Tablet Coating Equipment: The Complete Buying Guide In 2025

Does your business involve manufacturing of different types of tablets? Do you apply coating on your tablets and use tablet coating process in manufacturing of tablets? Does your business use a tablet coating equipment or are you interested in buying a tablet coating equipment? If your answer is yes then you are on the right platform.

Here you will get all information related to a tablet coating that will help you in selecting the right type of equipment for your process. Go through the complete guide and get your queries solved.

1. What Is A Tablet Coating Equipment?

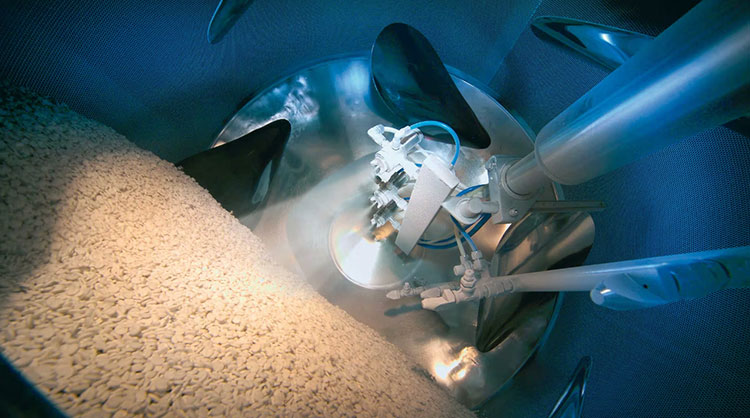

Tablet Coating Equipment

A tablet coating equipment is a highly flexible machine used to apply coating on various types of tablets. This applied coating protects degradation of active ingredients and supports tablets to have both color and taste. Other than this the tablets are also prevented from environmental factors like moisture and oxygen.

2.What Are The Industrial Applications Of A Tablet Coating Equipment?

Some of the industrial applications of a tablet coating equipment are

Pharmaceutical Industry

Pharmaceutical Tablet Film Coating – Picture Courtesy: PharmaCentral

Various types of film and enteric coating medicines that are produced in pharmaceutical industries undergo coating process in a tablet coating equipment. This equipment is highly capable of applying coating on all types and sizes of tablets to make the patient feel ease while taking it.

Food Industry

Milk Chocolate Coated

Tablet like chocolates, chewing gums, beans, candies, toffee and other attractive products produced in food and confectionary industry are coated using a tablet coating equipment. This equipment preserves the flavor and essence of the product for a longer period and attracts people of all ages.

Nutraceutical Industry

Nutraceutical Tablet Coating – Picture Courtesy: Univar Colour

For protection and safety of nutraceutical tablets, a tablet coating equipment is highly recommended in this regard. Tablet coating supports in handling the nutraceutical tablets under controlled environment so that its delicacy remains preserved for much longer time.

Chemical Industry

Agroblen Tablets – Picture Courtesy: ICL Growing Solutions

Various types of chemical fertilizers and special tablets are coated using a tablet coating equipment. It improves the internal properties of these tablets and enhances their efficacy. Also, when these chemical tablets are used, the coating controls their releasing process with both heat and moisture resistance.

Cosmetics Industry

Strawberries & Cream Waxing Dots Hair Removal Wax Beads – Picture Courtesy: Ultra Beauty

Cosmetics tablets also involve variety of chemical agents in their manufacturing. These tablets are directly applied on human body this is why it requires a greater secure and effected coating on their outer shell to maintain their purity. Cosmetic products like serums, wax beans and other pedicure related products undergo tablet coating process in a tablet coating equipment.

3.What Are The Benefits We Can Get From A Tablet Coating Equipment?

While opting for a tablet coating equipment, you should know its wide range of advantages that it offers. Out of several advantages some are

Quality Tablets

High Quality Film Coated Tablets

The most important benefit of a tablet coating equipment is that it applies highly quality coating with precise and consistent spray rate. Complete batches are produced without any chipping or defect.

Uniform Coating

Uniform Sugar-Coated Tablets – Picture Courtesy: Glehill Condos

Each of the tablet that undergoes coating in a tablet coating equipment has uniform and authentic coating. All of the edges are coated in a way that the profile of each tablets appears to be similar in shape, size and appearance.

Preventing Material Wastage

Film Coating – Picture Courtesy: Merck KGaA

During the application of coating spray, the solution of polymer or pigment is directly applied on tablets in a tablet coating equipment. This prevents the spray material from wastage and do not allow it to fumigate in air.

Preventing Tablet Damage

Preventing Tablets Damaged

Like spray material, the tablet coating also prevents the tablet from damaging when handled or traveled globally. This coating provides an extra layer to the tablet and acts as a shell on it. As a result, no wastage of powder occurs even if it is kept for a longer period.

Tamper Resistance

Tamper-Resistant Coated Tablets – Picture Courtesy: UNSW Sydney

Both the shape and size of tablets remains preserved and tamper evident when they are coated using a tablet coating equipment.

4.What Are The Materials Used To Apply Tablet Coating?

Varieties of tablets are found with coating on their surface. Some of the materials used for applying tablet coating are

Acrylic Polymer Coating

Tablet Coating Process– Picture Courtesy: LFA Tablets

Most of the immediate and extended release tablets are coated using acrylic polymers like polyvinylpyrrolidone and polyvinyl alcohol. These materials are highly intense that they protect tablets from moisture and also increase their internal strength. Also, these acrylic polymers are used for binding tablet powders together.

Hydroxypropyl Methylcellulose

HPMCP Enteric Coating– Picture Courtesy: SE Tylose

Cellulose like materials that are moisture and humid free are ideally used for applying film coating on various tablets. These materials include hydroxypropyl and hydroxypropyl methylcellulose that hold the property to coat tablets in an efficient way.

Polymethacrylates

Polymethacrylates Film Coating – Picture Courtesy: Bio Grund

Polymethacrylates are the materials that have high permeability and water solubility properties. Tablets coated with Polymethacrylates are intense that they dissolve in a slow pace when get in contact with water and also prevents any type of acid and drug reaction in the stomach.

Wax

Sugar Wax Coated Tablets – Picture Courtesy: IK Pharma Machinery

Some wax like materials that are generated from carnauba leaves are also suitable for applying coating of different types of tablets. It is mostly used to give a waxy or glossy appearance to tablets that appeals the consumers and also protects the entrance of any environmental microbe.

5.What Is The Working Principle Of A Tablet Coating Equipment?

Tablet Coating Machine Process

A tablet coating equipment has a simple yet important working principle to be considered with following standards. Some of the steps involved in it are

Step 1: Material Preparation

The very first process involves preparing the coating material according to the tablet powder. This step is the most crucial one as it needs to be handled with great expertise and efforts. The coating material is filled into the equipment as per the required formulation in this step.

Step 2: Feeding Tablets

Once the coating material is filled, the tablets are placed in to the rolling drum where the material will be applied on them.

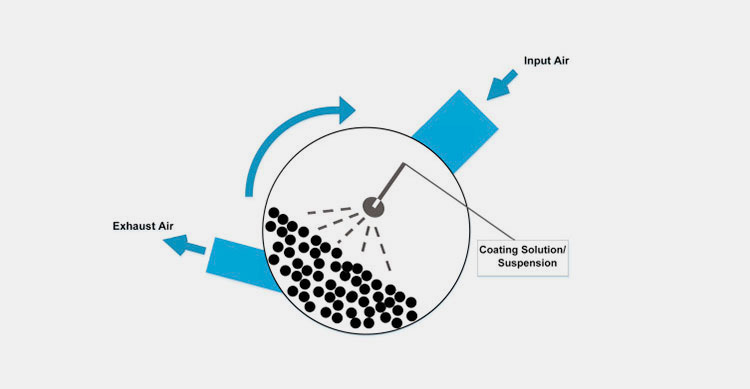

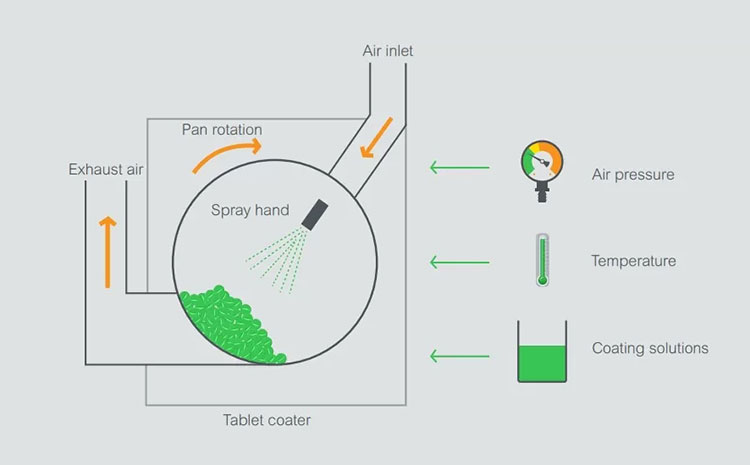

Step 3: Spraying

The most important step is of spraying. As the drum starts rotating, the tablets experience a spray from the spray nozzle gun that are present in it the spraying process remains completely automated and is applied in a way that each of the tablet experiences uniform and equal amount of coating material.

Step 4: Drying

In the fourth step, along with the spraying of material, a hot air is introduced into the drum of tablet coating equipment to dry the applied coating material. This process also helps in dispersion of solvents from the solution and leaves the solid tablets back. These tablets get completely coated during the exposure of controlled hot air and become uniform in total.

Step 5: Discharging

Once the process gets completely, these coated tablets are removed from the tablet coating equipment via discharging ports and further moved for packaging and curing processes.

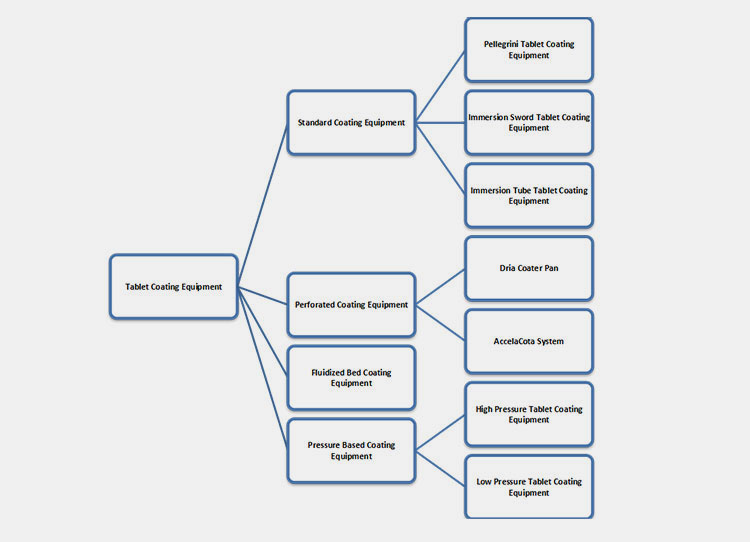

6.What Are The Types Of Tablet Coating Equipment Available Globally?

Tablet coating equipment is classified on the basis of their working and pressure handling capability. Some of the types of tablet coating equipment are

Standard Coating Equipment

Allpack Standard Coating Equipment

The most common type of tablet coating equipment is a standard coating one. It has a rotating pan with continuous spraying at 45 degrees to apply coating on each tablet precisely. It is further classified into three types

Pellegrini Tablet Coating Equipment

For a uniform supply of both hot and warm air, a pellegrini baggled diffuser is installed in this type of standard tablet coating equipment. It gives evenly prepared tablet results throughout the process.

Immersion Sword Tablet Coating Equipment

A long sword in associated in this type of standard tablet coating equipment for spraying hot air in the pan. An immersion sword standard tablet coating equipment gives high speed results in small fraction of time.

Immersion Tube Tablet Coating Equipment

As the name suggests, a double header immersion tube is installed in the drum of a standard tablet coating equipment that syncs both material and hot air supply in the pan. Heated air one making the system dry leaves the pan in upward direction.

Perforated Coating Equipment

Perforated Tablet Coating Machine

Perforated coating equipment has a partially perforated drum with a moving horizontal drum pan. It has a top atomizer spray along with an airflow gun that is responsible for coating of tablets. It also has two sub classes according to their structures.

Dria Coater Pan

A dria coater pan follows an opposite operation that an accelacota system pan where the exhausted air moves upward and flows continuously within the system to apply coating on each tablet precisely.

AccelaCota System

The hot air in an accelacota system enters the coating pan from upward direction and moves the exhausted air in the opposite direction. It gives effective and highly précised coating results due to its systemized process.

Fluidized Bed Coating Equipment

Fluidized Tablet Coating Machine

A fluidized bed coating equipment follows the principle of fluidization where an internal vacuum is created and the tablets are allows moving freely with the help of applied inlet air. This helps in proper coating of each of the tablet present in the vertically supported fluidized bed. The up and down movement of tablets support in uniform coating of each tablet.

Pressure Based Coating Equipment

Tablet coating equipment is also classified according to the applied pressure into the system. These types are

High Pressure Tablet Coating Equipment

High Pressure Based Tablet Coating Machine

For large scale industries where, bulk numbers of tablets are produced, high pressure tablet coating equipment are highly applicable due to their greater rate of atomization. This coating equipment experiences pressure ranging from 200 to 400 psi which in return gives high rate of spray.

Low Pressure Tablet Coating Equipment

Low Pressure Based Tablet Coating Machine – Picture Courtesy: Aipak

For low and modulated production setups, low pressure tablet coating equipment is highly applicable in small scale industries. A low pressure of 50 to 100 psi is observed in this equipment that makes the process highly suitable for low operating processes.

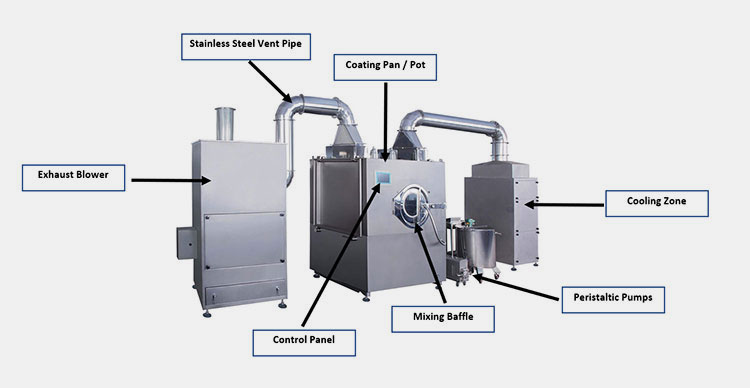

7.What Are The Main Components Of A Tablet Coating Equipment?

Tablet Coating Equipment

Some of the main components of a tablet coating equipment are

Stainless Steel Vent Pipe

The pressure and air inlet are maintained by this stainless-steel vent pipe in a tablet coating equipment. It also takes the solvent out of the system to give efficient results and works as an exhaust system. Stainless steel ensure that the vent pipe is used for a longer period without any contamination.

Coating Pot

A coating pot is the most important part of a tablet coating equipment. It is the place where the tablet coating material gets prepared and the spraying process takes place. It is also made up of stainless steel to prevent corrosion and contamination.

Exhaust Blower

The humidity, moisture, microbes and air content is removed from a tablet coating equipment through an exhaust blower while performing coating process.

Control Panel

A control panel in a tablet coating equipment is the component from where all the operational parameters are controlled including spraying speed, rotating speed, pressure and etc. This is the place from where the operator directly monitors the process and controls it.

Cooling Zone

Once the spraying and drying process gets complete, the tablets undergo cooling process via cooling zone. It helps in solidification of coating material and allows the tablets not to clump in lusters. It is used to separate each one of it to make the process efficient.

Mixing Baffle

Inside the coating pan there is a mixing baffle that is responsible even mix the tablets with solvents and provide them uniform tablet coating material.

Peristaltic Pumps

Peristaltic Pump – Picture Courtesy: LEWA

Controlled pressure is necessary to be ensured within the pan of a tablet coating equipment. This pressure is maintained through these peristaltic pumps that support smooth spraying throughout the process.

8.What Type Of Solvents Are Involved In Performing A Tablet Coating Process Using A Tablet Coating Equipment?

Different coating materials use different types of solvents to complete a tablet coating process. Some of the widely used solvents are

Alcohols

Isopropyl Alcohol – Picture Courtesy: Agar Cleaning Systems

Some of the alcohols like isopropyl alcohol, ethyl and methyl alcohol with their derivatives are highly preferred for tablet coating due to their effective dissolving properties and high volatility. Uniform coating is ensured by their even dispersion and good aqueous formation.

Ketones

Methyl Ethyl Ketone

Simple acetone and methyl ethyl ketones are used to prepare organic solvents for tablet coating process. These ketones can efficiently dissolve various polymers and their copolymers and have faster rate of evaporation as compare to other solvents.

Esters

n-Butyl Acetate – Picture Courtesy: RCI Labscan

Some of the esters like butyl acetate and ethyl acetate are ideally used as solvents when forming coating on tablets. Controlled rate of evaporation can be achieved when esters solvents are used as tablet coating material.

Chlorinated Hydrocarbons

Chlorinated Solvent Coating – Picture Courtesy: ECSA

Like other solvents chloroform and dichloromethane solvents were traditionally used as tablet coating material due to their greater solvency rate. These solves are effective on variety of polymers and have greater benefits.

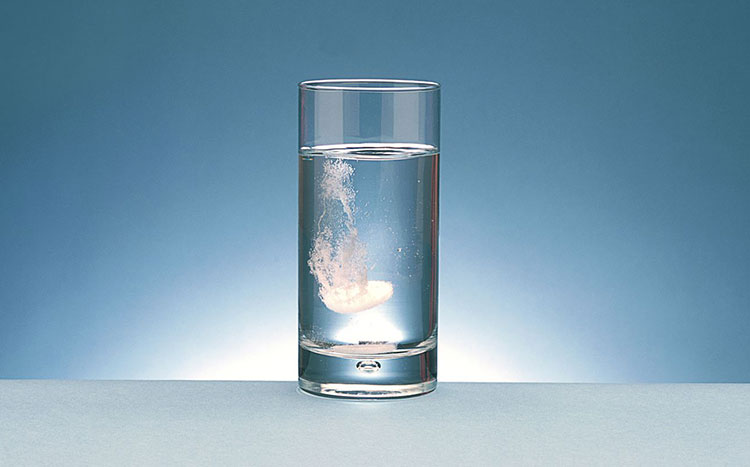

Water

Water As Universal Solvent

Most commonly used solvent globally that gives efficient coating results is water. As it is abundantly found on earth, it directly reduces both the operational and manufacturing cost of any tablet coating process. This solvent is friendly to any sort of environment and can easily get dissolved. Most of the immediately released tablets prefer water solvents due to its solubility and good appearance results.

9.What Factors Effect The Efficiency Of A Tablet Coating Equipment?

The efficiency of tablet coating equipment highly depends upon various factors. Some of the factors that directly or indirectly effect the coating process efficiency are:

Coating Material

Tablet Coating Powder

The properties of coating material selected affects the efficiency the most as it plays an important role. The properties like viscosity and solubility should be maintained in a way that each of the tablet gets uniform spray throughout the batch. In case of any improper mixing of material, greater material wastage can occur.

Coating Spray Design

Tablet Coating Spray Gun – Picture Courtesy: Spray Nozzles

The design including size and shape of a coating spray nozzle has a significant role in maintaining the efficiency of a tablet coating equipment. It is important to ensure that the material from the spray nozzle is distributed evenly in all directions and the design should be according to it.

Air Flow Capacity

Tablet Coating Air Flow – Picture Courtesy: Science Direct

Air is responsible for the removal and evaporation of solvent during the tablet coating process. It is important to maintain the internal air flow so that the tablet drying process can be carried out in a proper manner. If the flow is not controlled properly, wet tablets will be discharged from the tablet coating equipment.

Spraying Speed

Tablet Coating Parameters – Picture Courtesy: Eutherm

Even and uniform spray speed ensures that each of the tablet gets its proper coating time. The velocity and rate of distribution when maintained according to the standards will give highly efficient tablet coating results.

10.How To Maintain A Tablet Coating Equipment For Its Smooth Operation?

A tablet coating equipment requires several critical methods to maintain its operation and work without any troubleshooting. These methods improve the life of a tablet coating equipment and support in its smooth operation

Lubrication

Lubrication Of Gears

It is always important to timely lubricate all the moveable parts and joints of a tablet coating equipment to reduce friction between these parts. This will ensure their proper working and also will support all the parts to live for a longer period.

Cleaning

Cleaning Of Tablet Coating Equipment

Cleaning is also another important thing to consider while maintaining a tablet coating equipment. After production of each batch, it is necessary to clean all the parts including pot and rotating pan. These days CIP (clean in place) and WIP (wash in place) systems are highly suitable for cleaning tablet coating equipment as it allows cleaning without any disassembling of equipment and is done in a shorter period of time.

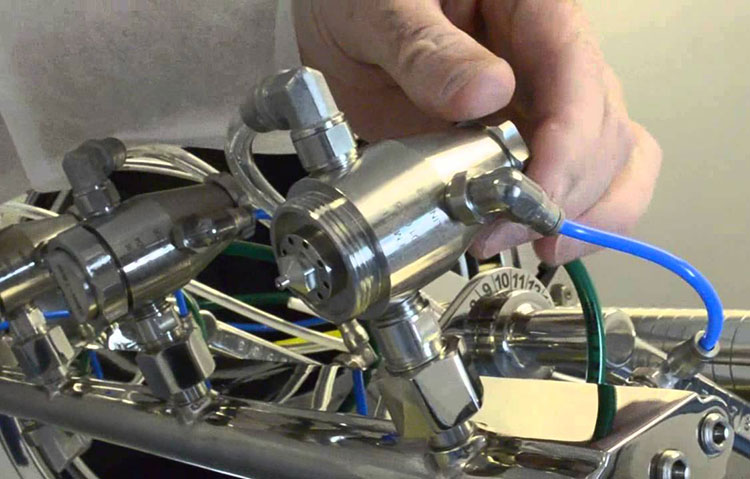

Spray Gun Servicing

Spray Nozzle Maintenance Tablet Coating Parameters – Picture Courtesy: Coating Systems International

There should be a maintained plan for servicing if spray gun with water and high pressure. This will ensure that no residual of coating material is left inside it and the new material can comfortably be entered into it.

Calibration

Calibrating Measuring Instrument

For maintaining uniformity and even coating application, calibration of parts like temperature gauge, flow meters, pressure gauges and other sensors is much important. This will help in proper functioning of these parts and will not cause any deformation in coating application.

Schedule Maintenance

Tablet Coating Equipment Maintenance – Picture Courtesy: Thomas Processing

Lastly, a schedule maintenance including both preventive and predictive should be made so that each of the component can be checked according to it. This data will also support for a longer period and indicate which component needs to be changed or modified for better working of a tablet coating equipment.

Conclusion

Variety of coatings are applied on tablets using a tablet coating equipment. This equipment not only support in application of different coating but also gives them a better and pleasant look. If you are interested in buying a tablet coating material, it is always important to get complete knowledge regarding its process and application. For this Allpack, is one of the most reliable sources to get complete guidance and information regarding a tablet coating equipment. If you have any sort of query and looking for guidance, feel free to contact our customer representatives that are available 24/7 for your assistance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide