8 Most Important Things About Tablet Coating Machine You Should Know

8 Most Important Things About Tablet Coating Machine You Should Know

Do you know why tablets are coated? Have you ever wondered how industries get a fine coating finish on tablets? How does a tablet coating machine ensure the quality and effectiveness of the coating? How does the right coating impact the tablet’s characteristics?

Tablet coating is an essential process in the pharmaceutical production line, providing stability, elegance, and smooth texture to tablets. The tablet coating machine is an indispensable component employed for the efficient coating of various tablets. It is a remarkable innovative technology that applies a thin uniform coat on tablets.

Tablets are coated for several purposes, including taste masking, controlled drug delivery, sustained drug release, environmental protection, and aesthetic appearance. The right coating machine is critical to getting coated tablets' desired consistency and quality.

In this blog, you will explore the 8 most important things that you should know about the tablet coating machine. So, let’s delve into the topic!

1.Tablet Coating Machine

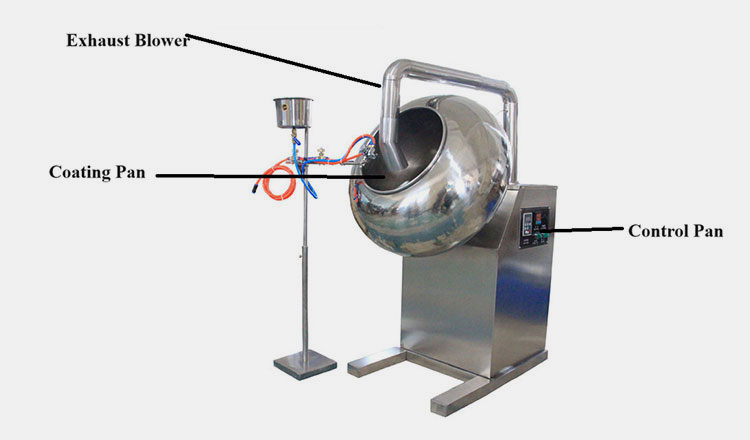

Tablet Coating Machine

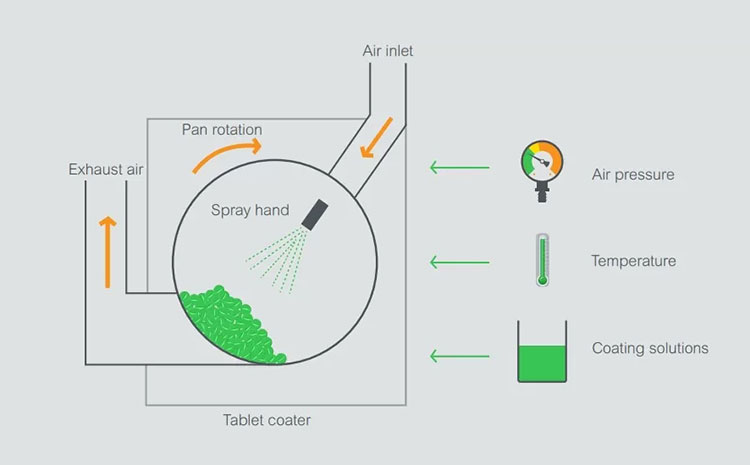

A tablet coating machine is an indispensable element in the pharmaceutical sector. It is used to apply different types of layering on tablets. The device carries out the process at a strictly controlled temperature and with moisture to ensure consistent coating.

The coating can be applied for several purposes, including taste masking of non-palatable drugs, making tablets more appealing, regulating the drug release within the body, or environmentally protecting pharmaceutical ingredients.

Apart from the pharmaceutical sector, the device can also be employed in other sectors for the same or different purposes, such as nutraceuticals, cosmetics, chemicals, and food.

2.Most Important Things About Tablet Coating Machine You Should Know

Understanding the tablet coating machine and its different aspects allows you to get the most out of it efficiently. Here you will explore the 08 most important things you should know about the tablet coating machine to get the desired outcomes. So, let’s get started!

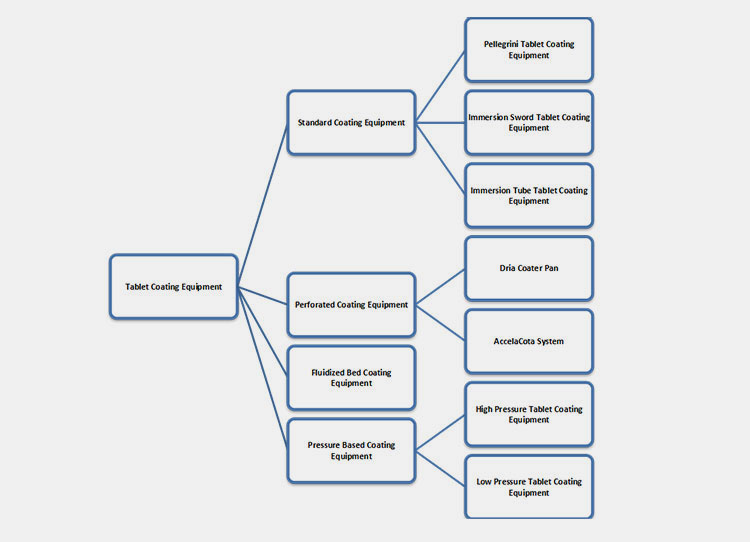

Types of Tablet Coating Machines

While we make a move towards the intricate aspects of the tablet coating machine, it is better to know about its common designs and their important characteristics. It will aid you in selecting the best solution for your needs. The latest tablet coating machines are classified into 3 types, which are described below:

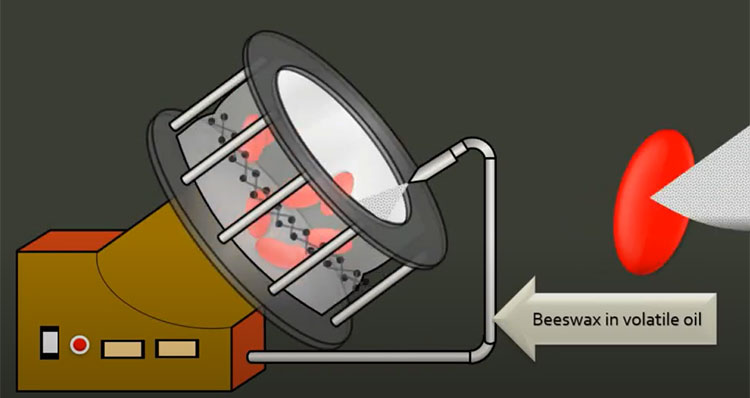

Conventional Coating Pan

Conventional Coating Pan

It is the fundamental form of coating gadget, designed in a circular shape resembling large drums. The pan/pot is staged at a specific angle. As the pot spins, the tablets stumble, ensuring their proper exposure to the coating fluid.

The pans have various sizes, each with a different processing capacity. The pot speed and angle can be adapted to obtain the required outcomes. The coating mixture is applied via a sprinkler mechanism installed in the pan.

Although these coating gadgets are easy to use, they typically need human involvement, resulting in processing errors.

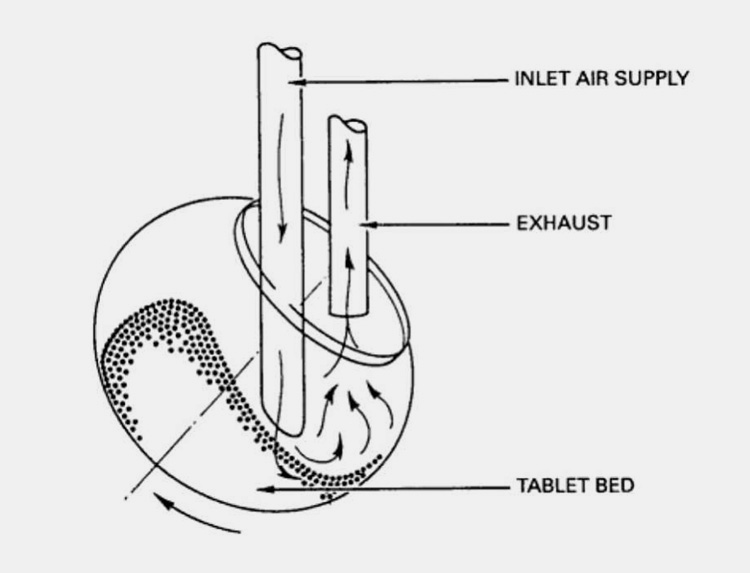

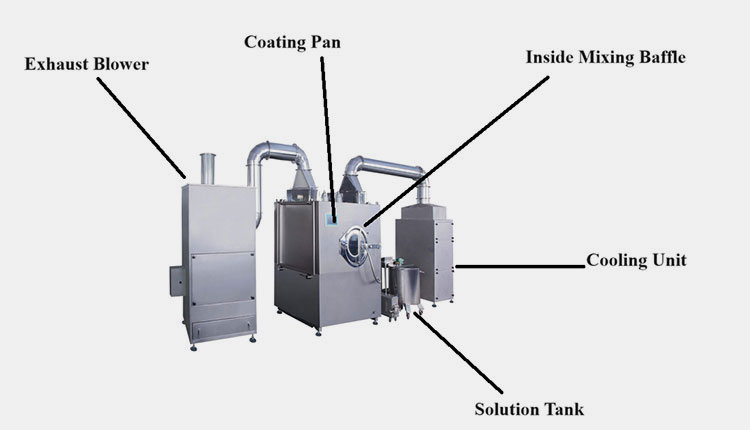

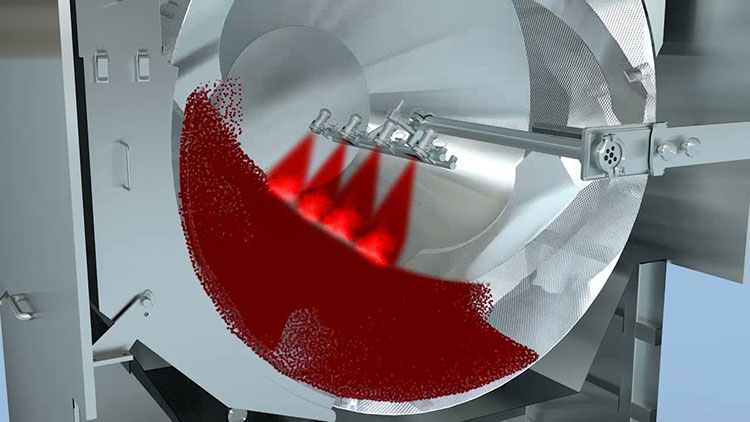

Perforated Pans

Perforated Pans – Picture Courtesy: Syntegon

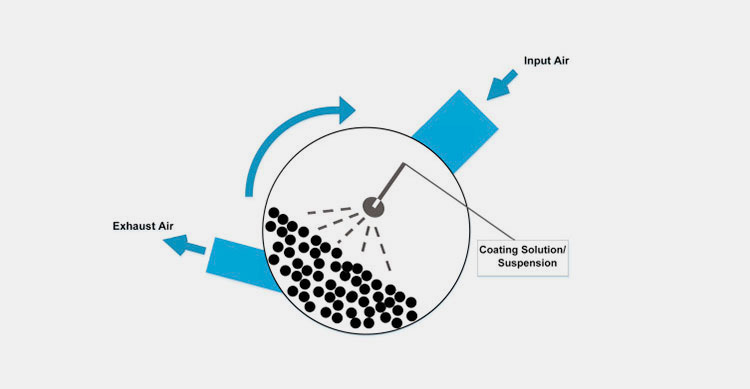

The most renowned and frequently employed tablet coaters are perforated pots. They contain partial or full perforations in the repository, allowing for better ventilation and efficient drying.

The pan performs horizontal rotations, toppling the tablets and a sprinkling system pours the coating mixture onto them. The holes allow the hot air to drift through the toppling tablets, which speeds up and evens out the coating's drying process. This lowers the possibility of tablets adhering or clustering and produces a more uniform and superior-quality layering.

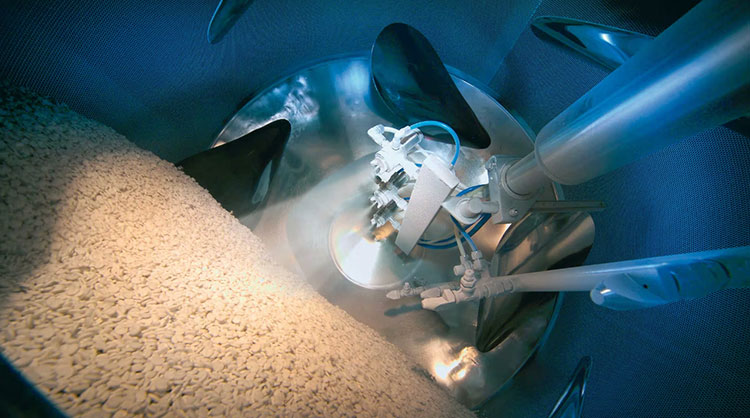

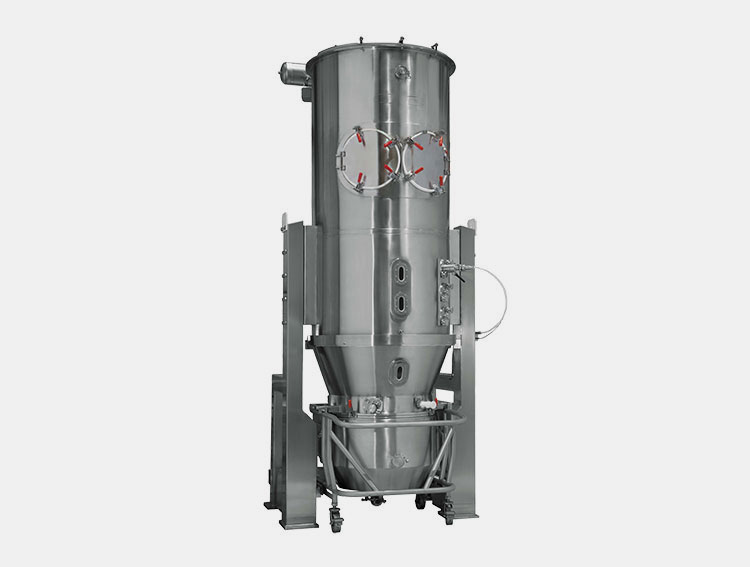

Fluidized Bed Coating Machines

Fluidized Bed Coating Machine – Picture Courtesy: Senieer

They are the specialized form of tablet coating machines. These devices coat the items while they hang in a vertical air surge within a chamber, forming a fluidized bed. The ingredients are in continuous motion due to the upward movement of air and a coating fluid is sprinkled onto them.

The effectiveness, reliability, and adaptability of fluidized bed coating machines in managing several coating materials—from huge grains or tablets to small powders—make them highly esteemed. Therefore, they are usually recommended for large-scale processing.

3.Capacity of Tablet Coating Machine

Capacity of Tablet Coating Machines

The quantity of materials a tablet coating machine can process in a specific time interval is referred to as the device’s capacity. You must know your requirements and should opt for the right piece of equipment according to your manufacturing needs.

Now, if you have no idea how to evaluate the device’s capacity, you’re at the right place. The formula to get your calculation correctly done is described below, you only have to put the correct values in it:

Capacity = (Coating pot’s peak volume × tablet’s bulk density) ÷ Average weight of tablets

In the equation;

The coating pot’s peak volume refers to the full volume of the coating pot when loaded to the edge/peak.

The tablet’s bulk density indicates the weight of tablet cores divided by their volume.

The average weight of tablets is the sum of each tablet core’s weight divided by the total number of tablet cores.

4.Uses and Applications

Now you know the tablet coating machine is versatile equipment capable of effectively coating different solution types onto multiple items. That’s the reason, it has a broad range of applications across industries. Some common industries utilizing a tablet coating machine are:

Pharmaceutical Industry

Uses of Tablet Coating Machines in the Pharmaceutical Industry

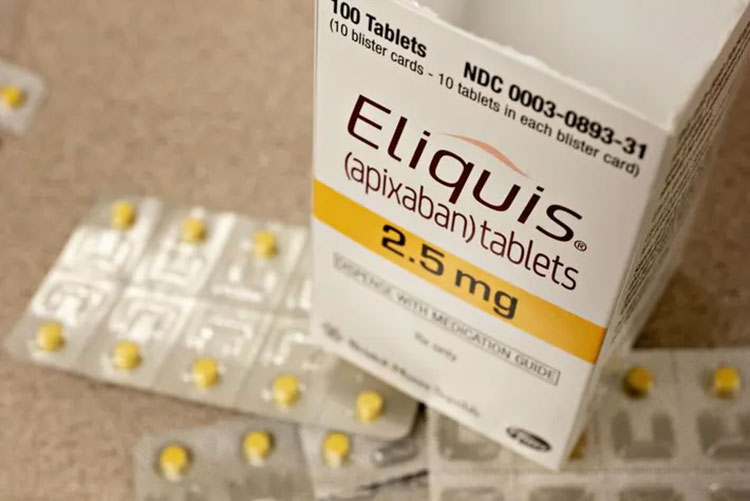

The tablet coating machine is primarily used in the pharmaceutical industry to coat several forms of tablets efficiently. Different coating types are applied for different purposes and to achieve the desired therapeutic effects.

Nutraceutical Industry

Uses of Tablet Coating Machines in the Nutraceutical Industry

Similar to the pharmaceutical sector, the tablet coating machine can be employed for nutraceuticals to hide unpleasant tastes and odors of vitamins, minerals, and other dietary supplements. Plus it can also improve the visual appeal of drugs.

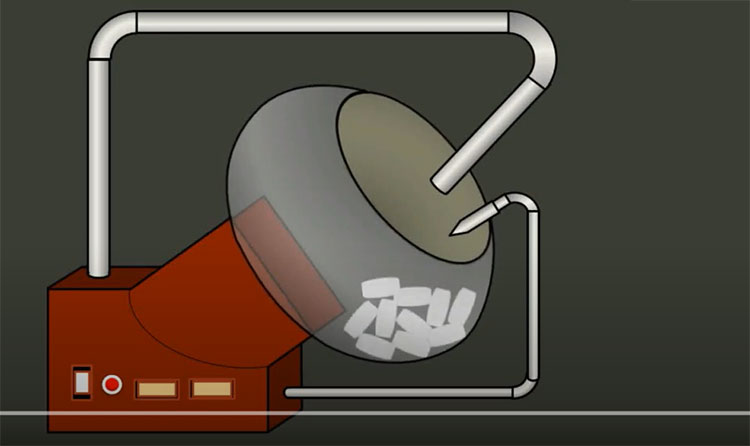

Confectionery Industry

Uses of Tablet Coating Machines in the Confectionery Industry

A tablet coating machine is frequently used in the confectionery industry to apply sugar coat to certain products, like candies and gums, to make them sweet and smooth.

Agricultural Industry

Uses of Tablet Coating Machines in the Agricultural Industry

Agricultural tablets or pellets can be coated to regulate the release of pesticides, fertilizers, and other chemicals. It is used to enhance the effectiveness of the product.

5.Different Coating Types

There are 3 basic coating types. They are frequently employed for several specified purposes. These types are sugar, film, and enteric coating. They can be efficiently applied using a tablet coating machine. You can find the fundamentals of these coating types below:

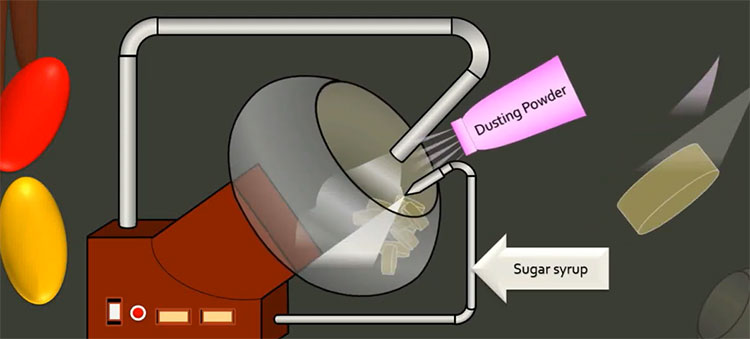

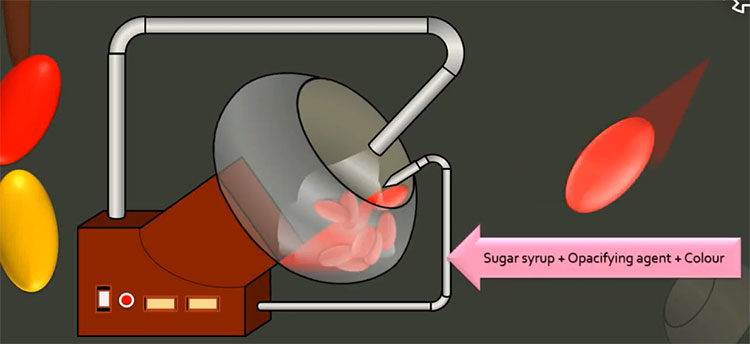

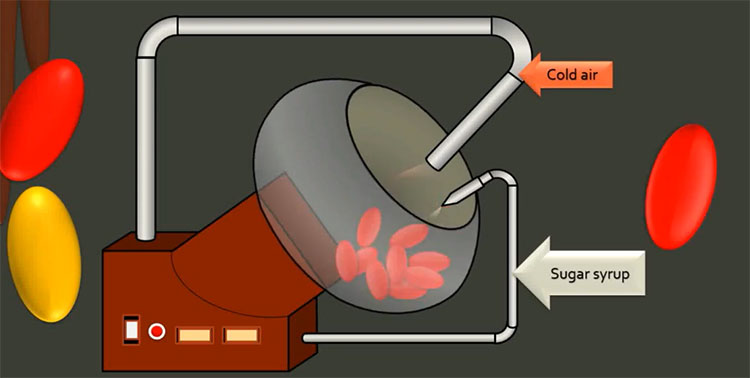

Sugar Coating

Sugar Coated Tablets

The sugar coating involves the thick layering of tablets from the sugar syrup, followed by drying and refining for a smooth appearance. This coating type is applied for several reasons, including masking the unpalatable taste of medicines, shielding constituents from light and humidity that can result in product degradation, or making the tablet aesthetically pleasant.

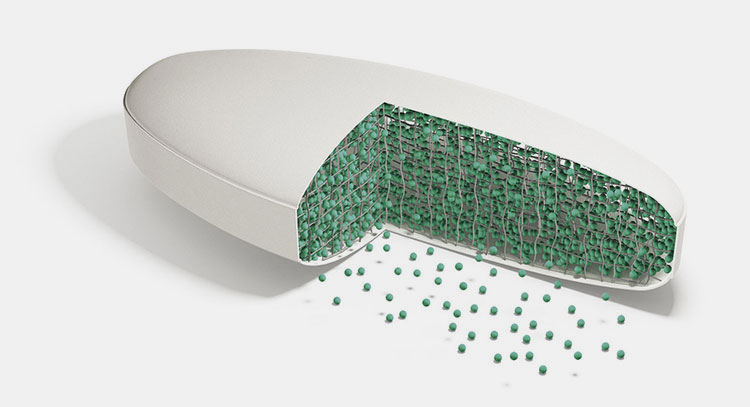

Film Coating

Film Coated Tablets

Film coating involves the implementation of a thin polymeric coating mixture on the tablet’s skin. It is a frequently used coating type in the drug sector nowadays.

Film coating is implemented on tablets to make them appealing, conceal the disagreeable taste or smell of medicines, regulate the discharge of active constituents, and shield tablets from environmental factors.

Enteric Coating

Enteric Coated Tablets

It is a special kind of coating developed to guard a tablet’s contents from the stomach’s acid. It has a unique characteristic of breaking down in alkaline conditions of the intestine. This feature permits the constituents to be discharged into the bloodstream slowly and effectively, enhancing their therapeutic effects.

Such coating is usually applied to acid labile tablets or tablets desired to discharge contents in the small intestine.

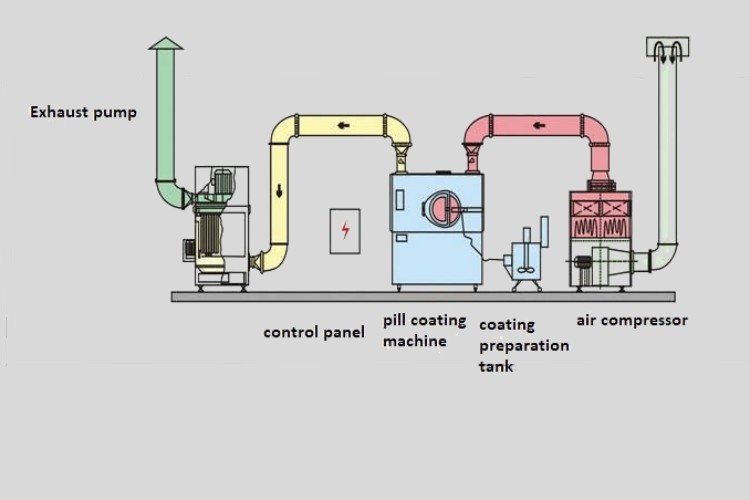

6.Fundamental Components

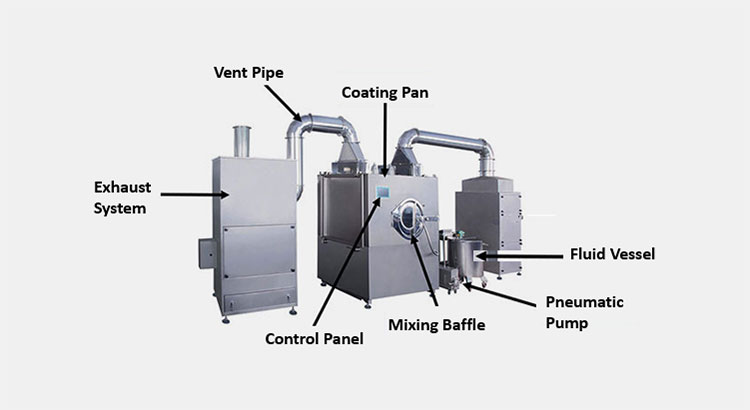

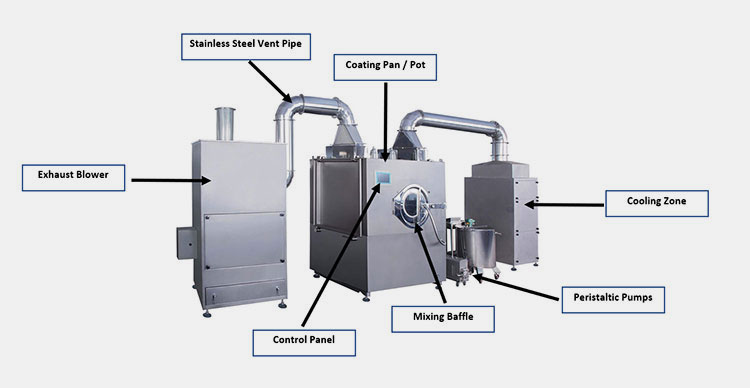

The tablet coating machine comes in several varieties but they all have the same fundamental components responsible for producing quality products. These components are discussed here:

Fundamental Components of Tablet Coating Machine

| Components | Description |

| Coating Pan | It is a large rotating drum, where the tablets are loaded for coating. The pan’s rotation causes tumbling of the tablets, exposing them evenly to the coating fluid. The pot speed is a critical parameter to be adjusted to get consistent coating results. |

| Mixing Baffle | The mixing baffle helps in stirring and movement of tablets within the pot during the coating phase. It avoids tablets sticking and ensures a smooth coating. |

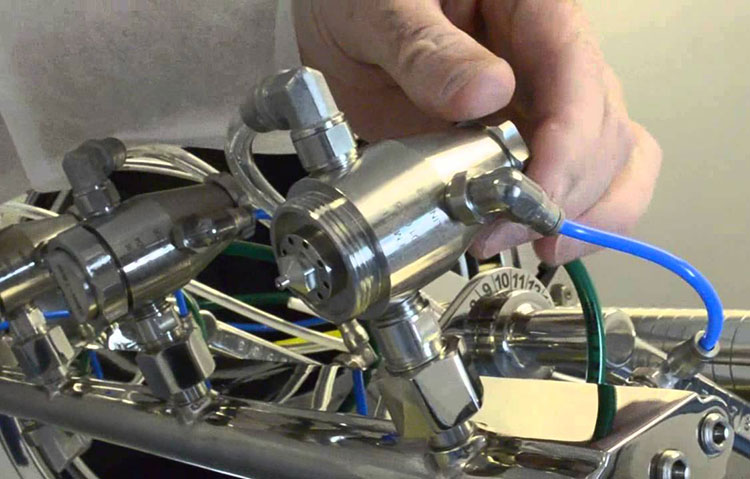

| Pneumatic Pump | The pneumatic pump delivers the coating fluid from the fluid vessel to the sprinkle spouts. Compressed air is utilized in its operation to provide a constant and regulated flow of coating mixture, which is important to obtain an even layer on the tablets. |

| Fluid Vessel | The fluid vessel holds the coating fluid. The fluid is continuously mixed, maintained at the required temperature, and timely delivered to the pneumatic pump. |

| Vent Pipe | It is an element of the air circulation system that aids in managing the airflow within the device. It is a crucial component that controls the coating pot’s interior temperature and moisture, ensuring a consistent drying process. |

| Exhaust System | The exhaust system removes the excess solvent droplets from the device, sustaining the essential air balance. It aids in the drying step by removing damp air and introducing dry air into the coating pot. |

| Control Panel | It is the touch interface through which the operational parameters can be monitored and adjusted accordingly, aiding in the precise and quality coating process. |

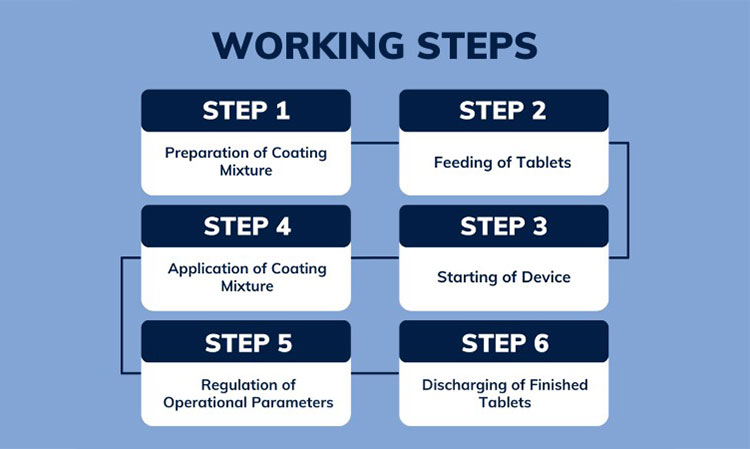

7.Working Steps

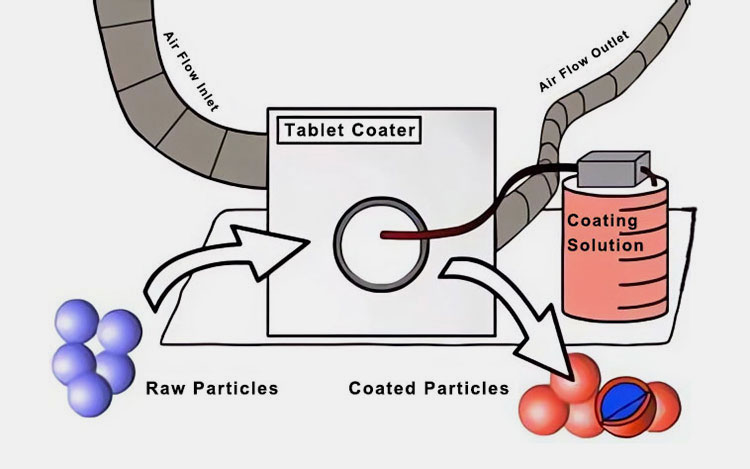

Proper operation of the tablet coating machine is crucial in getting the desired coating outcomes. Here are the fundamental working steps for using a tablet coating machine:

| Step 1: Preparation of Coating Mixture

Preparing a perfect coating mixture by mixing the required ingredients is the basic first step of the process. The mixture properties, such as viscosity, density, pH, etc., must be controlled accurately to guarantee consistently smooth coating. |

| Step 2: Feeding of Tablets

The next step is feeding tablets in the pot to be coated. This step can be performed by hand or a hopper system can be employed. The quantity of tablets to be fed into the pot is determined by the device’s capacity. |

| Step 3: Starting of Device

Now, start the device with the required rotational speed. The required speed varies with the coating type and the device model. |

| Step 4: Application of Coating Mixture

As the coating pot spins, the coating fluid is precisely and automatically sprinkled onto the tablets. Different machine models have varied techniques for coating application, for example, fluidized bed coating machines layer the tablets while they hang in the airstream. |

| Step 5: Regulation of Operational Parameters

During the entire coating operation, you must pay close attention to certain processing parameters, like spray rate and angle, inlet air temperature, and pan speed. It is essential to regulate these parameters to achieve smooth and consistent quality coating. |

| Step 6: Discharging of Finished Tablets

When the coating operations are completed, the coated tablets are expelled from the pan and can be guided further for packaging and distribution. |

8.Critical Parameters of Tablet Coating

Tablet coating is an intricate process that needs to be carefully observed to get the desired quality product meeting the required regulatory standards. So, let’s discuss these parameters one by one:

Critical Parameters of Tablet Coating

Spray Rate

Another critical parameter that must be managed strictly is the application rate of the coating mixture. It is required to ensure a uniform coating.

Pan Speed

It refers to the coating pan’s rotational speed during the process. It is mainly impacted by the tablet’s characteristics (i.e. shape, size, etc) and the coating fluid’s viscidity. An improperly adjusted pan speed can result in defective coating.

Inlet Air Temperature

Heated air is passed through the tablets to dry the tablet’s coat. The air temperature must be strictly regulated to make sure that the coat dries rapidly and consistently.

Atomization Pressure

Forceful thrusting of the coating fluid through a tiny opening results in atomization and expels the solution in the form of a mist. It should be precisely controlled as it directly influences vapor-drop size and fluid distribution.

CFM

The complete volume of air is usually expressed as cubic feet per minute (cfm). It refers to the air quantity utilized for drying the tablet’s coating and pulling through the tablet’s surface. This parameter must be regulated to adjust the airflow, which should be pulled more from the pan than entering the pan.

9.Proper Maintenance and Cleaning

Tablet Coating Machine Maintenance – Picture Courtesy: Filamatic

The tablet coating machine comprises several crucial components. These parts ensure their precise and accurate functioning due to the latest technologies. Continuous operation of this device might deteriorate these parts, resulting in reduced processing efficiency and accuracy.

It is, therefore, advised to maintain the optimal condition of your tablet coating machine by developing and following proper and timely maintenance protocols. Here you will find some crucial pointers to be followed to maintain your device in good working condition for a long time.

Regularly follow cleaning protocols for all the machine parts, particularly spray spouts, coating pan, and pneumatic pump.

Clean parts using a gentle fabric to remove dust. Clear the spouts using water pressure or a suitable cleanser (as recommended).

Periodically, disassemble the device and deep clean the entire parts.

Oil the pneumatic pump and other moving parts, such as the electric motor belt and rotational system of the pan to ensure smooth functioning.

Conduct a regular inspection of all the parts for any kind of damage and tear. If found, consider immediate repair or replacement of that component to avoid costly breakdowns and tablet defects.

Remember to maintain your tablet coating machine by trained personnel.

Conclusion

Tablet coating machine is a crucial element of the pharmaceutical industry. The device provides a uniform coating on tablets, which is crucial for multiple purposes, including their efficacy, safety, and quality. Familiarizing yourself with the most important parameters of the tablet coating machine can certainly help you in getting the right equipment plus the right method of operation and maintenance. This will assist you in manufacturing high-quality coated tablets efficiently and consistently that satisfy the regulatory demands and consumers' expectations. If you need further assistance regarding tablet coating machines, don’t hesitate to reach out to one of the most reputed industrial equipment manufacturers, Allpack!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

8 Most Important Things About Tablet Coating Machine You Should Know Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours