Sugar Packaging: A Complete FAQ Guide in 2025

Do you know that sugar was first used as a spice, not a sweetener in the Western World? People in the world consume hundreds of tons of sugar per year. Sugar packaging plays an integral role in the satisfaction of the sweet tooth of individuals. Sugar packaging is a small word, but it packs a power punch of benefits.

Water-proof, chemical-proof, moisture-proof, weather-resistant and cost-effective are a few of the benefits of sugar packaging. Furthermore, sugar packaging enhance brand image and boosts sales figures.

In search of new ideas for your sugar packaging then read this blog to understand format style, benefits, quality test, and more about sugar packaging.

1.What is Sugar Packaging?

Sugar Packaging- Picture Courtesy: ERD

Sugar packaging is a way of enclosing and containing sugar products in protective covers. It airtightly wraps the sugar blends, granulated sugar, powdered sugar, brown sugar, white sugar, and refined sugar.

It includes every step from designing sugar packaging to fabricating sugar packaging. Its first and foremost aim is to uphold quality and maintain the structural integrity of sugary goods,

Sugar packaging is the means for preparing sugar items for shipment, retailing, delivery, and storage. A variety of sugar packaging styles such as pouches, tins, and jars, are seen on retail shelves for brand promotion.

2.What are the Pros of Sugar Packaging?

Sugar packaging is popular because of its tons of benefits that augment the sales profit of the brands. This packaging is useful for not only sellers but also for buyers. These benefits are detailed below:

Weather-Resistance

Weather-Resistance by Sugar Packaging- Picture Courtesy:Dieline

Sugar packaging is known for its resilience and sturdiness. It is a climate-resistance wrapping that isolates inner contents from air and sunlight. Moreover, it is the best protective barrier for hygroscopic sugars that readily absorb moisture in a highly humid environment. It keeps sugar in perfect condition for the end-user.

Physical and Biological Protection

Protection by Sugar Packaging- Picture Courtesy: A' Design Award

Vermin, pests, and ants love to consume open sugars. With sugar packaging, manufacturers only not shield their sugar from biological agents but it is also essential in maintaining the quality of packed sugars upon physical stress. It preserves the integrity of sugars and minimizes their deformity.

Cost-Reduction

Cost Reduction by Sugar Packaging- Picture Courtesy: Packaging of the World

Every brand wants to earn a huge fortune by making small investments. Thus, with packaging, the manufacturer easily accomplished this goal. By sugar packaging, brands can lower product wastage, which earns more profits for the brands. Tough packaging has less wear and tear, making it them right fit for rough transportation while dented or scratched packaging cuts the profit margin.

Boosts Brand Image

Boosts Brand Image- Picture Courtesy: iktva forum

As first impressions always matter that saying is also applied to sugar packaging as well. Customers are tempted to buy the product if it has a magnetizing look. They first observe the packaging before seeing its inner contents; hence with distinctive and outstanding sugar packaging brands improve their brand image and fashion a lasting experience that resonates with clients.

Ease in Transportation

Ease in Transportation by Sugar Packaging- Picture Courtesy: Packaging of the World

Sugar packaging is a containment system that is increasingly used for transporting sugar. With the packaging, it is easier to transport sugar and it reaches the hands of end-users intact than loose ones. Unpackaging sugar spills in transport vehicles causing mess and loss of inventory.

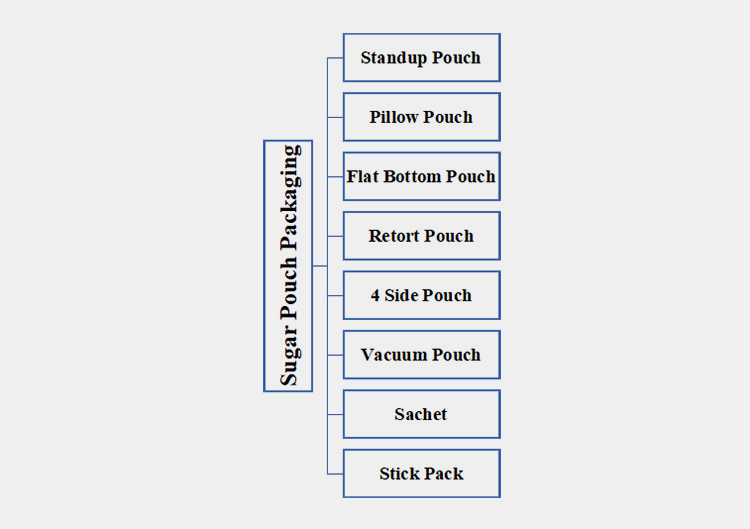

3.What are Widely Used Sugar Packaging Styles?

Standup Pouch

Standup Pouch- Picture Courtesy: Trend Hunter

This pouch is known for its distinct shape and tall structure that is easily observed from afar. This design with bottom folding makes a huge contribution to the marketability of the product. It is a high-demand packaging format because of its cost-cutting feature.

Pillow Pouch

Pillow Pouch- Picture Courtesy: Packaging of the World

It has two top and bottom seals that give this pouch a pillow shape. Moreover, it has a central back seal called T-seal, therefore, it is also known as a T-seal pouch. It is the most economical multi-serve retail packaging.

Flat Bottom Pouch

Flat Bottom Sugar Pouch- Picture Courtesy: The One Club for Creativity

It has a flat base and side gussets that create a box-like look This pouch expands during filling so can house more product. Its unique appearance steers the customers towards the packaging. in turn boosting impulse buying.

Retort Pouch

Retort Pouch- Picture Courtesy: Paper Bag Ethopia

For higher barrier protection, this pouch is manufactured with multi-layer laminate. This pouch is highly sought after because of its resistant and durable characteristics that protect quality over a long time.

Vacuum Pouch

Vacuum Sugat Pouch

This pouch derives its name from the vacuuming technique that is performed to eliminate air molecules from the pouch, subsequently making olive oil safe from contamination. The olive oil filled in this pouch has a lengthy expiry date.

Sachet

Sugar Sachet-Picture Courtesy: Packaging of the World

It is a one-time serving packet and features patterned or simple seals at its 3 or 4 edges. It is best for on-the-go cooking. It is available in square as well as rectangular shapes.

Stick Pack

Stick Pack- Picture Courtesy: Grey Dash

It is another individual serving pack but unlike a sachet, it features a narrow tubular design with a central seal. It has more length than width. It is also made with top and bottom seals.

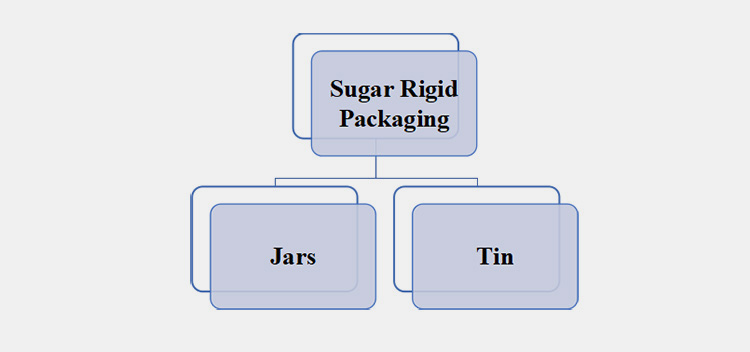

Rigid Packaging

Jars

Sugar Jars- Picture Courtesy: Jenn David Design

It is mostly made with glass and rigid plastics, for example, HDPE. It has a cylindrical design with a wide base and little to no neck. Jars house multi-serve of sugar.

Tins

Sugar Tins- Picture Courtesy: Packaging of the World

Tins are formed with kraft paper for sugar packaging. This sugar packaging generates a classy and sophisticated look for high-end customers.

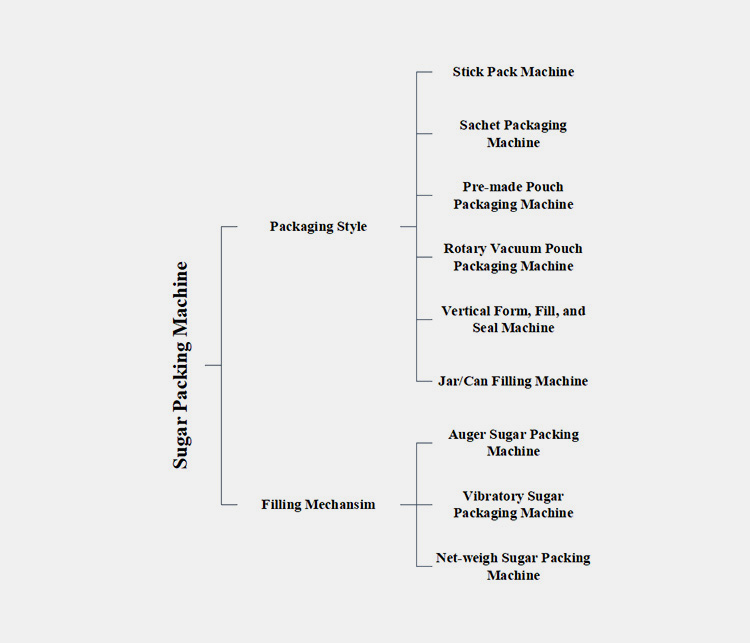

4.What are the Machines for Sugar Packaging? How Do They Package Sugar?

Because there is diversity in sugar packaging, so wide range of sugar packaging machines have been introduced in the market to process such packaging styles. A list of sugar packaging machines and their working principle are penned below:

According to Packaging Style

Stick Pack Packaging Machine

Stick Pack Packaging Machine

This type of sugar packaging machine boosts one to twelve lanes for efficient and speedy sugar packaging. This machine is dominating the sugar packaging market because of the high demand for one-time servings of sugar. The hospitality and catering industry prefer using this machine because of its convenience and straightforward design.

Working Principle

The sugar packaging operation begins with the loading of sugar in the hopper and placing the film roll on the film holder. The film is cut into individual fragments, depending on the number of lanes. In the next step, the strips are moved to respective forming tubes, where strips are doubled and fashioned into tubular sacks. After sealing of the lower end by the horizontal jaws, the sugar is deposited inside the sachet. Then topside is sealed by horizontal sealer and the finished stick pack is discharged into the outfeed.

Sachet Packaging Machine

Sachet Packaging Machine

It is another prime machine for packaging single-serve sugar. It has a compact design configuration and is more popular because of its minimal footprint than the stick pack packaging machines. It lowers operational costs due to its lesser use of packaging materials. It is an adaptable unit processing plastic polymer films (HPDE, LPDE, PET, PP), aluminium, and paper.

Working Principle

The film on the film roller unravels through the combined action of unwinding disk and roller. After going across the roller that maintains film tension, it comes to forming tube. Here forming collar, vertical sealers and horizontal sealers shape a sachet. The filling devices dispense sugar inside the sachet. Then horizontal sealers and cutter act to seal and cut sachet, respectively.

Pre-made Pouch Packaging Machine

Pre-made Pouch Packaging Machine

It is a prominent type of sugar packaging machine, highly seen in sugar packaging productions owing to its adaptability as it packs standup, pillow, flat bottom, and quad seal pouch to name a few. It has increased processivity as it only fills and seals sugar bags. A rotary turn table with multiple filling heads also boosts its output capacity.

Working Principle

Its working stages are straightforward, in which the premade bags are loaded in the bag magazine. From the magazine, the bags are carried by the holder one by one to the opening and inflating area. Then, the bag is moved to the filling area, and here pre-determined amount of sugar is fed into an inflated bag. The bag is carried to the sealing area, the heated sealer fuses the edges.

Rotary Vacuum Pouch Packaging Machine

Rotary Vacuum Pouch Packaging Machine- Picture Courtesy: lenis machines inc.

This type of sugar packaging fills premade sugar pouch. It has a vaccum station that maintains 99.9% vacuum inside the sugar pouch. It is a state-of-the-art equipment conserving space. It has eight to sixteen stations for filling, vacuuming and sealing bags. It is a continuous type of sugar packaging machine that has high-throughput.

Working Principle

At first, empty bags are loaded in the bag magazine from where they are transported to the inflating area. After opening the bags, they go to the filling station, where different devices, for instance, an auger, net weigh filler, and vibratory filler, feed the sugar into the sugar bags. Upon filling, a vacuum is introduced- to remove air from the bag- at the vacuuming section. Finally, ultra-sonic, cold, or heat sealer seal the filled sugar bags.

Vertical Form, Fill, and Seal Machine

Vertical Form, Fill, and Seal Machine

This machine has prominence in the sugar packaging industry because of its minimum floor space, rapid packaging, straight forward working. Moreover, it fills self-formed sugar pouches thus, it can be tailored to pack diverse styles of sugar bags. This machine is easier to clean and maintain than its premade sugar packaging machine counterparts.

Working Principle

The packaging is loaded on the unwinding disc and, after unfurling is guided over the film roller for moving to the forming tube. Forming collar and sealer convert this film into tube-like pouch. After that, the filling process takes place through filling nozzles. Finally, horizontal heated sealing bars seal the topside of the sugar-filled pouch.

Jar/Tin Filling Machine

Jar/Tin Filling Machine- Picture Courtesy: Powder Filling Machine

Due to demand for premium packaging, jar/tin filling machine is increasingly utilized in the packaging sector to fill jars and tin with sugar products like white, brown, blended, or caramelized sugar. Its digitization and automation enhance its popularity among industries. These machines are designed in both rotary and linear configuration, consequently, they have variations in packaging speeds.

Working Principle

First the jar/can unscrambler positions the jar and tin in the upright configuration on the conveyor. These conveyors transport them to the filling station or rotary turn table, depending upon the configuration of the machine.T filling nozzle gradually introduces sugar inside the containers via filling devices. After filling the desired amount, the containers move to the sealing station, where they are tightly packed for protection.

According to the Filling Mechanism

Auger Sugar Packing Machine

Auger Sugar Packing Machine

It is a preferred choice of brands for filling sugar in different containers. Auger is a closed device, therefore, it is routinely seen in the industry for contamination-free loading of sugar. This machine has one to three filling heads, thus allowing manufacturers to attain swift packaging.

Working Principle

Immediately after sensing the container, the magnetic drive begins the rotation of the auger. With the rotation of auger screws, sugar from the hopper moves inside the auger funnel and is slowly dispensed into the container. The agitator blade in the auger device rotates in the opposite direction of the auger screws to de-aerate sugar powders and granules.

Vibratory Sugar Packaging Machine

Vibratory Sugar Packaging Machine

It is a filling equipment with a vibratory plate in which accuracy and speed are perfectly balanced. It is comprised of a hopper, feed plate, and PLC system. It is best for loading delicate sugary products that could be crushed when filled with an auger filler. Moreover, the vibratory sugar packaging machine is designed with stainless steel materials to meet stringent food processing regulations.

Working Principle

Upon the detection of the empty container, a vibratory unit creates a vibration that is transmitted to the feed bowl. This vibration fluidizes the sugar and it moves forward across the vibratory plate. Then vibratory plate transfers materials into the filling nozzles and sugar is loaded into the container from the filling nozzle.

Net-weigh Sugar Packing Machine

Net-weigh Sugar Packing Machine- Picture Courtesy: Landpack packing machine

It is employed for loading precise weight of sugar instead of volume of products. It is a highly sensitive machine consisting of hopper, weighing scale, and PLC control system. It uses gravitational force for loading sugar into the containers at quick pace. It is often used for duispensing bulk-quantities of sugars.

Working Principle

As soon as, a container is sensed by the sensor, sugar from the hopper flows into the filling nozzle. First, the load cell located underneath the loading plate measures the tare weight of the container, then sugar moves in laminar flow to filling nozzles from where it is loaded inside the container. Load cell measures the weight while filling. Once the load cell signals that the pre-determined weight is reached, the filling stop.

5.Is Sugar Packaged in Paper?

Paper Sugar Packaging

Yes, packaging sugar in paperis an extremely popular way. Brands prefer to store their sugar products in paper materials because, for one, paper is way cheaper than glass or plastic. Paper is easily availabl,e making paper packaging cheaper than other materials

As paper is a lightweight material, hence sugar paper packaging is easier to move around. Brands use specialized equipment and techniques to pack sugar in other materials besides paper. However, it is easy to dispense sugar in paper, offering more packaging speed.

Last but not least, sugar needs room for breathing which is only possible in paper materials. Kraft paper is ideal for packaging sugar as it is durable and sturdy, protecting sugary items against weather elements.

6.How to Determine the Quality of Sugar Packaging?

Quality Test for Sugar Packaging- Picture Courtesy: Dieline

Seal integrity and quality of sugar packaging is essential in protecting sugar from external environmental and biological agents. There are various tests for determining the quality of sugar packaging, for instance:

| Drop Test | It is one of the simplest ways to test the quality of sugar packaging. The impact resistance of packaging is estimated using either a drop tester equipment or manually dropping the packaging from various inclinations. After that, packaging is checked for scrapes, perforations, pops, and splits. Moreover, the weight of packaging before and after the drop test gives an idea about impact resistance. |

| Compression Test | It is employed for estimating the resilience and sturdiness of sugar packaging when it is exposed to high pressure. By stacking sugar packaging one over another or by putting them under a hefty load, you can check for deformity and bursting of packaging. |

| Vibration Test | The sturdiness and stability of sugar packaging are measured by the vibration test. By using a vibration tester equipment or by producing the vibration- that sugar packaging faces during shipment- damage to packaging, labels, fading, or loss of seal integrity can be checked. Moreover, you can also access the sound and movement of packaging due to vibration. |

| Climate Test | This is the way to ensure weather resistance and malleability of sugar packaging. By exposing products to extreme temperatures, highly humid conditions, and sunlight, you can inspect the packaging for degradation, fading, rusting, and moulding under extreme climate settings. |

7.How Does Sugar Packaging Decrease Environmental Impact?

Sustainable Sugar Packaging- Picture Courtesy: sugarstick.de

Nowadays, customers demand such packaging that has minimal environmental impact. The brands are now adopting different sustainable measures to fulfil the demand of their customers. Here is a list of such handy measures:

First of all, brands are using sustainable and recyclable materials, for instance, paper and sugar cane packaging. These are the natural materials that are biodegradable and are readily decomposed by microbes. These paper and other materials have minimal environmental impact.

Secondly, the brands are introducing lightweight sugar packaging that is stackable to lower fuel consumption while transporting. This promotes carbon-neutral efforts. Also, brands are opting for simple minimalist designs that use little inks and less packaging, so that fewer materials results in landfill.

This minimalist sugar packaging requires less fuel and water for manufacturing, further lowering the impact on ecosystems. Manufacturers are also trying to produce their packaging with renewable energy sources that have reduced carbon emissions.

8.What Are the Safety Ideals for Sugar Packaging?

Safety comes first to protect end-users and this safety is essential in satisfying strict regulations by food authorities. The following are the safety ideals in sugar packaging:

Food-Grade Materials

Food-Grade Materials

Brands packaging sugar use food-grade materials that do not leach harmful chemicals when they come in contact with sugar. Moreover, these food-grade materials are not toxic to the health of consumers.

Safe Labels

Safe Labels

When designing labels for sugar packaging, brands include every essential health-related information. These labels have nutrition, ingredient, and usage information. Furthermore, it also has allergen information to notify users about allergens found in the packaging or sugar, that may endanger the health of customers if sugars are consumed.

No Product Tampering

No Product Tampering

Product tampering and adultering are some of the biggest concerns of the brand, as they jeopardize the products. However, with innovative technology and tamper-evident closures, this problem is easily resolved. Brands use tamper-evident seals, tapes, shrink film, and many more to form tamper-proof packaging.

9.What Latest Innovations in Sugar Packaging?

Due to the different benefits of sugar packaging, brands are always in pursuit of fabricating innovative packaging that is distinct from other competitors. Hence, sugar packaging has evolved from simple confinement systems. Here are some latest innovations in sugar packaging:

Intelligent Packaging

Intelligent Sugar Packaging- Picture Courtesy: Cosmo Films

Sugar packaging is now innovated to include different kinds of sensors for continuous monitoring of the freshness of sugar. It notifies users and handlers in the supply chain about the temperature and humidity level of the packaging. Some packaging systems tell consumers about the level of microbial growth in the packaging.

Active Packaging

Active Packaging- Picture Courtesy: Bechance

The technology in sugar packaging that interacts with sugary contents or the environment to prolong its serviceable life is known as active packaging. Unlike a passive protective barrier, it actively plays a pivotal role in improving the freshness of sugar.

Connected Packaging

Connected Packaging- Picture Courtesy: Assemblies Unlimited

Sugar packaging is revolutionized by the integration of QR codes and smart labels that are scanned by mobile phones. This connected technology is deployed by the brands to give exclusive information such as recipes, brand value, and many more.

10.Does Packaged Sugar Expire?

Expiry of Sugar Packaging- Picture Courtesy: Packaging of the World

Are you craving for a sugary treat, but are worried about the quality of your packaged sugar? Well, here is the good news for people who have a sweet tooth packaged sugar never expires according to scientists.

Airtightly closed sugar that is stored in a cool and dry place, for example, pantry lasts indefinitely. It is a misassumption that sugar present in the pantry has a short shelf-life and spoils with time but this is not the case. Although it seems that sugar is a perfect growing ground for microbes, sugar is a microbial growth-inhibiting agent like salt.

The sugar enclosed in opaque and impermeable barrier packaging, for instance, pouches, jars, and tins has a longer shelf life. Nevertheless, it is suggested by the expert to use sugar within two years of packaging. Sugar loses its taste, texture, and quality if not stored properly because it absorbs external odours and is a favourite food of bugs.

Furthermore, vacuum sugar packaging has a higher shelf-life than normal sugar packaging.

Conclusion

Today, sugar is used in every recipe from desserts to sauces. This increased sugar consumption propels a huge demand for sugar packaging. Sugar packaging plays both an active and passive role in protecting sugar from environmental and biological culprits. In addition to weather resistance, sugar packaging also provides a leg up in sales. QR codes, intelligent labels, and smart sensors have transfigured sugar packaging. The inclusion of safety features in sugar packaging like tamper-proof, safety labels shows that the brand values the safety of its customers. Want sugar packaging for your products? Then message us. We, Allpack will help you to create perfect packaging for your brand.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours