, drug inspection institutes and hospitals. It is an indispensable and necessary equipment in drug testing.The revolution of the drum can be preset at any time, either preset or real data is displayed on the LCD. Microprocessor unit is used to control all operations, high accuracy is achieved in testing rotary speed and circle number.

Allpack Tablet Friability Tester

Tablet Manufacturers Drug Testing Institutes Hospitals Tablet Friability Tester

Allpack tablet friability tester is used to test the physical properties of non-coated tablets in mechanical stability, abrasion resistance collision resistance and so on in the process of production, packaging and storage. The tablet friability tester can also test the friable condition of tablet coating and capsules. The tablet friability tester can display the he preset value and real-time value through time division.The number of turns and rotating speed adopt the standard of Pharmacopeia, dispensing with modification, which enables the operation to be simple and convenient.

Two drums run synchronously. Auto stop at timing point.

The drum is made of high quality hyaline acryl.

The speed and revolution of the drum is constant

The Buyer's Guide

Tablet Friability Tester: The Complete Buying Guide In 2025

In the dynamic era of the manufacturing and packaging world, you cannot ignore even minor parameters when it comes to producing pharmaceuticals and related items. Do you know how it is estimated that tablets are capable of marketing and suitable for distribution worldwide? Have you ever wondered how tablets show integrity when subjected to various machines and packaging?

This is tested and passed by subjecting them to a tablet friability tester. This is an excellent solution to assess how much a tablet is mechanically strengthened to proceed with other steps till it reaches you. So, this buying guide is aimed at exploring useful knowledge about a tablet friability tester and associated discussions. Let’s read it now!

1.What is a tablet friability tester?

Allpack Tablet Friability Tester

During handling, packaging, and transportation, due to excessive physical forces, the tablets are more likely to chip and in severe cases break or cap. Tablets therefore must be formulated to resist this strain.

To assess the friability of prototypes tablets-whether coated, uncoated, or compressed- and their knack to endure physical stress, friction, pressure, and vibrations, pharmaceutical firms rely on a unique device called a tablet friability tester.

It analyzes the resilience of tablets; therefore, it has a significant role in quality control operations. It enables developers to ascertain the quality and efficacy of their products by evaluating the weight loss that transpires when tablets undergo handling, transit, and coating procedures.

2.How is a tablet friability tester so important?

A tablet friability tester is part of routine pharmaceutical developmental procedures to assess the strength and friability characteristics of tablets. Manufacturers use it to ensure the durability and stability of their products. Let’s have a detailed look at the important benefits of a tablet friability tester.

Valuable to Patient Safety

Valuable to Patient Safety- Picture Courtesy: InformedDNA

Tablet breakage results in dosing errors, loss of important medication components, and jeopardizes patient safety. As a result, determining the friability of tablets is crucial. Therefore, a popular tool- tablet friability tester is utilized at each developmental step to reduce the danger to patient safety.

Role in Quality Control

Quality Control- Picture Courtesy: Etcon Analytical

Manufacturing sectors use a tablet friability tester to check for quality control problems in tablet formulation. It guarantees that tablets are produced following the highest quality standards for manufacturers and regulators. It assures the tablets' physical stability and durability while being transported to patients by assessing their strength.

Easy Product Optimization

Easy Product Optimization- Picture Courtesy: Copley Scientific

Valuable insights provided by a tablet friability tester, aid manufacturers across the globe in improving their formulation characteristics. In light of these findings, manufacturers understand aspects that influence tablet resilience and alter their active pharmaceutical components, production approaches, and coating controls to improve tablet durability thresholds.

Maintaining Cost-effectivity

Maintaining Cost-effectivity- Picture Courtesy: CDPHP Blog

Friability testing with a tablet friability tester can reduce product wastage and losses by assessing tablets that tend to crumble early in the manufacturing process. This averts the possibility of defective tablets from going further in the logistics network, decreasing expenses related to re-formulation.

Regulatory Compliance

Regulatory Compliance- Picture Courtesy: Romaco

Reputable pharmacopeial organizations, including the European Pharmacopeia (EP), Japan Pharmacopeia (JP), and United States Pharmacopeia (USP), mandate complying with specific friability requirements for tablet approval. For this reason, tablet weight loss with a tablet friability tester must be verified before going for product approval.

No Product Recalls

No Product Recalls- Picture Courtesy: PhillyVoice

Tablets are recalled from the market owing to higher friability and breakage rates, rigorously deteriorating brand reputation. Hence, formulators carry out friability testing with a tablet friability tester to recognize and rectify probable formulation issues before they result in product recalls and company blacklisting.

3.How is a tablet friability tester used in various industries?

Tablet friability tester is usually associated with pharmaceutical development, but its applications encompass other industries that develop solid or molded items. Some industries in which tablet friability tester has a key role are discussed below:

Pharmaceutical Industry

Pharmaceutical Tablets- Picture Courtesy: CNET

This testing machine accesses friability percentages, quantifies weight loss, and gives surety that testing samples will handle the demands of packing, shipment, and retailing in pharmaceutical manufacturing. This evaluatory data enables assaying of miscellaneous excipients elemental in enriching the robustness of the tablets.

Nutraceutical Industry

Nutraceutical Pills- Picture Courtesy: Atlas Health Institute

Friability studies are also conducted in the nutraceutical industry to examine the crumbling tendency of vitamin pills, mineral tablets, and herbal supplements. Tablet friability tester is pivotal in the dietary supplement manufacturing sector because it ensures that tablets retain their dimensions and integrity throughout the supply networks.

Food Industry

Food Confectionary- Picture Courtesy: Best Products

A tablet friability tester assesses the fragility of food products, such as chocolate, candies, chips, etc. It ensures that these products are robust and stable, and have desired texture and optimal appearance. It also notifies that high-end confectionaries, while being delicate are resilient enough to resist physical forces.

Cosmetic Industry

Cosmetics Powders

In the cosmetic industry, several compressed powders are routinely processed for developing beauty products, for instance, eye shadows, blushes, and face powders. Therefore, a tablet friability tester is excessively used in this industry to determine the strength of compressed powders and verify that do not fragment under physical pressure.

Agricultural Industry

Agriculture Pellets

A tablet friability tester is utilized in agriculture facilities with the singular purpose of determining the sturdiness of agriculture products, for example, pesticide pills, fertilizer tablets, and seed coating. It estimates the nutritional dosing of animal feed pellets.

Chemical Industry

Chemical Tablets

Solid chemical tablets are developed by compressing powders. These chemical tablets like water treatment pills or detergent tablets are often checked by the tablet friability tester in the chemical industry. This instrument aids in establishing product efficacy and maintaining batch-to-batch consistency.

4.Do you know how a tablet friability tester works?

The principle behind the working of a tablet friability tester is based on the rotation of tablets in the drum and the estimation of weight loss due to mechanical forces of friction and vibration. The tablets in the drum are exposed to controlled tumbling for a predetermined number of rotations.

A sequence of working steps of a tablet friability tester is penned below:

Sample Preparation

Sample Preparation- Picture Courtesy: Merlin Powder Characterisation

First, before starting the operation, experts advised calibrating your tablet friability tester to attain the right breakability estimates. Tablet dedusting is a must because any powders on the exterior of tablets contribute to inaccurate evaluation.

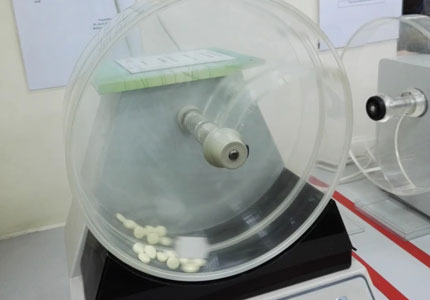

Loading the Drum

Loading Drum- Picture Courtesy: RAAB Scientific Solution

When stocking sample tablets weighing up to 650 mg, put 6.5g of the sample in the drum; in case the sample tablet weighs more than 650 mg, it is best to stock 10 tablets in the machine drum. So after inserting samples into it successfully, it's time to configure the rotation speed and number of rotations to about 25 RPM and 100 times, respectively.

Tablets undergo the same mechanical strain as they endure in real-time handling because of the drum movement.

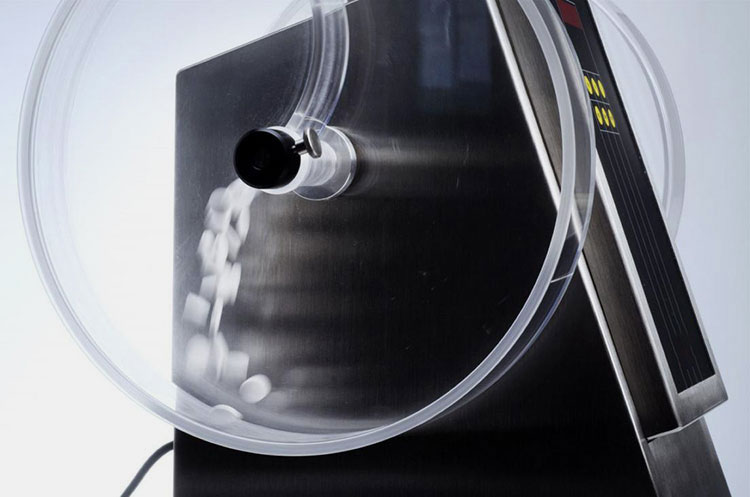

Tablet Movement

Tablet Movement- Picture Courtesy: Pharmaceutical Networking

Tablets are moved in the upward direction by the baffles and then dropped from a preset height of around 6 inches. With each rotation, tablets are raised and dropped. The rotations last for about 4 minutes.

When preset rotations are completed, the machine stops, and tablets are removed from the drum. These tablets are dedusted and weighed to determine weight loss due to breakage or chipping.

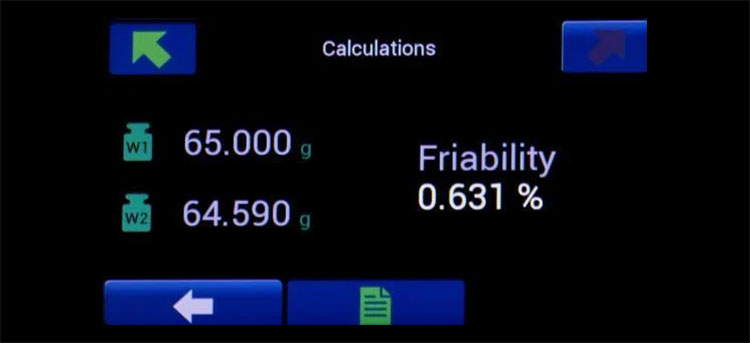

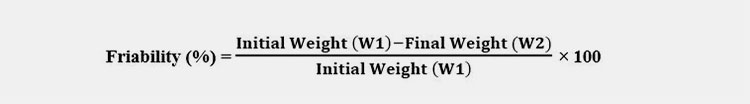

Calculation of Friability

Calculation of Friability- Picture Courtesy: Copley Scientific

This formula determines the friability percentage:

Prototype tablets are resilient and can handle mechanical forces if the friability percentage is determined to be less than 1%. Tablets are liable to breakage and crumbling due to rigorous forces developed during shipment and handling if the said percentage is higher than 1%.

5.What are the parts of a tablet friability tester?

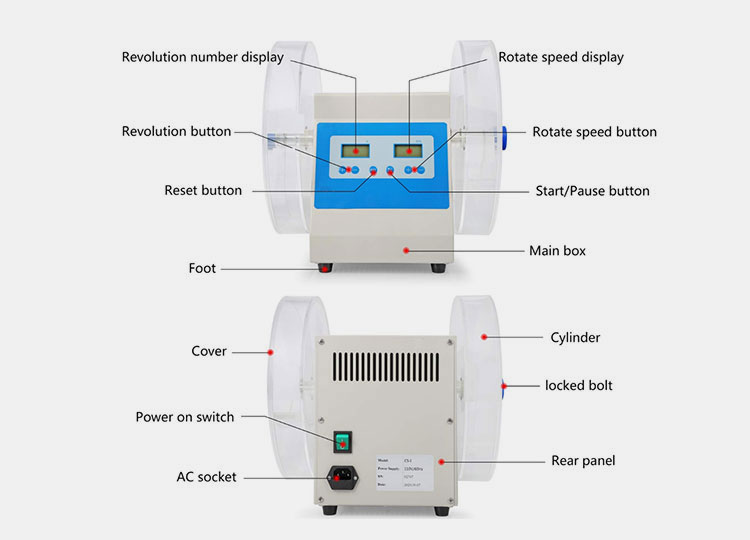

A tablet friability tester is furnished with various fundamental parts, imperative in inducing strains of shipment. A list of major parts of a tablet friability tester is summarized below:

Parts of Tablet Friability Tester

| Revolution Number Display | It indicates the values of drum revolutions. |

| Revolution Button | Operators input and control the drum rotation by pressing the revolution button. |

| Reset Button | This button clears the different programming options and readies the instrument for the new friability examination. With this button, the device returns to its original setting. It prevents miscalculations and overlapping from earlier tests. |

| Rotational Speed Display | This display assists the workforce in checking and confirming the rotation speed of the drum component. |

| Rotational Speed Button | This button allows operators to finetune the revolution speed of the drum. |

| Start/Pause Button | Operators can instantly set off and halt the equipment with the start/stop button. |

| Main Box | This part encloses the main components and electrical parts, such as motors, regulators, drives, timers, etc. that power and drive the machine. It keeps delicate components safe from dust or external environmental agents. |

| Cover | This protective module encompasses important internal parts of the tablet friability tester, for instance, the rotating drum. It has many safety functions, for example, acting as an external barrier to the rotating drum, safeguarding it from environmental agents, and stopping operators from directly accessing the rotating drum. |

| Power on Switch | It supplies the electric current to the core components of the tablet friability tester, for instance, the motor, displays, and control panel. The machine display lights up on turning on this switch. |

| AC Socket | It is a connector by which the instrument is connected to the external power line. It turns on the machine by aiding the flow of electrical power to core parts. |

| Cylinder/Drum | The drum or cylinder is the pivotal part of a tablet friability tester. In this part, tablets are loaded for evaluation. It is fabricated from acrylic or polycarbonate material that facilitates the monitoring of tablets during analysis. The drum is cylindrical with an inner curvature and has durability to tolerate recurrent use. Its standard dimensions according to pharmacopeial regulations are 287 mm in diameter and 38 mm in depth. |

| Locked Bolt | Its function is to lock the drum or protective covers. It keeps the drum and its associated cover secure and aligned during the rotational movement. It allows ease in part removal during maintenance and cleaning. |

| Rear Panel | This is a structural part present at the rear side of the tablet friability tester. It features ports vents, and connectors. |

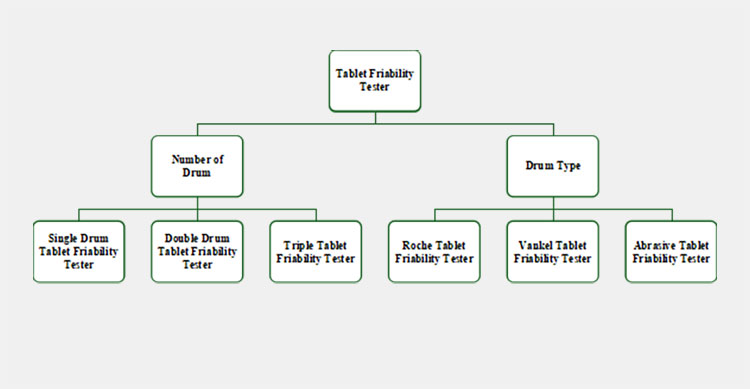

6.What are available types of tablet friability testers?

A tablet friability tester is subdivided into two different categories based on the number of drums and the design of drums. These types of tablet friability testers are listed below:

Number of Drum

Single Drum Tablet Friability Tester

Single Drum Tablet Friability Tester- Picture Courtesy: Copley Scientific

It is the most basic and prevalent kind of tablet friability tester. It has only one drum, where tablets are loaded for evaluation. It has a straightforward design that is easier to access, operate and maintain. It is well-matched to small-scale laboratories that only examine a few samples infrequently.

It comes with a lower price tag; however, it can inspect one batch of tablets in one cycle, thus it is less effective for mass-scale testing.

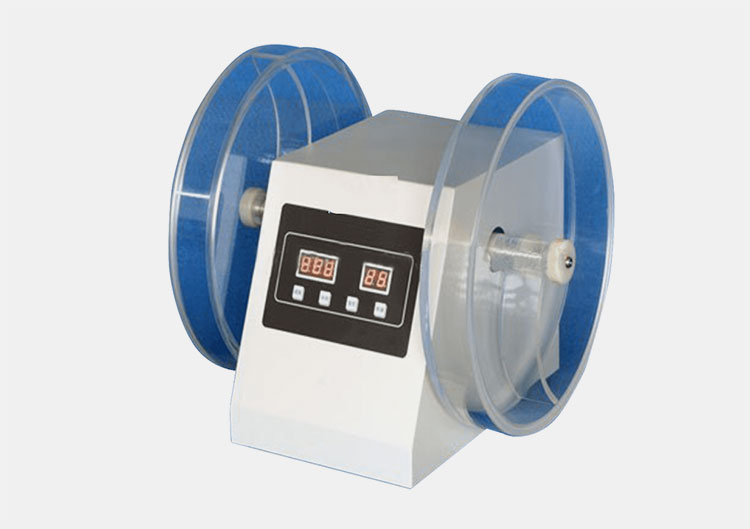

Double Drum Tablet Friability Tester

Double Drum Tablet Friability Tester- Picture Courtesy: Erweka

This type of tablet friability tester consists of two drums; therefore, it has the capability of carrying out two simultaneous tests per cycle. It can also compare the friability characteristics of two diverse tablet batches concurrently.

Each drum rotates independently and this dual design leads to higher operational throughput and testing power. Due to its multiple analyses per go, it is usually seen in large-scale developmental sectors.

Triple Tablet Friability Tester

Triple Tablet Friability Tester- Picture Courtesy: Pharma Test

It is the latest and most sophisticated kind of tablet friability tester, consists of three independent rotating drums, and is engineered for mass-scale environments where three samples are processed at once.

Different testing conditions are programmed in the triple tablet friability tester; hence, it has the versatility to handle different types of formulations. It has three times more efficiency than a single drum tablet friability tester. However, it is more expensive than the other two types of tablet friability tester.

Drum Type

Roche Tablet Friability Tester

Roche Tablet Friability Tester- Picture Courtesy: Labotronics

It is the most popular type of tablet friability tester, used all over the globe for determining the friability properties of tablets. The drum in the Roche tablet friability tester consists of a single arch and a single chamber, thus, it evaluates one sample in one go.

Tablets are introduced in the chamber of the drum, and with the rotation of the drum, tablets are lifted and fall, mimicking disruptive forces during handling.

Vankel Tablet Friability Tester

Vankel Tablet Friability Tester- Picture Courtesy: Triad Scientific

This type of tablet friability tester features a drum with a double chamber and two arches, consequently, it assesses two samples simultaneously. Each chamber performs tests independently in the same rotating drum, therefore, samples are examined under similar settings but in separate chambers.

It has more throughput than a Roche-type tablet friability tester.

Abrasive Tablet Friability Tester

Abrasive Tablet Friability Tester- Picture Courtesy: Pharmaceutical Networking

It has multiple baffles in the drum structure that produce more mechanical pressure on the tablets with their presence of colliding surfaces. These structures lead to more intense tumbling, thus it readily tests both friability and abrasion resistance.

It induces more harsh mechanical forces, thereby, analyzing physical strength and surface abrasion.

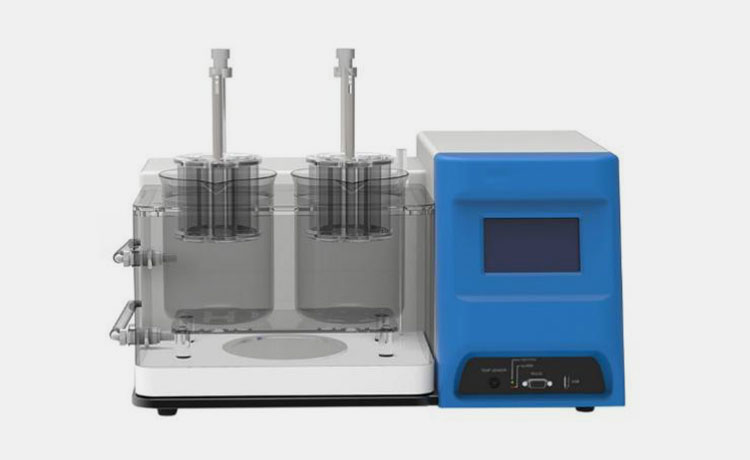

7.What is the difference between a tablet friability tester and a disintegration tester?

The tablet friability tester and disintegration tester are both used in quality control inspection but they are vastly different from one another, having different testing objectives. Let’s have a look at the differences between a tablet friability tester and a disintegration tester.

| Properties | Tablet Friability Tester | Disintegration Tester |

| Picture |

Picture Courtesy: Pharmaceutical Networking |

Picture Courtesy: Allpack |

| Objective | It assesses the mechanical strength and tolerance of tablets to breakage. | It estimates the time at which the tablet is broken into its contents. |

| Functioning | Tablets rotate and tumble in the rotating drum. | Tablets are immersed in the liquid medium and moved with the flow of liquid. |

| Test Outcomes | It calculates the weight loss percentage owing to physical forces. | It determines the disintegration time, which is in seconds or minutes. |

| Testing Condition | It takes place in a dry environment, mimicking the mechanical forces during tablet handling. | It takes place in a wet environment, inducing the changes that occur in the stomach and intestine during drug fragmentation. |

| Use | It measures tablet durability and friability. | It measures drug release rate and bioavailability. |

| Standard | It adheres to USP <1216> and EP. | It complies with USP <701>, BP, and EP. |

| Device Construction | It uses a rotating drum for lifting and falling of tablets. | It uses basket-rack assembly for tablet movement. |

8.What are the common problems and solutions of a tablet friability tester?

A tablet friability tester is worthwhile in both quality control and quality assurance procedures. It may acquire occasional problems, subsequently disrupting the throughput of operation. Hence, for your facilitation, we are stating common problems and solutions of a tablet friability tester:

Inaccuracy of Test Readings

Inaccuracy of Test Readings- Picture Courtesy: Pharma Test

Occasionally, a tablet friability tester displays erroneous or varying readings for weight loss percentage, number of rotations, and rotational speed. Sometimes, test inputs and outputs do not correspond to expected ranges.

Solution

To solve this problem, calibration of a tablet friability tester daily must be carried out following producer recommendations or pharmacopeial regulations. Also, examine and replace defective motors and drives.

Variation in Drum Rotation

Variation in Drum Rotation- Picture Courtesy: Pharma Test

It is observed that the drum does not have an accurate rotational speed or stop rotating during assessment.

Solution

To resolve this issue: first, check if the machine is connected to the power supply and if no electrical fault is present in the machine. Tighten loose drive belts and verify that the motor is running at the correct speed and is not facing any issues. Evaluate the machine at different speeds to assess the performance of the speed control mechanism.

Errors in Revolution Count

Issues in Revolution Count

In some cases, the machine does not halt after finishing the predefined number of rotations, or the rotation display shows inaccurate values.

Solution

To rectify this problem: you must readjust and re-input program options. The rotation sensor must be inspected to confirm its proper functioning. Clean it to remove debris that affects its sensing ability.

High Tablet Breaking Rate

High Tablet Breaking Rate- Picture Courtesy: Public Citizen

From time to time, tablets break more frequently, leading to more friability percentages than the anticipated limit.

Solution

The tablet hardness status- for tolerating the rotational strain- must be assessed by rechecking the formulation practices. Examine and re-enter the rotational parameters so they are in line with specified pharmacopeial guidelines. Friability analysis should be carried out in controlled humidity and temperature conditions.

Non-Uniform Tablet Tumbling

Non-Uniform Tablet Tumbling

Sometimes, drums are not properly adjusted, contributing to non-uniform tablet tumbling and imprecise test outcomes.

Solution

Properly secure and align the drum to the machine. Loose screws and bolts must be tightened to ensure even tablet tumbling. Routinely inspect the drum positioning and attachment to avert rotational issues.

High Rate of Dust Generation

High Rate of Dust Generation- Picture Courtesy: Healthline

A high amount of drug dust is generated during evaluation, which impacts test outcomes and results in contamination of the testing station.

Solution

Recheck formulation steps to prevent dust production in the drum. Frequently clean the testing station and employ a dust extractor in closed settings. Dust production is also reduced by cleaning the tablet exteriors.

9.What are the prospects of a tablet friability tester?

Future Prospects of Tablet Friability Tester

The market of tablet friability testers is continuously revolutionized due to calls for potent and safe pharmaceuticals. Strict regulatory measures are enforcing positive changes to the design, functionalities, and estimation power of the tablet friability tester. It is anticipated that the market share of a tablet friability tester will rise with a CAGR of 14.2% during the projected years between 2024 to 2031.

Modern tablet friability testers will be customized using smart technologies, for example, the Internet of Things, remote connectivity, and artificial intelligence. This will promote accurate outcomes and effortless real-time data appraisal. These futuristic instruments facilitate both skilled and non-skilled users due to their intuitive touchscreen interfaces.

There is a plan to boost the use of a tablet friability tester by customizing its functional requirements. Furthermore, higher environmental awareness is leading to the utility of sustainable constituents and procedures in the tablet friability tester.

Conclusion

In summary, there are specific aims of a tablet friability tester- establishing tablet durability and quality. It is engineered with sophisticated and state-of-the-art calibration assemblies and rotational drums to produce accurate test data for testing and formulating sectors. For producing safe therapies and compliance with austere pharmacopeial standards, you should opt for a competent and ultimate quality tablet friability tester. So, for checking in with experts, get in touch with Allpack. We are dedicated to helping you with your tablet friability testing queries and problems.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586