Pet Snacks Counting Machine: The Complete Buying Guide in 2025

Pet Snacks Counting Machine: The Complete Buying Guide in 2025

What shows your pet is really important to you? Pet snacks with full nutrition!

They show affection by tail-wagging and jumping all around. Have you ever thought about what integral unit helps you in dosing the exact food inside the packaging? Yes, it is a pet snacks counting machine. How does this machine equally count and pack the bulk quantities of pet snacks? Does this machine ever get wrong?

Please read this super interesting article if you belong to the pet industry business; this is the right place for you to see and know about pet snacks counting machine.

1.What is the pet snacks counting machine?

Pet Snacks Counting Machine- Picture Courtesy: Cremer

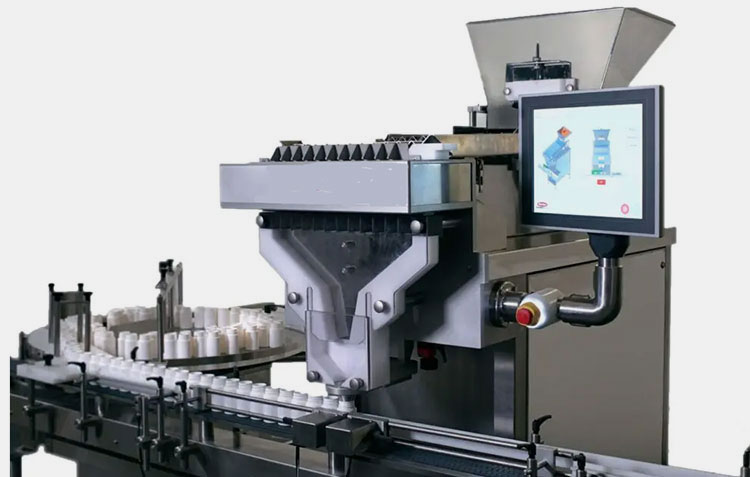

This is the most widespread solution for packaging pet snacks and related products. It is a machine that is capable of dispensing an accurate amount of pet snacks into each packaging material with the help of sensors, detectors, and related components that make a flexible counting process.

A pet snack counting machine is considered the most reliable and inexpensive solution that gives a correct amount of dose delivery but also carries out the processes in a timely manner.

This is the broad range solution which is designed in a specialized way and available in various types such as semi-automatic, automatic, and other. Thus, it allows you a user-friendly and convenient way to deal with pet snacks and various customized packaging.

2.Why the pet snacks counting machine is so important?

Significance Of Pet Snacks Counting Machine- Picture Courtesy: K9Natural

When you buy pet snacks counting machine; you should be confident that it will pay you a high profit. Yes, there are various reasons why it is so fundamentally important for you. Check the benefits of the pet snacks counting machine just right below:

Accuracy and Customer Satisfaction

Happy Customers- Picture Courtesy: Pet Snacks

Every manufacturer has the goal to attain accuracy and customer satisfaction which is possible only with the pet snacks counting machine as it handles pet snacks correctly for distribution and timely counting thus avoiding the risk of errors or affecting your brand reputation.

Handling Large Volume Easily

Large Volume Packaging- Picture Courtesy: Frontier Pets

This is a common way to deal with large or bulk volumes of pet snacks in manufacturing industries. Therefore, you will always seek a machine that is easy to cater to pet snacks packaging in bulk quantity. That’s why, companies prefer this solution to get benefits from longstanding techniques that make your packaging process possible without wasting product and assort the product in a divided and precise form.

Tracking Minor Deviation

Error Free Counting- Picture Courtesy: ASPCS

For the manufacturers who sell pet snacks, this robust device provides an accurate working process in a way that it can pick up or detect even a minor defect or unwanted error and notify you on the system display. Thus you will be able to know everything going on in the packaging pattern.

No More Cross-Contamination

No Cross-Contamination

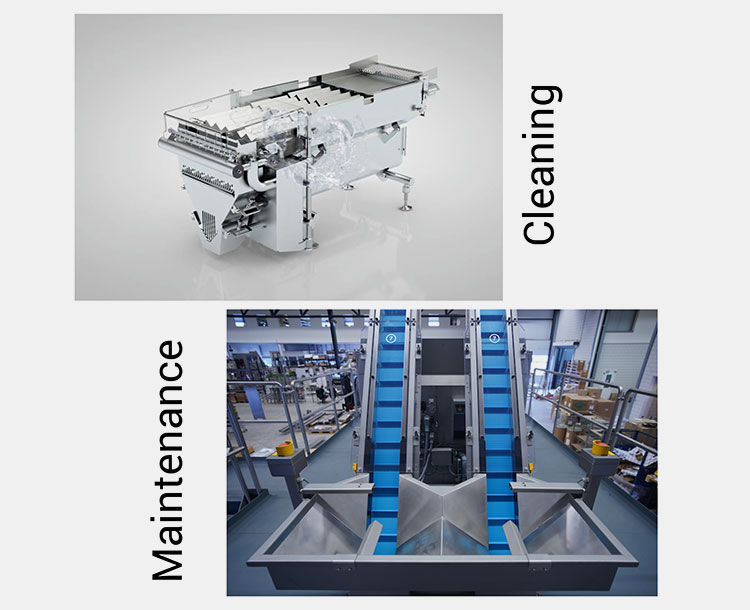

The machine construction is designed with food-grade materials and it is very easy to clean especially counting trays and all those parts where pet snacks are contacted. Therefore, this machine is recommended for foods, medicines, and other health-related sectors because it ensures that your materials are safe when dispensed by the pet snacks counting machine.

Compact Designs

Compact Design- Picture Courtesy: Wholefully

A pet snack counting machine is mainly designed with compact structures that do not require greater space for installation. You can incorporate this machine into your production line easily as it is available in various designs, such as for small areas; you can go for either semi-automatic or desktop options.

3.Where the pet snacks counting machine is applicable in the industrial sector?

The pet snacks counting machine presents unique benefits due to which it has countless applications in diverse industrial settings. Let’s discuss some common uses of the pet snacks counting machine.

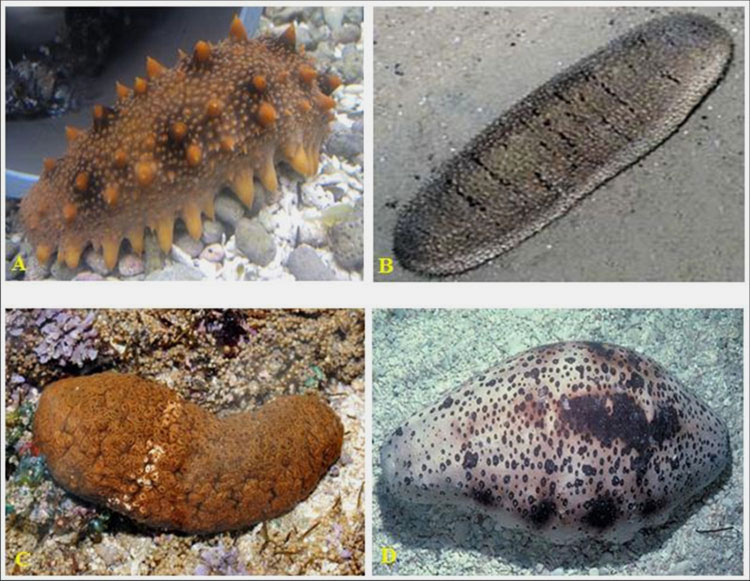

Pet Snack Industry

Pet Snacks

First and foremost, the pet snacks counting machine is a need of the pet snack industry. This device competently counts pet snacks without miscounting calculations. It sorts and identifies different types of pet snacks and facilitates their market distribution. It is a one-stop solution to accurately handle pet snacks.

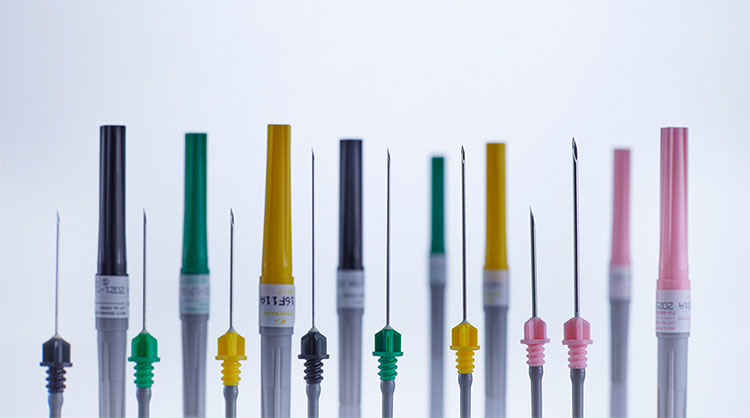

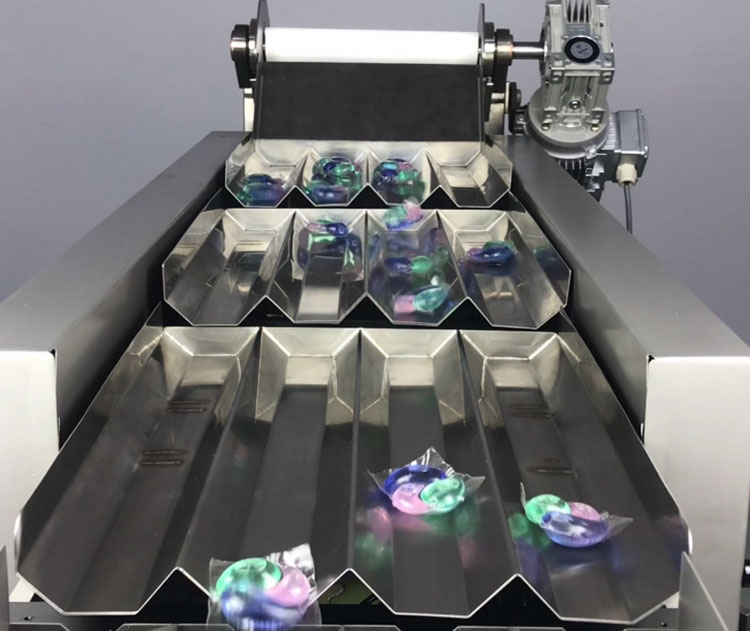

Pharmaceutical Industry

Pharmaceutical Pills- Picture Courtesy: GoodRx

Safety and accuracy are two main pillars of the pharmaceutical industry. Therefore, the pet snacks counting machine is available in almost every type of pharma industry because of its accurate counting results and contamination-free processing. It is known for its consistent counting of pills (capsules, tablets), granules, pellets, and other related products.

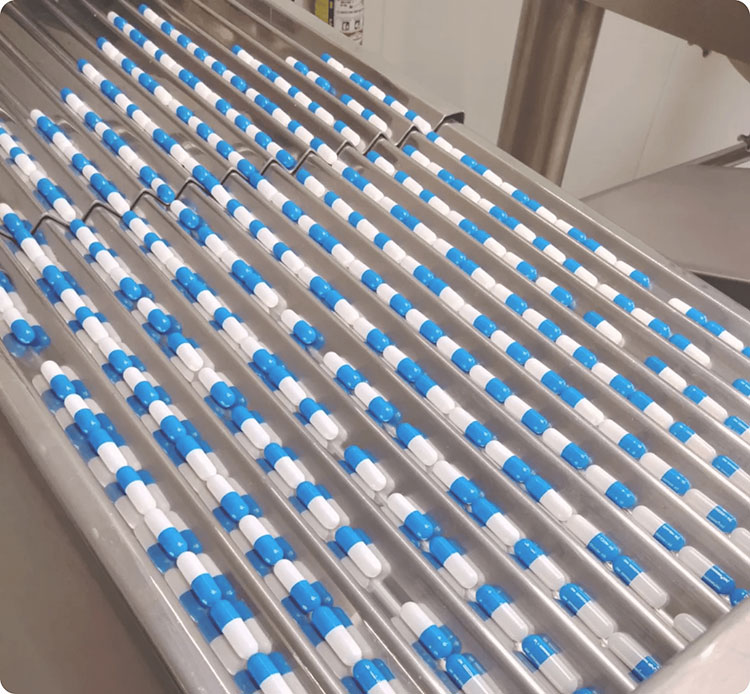

Nutraceutical Industry

Nutraceutical Pills- Picture Courtesy: GVSK Nutraceuticals

This industry offers nutraceutical formulation that provides necessary nutrients to adults and children alike. These supplements such as probiotics, enzymes, growth boosters, multivitamins, mineral balancing agents, etc. are loaded with health benefits. So, to retain their potency and effectiveness, these nutraceutical products are packed by the pet snacks counting machine.

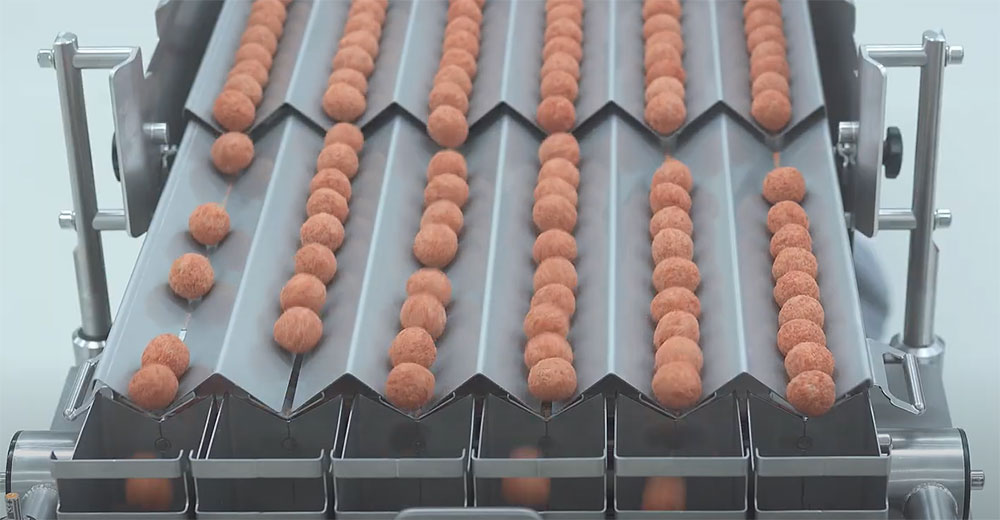

Food Industry

Foods Items

Food packaging is a necessity in the modern era. Hence, you see pet snacks counting machines routinely in the food industry. Whether dry food or frozen products, it can count any type of food. There is no miscalculation with this machine, so, it plays a vital role in the packaging of confectionery, meatballs, cheese sticks, dried fruits, egg yolk and so many more.

Cosmetic Industry

Cosmetic Bath Bombs- Picture Courtesy: bubble-baths

Hundreds of thousands of cosmetic items are daily processed because of their increased demand. These items need regular counting before their end packaging. For this purpose, a pet snacks counting machine is utilized in the cosmetic industry. It assists in the consistent packing of wax beads, makeup applicators, artificial nails, skin treatment products, and many more.

Chemical Industry

Chemical Granules- Picture courtesy: Brada Global

Pet snacks counting machine is best fit for packaging different harsh, toxic, and mild chemical granules and tablets without any counting error. It is involved in determining counts of pH tablets, chlorine pills, naphthalene balls, and other neutralizing granules. It maintains operator safety by eliminating the need for manual handling of chemicals.

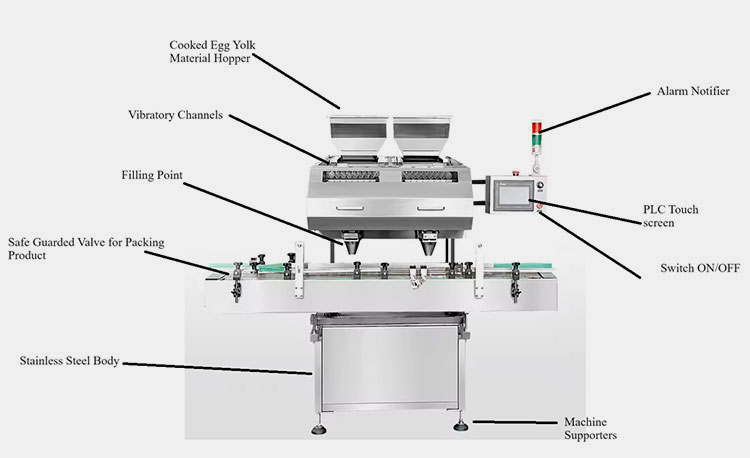

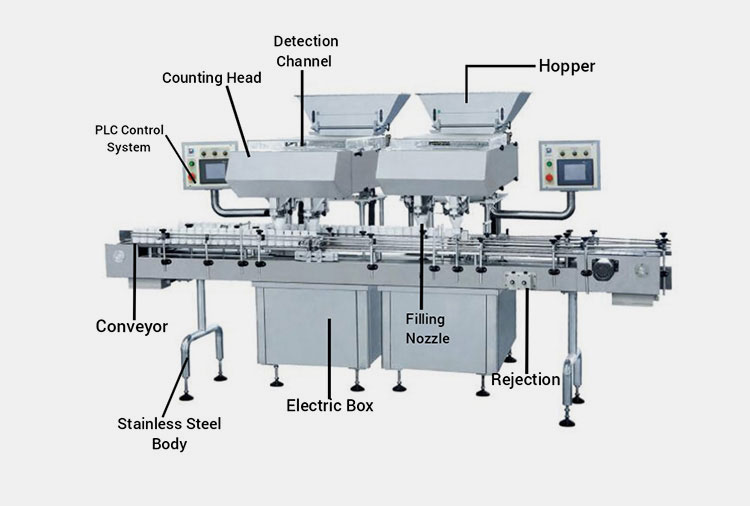

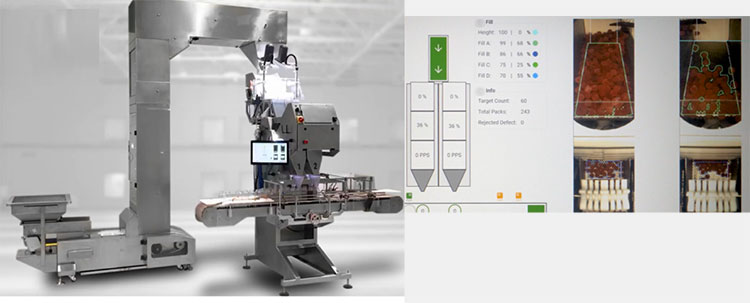

4.What is the structural design of a pet snacks counting machine?

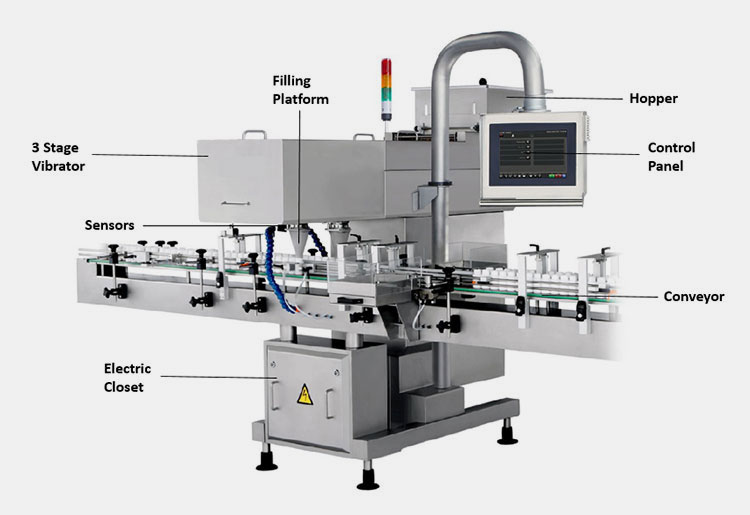

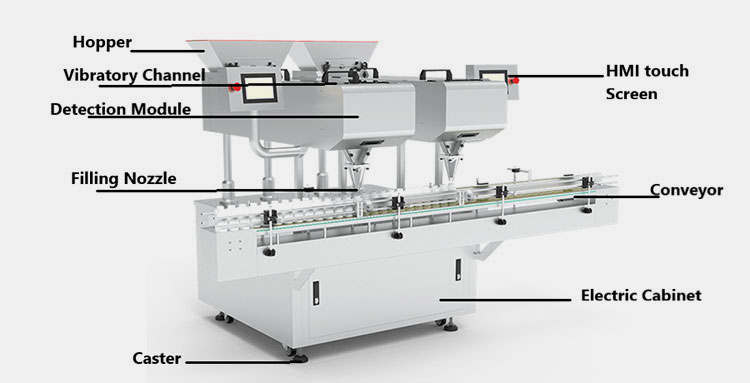

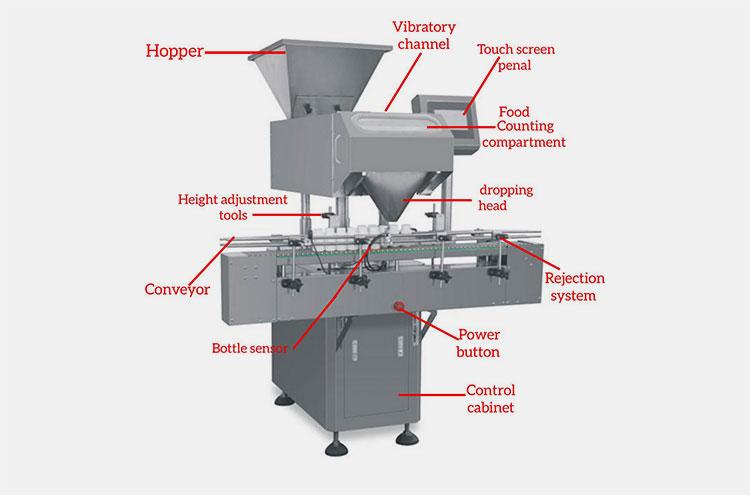

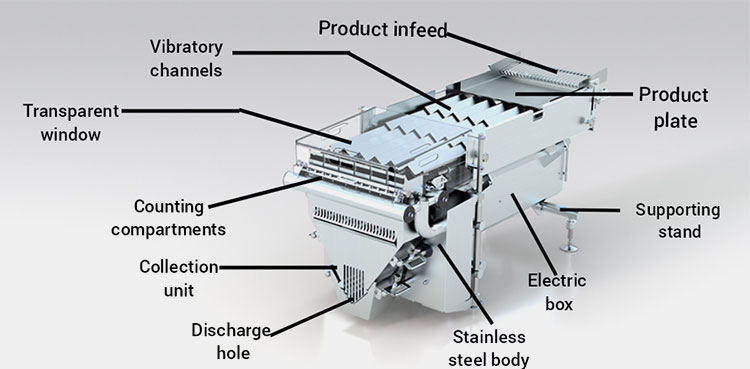

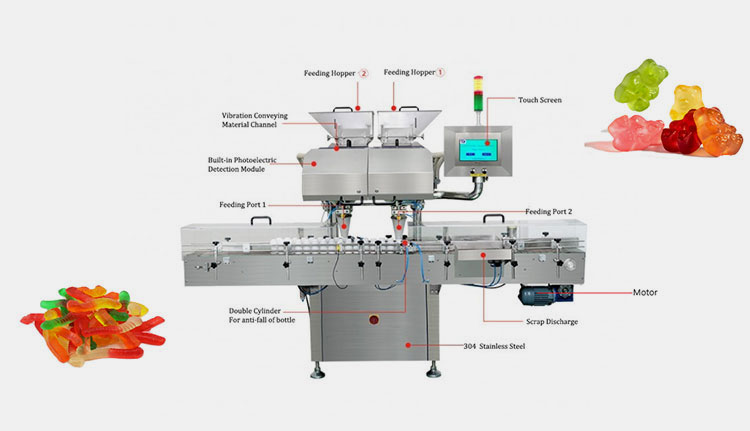

The structural design of the pet snacks counting machine consists of several mechanical and electric components that are essential in maintaining the functional efficiency of the machine. Let’s delve into the structural design of the pet snacks counting machine.

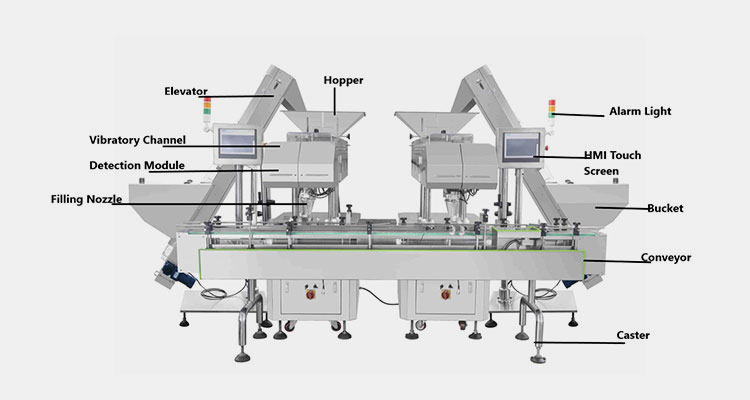

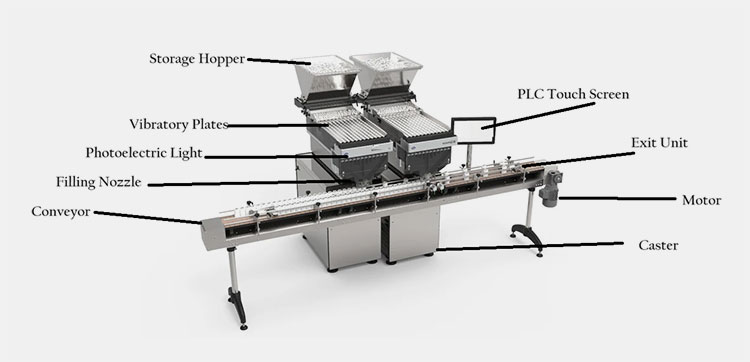

Parts of Pet Snacks Counting Machine

| Hopper | This part is integral in the accurate working of the pet snacks counting machine. It is situated at the topmost position of the machine. Hopper temporarily houses pet snacks for counting and then transports them steadily toward the vibratory channel.

Typically, a single hopper is found in the machine but some advanced models have more than one hopper to boost the counting efficiency. |

| Elevator | It is also called the pre-feeder of the machine and is responsible for moving the product materials from lower buckets to the hopper. It automates the loading process and ensures a smooth and continuous supply of products to counting units. |

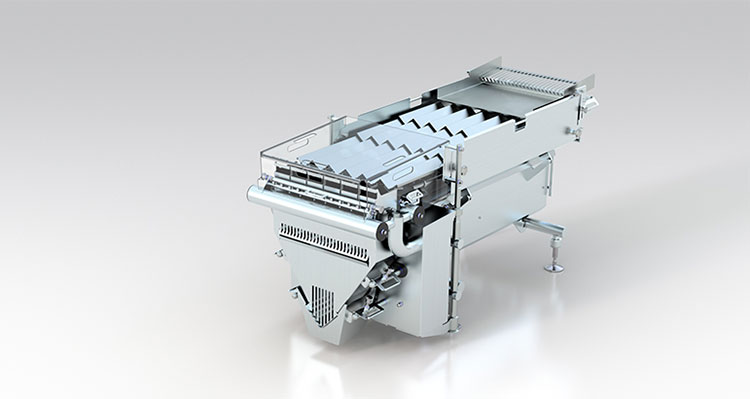

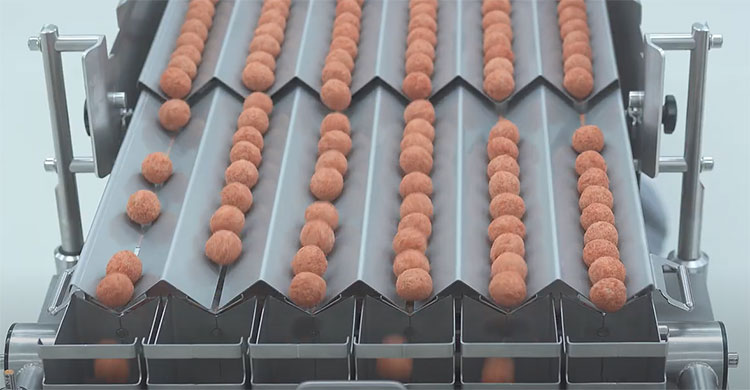

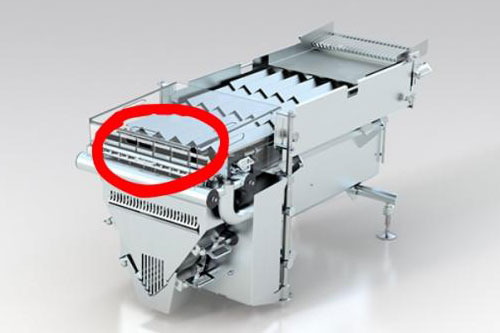

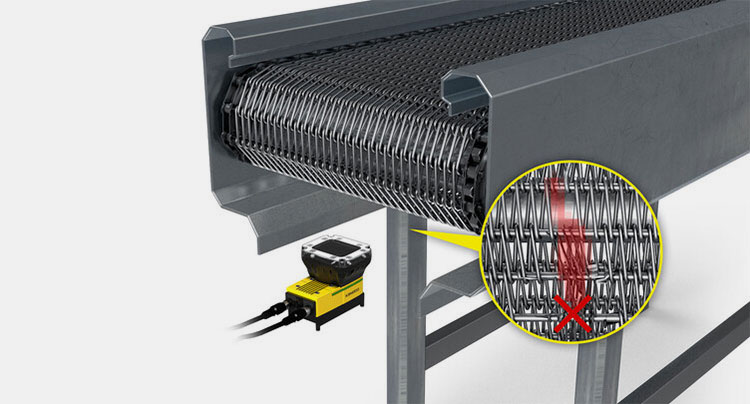

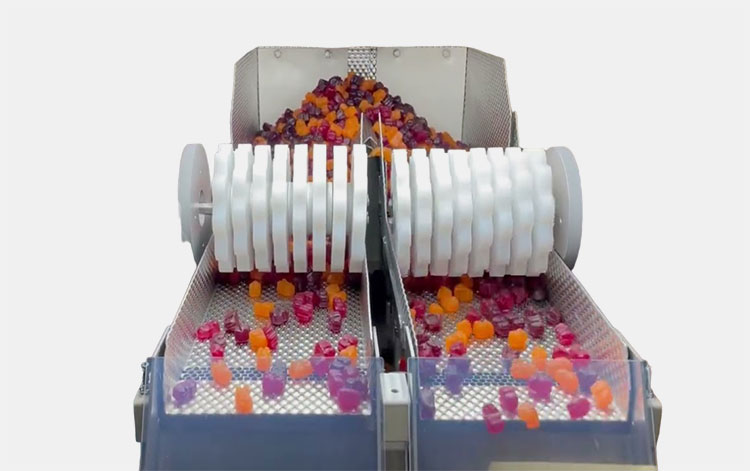

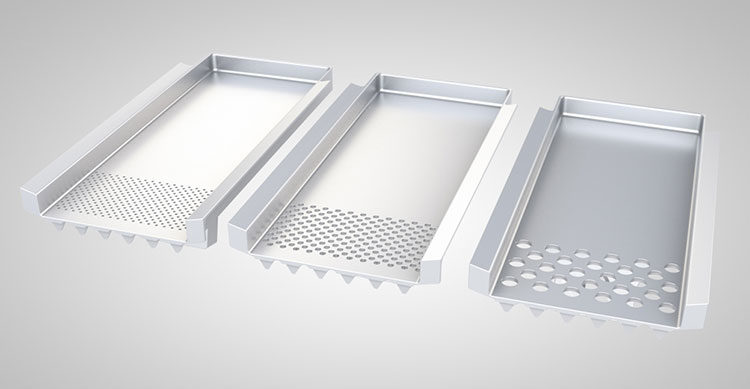

| Vibratory Channel | It is one of the fundamental components of the pet snacks counting machine. It is involved in the separation of the products. It is fitted with trays or plates that carry out the arrangement and transportation of the materials by their vibrations. |

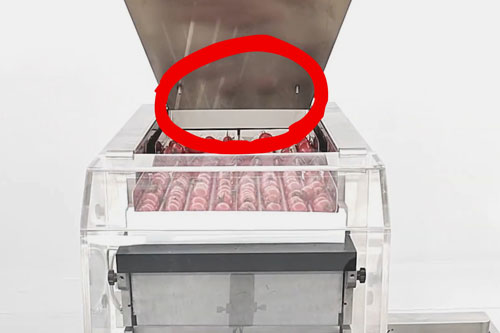

| Detection Module | At the core of the pet snacks counting machine, a detection module is present. It has various sensors that detect the products with the disruption of light beams. Moreover, some advanced versions of equipment have camera vision systems that identify and count the pet snacks by image processing software. |

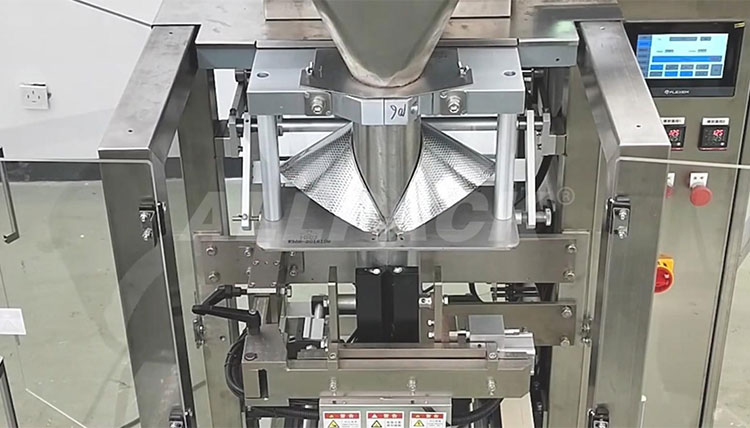

| Filling Nozzle | It makes the filling platform and is responsible for guiding and filling pet snacks in different kinds of containers. Alignment of filling nozzles with containers results in the product packaging. |

| Alarm Light | It is a brightly colored light, located at the top of the machine. It acts as a visual indicator that indicates abnormal functioning in the machine. It flashes light to gain the attention of the operators. |

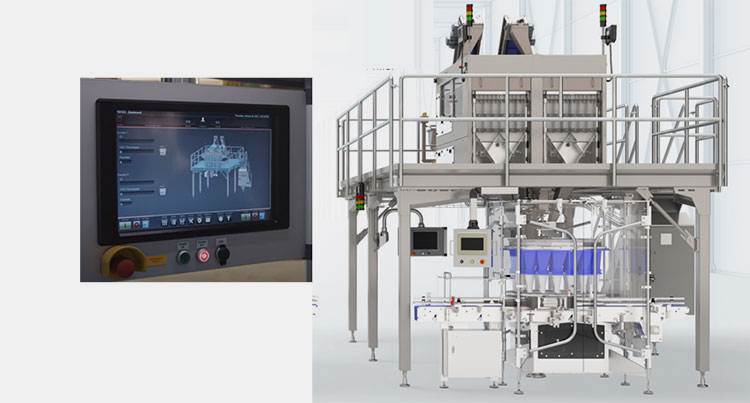

| HMI Touch Screen | This part is the user-friendly interface that helps in the processing and supervision. It controls the counting process using different programmed options. |

| Bucket | It is a rectangular container present at the lower portion of the machine. It assists in a consistent supply of pet snacks by briefly storing the products. |

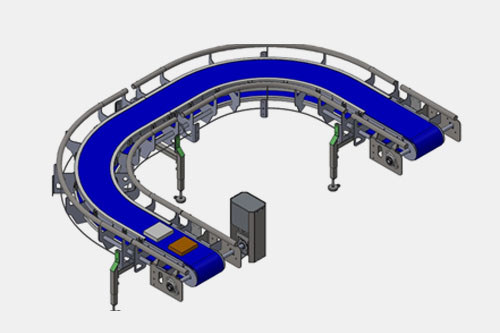

| Conveyor | It is a long transportation platform. It takes empty containers to the filling nozzles for filling. A conveyor is formed by different types of supporting units like chains, drive belts, and rollers. |

| Caster | The caster forms the base of the pet snacks counting machine. It consists of holders and wheels that provide support, stability, and portability to the device. |

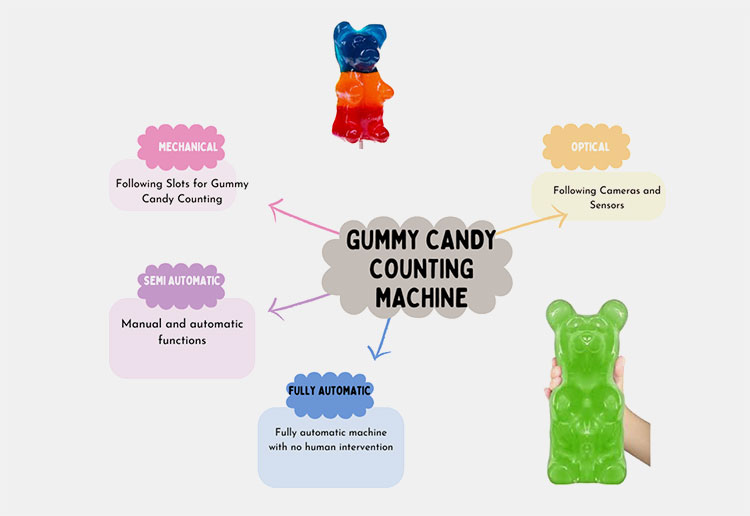

5.How many types of pet snacks counting machine available in the market?

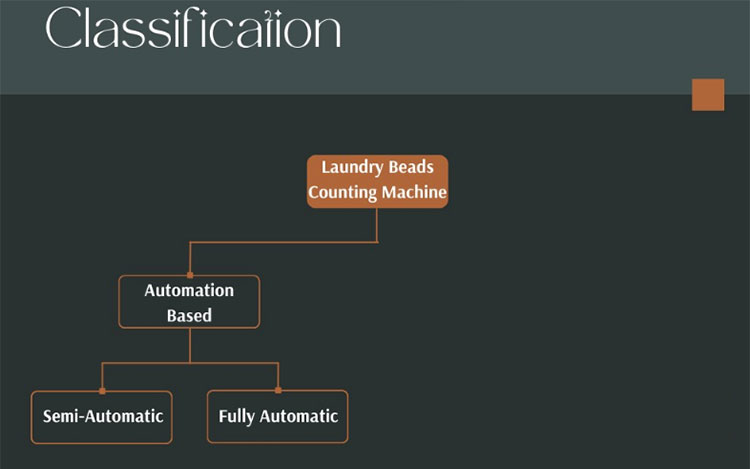

You see a vast collection of pet snacks counting machines in the market differing in their functionalities, components, and designs. These types meet the needs of all and sundry industries. The main types of this equipment are stated below for your knowledge:

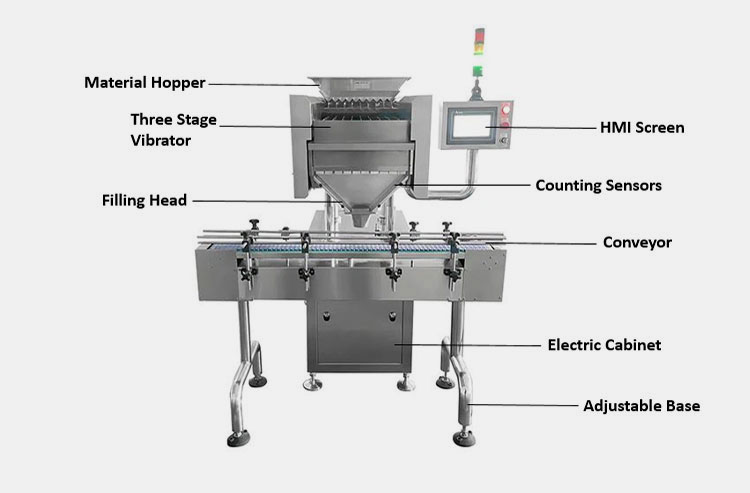

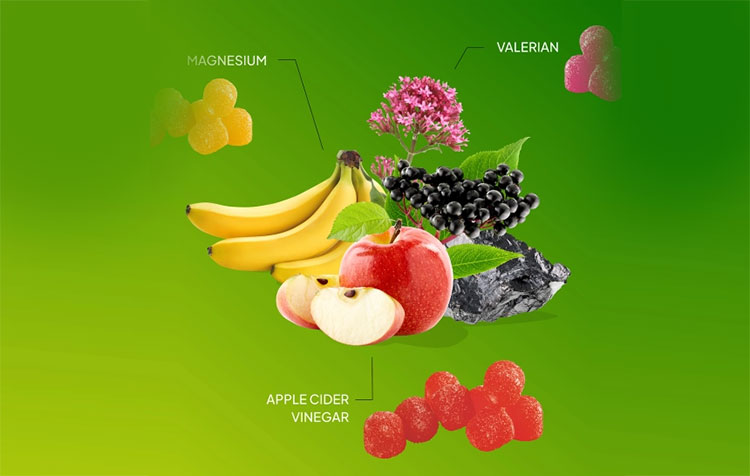

Semi-automatic Pet Snacks Counting Machine

Semi-automatic Pet Snacks Counting Machine- Picture Courtesy: SED Pharma

This machine is specially designed for small and home-based industries. It combines an automatic mode of counting with manual loading and unloading of products, empty containers, and packed containers.

Because of its human involvement, it has slow processing speed and efficiency. However, the counting process in this machine is automatic and consistent. Semi-automatic pet snacks counting machine has a small hopper and, therefore, requires continuous feeding of pet snacks for smooth counting.

It is easily installed in small spaces like benchtops and desktops because of its smaller footprint. Furthermore, the semi-automatic pet snacks counting machine is easily moved from one location to the next because of its lower weight.

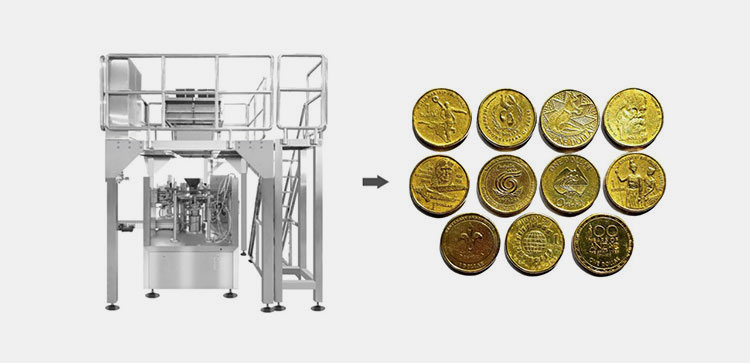

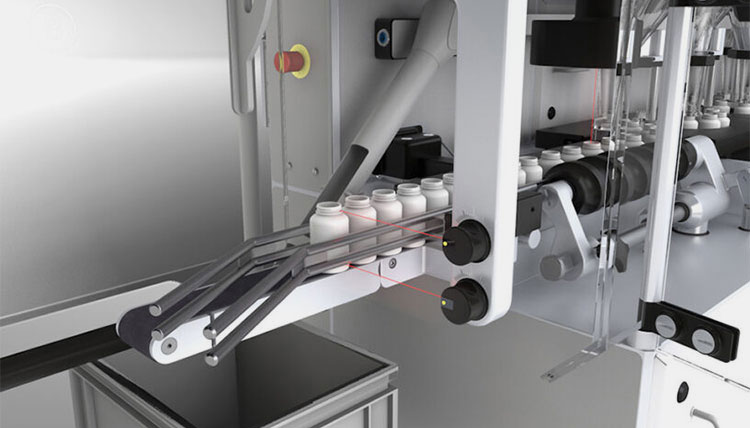

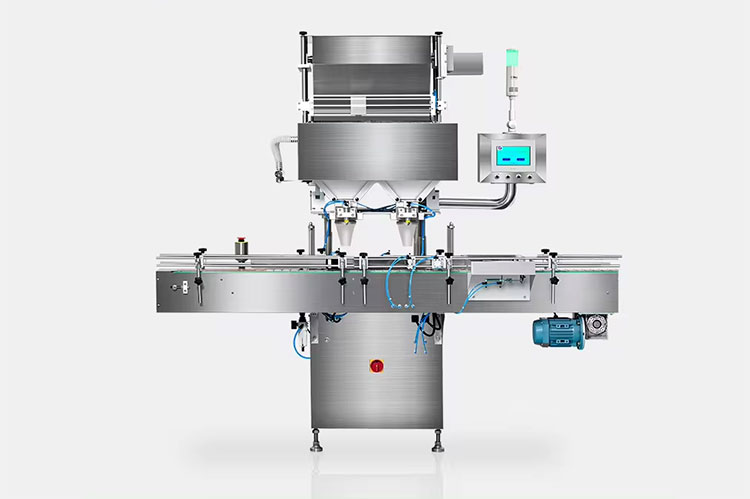

Automatic Pet Snacks Counting Machine

Allpack Automatic Pet Snacks Counting Machine

This machine has a fundamental role in the large-scale pet snack and food industry because of its high-speed processing. Unlike the semi-automatic pet snacks counting machine, the automatic pet snacks counting machine is equipped with 4-32 vibratory channels and filling heads for steady and accurate counting.

These processing components offer unmatched superior results in a limited time frame. It has a large-quantity hopper, ultra-sensitive photodetectors, and a customized control panel for counting and authenticating pet snack products.

It can accommodate diverse kinds of product materials and packaging containers because of its flexible ergonomic structure. It is capable of transforming massive-scale productions because of its human-free working and high-tech gadgets.

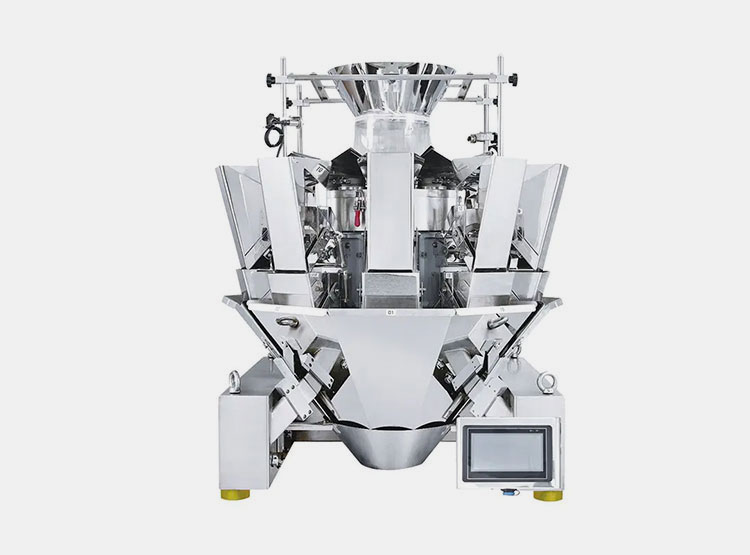

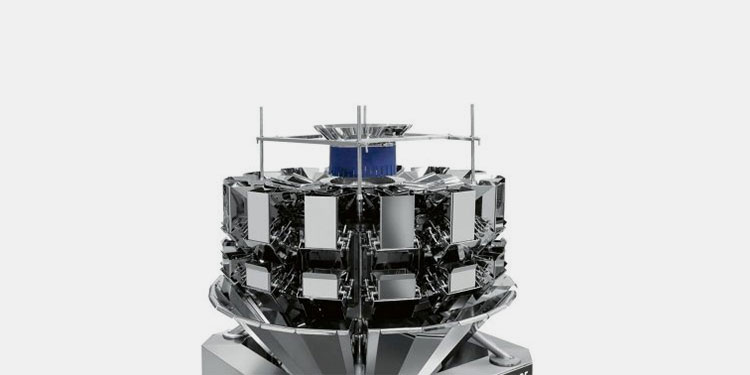

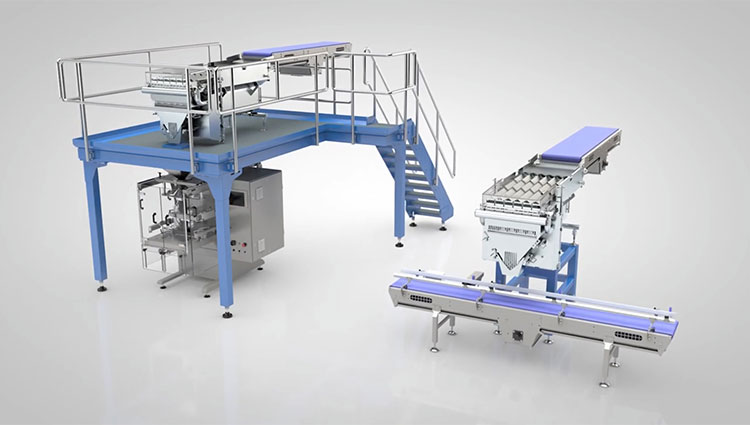

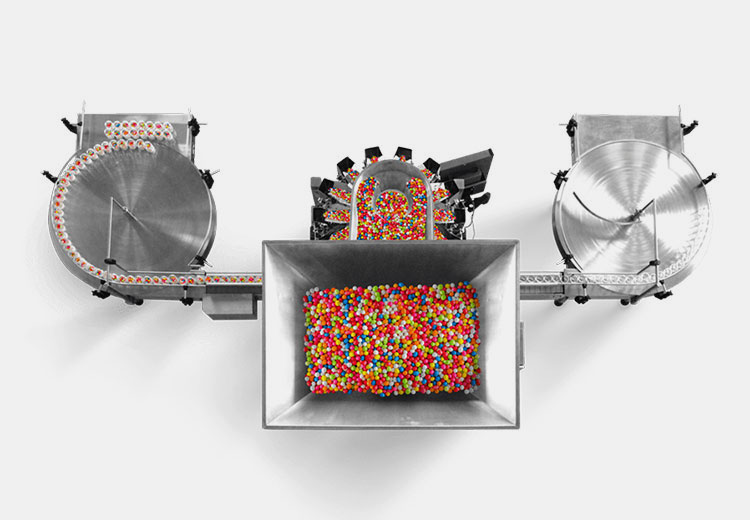

Multi Head Weigher Pet Snacks Counting Machine

Multi Head Weigher Pet Snacks Counting Machine- Picture Courtesy: Kenwei

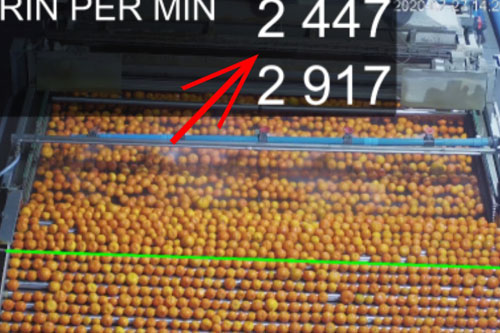

It is one of the biggest pet snacks counting machines, considered a superb counting solution because of its swift counting speed. It can count diverse varieties of pet snacks simultaneously because of its multiple weighing heads. Usually, this machine contains about 10-24 weighing heads.

In every minute, it can process thousands of objects due to its high-tech detection units. They not only accurately count products but also identify unusual errors in the products.

Multi-head weigher pet snacks counting machine is safe for pet snacks processing because of its food-grade construction and gentle handling.

6.How does a pet snack counting machine work?

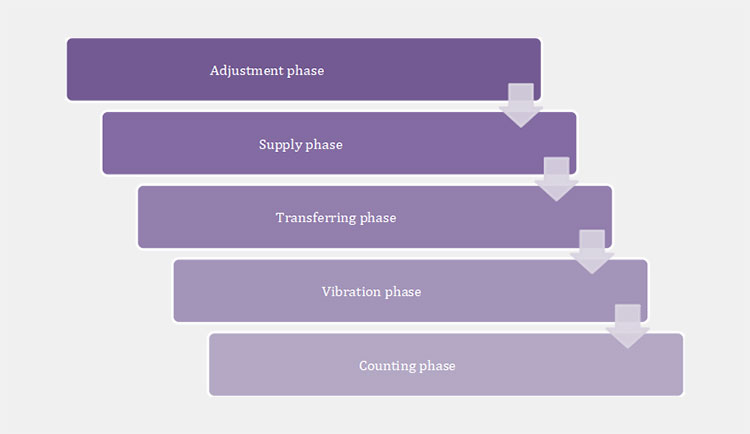

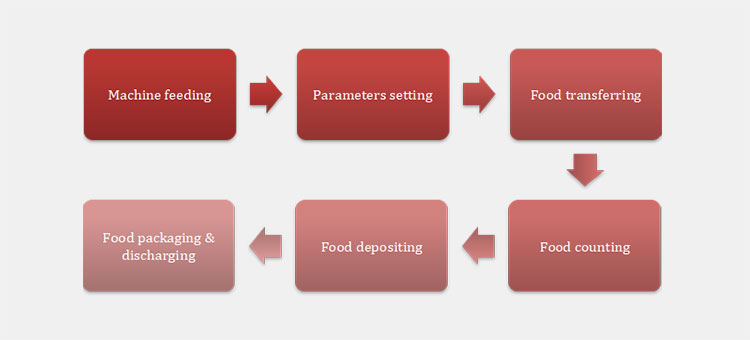

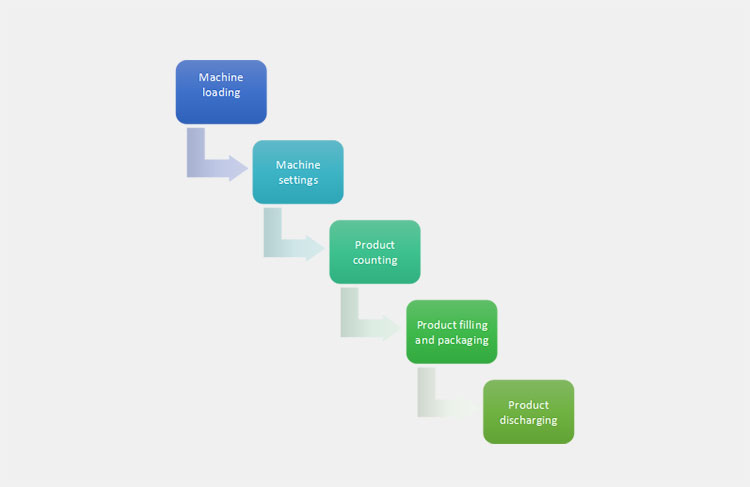

The highly sophisticated pet snacks counting machine is able to cope with production on a bigger scale. Its mode of action is mentioned below:

Working of Pet Snacks Counting Machine- Picture Courtesy: Cremer

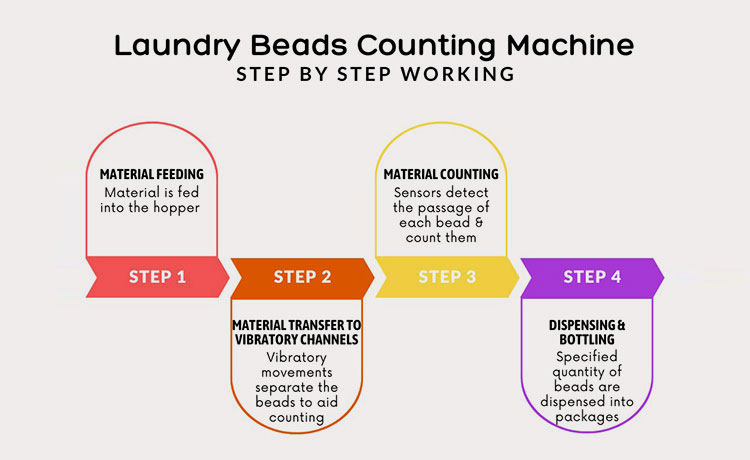

| STEP 1 | Pet Snacks Filling | It is preferable to assess that the pet snacks counting machine is in a running state prior to initiating the process. The first step involved filling up the feeding hopper with pet snacks. |

| STEP 2 | Setting Conditions | Since you have filled the feeding hopper with pet snacks, further you have to specify the terms and set the conditions using the PLC touch screen such as working speed, time of run per minute, movement of vibratory channels, etc. |

| STEP 3 | Movement of Pet Snacks | Upon starting the process, the feeding hopper allows pet snacks to flow towards the multiple channeled vibratory plates contributes ensures well-oriented movement. |

| STEP 4 | Pet Snacks Counting | The pet snack moves gently towards the filling nozzles and drops gradually and is marked as counted with simultaneously filling towards packaging containers. |

| STEP 5 | Discharge | After finishing, the filled container is moved forward and replaced with the empty materials. The finished product leaves the unit with the help of the conveyor. |

7.What other food options can be dealt with a pet snack counting machine?

A pet snacks counting machine with its all-inclusive traits can deal with various other food types commercially. Some of them are mentioned as:

Freeze Dried Fruits

Freeze-dried banana slices- Picture Courtesy: Merlin's Magic Pet

You can count and pack frozen dried fruits using a pet snack counting machine. Its manufacturing design of stainless steel enables counting the food items safely. Furthermore, it preserves standards of quality by eliminating the chances of foreign entities or contaminants.

Nuts (Walnut, Peanuts)

Dried fruits- Picture Courtesy: thefeulgreen.com

The pet snacks counting machine can deal with a broad range series of nuts like walnuts, peanuts, and cashews in bulk quantities. Because of the automated operations, it bring greater efficiency and accuracy to the counting process of various kinds of nuts.

Confectionaries

Confectionery Items- Picture Courtesy: Herbaland Canada

This is way more convenient for counting confectioneries than conventional methods. Gummies, candies, chocolates, chewing gums, and bubble gums are commonly packed with pet snacks counting machine on a large scale. In case of any defective items, the machine can detect them automatically and without wasting your time it is sent to the rejection unit.

Bakery Products

Bakery items- Picture Courtesy: Foodandsnacks

The pet snacks counting machine is one of the most user-friendly and handy options for counting bakery products like cupcakes, bread, rusks, cookies, pies, biscuits, etc. Its demand in packaging bakeries is high position globally due to its most suitable features and the greater degree of performance.

Coffee beans

Coffee Beans

An accurate dispensing of coffee beans is possible with a pet snacks counting machine which is specially used for rapid and hygienic coffee beans packaging.

Grains

Cereals- Picture Courtesy: CHOICE

The pet snacks counting machine deals with counting cereals in various industries worldwide. It is a better choice for supporting the full-scale packaging line of cereals, including maize, rice, wheat, and barely, etc.

8.How flexible is a pet snacks counting machine with packaging materials?

There are various packaging materials that a pet snacks counting machine can deal with conveniently. The following list of packaging materials are discussed below:

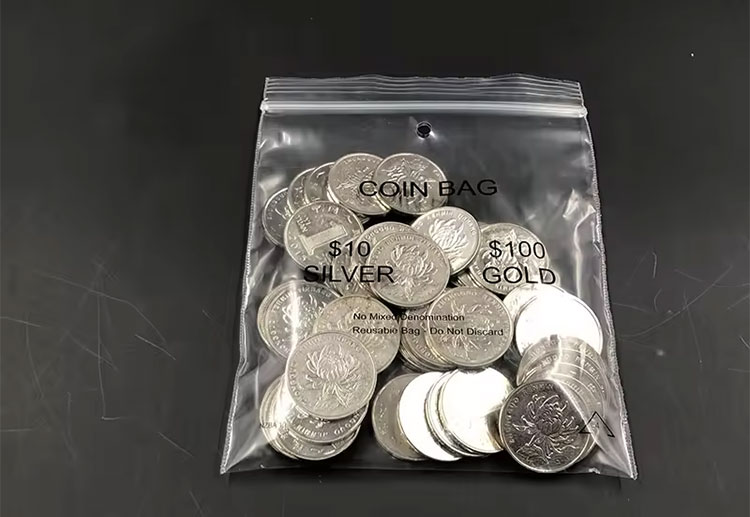

| Bags | The bag is a remarkably affordable mode of packaging that the majority of businesses prefer for storing pet snacks. It offers an adaptable solution for packaging that is customer-compliant and cost-effective. |  |

| Jars | The jar is a highly reliable packaging item that can be allowed by a pet snack counting machine. This is a commonly used mode of packaging ensuring a high barrier against physical hazards such as light, moisture, or product damage. |  |

| Cans | Cans are the finest choice among various packaging materials which is beneficial in term of handling, reusing, and protecting the pet snacks. There are various different types of can sizes available that are selected by customer’s demands and manufacturer’s preference. |  |

9.What should you consider when going to purchase a pet snacks counting machine?

While purchasing a pet snacks counting machine, taking the below factors into account will assist you in selecting the correct machine. Hence, do not forget to consider the following information while making your deal.

Determine the Cost

Your affordability- Picture Courtesy: eurekapet

Firstly, assess your pocket and affordability. The machine prices influence the demand and marketability of your pet snack products. You should plan carefully and according to your budget. Never compromise to invest in a machine that may be a bit expensive, because it is a one-time investment but can give a profitable future.

Machine’s Specification

Pet Snacks Counting Machine Specifications

If you are aiming to achieve long-term capital growth, you should never ignore knowing about features. Make sure that the pet snacks counting machine you are going to buy possesses advanced features that meet the criteria of emerging trends in your industry.

Expected Output

Pet Snacks Counting Goals

Compliance of the machinery with your requirements is fundamental to take into consideration when buying a pet snacks counting machine. You should not make an immediate decision while making such a heavy investment with regard to money and time. Go for the one that works and produces the expected outcomes absolutely as you planned.

Accuracy Level

Pet Snacks Counting Machine

The accuracy of the pet snacks counting machine ought to be your top priority. Therefore, it is imperative to examine and verify the working by examining the features of the machinery in order to achieve the intended accuracy level.

Conclusion

The pet snacks counting machine is the most efficient and economical alternative to the conventional mode of counting and is presented with an amazing innovative series with bespoke solutions. So, now counting and packaging pet snacks is no longer a challenging task. Allpack is a world-renowned operating industry offering and supplying a counting and packaging series of types of machinery for various industries. For example, pharmaceuticals, foods, pets, chemicals, and related sectors. To know about our services and various counting and packaging options, we would suggest contacting our team now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Pet Snacks Counting Machine: The Complete Buying Guide in 2025 Read More »