Tablet Counter Pharmacy: The Complete Buying Guide In 2025

Do you know how pharmacists take advantage of the tablet counter? As pharmaceutical manufacturing industries, research centres, healthcare departments, are growing with more and more competition, the surge of constant quality maintenance and automation is also to be established.

You should know that the evolution of tablet counter pharmacy is one of the most demanding tools that can benefit various packaging processes due to its high efficiency and excellent performance.

How? For that, we have designed this post for you. Here, you’ll find simple and basic information about tablet counters; if you’re a pharmacist, researcher, manufacturer, or related concerned person. We believe, you will enjoy this post. So, come on and read!

1.What Is Tablet Counter Pharmacy?

Tablet Counter Pharmacy

A tablet counter pharmacy is a specialized device used for counting and dispensing of tablets. The machine working is basically relying on ‘specialized sensor system’ that detects falling or dropping of tablet on the surface and mark it as counted.

This machine is designed to carry streamline processes related to counting of medicine in pharmacies as there’s huge function for counting and packaging medicine take place day and night to provide prescriptions to patients on time and accurate manner.

That’s why, medical biosciences have designed tablet counter pharmacy ranges from desktop to large machines that typically helpful to bring difficult and large tasks in an easiest way with reduced time and efforts.

2.How can you take benefit of tablet counter pharmacy?

A tablet counter pharmacy is very friendly and flexible innovation with several advantages. Some of them are described below:

Say Bye Counting Headache!

Easy counting

A tablet counter pharmacy has reduced manual counting headaches, means this is a blessing to all pharmacists as it saves your time and energy in tedious counting. The counting of tablets now carried out in a breeze in minimum time. So, pharmacy team can enjoy catering patient and healthcare unit with their best.

Error Proof Medicines Dispensing

Error less results

Whether pharmacy or pharmaceutical industry; a tablet counter pharmacy is now offering you an ‘oops proof tablet counting’ mean no chances of error. Now you clients will be happier and more satisfied with your throughput; thank to ‘tablet counter pharmacy’.

Speedy & Quick Counting

Quick Turnover

This machine is so much reliable and working fast and quick. Once you need it, simple pour or subject the tablets and allow the machine to bring it results to you in the form of correctly counting as prescribed.

Happy Patient, Happy Customer, Happy You

Safest Procedure

A tablet counter pharmacy allows quick action; hence you and your customer don’t need to wait at all. Similarly, in large industries, you can supply large amount of production batches in no time- this ultimately gives you ‘5-star’ reviews from your customers; thus, you’re having more production satisfaction and high-market value.

Easy Working

User-friendly with flexible workflow

A tablet counter pharmacy is sensitive to work with easy operating keys, machine is flexible to understand and gives you accurate results. Anyone can use it, we promise, this tool is easy to use and easy to handle.

3.How does tablet counter pharmacy work?

The working of the tablet counter pharmacy includes automation of counting and filling tablets following a greater ratio of accuracy. The exact working principle of the machine may vary from model to model and brand to brand, though the basic working of the machine is overview here:

Step 1: Loading of Tablets

Tablet Loading

The batch of tablets is subjected to the machine via pouring directly into the machine’s hopper or using tablet feeding mechanism including automatic addressing of tablets.

Step 2: Vibratory Channels and Counting Sensors

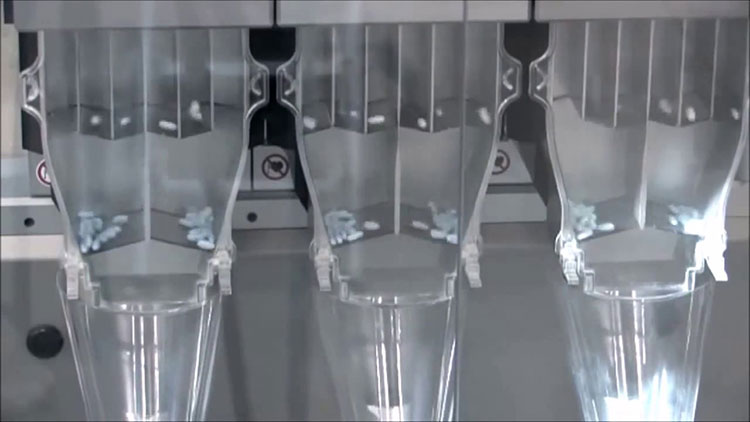

Sensory Detection and Counting

Upon loading the tablets, these are passed through vibratory channels where detectors and scanners are subjected to assess the correctness of the tablets. If tablets are faulty, it sends to rejection without considering them as counted. The sensors/cameras/scanner detect the presence and mark them by using photoelectric or infrared sensors and display results on a PLC touchscreen where the pharmacist can see and verify the exact quantity of the tablets present inside the container.

Step 3: Discharge

Discharging of the finished product

Once tablets are counted and dispensed into either bottles, pouches, or vials; they’re now discharged by using a conveyor. In a manual machine, you can pick the sample manually, while in other machines, conveyor send the material towards other machines integrated with it continuing further process.

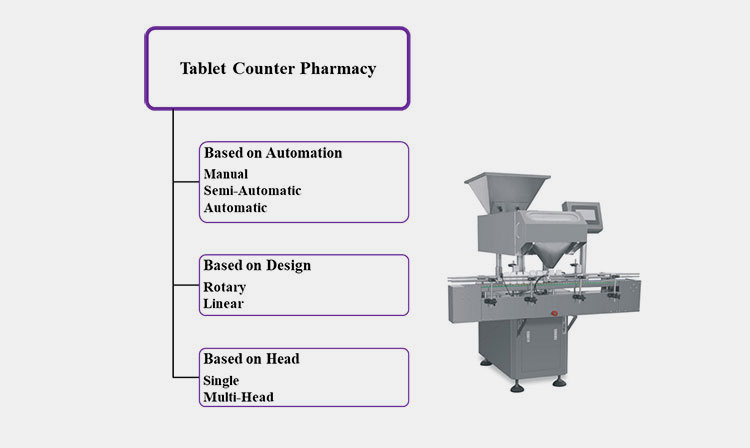

4.How many types of tablet counter Pharmacy?

There are various types of tablet counter pharmacy, please check an illustration and details below:

Classification of Tablet Counter Pharmacy

BASED ON AUTOMATION

It refers to machine working incorporated with technology and smart processing. In this category, three types of machines lie, for example:

Manual Tablet Counter Pharmacy

Manual Tablet Counter Pharmacy

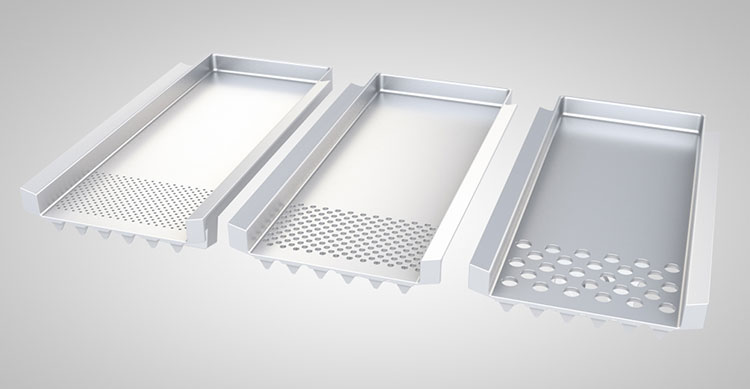

This is a conventional way of counting tablets. In previous decades, pharmacies, herbalists, and homeopathic medicines were counted and packed using this simple tool. Still, this machine is advantageous in small sectors as it is pocket-friendly and requires no training. You have to pour the tablets and count them by using a spatula to avoid touching them; pouring, counting, filling, these three jobs can be done manually.

Structure

This is a small tray-based tool which is a counting platform with a handle to manage and pour counted items into bottles or pouches.

Semi- Automatic Tablet Counter Pharmacy

Allpack Semi-Automatic Tablet Counter Pharmacy

Semi means half, similarly a semi-automatic tablet counter pharmacy is a half automatic and half manual machine. according to our expertise, its main functions are automatic. You just need to put the container and after counting remove it. How simple! Isn’t it?

Structure

A semi-automatic tablet counter pharmacy has a simple structure which is including container placement area, counting nozzle, vibratory channels, and a control panel.

Automatic Tablet Counter Pharmacy

Allpack Automatic Tablet Counter Pharmacy

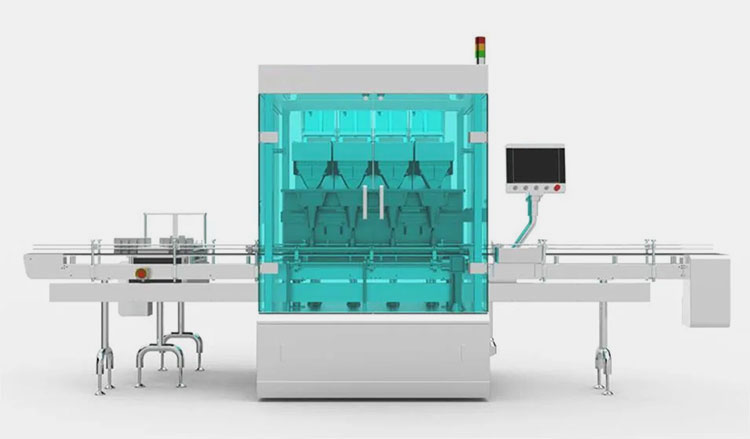

This is a more complex machine but offers high flexibility and convenience. You can integrate this machine with other production units thus entire function can be operated with no need to human intervention. From beginning to end, the entire operation can be performed by the machine itself.

Structure

The machine is featured with a PLC touch screen, conveyor, sensors, cameras, filling nozzle, filling head, visualizing window, and other high-tech units to bring a sophisticated operation.

BASED ON MACHINE DESIGN

A tablet counter pharmacy has two basic types depending upon the design such as rotary and linear.

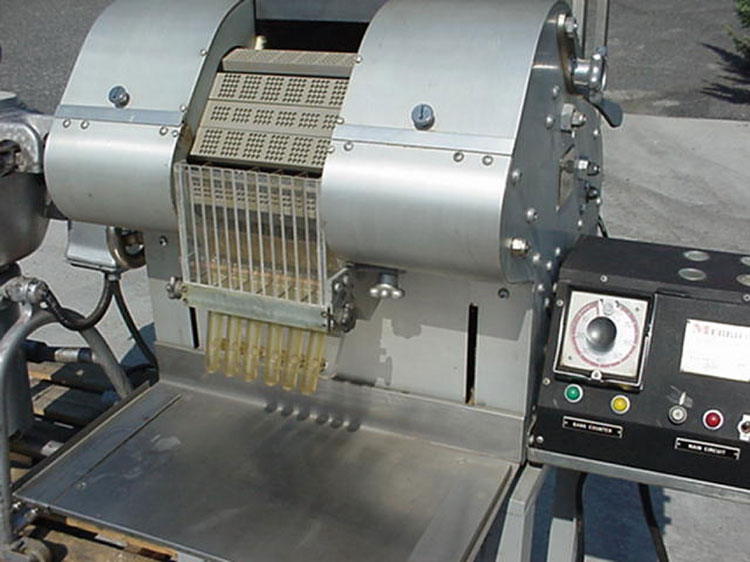

Rotary Tablet Counter Pharmacy

Rotary Tablet Counter Pharmacy

This machine is simple and offers high automation. The machine working based on the rotation of a carousel which is composed of tiny pockets to fix the tablets and make them count.

Structure

The machine is composed of rotary plates that shake and allow movement and alignment of tablet. Inside the machine, you can find sensors and scanners to assess faulty tablet. The machine is featured with filling head and nozzle and PLC touchscreen, the entire design is enclosed in a glass chamber that’s why it is preferable to use to count sensitive or hygroscopic dosage products as well as general tablets.

Linear Tablet Counter Pharmacy

Multi-Channel Pharmacy Pill Counter- Picture Courtesy- CVC Tech

This is the basic machine that follows a vibratory channel pathway to move tablets toward the counting unit. This equipment is commonly used in various industrial counting sections and can deal with large production batches.

Structure

This machine is composed of counting channels, filling head, filling nozzles, sensor, visualizing windows, and PLC touchscreen to bring tasks effectively.

BASED ON COUNTING HEAD

Based on counting heads there are various types of tablet counter pharmacy:

Single Head Tablet Counter Pharmacy

Allpack Single Head Tablet Counter Pharmacy

This machine is available in semi-automatic and automatic versions that is accurate bring the counting and filling job. As it names show, you can see, there is single filling head associated with the machine. This is mostly used in medium to large industries for streamline production and packing processes.

Structure

This machine is composed of simple structure including single head, filling nozzle, PLC touchscreen system, and sensor to detect tablets.

Multi Head Tablet Counter Pharmacy

Allpack Multi Head Tablet Counter Pharmacy

This machine is featured with more than a single head, therefore offering you a tremendous counting and filling tasks. All large industries own this machine as it gives to hundreds of counting tablet in few seconds. You this an automatic machine with high investment but convenient results.

Structure

This machine is composed of multiple counting heads, multiple sensors, multiple nozzles, and diverting funnel to passage counted tablet into specific container.

5.Who Uses Tablet Counter Pharmacy?

Apart from pharmacy, a tablet counter pharmacy equipment has extensive usage in various other fields belonging to production, filling and packaging sectors. These include:

Nutraceutical Industries

Tablet manufacturing in Nutraceutical Industries

Here, major health related, and wellbeing-boosting supplements are prepared, filled, and packed. For example, multivitamins, minerals, trace-elements and other products in the form of pills, tablets, capsules are regularly manufactured under controlled conditions. A tablet counter pharmacy is worthwhile to bring this process effectively.

Cosmetic & Personal Care Industries

Tablet manufacturing & counting in Cosmetic & Personal Care

You have observed various cosmetic and personal care products available in the form of softgel capsules (serums, facial oils, essential oils, creams), as well as some personal care products such as bath bubbles, pedicure tablets, etc, need a tablet counter pharmacy for packaging in order to provide satisfactory packaging to end users.

Pharmaceutical Manufacturing & Packaging Industries

Pharmaceutical medicines counting

This industrial sector is world’s richest sector where billions of dollars business is carried out annually related to the manufacturing and packaging of medicines available in the form of capsules (softgel & hard gel), pills, granulated matters, tablets, lozenges, etc., require tablet counter pharmacy for accurate counting and packaging.

Food & Beverages Industries

Food & beverages products

You must have seen soda tablets, when putting in water yummy, delicious drink gets ready to enjoy. Similarly, various other food products are made up of tablets shapes, such as gummies, coffee beans, sweeteners, etc., all of them need a tablet counter pharmacy for proper counting and packing.

Chemical Industries

Chemical Tablets

Various chemical products such as bleaches, acids, alkali bases, salts, ph. neutralizing tablets, buffers, and other items are manufactured in the form of tablets, granules, or pills that can be counted using tablet counter pharmacy for final finished products to maintain accuracy and quality.

Veterinary Medicine

Vet related tablets and pills

The veterinary industry is concerned with manufacturing and packaging of pet related items such as energy boosters, supplements, antibiotics, anti-pyrectics and painkillers are mainly counted using tablet counter pharmacy.

Stationery Industry

Stationery products

Using a tablet counter pharmacy, various stationery items can be properly counted and filled in pouches, bottles, and containers, Such as pen toppers, rubber/erasers/, sharpeners, holders, clips, etc.,

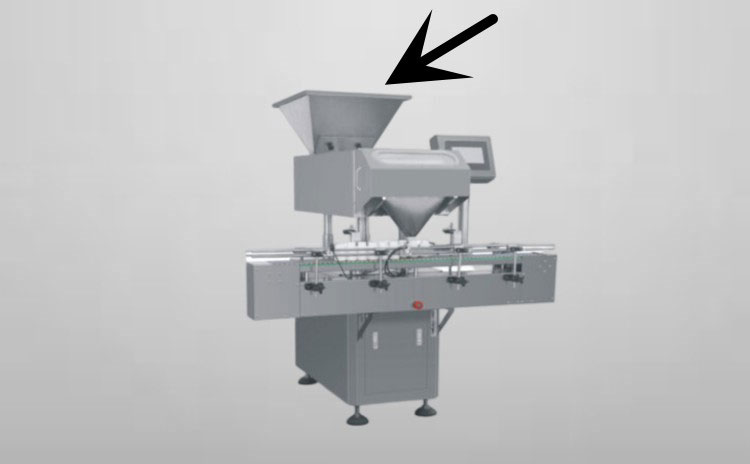

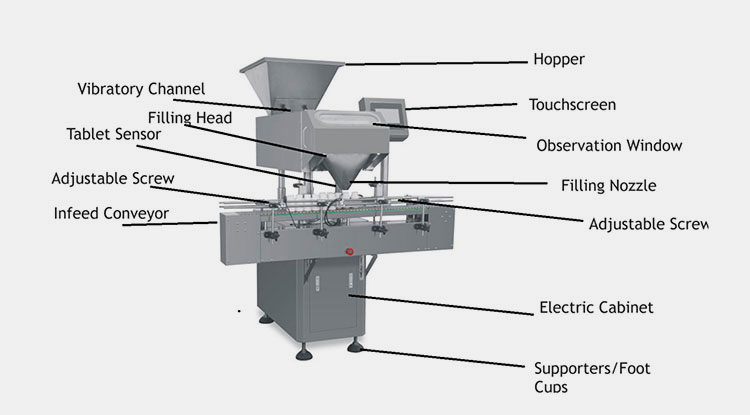

6.What is the structure of a Tablet counter Pharmacy?

Allpack Tablet counter pharmacy Parts

Hopper: This is like a storage tank which allows tablets to pour or drop down for further process steps. That’s why it is commonly located at the upper part of the machine to bring these steps in an easy go.

Touchscreen: Just like a smartphone or your iPad, you can put commands using the touchscreen and results display on your screen. Similarly, you can set things and visualize A to Z going on inside and outside the machine with proper counting as well as graphics of the process.

Vibratory Channels: Small, straight and narrow pathways where tablets can move and transfer from the upper body towards the counting unit. these vibratory channels are also featured with scanners to detect any faulty or unusual tablet. The purpose of these channel to bring smooth counting process without piling or tablet jamming.

Observation Window: If you’re still worried about inside processing, just hold on- you can peek to monitor tablet counting using the observation window which is made up of transparent glass allowing you easy seeing.

Filling Head: This is the part where process begins, this unit acts like a transporter that facilitates easy movement of tablets to move down towards the nozzle.

Filling Nozzle: This is unit allow tablets to come out as a counted items just like a fountain that allows the easy flow of material (tablet) toward container.

Tablet Sensor: This is the part where exact/major process takes place, once tablet comes or drops into this unit, a beam of light or sensor light fades and transmits signal as a marked one.

Adjustable Screw: There are different types of containers, such as sizes, shapes, weights, hereby an adjustable screw provides support to filling container to become stable by using fine tuning to adjust the easy and firm gripping.

Infeed Conveyor: The container comes in contact with filling nozzle by the help of conveyor belt. Once tablets are counted and filled, conveyor belt also support them to leave the system and drop them towards the next machine. the speed of conveyor belt is also controllable.

Electric Cabinet: Just like other parts of the machine, electric cabinet functions as a heart of the machine where major electrical components are fixed and can transmit electrical energy into the machine to streamline everything flexibly.

Supporter/Foot Cups: The machine can absorb shocks, and vibration, and remained in a balanced position by the help of supporter and foot cups.

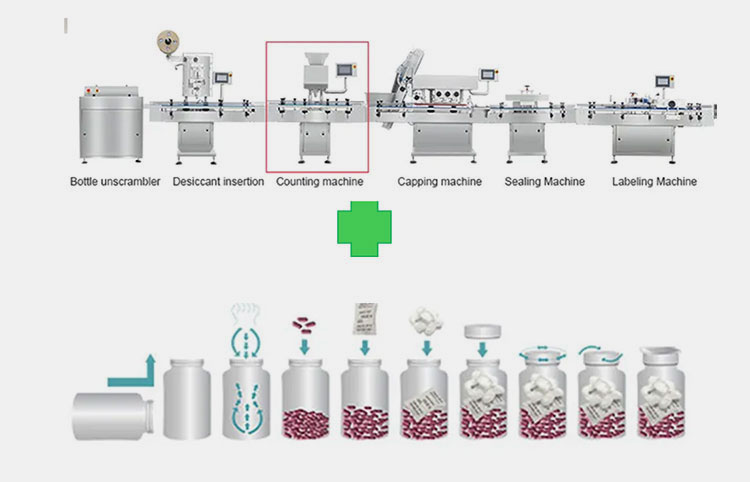

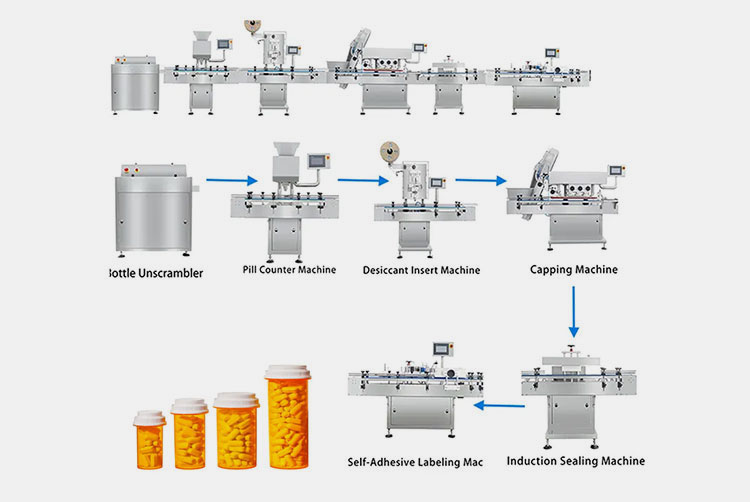

7.What is a production line of a tablet counter pharmacy?

Production line of tablet counter pharmacy

The tablet counter pharmacy can streamline working flow in combination with other machines to bring process in effective way.

Types of machines include in a complete production line of tablet counter pharmacy is mentioned below:

Bottle Unscrambler

Allpack Bottle Unscrambler

Before starting the process, machine must receive bottles or containers in an upright and arranged position thus it would be directly ready to fill and move toward the next machine. a bottle unscrambler is an excellent machine responsible for correcting the position of random bottles.

Working

The machine is mostly designed with a rotating plate with a fixed strong blower. The power of rotation and high-velocity blower can typically used to arrange bottles and orient them correctly and send to the next step.

Tablet Counter Pharmacy

Allpack multi-channel tablet counter pharmacy

Arrange set of bottles are conveyed to the machine using conveyor and counted number of tablets are filled and send for further steps.

Desiccant Inserter

Allpack desiccant inserter

Once tablets are counted, a desiccant inserter is responsible for inserting small stripe of desiccant inside each bottle to protect tablet against moisture content and keep them stable.

Working

The machine works by opening stripes of the reel hooked in the arm of unit. By the help of sensor, each pack is separated by cutters and direct inserted into the bottle, thus a precise process is taken place.

Capping Machine

Allpack Capping Machine

Now bottles are moved for closing, for that a capping machine is integrated which applied caps over each bottle subjected to this machine.

Working

A capping machine is capable of screwing caps and can be compatible to deal bottles of various sizes. The robotic arms pick caps and close them by applying pressure, tuning, and twisting to secure bottle completely.

Induction Sealing Machine

Allpack APC- Induction sealing machine.

For medicinal, foods, and other products, a tamper evident sealing is essential to ensure customer satisfaction and integrity of your brand. This is done by application of firm foil over the surface of the product that keeps it promising fresh and original.

Working

The machine works by inducing electromagnetic radiation, it happens when bottles come in contact with the machine. this ultimately, melts the sealing layer of the cap. Upon cooling the sealing layer forms a strong bond with the bottle neck and forms unbreakable sealing till end-user.

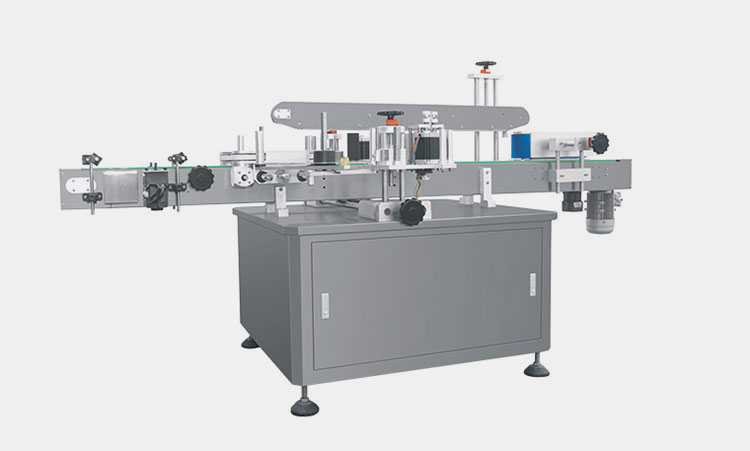

Labeling Machine

Allpack Multifunction Labeling machine

All essential information about a product, dosage, manufacturing date, expiry date, precautions, and other are mentioned in labels. A labeling machine is useful to bring this task on aligned position of each bottle.

Working

When bottles come in contact with the machine, the label applications take place by using adhesive labels unwinding from roll and stick on each side followed by a presser ensuring complete fixation. In our blogs, you can see various label machine types, some of pressure- sensitive, while some are hot-glue, etc. every manufacturer use machine depending on their choices.

8.How tablet counter pharmacy deal with Hygroscopic tablets?

A Tablet Counter Pharmacy Is Ideal Tool for Counting Hygroscopic Items

A tablet counter pharmacy is well-designed equipment that is suitable for counting hygroscopic tablets effectively. This is basically relying on its compact and enclosed structure which provides a controlled conditions to those dosage forms that are prone to entrapped moisture from outer conditions.

Secondly, the fast action of tablet counter pharmacy allows limited time of exposure to tablets hence lesser chances of de-shaping and water adsorption and attraction.

Thirdly, the machine is now a days available that offer pre-heating option to their users which is very important because it controls chances of moisture content presence during the procedure and maintain accuracy without harming by no- clumping or aggregation of solid-dosage forms.

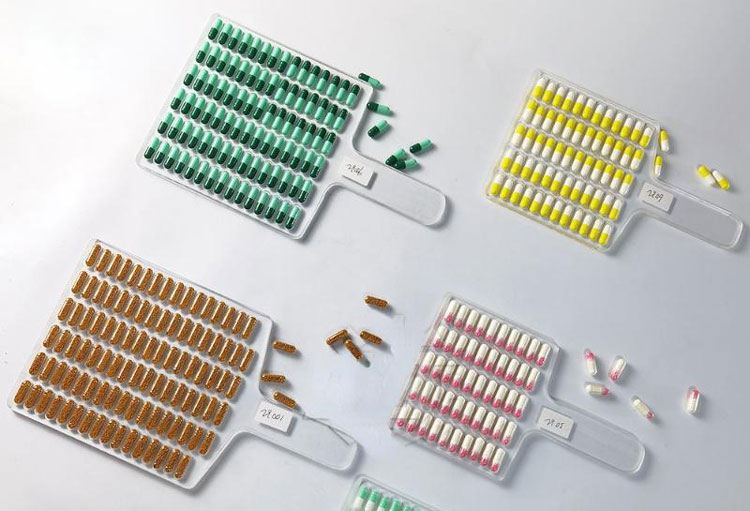

9.What common products are used in tablet counter Pharmacy?

There’s simple logic, anything counting by hand can be counted by a tablet counter pharmacy. Such as

| Product | Description | Picture |

| Capsules | Generally hard gel and softgel capsules can be counted. |  |

| Gummies | Elastic, chewy, and sweet gummies can be counted and packed using tablet counter pharmacy. |  |

| Tablets | Including various sizes, weights, shapes, and medicinal and non-medicinal dosages. |  |

| Lozenges | Commonly used to treat colds, flu, and related problems can be counted and filled with this machine. |  |

| Candies | Confectionery items including candies with various shapes, tastes, textures, and weight can be dealt using tablet counter pharmacy. |  |

| Troches | This is a dissolvable medication can be subjected to a tablet counter pharmacy for accurate filling. |  |

10.What are 5 Factors Affecting Accuracy of tablet counter pharmacy?

There are important factors that ignoring would affect the overall efficiency of tablet counter pharmacy. Such as:

Factor I- Unpolished Tablets or Dust

A clean counting using tablet counter pharmacy- picture courtesy: Cremer.

If tablets or pills are unpolished or have dust around their surface it can harm the effectiveness of the machine by accumulating of dust or forming dust piles on sensors that will ultimately affect the accuracy and sensitivity of sensors to count tablets by obstruction.

Factor II- Weight Variation

Weight variation affects accurate counting.

If tablet groups are of different weights and sizes, it may affect the accurate results as a machine may does not show accurate results due to this factor. It is suggested to the subject tablet of same group/batch.

Factor III- Environment

Controlled working environment can safe humidity interference- Picture Courtesy: C.E Limited

If the working environment has facing excessive moisture content or humidity; this may affect the efficiency of the tablet counter pharmacy. Therefore, the machine itself has pre-heating feature also, it is recommended to use a humidifier at the workplace.

Factor IV- Machine Settings/ Calibration

Taking right approach to calibrate machine- Picture courtesy: MC.

Every machine calibration is very important to obtain sharp and finest results. In this case, tuning and calibration is essential to get a perfect result before setting into the counting process. Ignoring this factor may cause irregularities and inaccuracies in counting.

Factor V- User Understanding

Tablet counter pharmacy need essential understanding from user- picture courtesy: Makewell

Whether using manual or automatic tablet counter pharmacy, it is essential to have deem knowledge about the equipment to bring effective outcomes. An operator must have understood when to pre-heat the equipment, dealing machine before and after use, integrating properties with another unit, and other. The proper knowledge about the following factors would make your process ultimately promising.

11.How to Prevent Tablet Counter Pharmacy from Cross-Contamination?

Monitor and clean machine to avoid cross-contamination.

Recently, A competitive swimmer from Brazil observed a furosemide (anti-diuretic tablet) drug which was combined with another compound via cross-contamination. Because of this, he got health threats that could be much worst. In pharmaceutical industries or pharmacies, the risk of cross-contamination could lead to patient’s death. Therefore, a tablet counting, or other packaging process must be so sterile and cleaned.

There are few ways that allows you to prevent tablets from cross-contamination.

Regular Cleaning

Clear dust particle to prevent contamination.

Dealing with multiple products like tablets, capsules, and pills using the same machine can cause this problem, therefore it is recommended to clean your apparatus extensively using a dry cloth. For sticky particles, it is suggested to spray 70% IPA to sterile the surface.

Maintenance

Maintain your machine is essential- picture Courtesy: Cremer

For adjoining parts of the tablet counter pharmacy, it is easier to monitor and replace worn out components. You need to inspect the machine on weekly, monthly, and annual basis. For movable parts, it is recommended that you lubricate to avoid noise and unwanted shock.

12.How do you troubleshoot tablet counter pharmacy?

There are certain problems associated with tablet counter pharmacy; to troubleshoot them, please find solutions below:

| Problem | Troubleshooting Tips |

| Tablet Counting with Inaccuracies |

This might be due to presence of obstruction in the vibratory channels, or any passage allows movement of tablets, hence causing inaccurate counting. Also due to presence of dust or accumulation of dust may be the reason that can be dealt by cleaning and removal of obstruction. Ensure machine is calibrated, and sensors are cleaned, Also, verify and adjust the settings of counter using touchscreen. Run a test before final procedure. |

| Tablet Jamming |

This problem may be due to mechanical problems such as improper vibration for that check vibratory plate and replace worn out parts. Moreover, high speed of the tablet may be the reason that can be solved by regulating the counting speed. |

| Sensor malfunction |

The presence of debris or dust causes sensor malfunction that can be solved by cleaning the surface. Check if any loose connections so it can be corrected by replacing them with new. Calibrate the machine and check the operation of sensor before the initiation procedure. |

13.What is the future forecast of tablet counter pharmacy in medical technology?

Future forecast of tablet counter pharmacy- Picture Courtesy: Pill Counter

Tablet counter pharmacy has huge applications and demand with greater improvement of models for the fastest and the most accurate outcome. In this case, there’s no problem with any shape, weight, or type (coated & uncoated) of tablets.

Recently, it has been found that you can count nearly 100 tablets in 20 seconds and fill them directly into bottles, thus no chances of cross-contamination as compared to previous inventions.

Considering new technologies, a tablet counter pharmacy will be even faster than now, in future with fastest counting abilities, there will be an easier-to-operate feature with lesser user-errors with easy data understanding properties.

According to PharmTech, it is expected that you will see more tablet counter pharmacy equipped with auto-inspection units that will push more greater quality.

14.What are the points to be considered when selecting a tablet counter pharmacy?

When purchasing tablet counter pharmacy, we have jotted down some important things to consider:

Consider Your Needs

Evaluate your needs!

List your priorities, it will help to save your time. Look for model and select companies offering you higher quality sensors and detecting optics.

Consider Properties of Machine

Assess the Type of Machine You Need

What type of machine do you need to enhance your performance? There are various categories we discussed above. Such as manual for smaller pharmacies or businesses, semi-automatic for medium, and automatic for large. But this is not the rules, you can employ digital one or automatic machine for limited business too. Thing is, your budget, time -saving and faster results. You need to consider when selecting type of machine.

Consider Flow of Work

A tablet counter pharmacy with integrated units

The machine must be capable of dealing a large number of tablets and can be able to integrate with out unit of the workplace. Your operators should be able to deal machine with clear instructions also, it must be compatible with your manufacturing process.

Competitive Vendor

Competitive Vendor Can Bring Tremendous Outcomes

Last but not least, a competitive vendor like Allpack always plays a key role in providing solutions in the form of proper guidance, promising types of machinery, and understanding your budget.

Conclusion

A tablet counter pharmacy is a traditional machine with high adaptability and new development that is capable of picking up tablet’s presence as well as incorrect or wrong particles to remove without interruption. Want to know more about tablet counter pharmacy? Or purchase? Get in contact with Allpack experts to avail free counselling, machine quote and knowledge about new offers. Message us now!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide