Tablet Counter Machine: The Complete Buying Guide In 2025

Tablet Counter Machine: The Complete Buying Guide In 2025

Do you want to make your pharmaceutical production line more efficient? Do you feel that manually counting pills takes too much time and effort? If so, this might be a good time to consider purchasing a tablet counter machine. These cutting-edge tools may greatly improve your manufacturing process's productivity, precision, and efficiency.

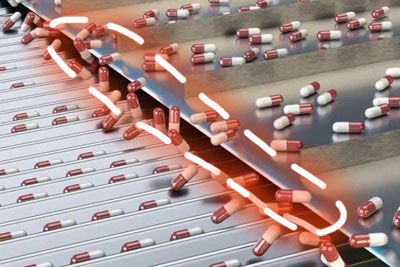

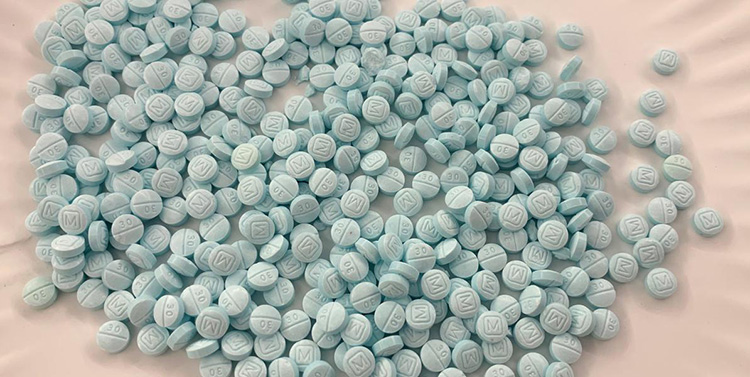

Picture Courtesy: Popular Science

Tablet counting can be a daunting task as it takes too much time, focus, and labor, particularly in large manufacturing industries, where the demand for production is extremely high. That’s why considering and investing in a tablet counter machine can be of high value for your business.

A tablet counter machine has gained so much importance in the growing market of industries. With technological advancements, the tablet counting machine has also evolved over the years. However, with a heft of options available on the market, selecting a suitable and best tablet counter machine might be a difficult task.

Don’t worry. We are here to ease your difficulty and assist you in choosing the right tablet counter machine. In this buying guide, you will be provided with comprehensive details about the tablet counter machine. So don’t go anywhere and join us on this blog;

1.How would you define a tablet counter machine?

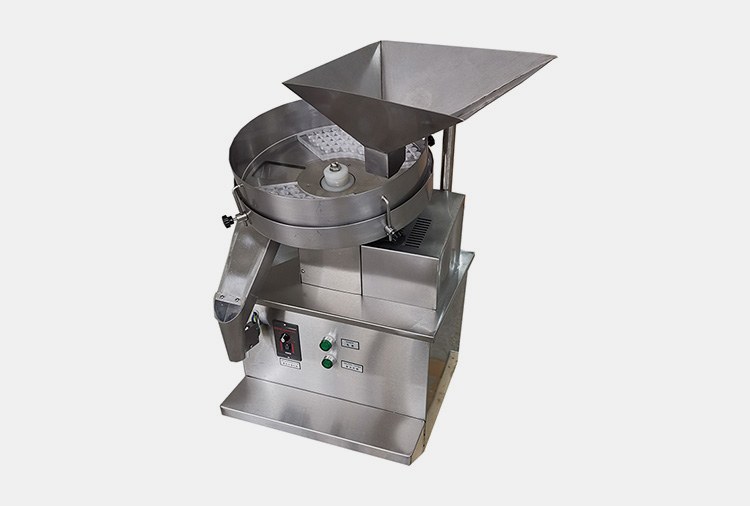

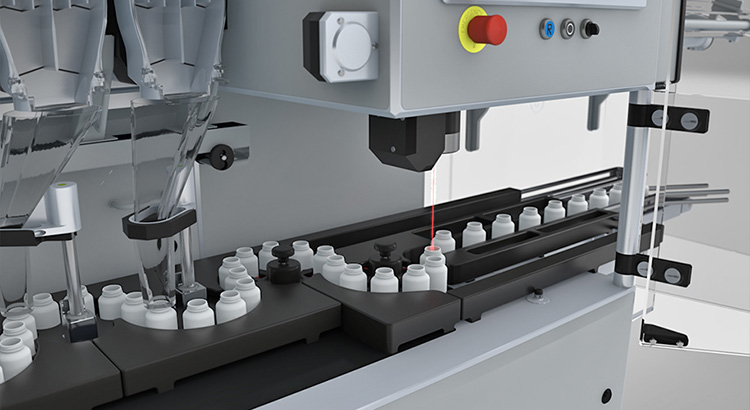

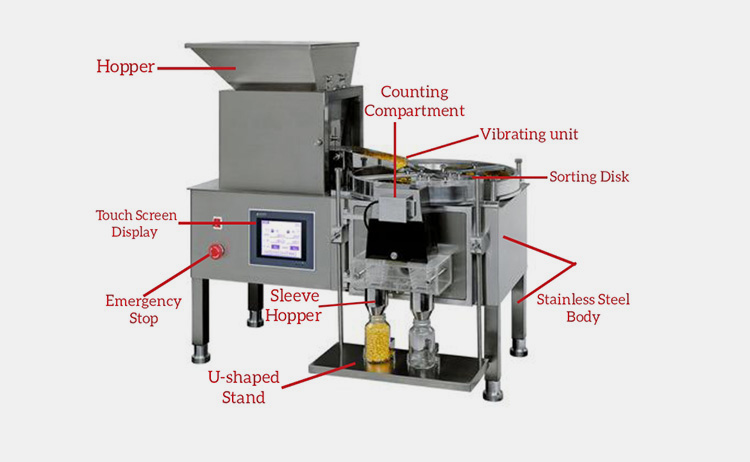

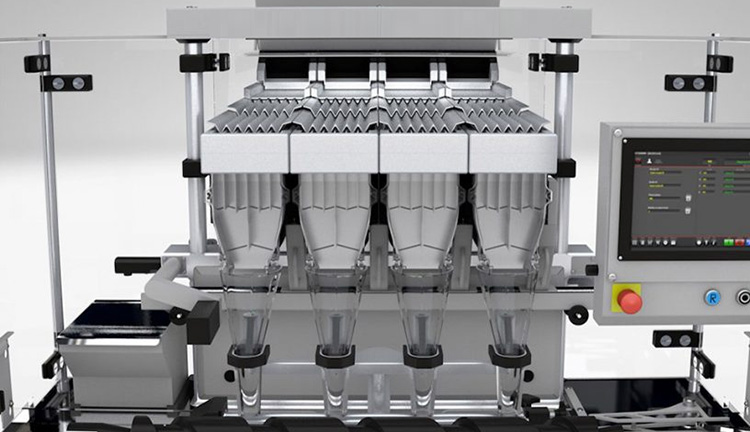

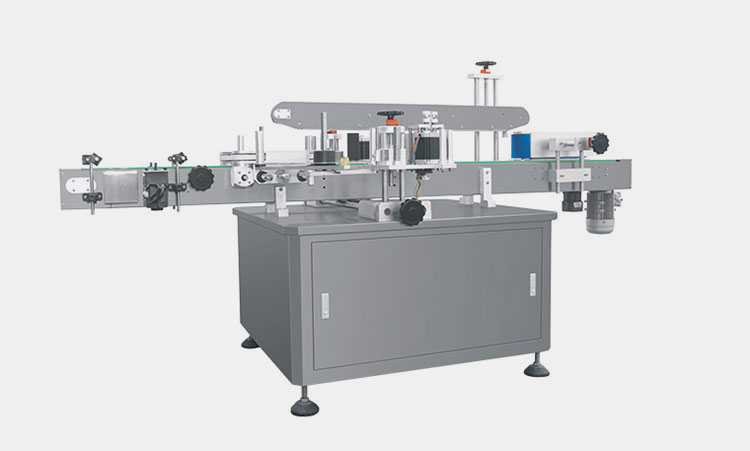

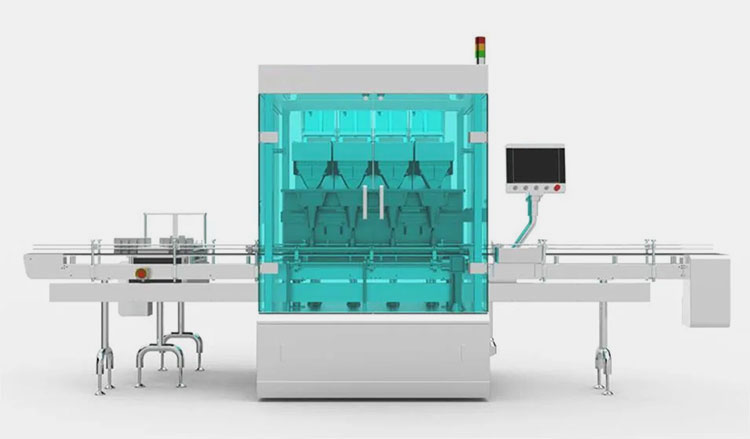

Allpack Automatic Tablet Counter Machine

A tablet counter machine is an advanced piece of equipment employed in the pharmaceutical industry for efficiently counting and dispensing manufactured tablets.

Tablet counting is a process done for the accurate dispensing of tablets in a package for treatment as the drug products are expensive and have a record of production. The tablets are being produced at a high volume in the industries and counting them manually can be a daunting task.

Therefore, a tablet counter machine is the ultimate solution for this problem as it offers a much faster, more efficient, and accurate counting of pills. The device is designed to precisely count and dispense tablets into packaging containers.

2.What is the need for a tablet counter machine?

A tablet counter machine is widely employed not only in the pharmaceuticals but also across various industries for various applications. Some of the sectors in which a tablet counter machine plays a range of important roles are;

Pharmaceuticals

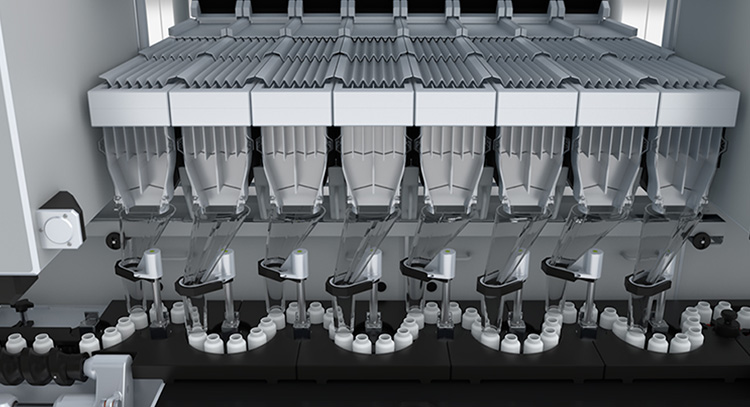

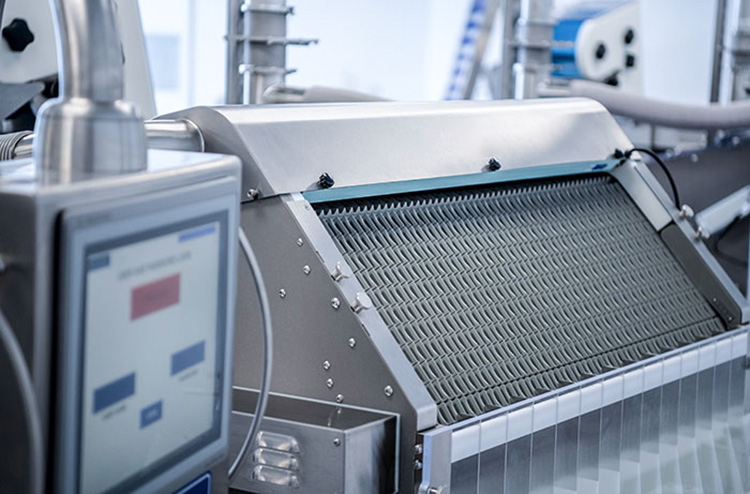

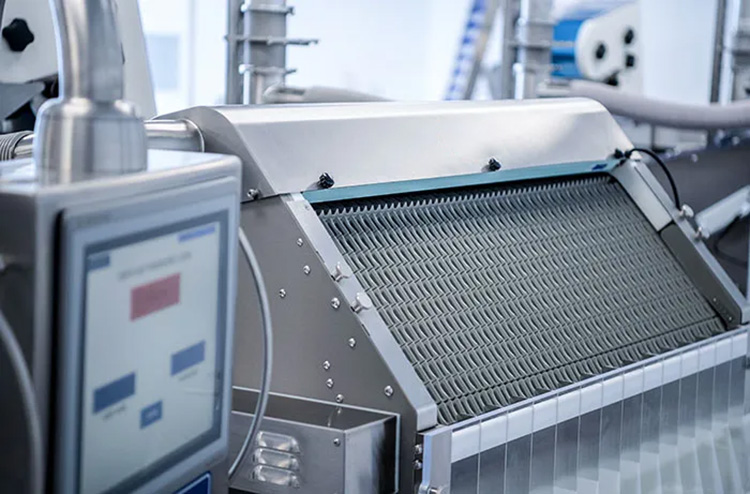

Pharmaceutical Tablet Counting – Picture Courtesy: Fette Compacting

In the drug industry, the tablet counter machine is utilized for the precise and efficient counting of a variety of pills. The accuracy of the tablet counter machine has significant benefits.

The medicinal products are costly and their precise counting and distribution within packages for a treatment protocol are very crucial.

That’s why employing a tablet counter machine benefits not only the consumers but also the manufacturers by meeting the market demands.

Food

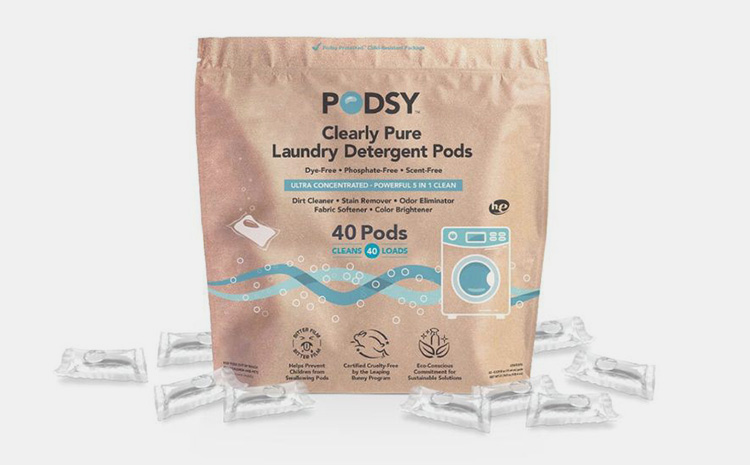

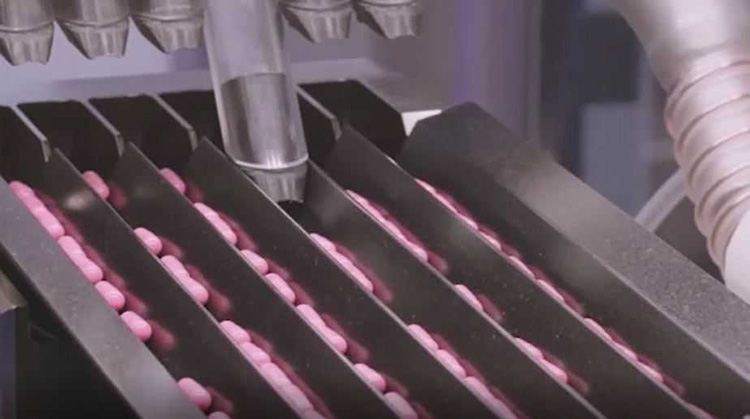

Caffeine Pills – Picture Courtesy: Positive Choices

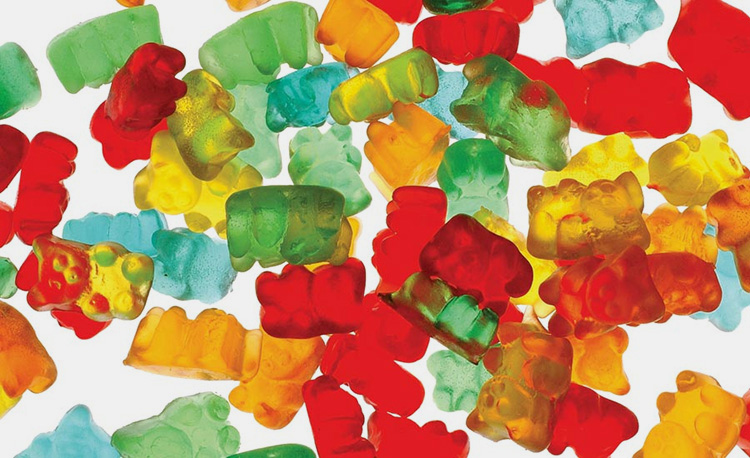

Yes, that’s true. A tablet counter machine due to its versatile nature can also be employed in the food industry for the accurate counting of different food products, like candies, gums, beans, and jellies.

Nutraceuticals

Nutraceutical Applications – Picture Courtesy: Food Infotech

For the accurate counting and packaging of various dietary supplements, such as vitamins, minerals, and other products, a tablet counter machine is required and utilized in the nutraceutical industry.

Cosmetics

Beauty Pills – Picture Courtesy: Cosmostore

You will be amazed to hear that a tablet counter machine can be utilized in the skincare/cosmetics industry for the precise packaging of different skincare, beauty, and cosmetic products.

Chemicals

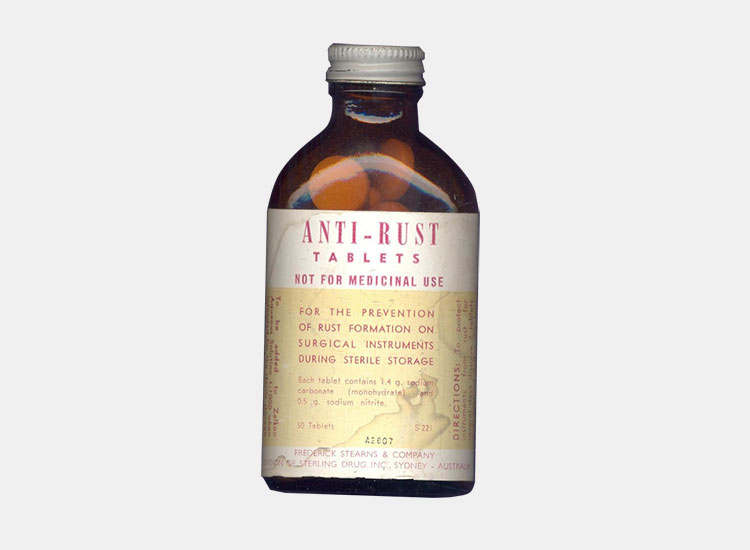

Chemical Industry/Applications – Picture Courtesy: eHive

Various types of chemical pellets, pills, and granules used in multiple chemical processes can be packaged efficiently with the help of a tablet counter machine.

3.What benefits can a tablet counter machine provide to you?

A tablet counter machine provides several remarkable benefits to manufacturers where precise counting and distribution of tablets can be of high value. Here we are discussing some of the vital benefits;

Efficiency

Efficient Working – Picture Courtesy: Altrimex

A tablet counter machine automates the process of counting, resulting in reduced time consumption and labor requirements. This feature leads to the high throughput and productivity of different production lines.

Accuracy

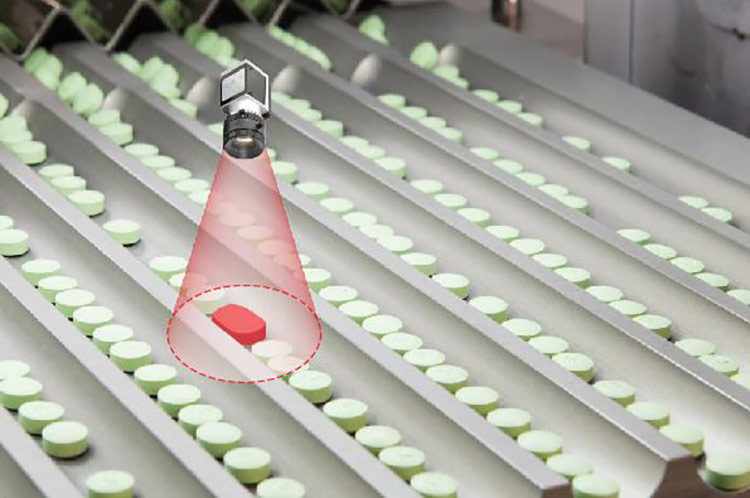

Accuracy in Processing

To ensure accurate operation, these machines are tailored with the precise mechanism of counting and highly advanced and sensitive sensors. These incredible features of the device lead to consistently accurate results.

Versatility

Flexibility in Handling of Various Products

The ability of a tablet counter machine to handle a variety of different tablets enables the manufacturers to utilize it for different formulations.

Time Leverage

Automated Working reduces Time Consumption

The automation characteristic of the tablet counter machine helps in high production in the least amount of time, maximizing the output and return on business.

Cost-effectiveness

Cost-effective in terms of Labor Requirement (Automation)

There is a long-term cost savings with the use of a tablet counter machine, as it provides automatic operation, resulting in the lower need for manual labor and thus reducing the operational cost.

Quality Control

Quality Operation – Picture Courtesy: Ipharmachine

By largely eliminating manual labor and thus human error, a tablet counter machine confers to improved quality control in the manufacturing process. It helps in the reduction of packaging errors and the maintenance of product consistency.

Streamlined Operation

Streamlined Workflow

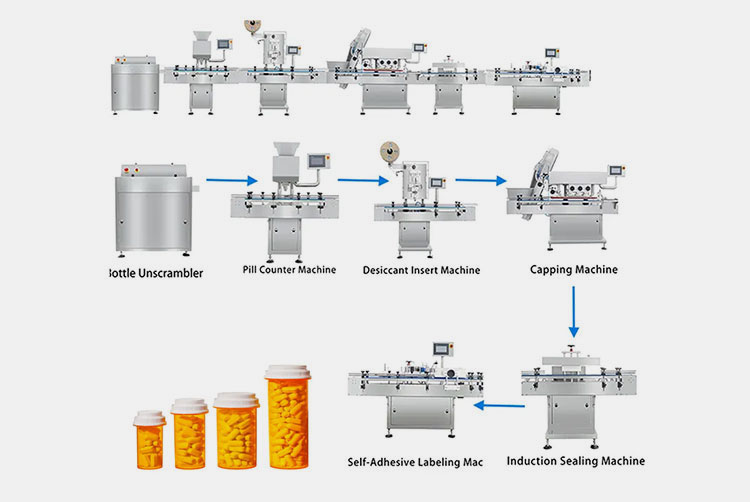

By connecting with other manufacturing industrial equipment, a tablet counter machine streamlines the operation by automatic processing, allowing the workers to focus on other tasks.

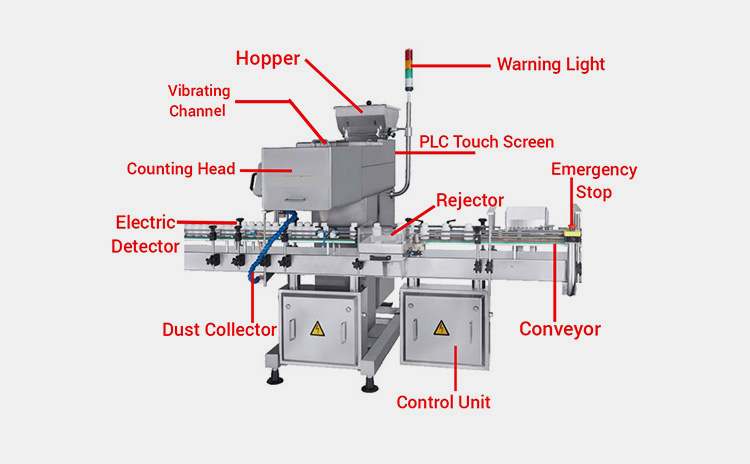

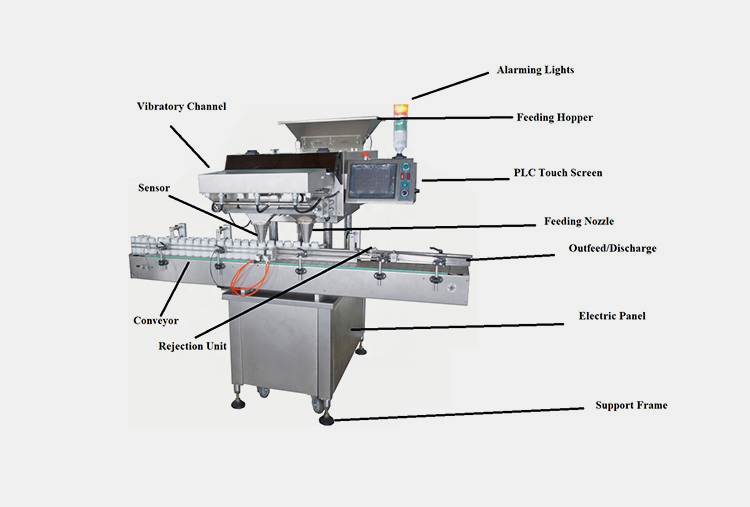

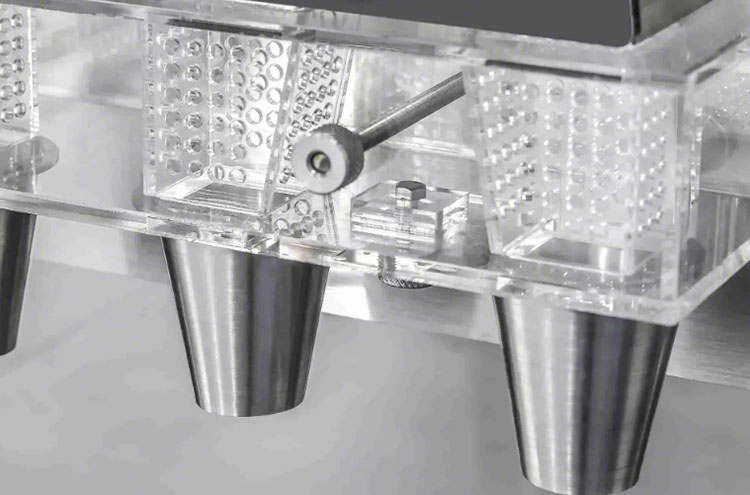

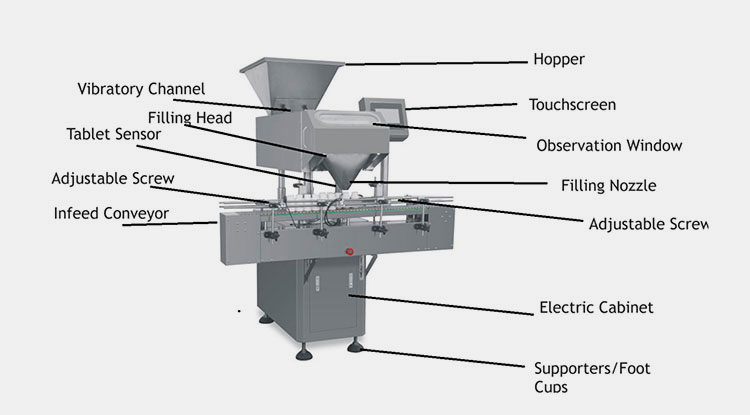

4.What are the fundamental parts of a tablet counter machine?

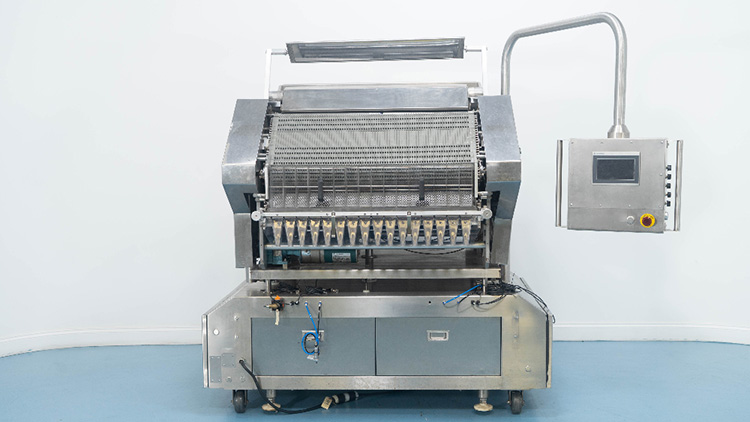

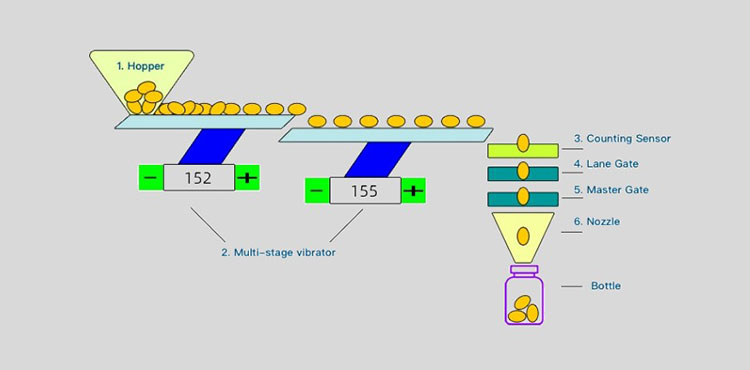

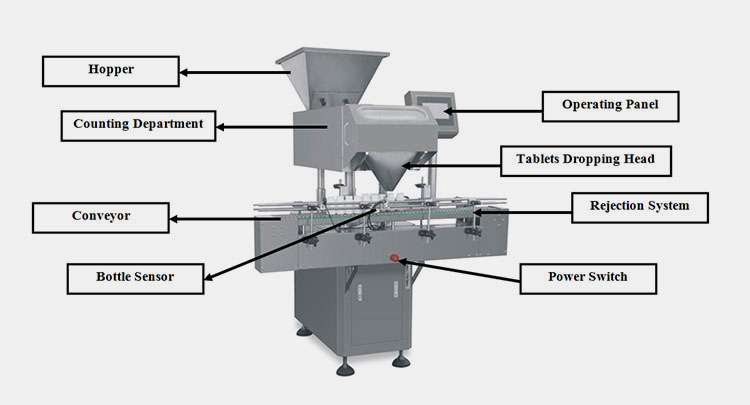

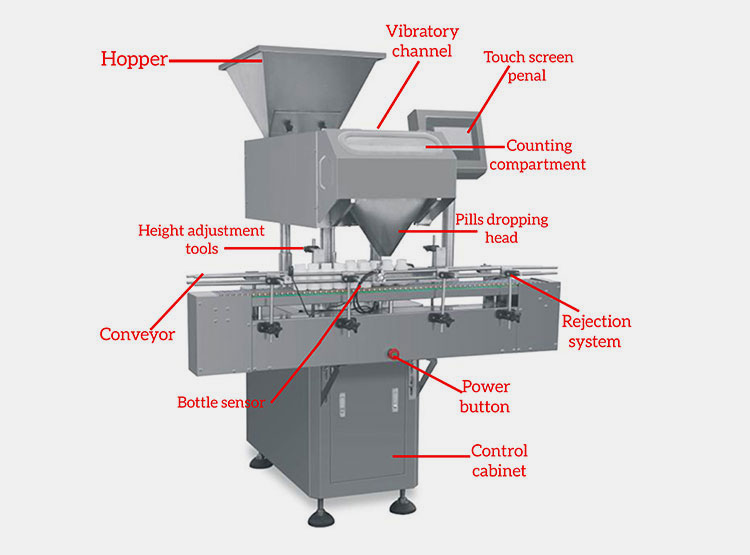

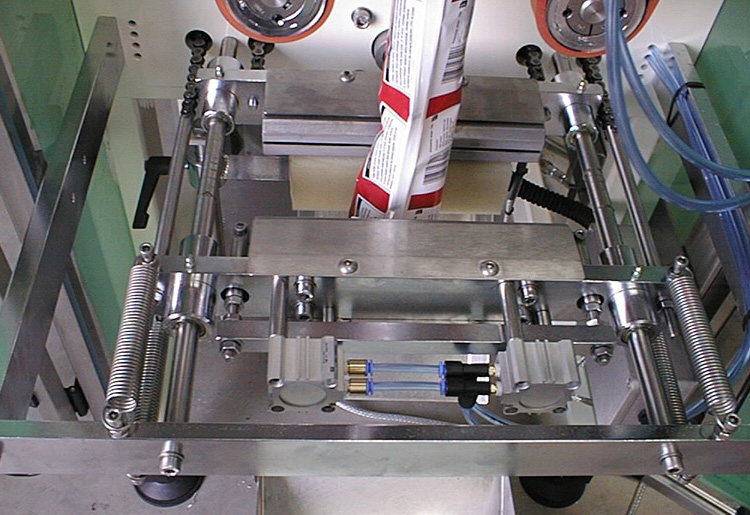

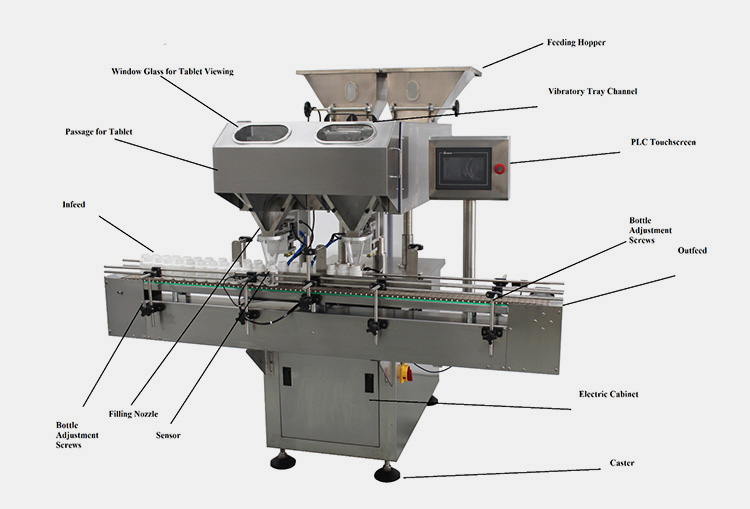

Parts of Tablet Counter Machine – Picture Courtesy: Makwell

The tablet counter machine has a simple compositional structure which is pretty easy to understand. In this section, we will converse about the machine’s fundamental components;

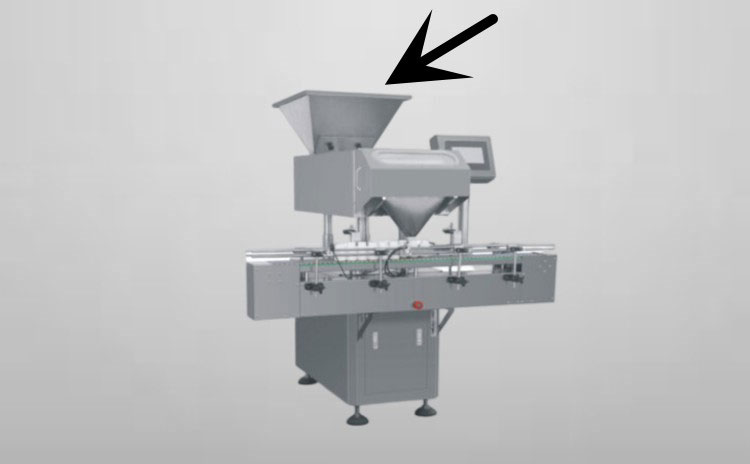

Material Storage Hopper

It is the topmost hollow structure of the device through which the tablets are introduced for counting, either by using manual methods or mechanized equipment. The hopper adopts a vibratory feeding feature.

This guarantees a steady and regulated supply of pills for counting. Furthermore, the design avoids bottlenecks and guarantees an effortless transfer of tablets to the subsequent level.

In certain advanced machine variants, the hopper is provided with a level sensor to determine the volume of tablets within. Its capacity and size vary with the model design.

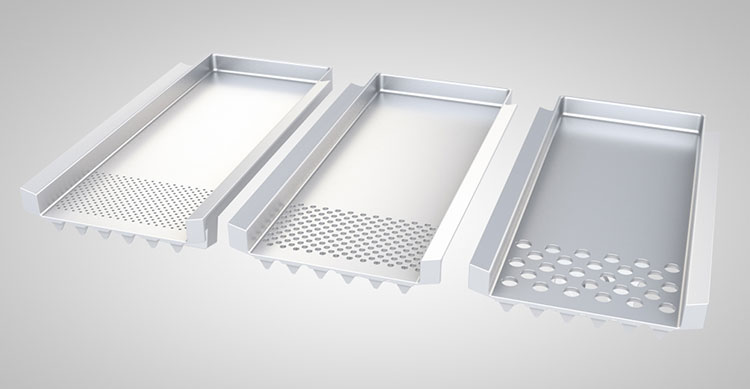

Material Handling Tray

The component that receives and handles the feed before entering into the processing mechanism.

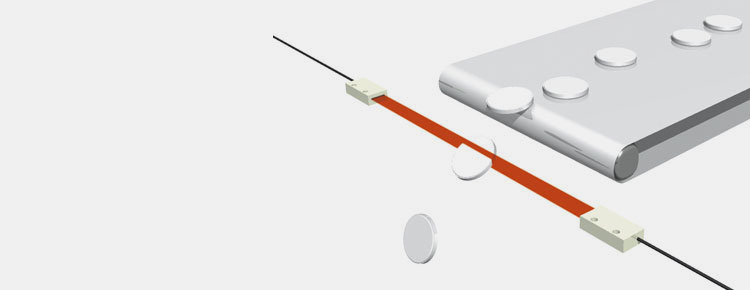

Fiber Amplifier

It is a sensor employed in the tablet counter machine for the detection of the tablets’ presence. It works by emitting a light beam and when the tablet interrupts it, the sensor identifies it, followed by sending of signal to the counting mechanism.

Counting Box

The space where tablets are summed up. It is assisted with the filling nozzle.

Electronic Eye

It is a photo-electric sensor utilized for the detection of tablets. When the light beam is interrupted by the tablets, it detects it.

Motor

It is the crucial component of the equipment, enabling the machine to work by providing the required power.

Belt Adjustment

It is employed for the adjustment of the conveyor belt as per requirements. For reliable counting and continuous tablet flow, proper belt adjustment is vitally important.

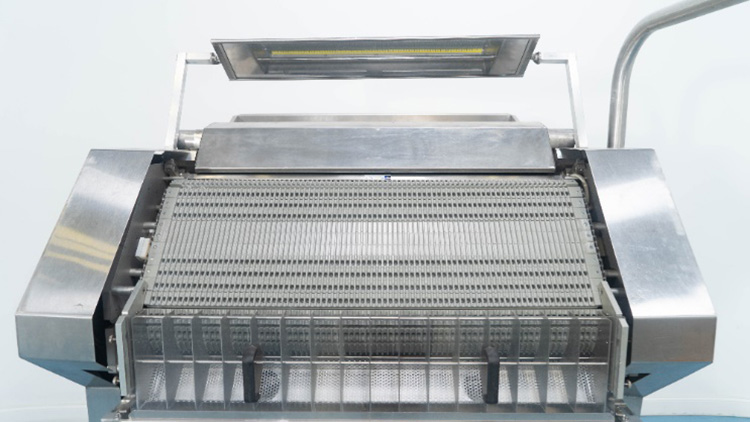

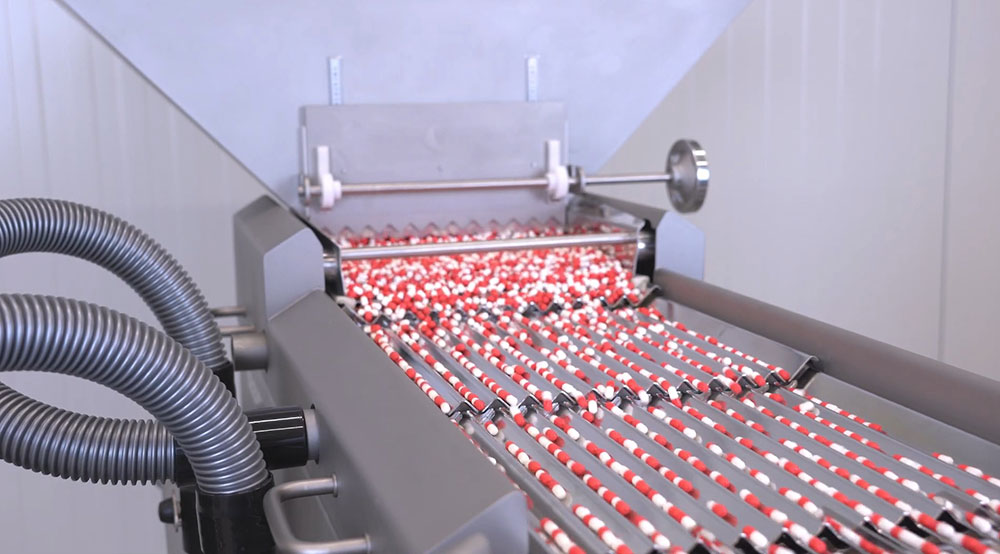

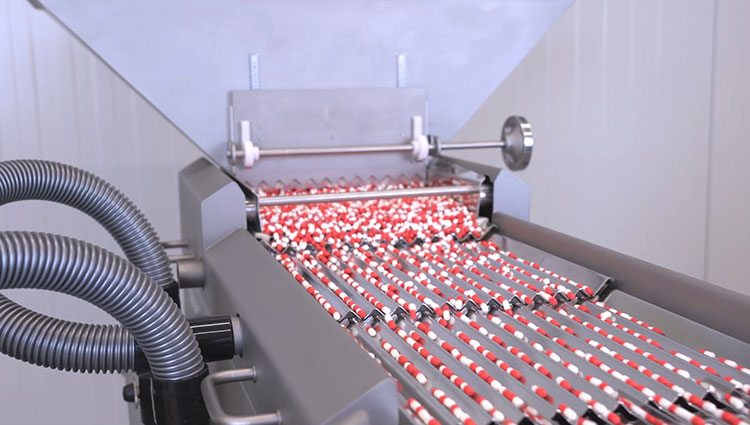

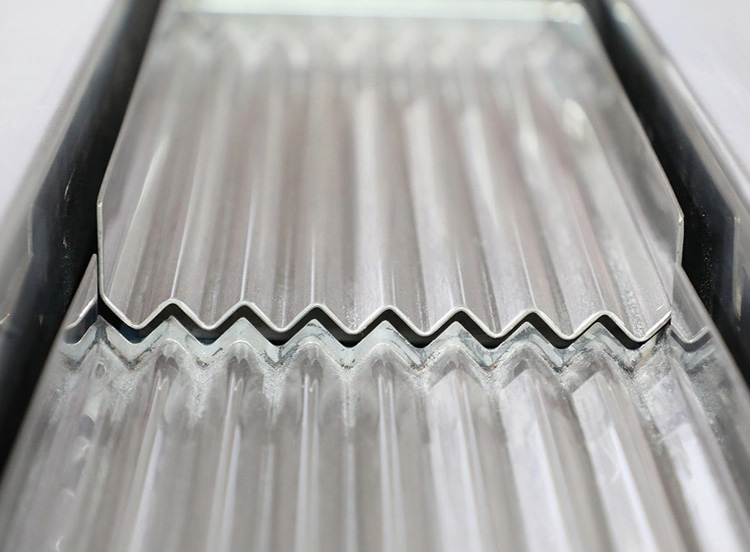

Shakers/Three-Stage Vibrator

It is one of the most vital elements of the equipment and is composed of vibrating plates. It operates by the vibrational principle and holds the tablets in place and order to facilitate the tally.

The vibratory motion guarantees that the tablets remain segregated from each other and do not stick. The regulated vibrations help in the transfer of tablets to the main counting mechanism.

PLC Touch Screen

It is a vital component of the device that enables the workers to surveil the activity and adjust the settings in case any fault occurs during the process.

Guide Rail

It is utilized to direct the tablets as they pass through the counting processing. By facilitating the regulated and seamless movement of tablets, they assist avoid counting faults or jams.

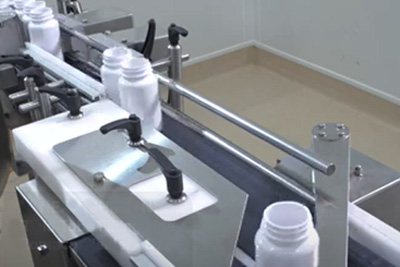

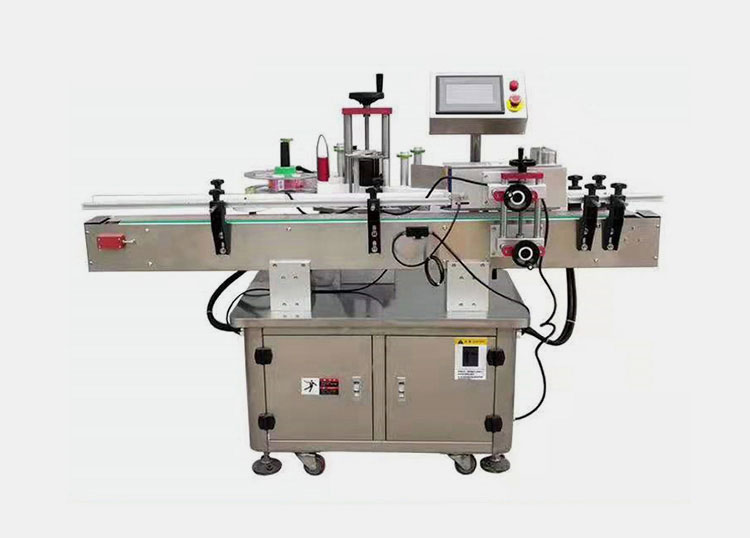

Conveyor

The component that guides the bottles to be filled with the tablets. The counting operation is accompanied by the conveyor. This guarantees that the tablets are released into the appropriate container at the right time.

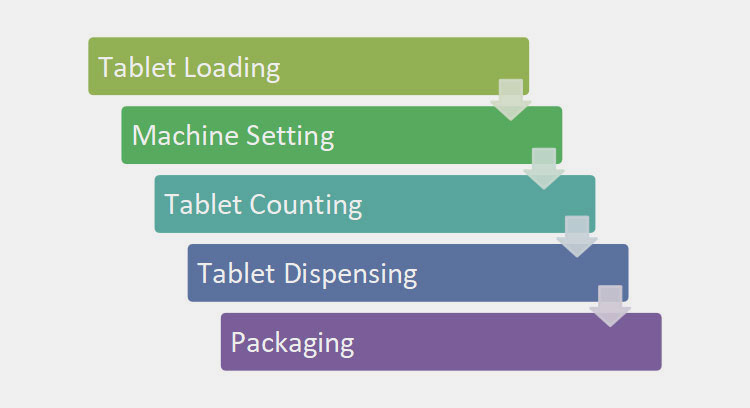

5.What is the basic operational principle of a tablet counter machine?

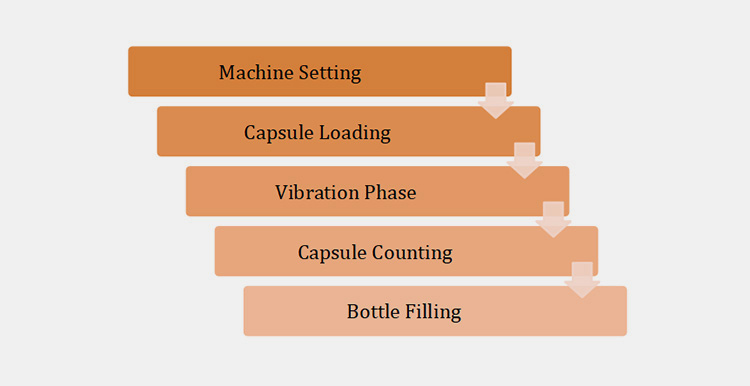

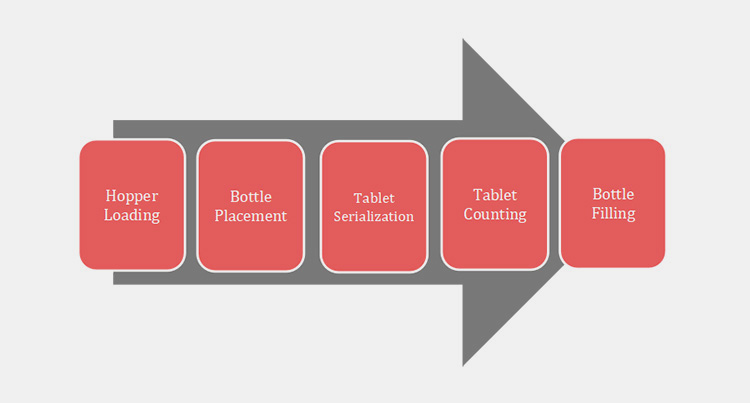

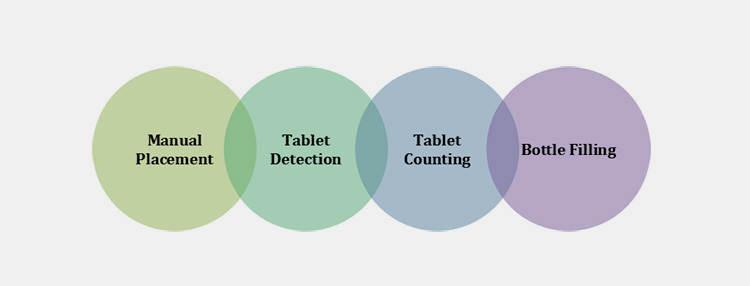

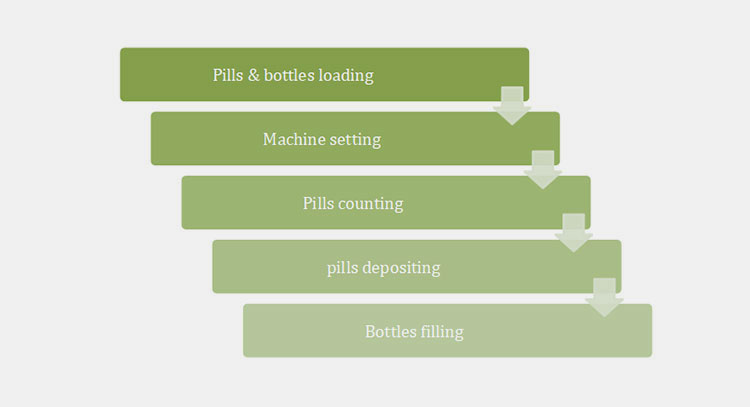

There are various machine variants, each having unique characteristics and functioning protocols. However, the basic operational proposition is mostly similar. In this segment, we will explore the key operational protocols of the advanced tablet counter machine;

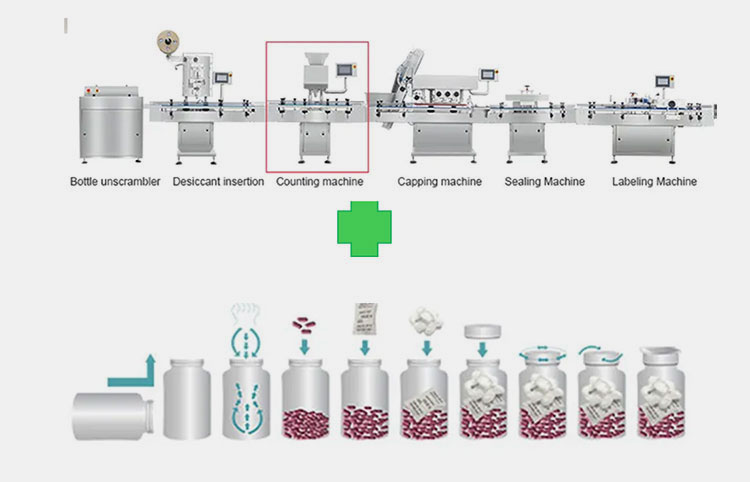

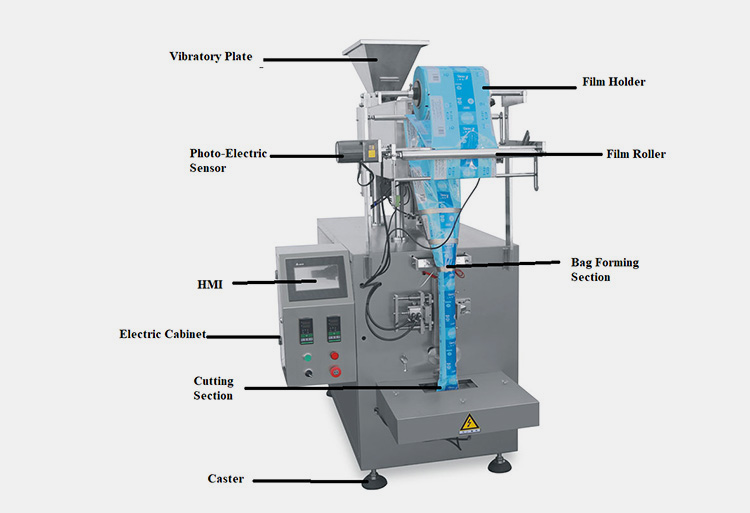

Working of Tablet Counter Machine

Filling the hopper with tablets

This can be done manually or by integrating a mechanized tool with the device. In some variants, it may be associated with the shaking/vibrating machinery to assist the filling activity.

Tablets transferred to the tray

A significant quantity of tablets is directed to the handling tray by the hopper. The tray/plate could handle a certain quantity of tablets as per its size and dimensions.

Tablets-transfer to the vibrating-channels

The hopper's regulated function moves the tablets to the vibrating plates. The vibrations produced by the plates ensure that the tablets remain segregated from one another and aligned appropriately for accurate counting.

Directing tablets to the exit funnel/nozzle

The segregated and perfectly organized tablets are now directed toward the exit nozzle for additional processing.

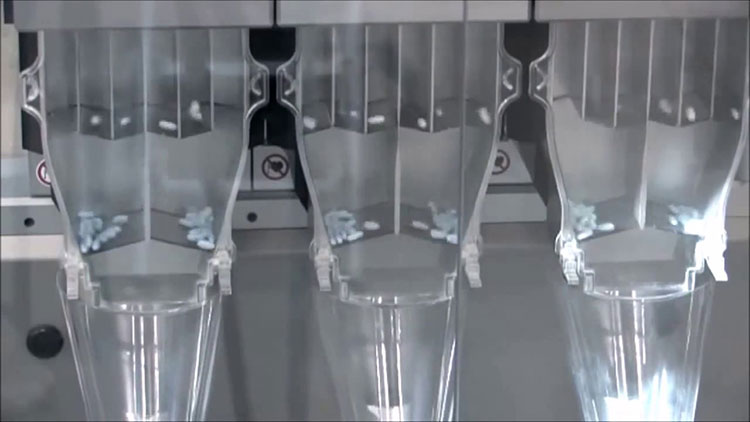

Counting and distribution of Tablets

The tablet counting is done by sensors that are stationed along the filling nozzle's route. Those sensors precisely identify the tablets' transit through the funnel. After that, the sensors sum up the tablets to make sure each package parcels out the correct number of pills.

Bottling and movement of the conveyor

Following the confirmation of the explicit count, the regulated process directs the outflow of the required quantity of tablets into the bottles which are transferred by the conveyor and placed under the exit nozzle.

After filling, they are transitioned seamlessly toward the next operational setting.

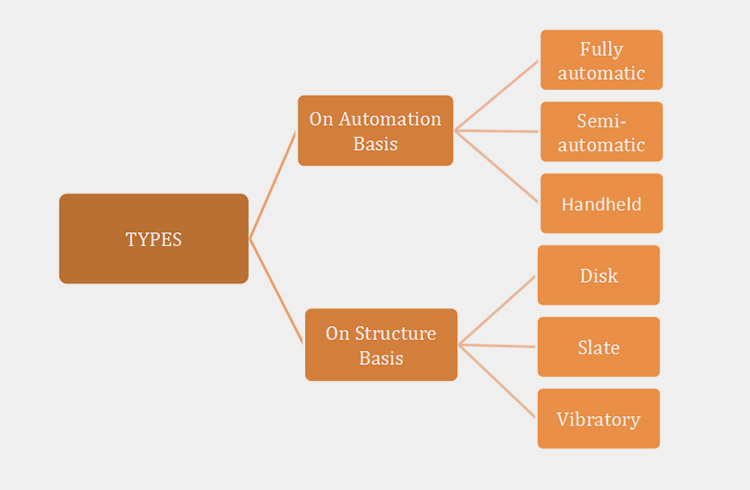

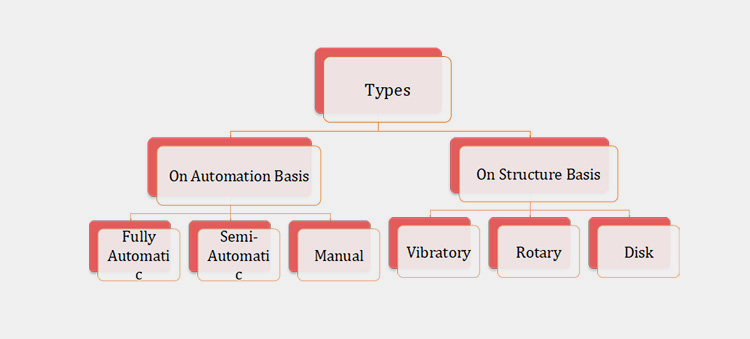

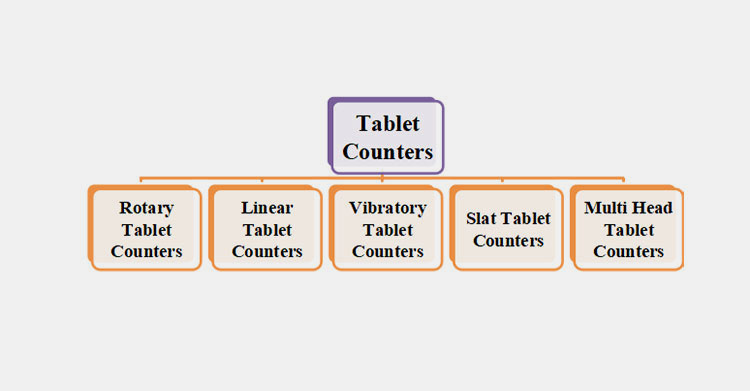

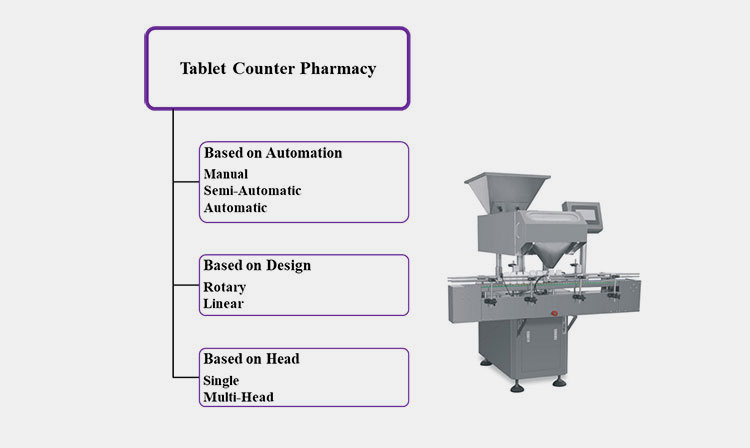

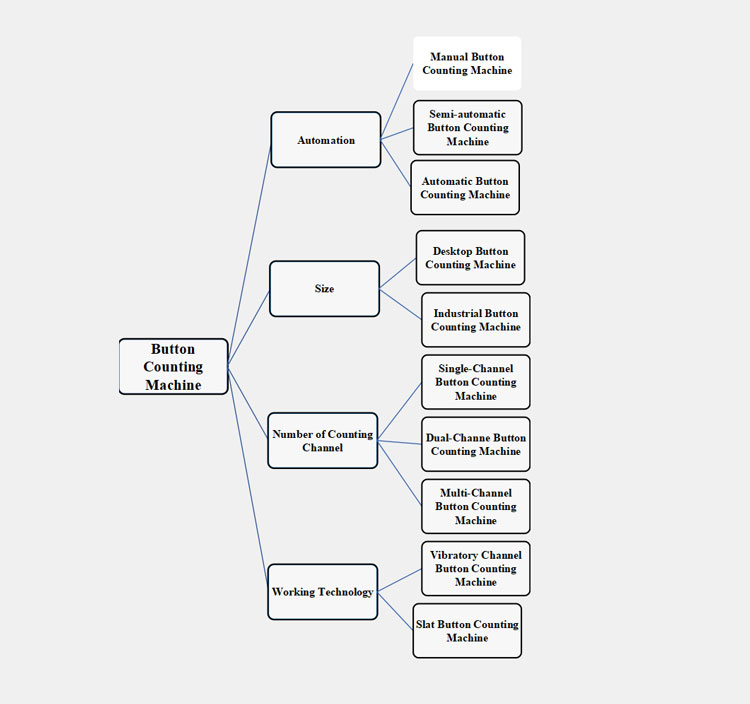

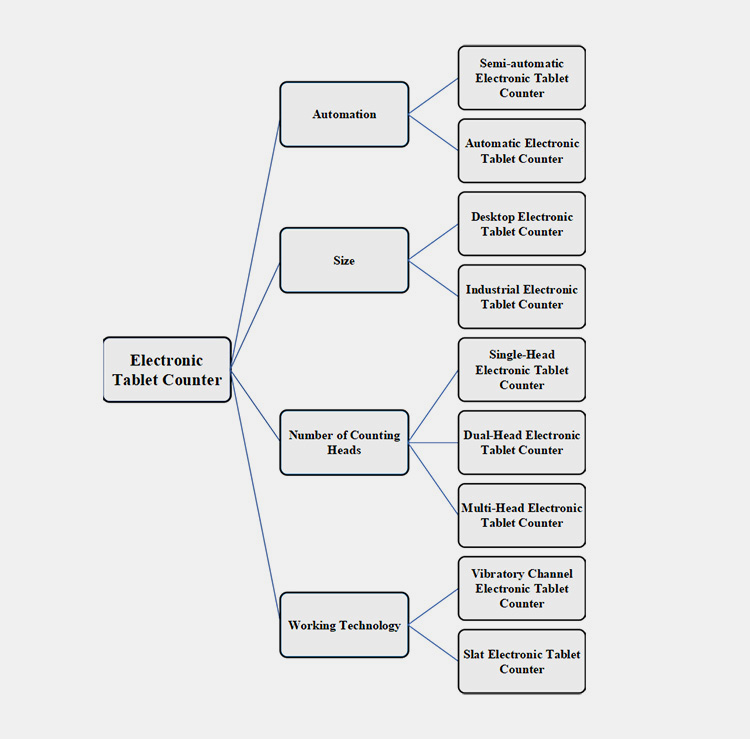

6.How do you classify a tablet counter machine?

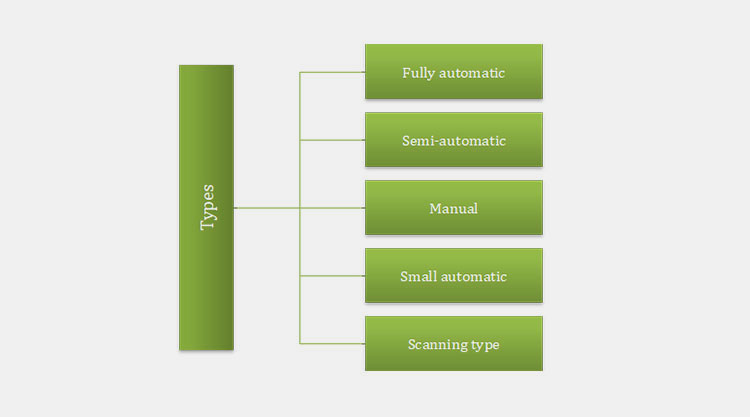

You will find various kinds of tablet counting machines on the market. They differ in several features. A tablet counter machine comes in a variety of different types, each having distinct unique characteristics and advantages. These machines can be categorized on multiple basis. So without any further delay let's have a look into different classes of tablet counter machines;

AUTOMATION BASED CLASSIFICATION

According to the level of automation, a tablet counter machine can be classified into 3 categories, which are;

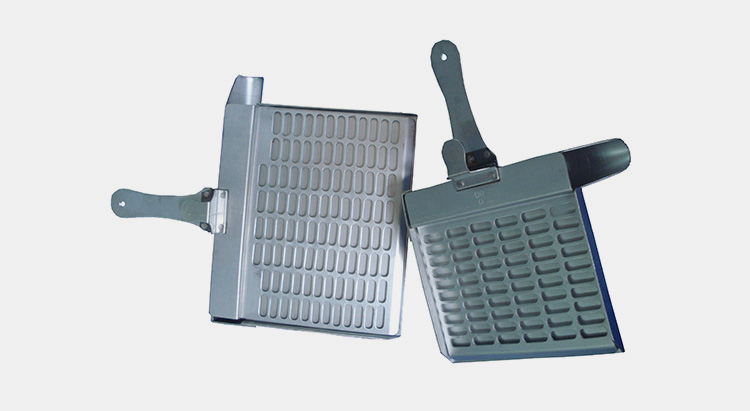

Manual

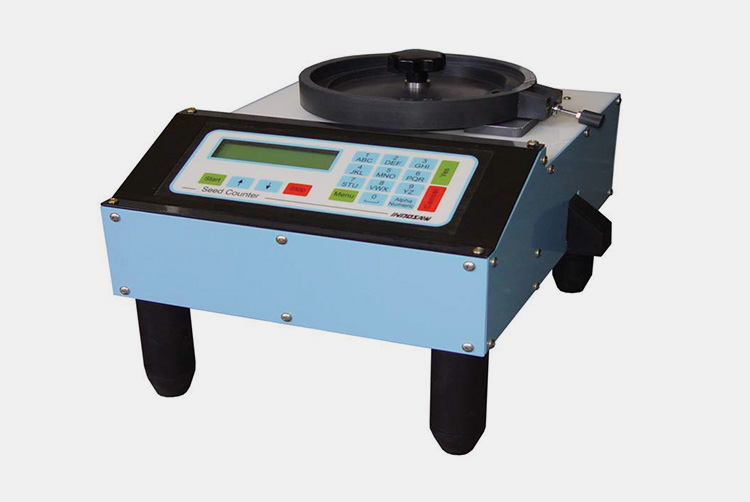

Manual Tablet Counter Machine

It is a simply designed machinery for the manual counting of tablets and other pills. It is beneficial for small enterprises and places where small-scale operations are performed, such as hospitals, laboratories, or pharmacies.

It consists of a uniform tray made of steel or plastic. The tray may or may not be designed with prearranged evenly placed holes to lodge the pills. The holes help in the separation of tablets and organize them for counting ease.

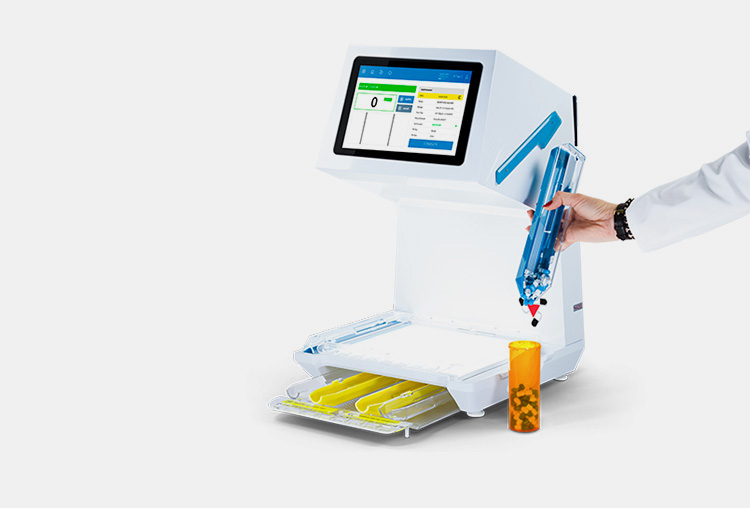

Semi-Automatic

Allpack Semi-automatic Tablet Counter Machine

It can be mechanical or electronic. It is a partially automatic device, commonly designed as a tabletop, with the feeding of tablets in addition to loading and unloading of containers/packages being done manually while the rest of the operation is done by an automatic mechanism.

Certain variants are combined with a conveyor to automatically load the packages.

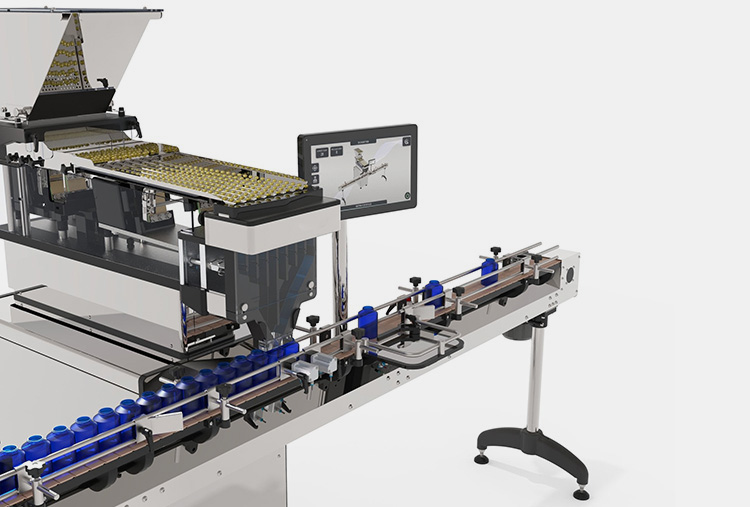

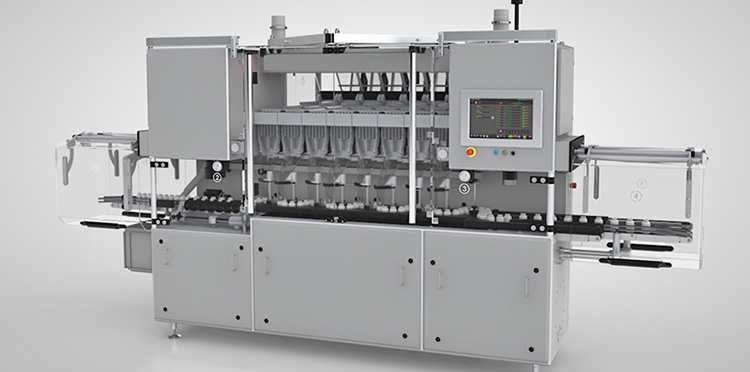

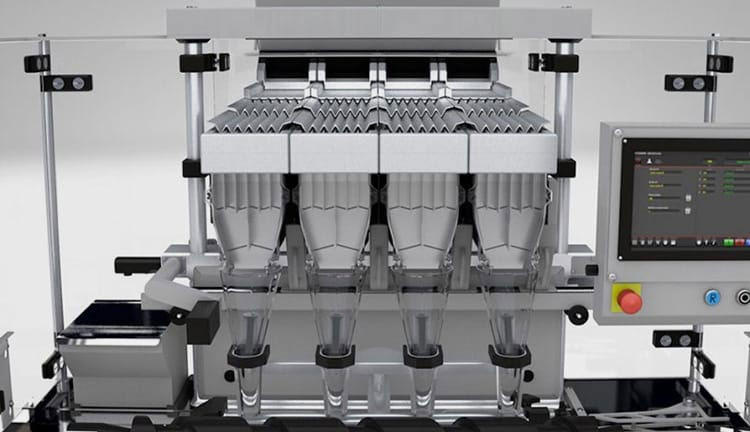

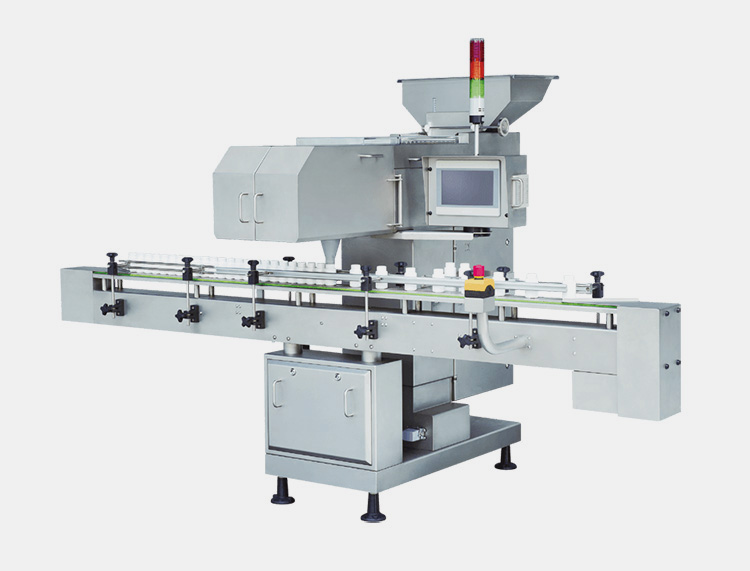

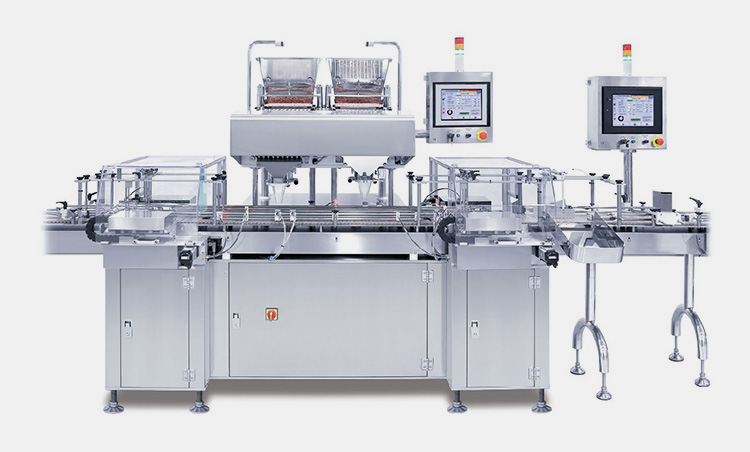

Fully Automatic

Automatic Tablet Counter Machine

It is the most advanced form of machinery with the latest built-in technology. It automates the entire process, from feeding of tablets to loading of containers and then counting and unloading of filled packages.

It is the most robust, reliable, accurate, and efficient form of equipment, designed to facilitate large production houses.

OPERATING PRINCIPLE-BASED CLASSIFICATION

Based on the principle of operation, a tablet counter machine can be classified into;

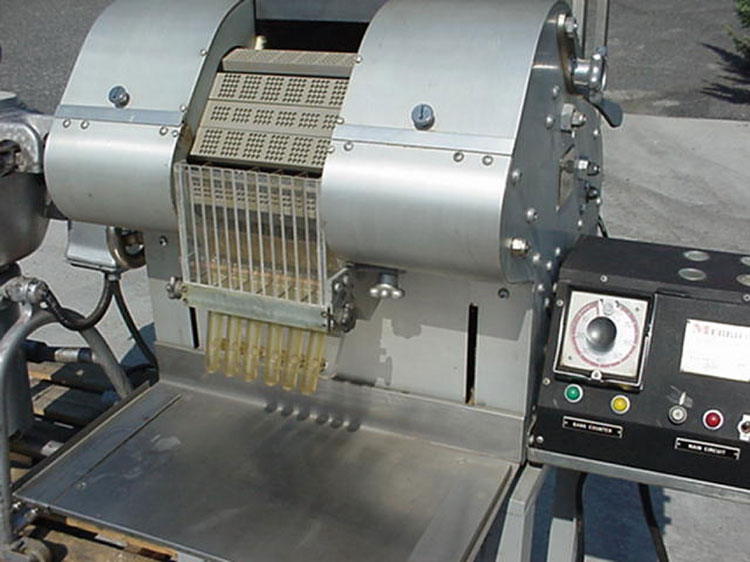

Mechanical

Mechanical Tablet Counter Machine

The separation and counting principle in such machines is mechanical type, such as vibrating channels or spinning discs. These machines are frequently employed in sectors where electric machinery may not be appropriate to use or if there are affordability issues.

Electronic

Electronic Tablet Counter Machine – Picture Courtesy: DirectIndustry

They use the latest technological features as the operating principle for counting pills, like photoelectric sensors. These machines are the most reliable and offer high precision. They are often used in the large manufacturing industries.

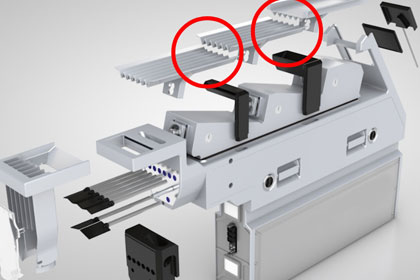

COUNTING MECHANISM-BASED CLASSIFICATION

Different tablet counter machine variants utilize different counting mechanisms. The categories include;

Vibratory

AiPak Vibratory Tablet Counter Machine

These devices are designed with vibratory channels that create vibratory movements to organize and count the tablets accurately. They are efficiently used for large-scale production.

There may be single or multiple vibratory channels installed to rapid up the processing.

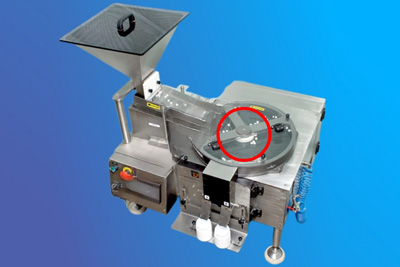

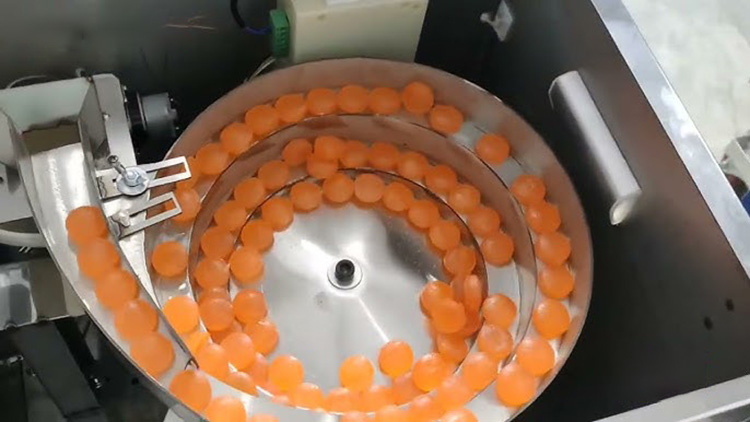

Rotary

AllPack Rotary Tablet Counter Machine

These specific machines utilize spinning discs with cavities to house the tablets separately. Due to the spinning motion of the disc, the tablets are fed into the pockets which are then guided towards the counting mechanism.

They offer operational ease and versatility but are not appropriate for large-scale operations due to their relatively lower output capacity.

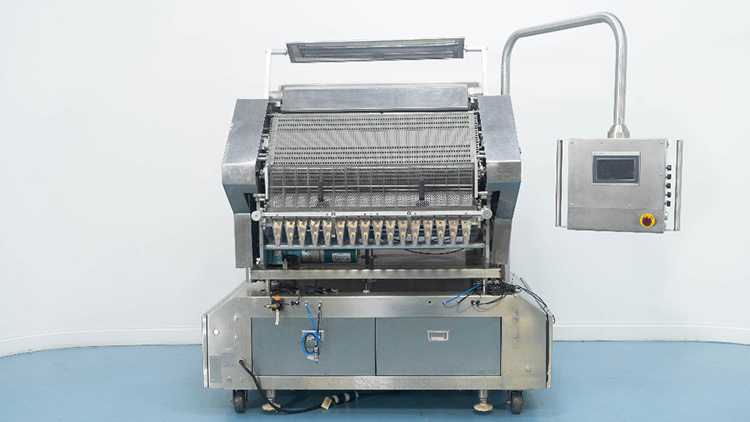

Slat

Slat Tablet Counter Machine

These devices make use of the partitioned bars/slats containing specifically shaped pockets, resulting in the precise housing of individual tablets in each pocket. It neglects the chance of any double-filling or empty pocket.

7.What are the significant differences between a fully automatic and a semi-automatic tablet counter machine?

| SEMI-AUTOMATIC TABLET COUNTER MACHINE | FULLY AUTOMATIC TABLET COUNTER MACHINE |

|

|

| It is suitable for small enterprises | It is designed for the large manufacturers |

| It has a medium level of operational speed | It can operate at a high-speed level |

| It can count relatively less number of pills per hour | It has a rapid counting rate |

| The workers are required for some steps of operation such as loading of materials | Minimal to no personnel requirements for working |

| Due to considerable human involvement, there may be chances of errors | The chances of errors are greatly reduced |

| It may or may not have integration facilities. | It can be integrated with other machineries |

| It is comparatively economical | It is an advanced form of device and thus expensive |

8.What are the maintenance protocols of a tablet counter machine?

Maintenance of Tablet Counter Machine

It is crucial for the longevity of life of any industrial equipment to regularly maintain it. The maintenance of a tablet counter machine is relatively easy but it requires a regular inspection schedule to enhance its lifetime. Here are some of the steps to follow to maintain the machine properly;

- Regular cleaning after every operation is needed to avoid any malfunction or interruption during the next processing batch.

- Deep cleaning of all the parts should be done at regular intervals, including the vibratory channels to remove any left-out residue.

- Mechanical parts can be cleaned using a detergent.

- Sensory/electrical components should be cleaned using a dry cloth.

- The managers should conduct a periodic inspection of the machine and its all components. The machine parts must be thoroughly inspected for any damage or wear.

- The worn parts should be repaired or replaced immediately to prevent runout.

- The inspection should be done by trained personnel.

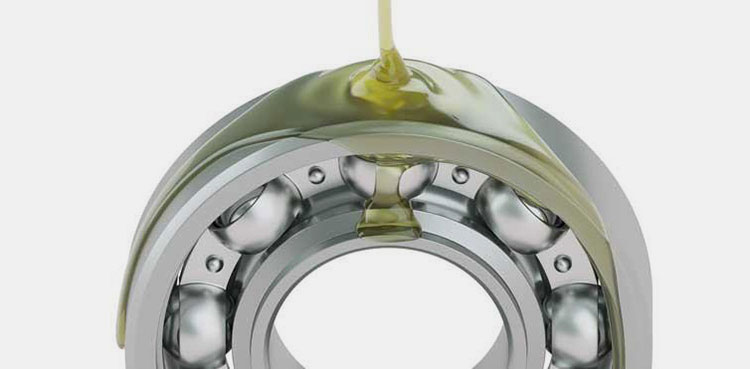

- Lubricate the moving parts periodically, as the continuous working of the machine can slow down their movements.

- Calibrate the machine regularly for efficient results.

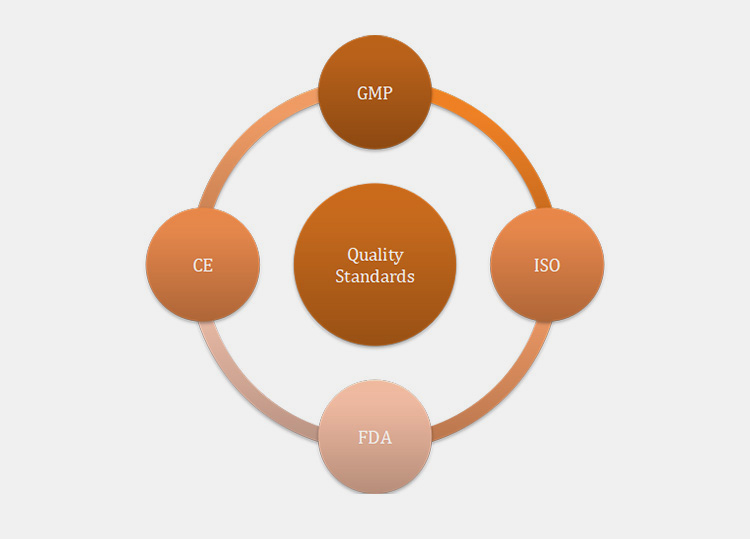

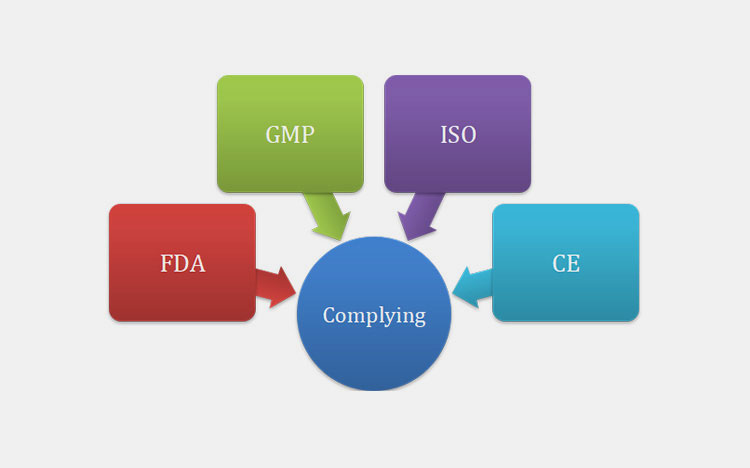

9.What are the standards of quality that a tablet counter machine should comply with?

In the growing industrial market, the demand for tablet counter machines has increased. Additionally, there are various machine variants available on the market that can make you overwhelmed.

But you have to make the right call while opting for a specific device. So you need to consider the quality standard guidelines of the models available.

The major quality standards to consider when investing in a tablet counter machine are;

- Verify that the conveyor’s structural design and construction material adhere to the requisite AISI 304 standards.

- The machine’s modular design has to be compliant with the cGMP regulations.

- CE certification is required for the electrical/electronic parts of the device.

- There must be a fully operational dust extraction system.

- The equipment’s optimal noise level should never be more than 70 decibel level.

- There must be an efficient HMI system and monitor panel.

- Every contact part of the device shall comply with FDA and AISI 316.

To find out the precise qualifications needed, it is usually a good idea to contact your local standardization organization. Certain models of tablet counter machines may lack a few certifications based on the particular region.

This is significant since it keeps you from buying shoddy or fake equipment.

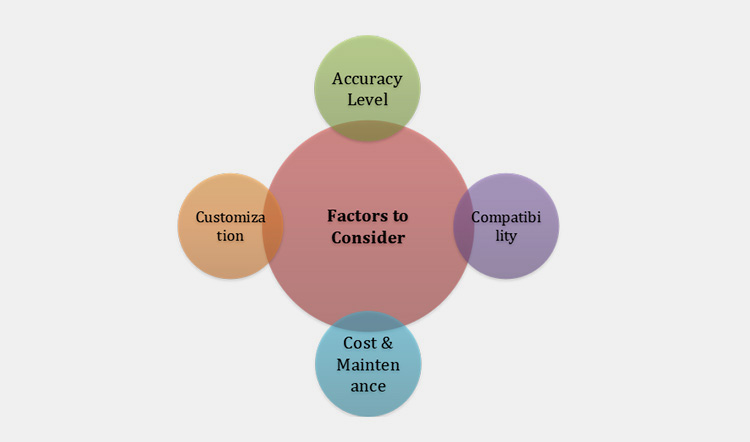

10.What factors do you need to consider while opting for a tablet counter machine?

Investing in a tablet counter machine can be an easy or complex game. It all relies on the research level you have done. There are a few important considerations to make sure you locate the appropriate machinery for your production requirements.

Budget

Cost Factor

Check out your budget before selecting a tablet counter machine as it is not a single piece of equipment but you have to buy multiple tools to integrate.

Don't forget to account for operating and maintenance costs in addition to purchase costs. By keeping these things in mind, selecting the equipment that balances the machine's performance and budget will be the right choice.

Compatibility

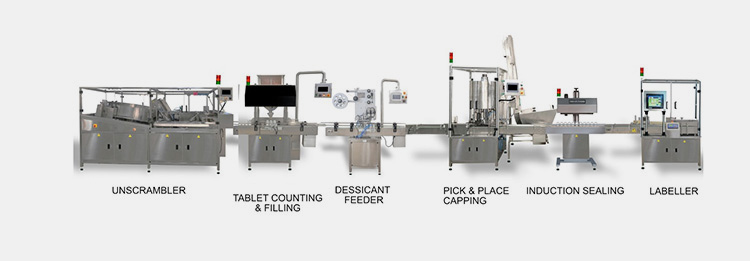

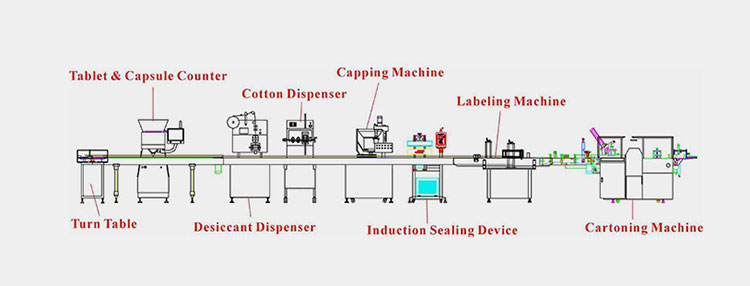

Tablet Counting Line Compatibility

It might be easy to adopt a single machinery that meets your requirements but opting for multiple tools that are compatible with your needs is a challenging task. That’s why proper research should be done and then choose the right equipment.

Capacity

Different Machine Variants have different Capacities

Different machine variants have different operational capacities depending on their design. Therefore, careful evaluation of your production needs is crucial. Consider the current plans as well as the future objectives.

Versatility

Flexibility of Processing Various Shapes of Pills

The flexibility in the equipment should be there. The device must have an easy changeover process and must be adjusted according to different packages and tablet shapes. This will allow your production efficiency to improve.

Integration

Integration of Various Industrial Equipment with Tablet Counter Machine

You should opt for the machinery that could be integrated with other processing machines effectively and smoothly. This feature is beneficial for uninterrupted tablet formulation processing, optimization of complete workflow, and lessening the chances of errors.

Safety Elements

Tablet Counter Machine with Necessary Safety Features

There are multiple mechanical as well as electronic components installed in the tablet counter machine and the workers are always exposed to them which increases the risk of potential hazards. So consider the device with essential safety elements incorporated, such as guards and warning indicators.

Regulatory Compliance

Regulatory Standards Compliance

A device that is compliant with regulatory standards like cGMP, CE, ISO, and FDA must be selected to guarantee safe and effective product processing.

11.What are the common problems you might face while using a tablet counter machine and what are their solutions?

Industrial machinery is being used continuously to satisfy consumer demands. Due to the continuous operation, the devices may encounter certain problems that must be assessed and resolved on time to guarantee smooth working. Some usual problems that might take place in a tablet counter machine and their solutions are discussed here;

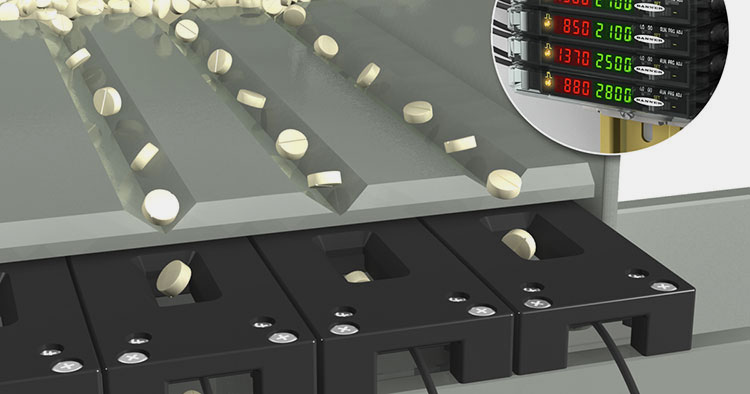

Tablet Jamming

Tablet Jamming within Machine – Picture Courtesy: Banner Engineering

The tablets may get jammed in certain parts of the machine. It often occurs due to the high-speed operation.

Solution: Adjust the rate of feeding and speed of vibrators.

Misaligned Bottle Stand

Misalignment in the Bottle Stand

The issue may arise because of the incorrect timing of bottles or due to the misalignment of the dropper with the opening of bottles.

Solution:

Adjust the settings from the monitor screen.

Replace the dropper station.

Adjust the space between the rails of the conveyor belt.

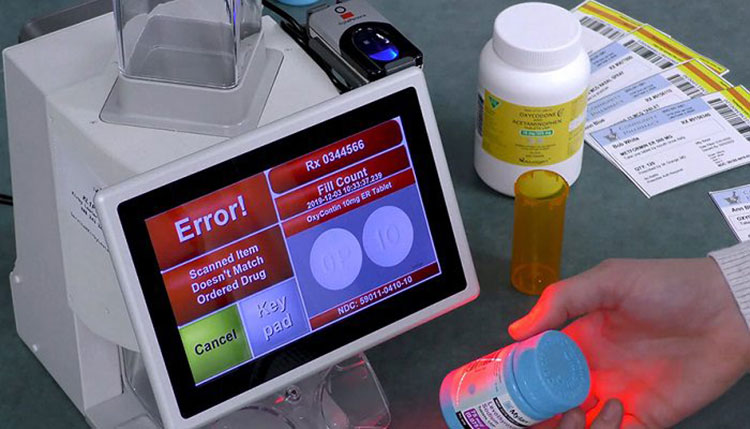

Counting Errors

Counting Errors – Picture Courtesy: MedicalExpo

This issue is possibly caused by incorrect timing and counting.

Solution: The timing of the photoelectric gate and the channels should be adjusted.

Spills of Tablets

Tablet Spills – Picture Courtesy: Sensum

It can be caused by having a large abyss between the opening of bottles and the filling nozzle.

Solution: Use a filling dropper that is always smaller than the diameter of the pill or bottle, both in terms of height and distance from the mouth of the bottle to the filler dropper.

Miscounting Sensors

Fault with the Sensor/Miscounting

It may be due to the buildup of dust on the sensor.

Solution: Regularly clean the dust from the sensor.

Alarm Signals

There may be multiple triggering factors involved in the noisy alarms on the tablet counter machine.

Solution:

Ensure the availability of bottles/containers.

Clean the sensors from the dust.

Turn out the lights.

Slipping of Bottles

Bottle Slipping

It may be caused if the opener has taken a long time to open the bottle, leading to the fall of the bottle.

Solution: Adjust the bottle’s passing time on the screen panel.

CONCLUSION

You must be aware of the fact that tablets are the most demanded and therefore the most manufactured dosage form in the health sector. So to catch up with the requirements of the customers, the fabrication and processing of tablets must be maximized and on time. A tablet counter machine is a reliable, robust, accurate, and efficient device for this cause and can help you achieve the desired outcomes and business growth. So if you are also looking to invest in the tablet counter machine for better results, then feel free to contact the Allpack Team to have more understanding about the device.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tablet Counter Machine: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours