Sticker Labeling Machine: The Complete Buying Guide in 2025

Why is there a sticker label on every packaging container? The purpose of sticker labeling is to improve aesthetics, conveying information, and the brand’s logo or message to every consumer. A sticker labeling machine is an advanced solution for today’s competitive market which every successful business relies on. Have you ever seen any product without a label? Of course not!

Visual attraction is an important factor that prospers your business, and that accounts for the use of labels that appeals any customer. For this a sticker labeling machine accommodates its advantage in many industries. If you’re planning to invest in a sticker labeling machine, then hold on! Go through this comprehensive article to get useful knowledge about this robust solution. Plus, how this machine can bring high profitability to your production; you’ll get to know this by reading this article.

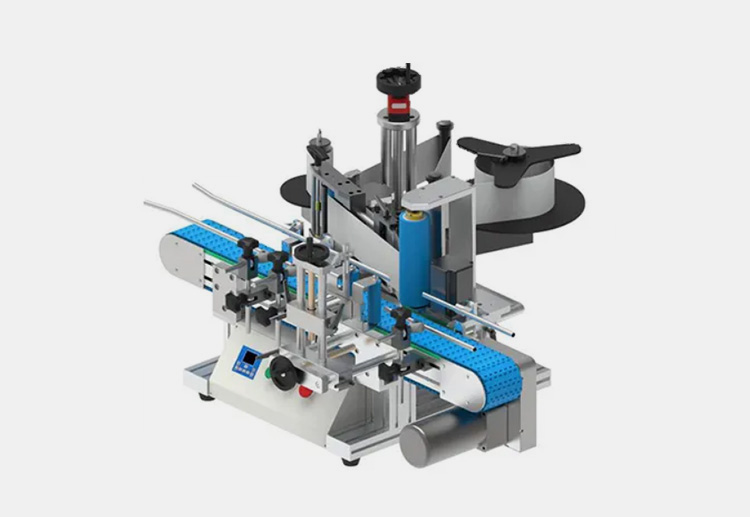

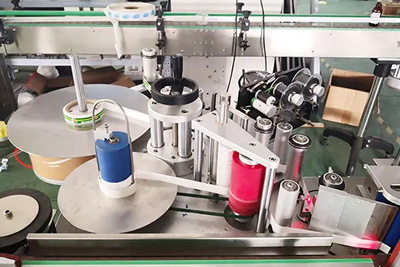

1.What Is A Sticker Labeling Machine?

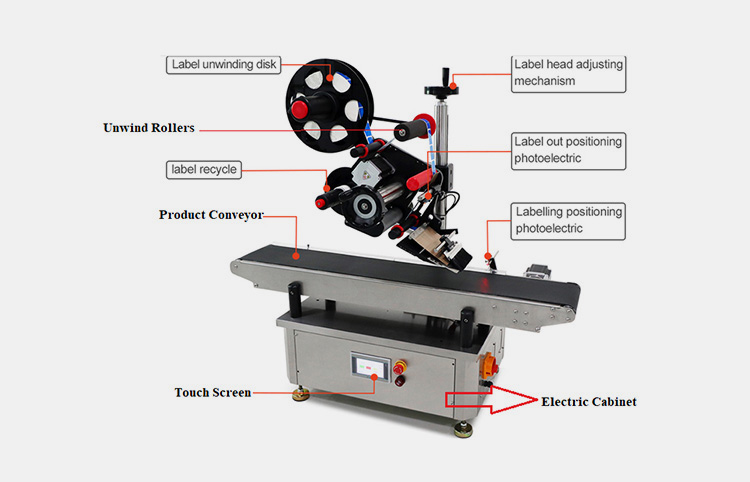

Sticker Labeling Machine

A sticker labeling machine is an equipment that works by applying various types of adhesives to your packaging material, working efficiently at high speed with automatic functioning making it a reliable choice for your business that would require a good labeling system. The sticker label mentions details like manufacturing date, expiry date, ingredients and any advice for storage or how to use.

2.What Are the Industrial Applications Of Sticker Labeling Machine?

In today’s world product identification is of immense importance. That is where sticker labeling machine play its role. This machine is the part of routine labeling and is essential in brand recognition and product information labeling. This handy instrument has found its use in several industry, some of which are listed below:

Chemical Industry

Use of Sticker Labeling Machine in Chemical Industry

This industry regularly deals with dangerous and explosive chemicals. So, it is very necessary to label these chemicals for safe usage and effective disposal. Sticker labeling machine is usually utilized in chemical industry to apply safety instruction and descriptive labels to large chemical containers such as drums, buckets as well as small jars and bottles.

Food Industry

Use of Sticker Labeling Machine in Food Industry

Have you thought from where food ingredient labels come? Well, these plastic or paper labels are frequently glued to food product container such as pouches, bottles, jars, trays, tins, etc by the sticker labeling machine. By using this machine, brands usually provide information regarding ingredients, nutritional value, calories, expiry date to their customers.

Pharmaceutical Industry

Use of Sticker Labeling Machine in Pharma Industry

Use of pharmaceutical products can significantly affect the health of patient. Hence, it is essential that these products must be correctly labeled. Sticker labeling machine perform this job of accurately labeling pharmaceutical containers. Labels having generic formulas, usage information, expiry dates, etc, are often glued to exterior of pharmaceutical containers by sticker labeling machine.

Nutraceutical and Herbal Industry

Use of Sticker Labeling Machine in Nutraceutical and Herbal Industry

Since nutraceutical and herbal industry is the part of pharmaceutical industry. Therefore, it is recommended by drug regulatory authorities that nutraceutical and herbal supplements must be labeled with 100% accuracy to avoid miscommunication about these products. Sticker labeling machine are part of packaging lines in nutraceutical and herbal industry for precisely adhering durable and readable labels to various kinds of supplement packs.

Cosmetic Industry

Use of Sticker Labeling Machine in Cosmetic Industry

Beautifully design and aesthetically pleasing labels helps cosmetic packaging to standout on retail shelves. So, these labels are applied with caution and great care by sticker labeling machine. This machine labels front and back information panels of cosmetic containers. Moreover, it also glues wrap around labels to creatively package atypical shaped cosmetic containers.

Agriculture Industry

Use of Sticker Labeling Machine in Pesticide Industry- Picture Courtesy: Cropaia

Weather-resistant and tough labels are adhered to large pesticide jerrycans, fertilizer pouches, and other agriculture packaging by sticker labeling machine in agriculture industry. This machine carries out traceable labeling and usually aids in sterilized information communication to guide farmers about usage of agriculture product.

Veterinary Industry

Use of Sticker Labeling Machine in Veterinary Industry

In veterinary and pet industry, sticker labeling machine plays a significant role in labeling pet related products such as pet feed, bathing products, pet supplements, etc. This machine prints superior quality barcode and other useful information on different containers to helps customers selecting right kind of products for their beloved pet friends.

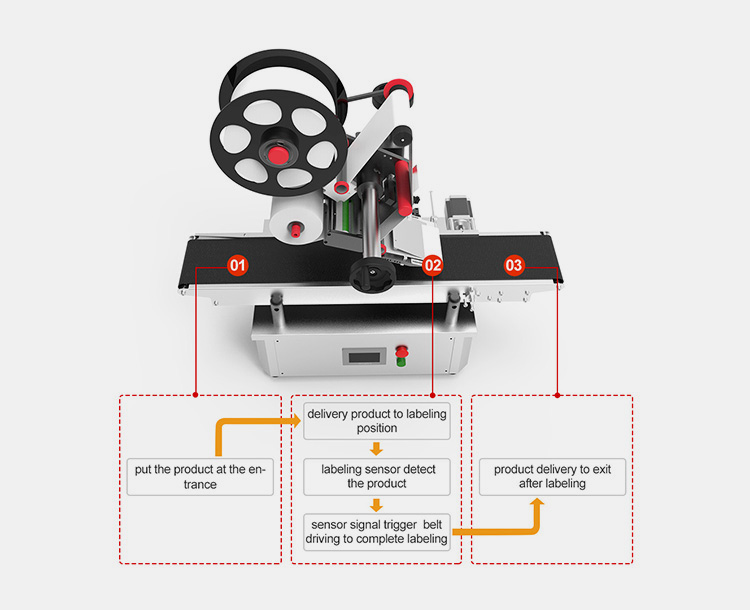

3.How Sticker Labeling Machine Works?

This machine is an integral component of different production lines because of its simple working process. Have a look at its undemanding working steps.

| Loading Labeling Film

For prefect working of sticker labeling machine, first bulk labeling film is loaded for the holder and adjusted correctly to prevent label slippage. After precisely positioning labeling roll next fine tune tension in the labeling film. Then run test to ensure labeling components are in ideal working order. |

|

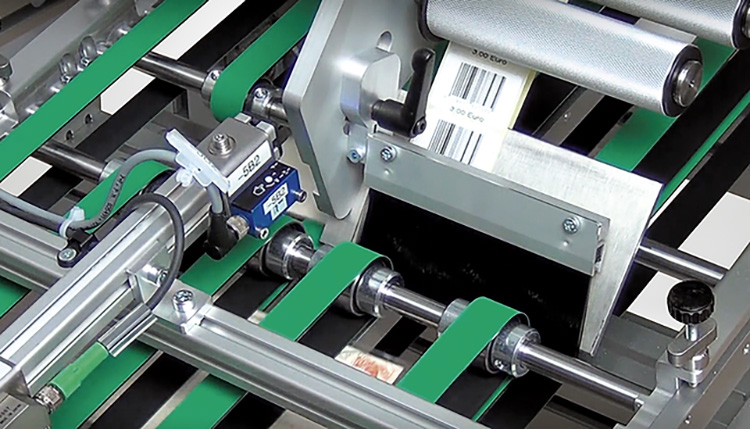

| Container Positioning

Next step is loading of containers on conveyor belts. A mechanical sensor detects the position of containers on the containers and keep them at fixed distance from each other. This part also moves the containers in the direction of conveyor. |

Picture Courtesy: CDA |

| Container Labeling

When containers reach labeling area, the drive wheel in this area force labeling belt to move which causes the labeling sticker to move out of the roll. The labeling wheel then sticks the labels to the surface of containers. |

|

| Discharging

After label adhering containers leave the labeling station and enter downstream packaging machine from where they are moved to final shipment area. |

|

4.Why Sticker Labeling Machine Is Important And How Beneficial Is It?

Sticker labeling machine are often employed for security purposes in different industry for tamper-proofing and anticounterfeiting purposes. Some handy pros of this equipment are discussed below for your understanding.

Accuracy and Precision

Picture Courtesy bb-automation

One of the biggest cons of manual labeling is-human error. Manual labeling can frequently result in misplacement or peeling of glued labels. But with sticker labeling machine you can accurately and precisely label your products. This results in durable and rightly placed labels thus reducing products recalls.

Flexibility and Versatility

Sticker labeling machine offers you flexibility in your product labeling. You can label tens of differently designed containers using sticker labeling machine. Moreover, this instrument is versatile as it can process various types of labels whether paper or plastic, peel-off or self-adhesive.

Product Communication and Brand Building

In this digital world people want to know what kind of product they are buying. Sticker labeling machine glues labels for better product information communication. These labels inform users about facts and details of products. Furthermore, labels are adhered on containers for brand building and awareness.

Tracing Products

Picture Courtesy: Labeling Machine

With the help of modern technology QR codes, RFID, tamper-evident labels, etc, are stick to containers by sticker labeling machine for security and safety of products while in transit. Sticker labeling machine is routinely employed in industry for better tracing and tracking of products and also by using products labels you can decrease anticounterfeiting activities.

Ease in Operation

Picture Courtesy: JDP Automation

Current sticker labeling machine is designed with high-tech components such as advanced HMI, sensors, safety gears, and PLC systems that allows for ease in operation and simplicity in machine programming. Furthermore, operators can easily change format with pre-saved data recipes.

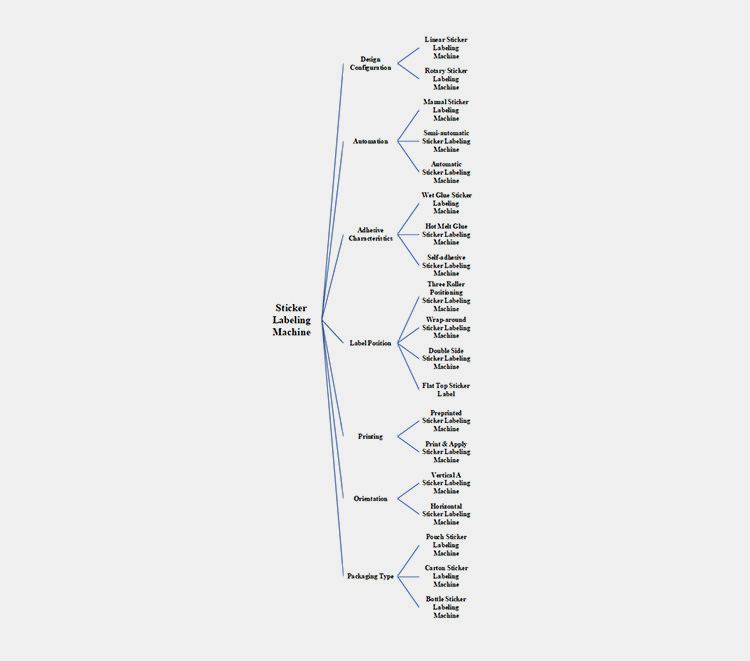

5.What Is the Basic Classification Of Sticker Labeling Machine?

Sticker labeling machine is classified in several different ways. Classification of this machine is discussed in detail below:

Based on Design Configuration

There are two sub-categories of sticker labeling machine based on design configuration.

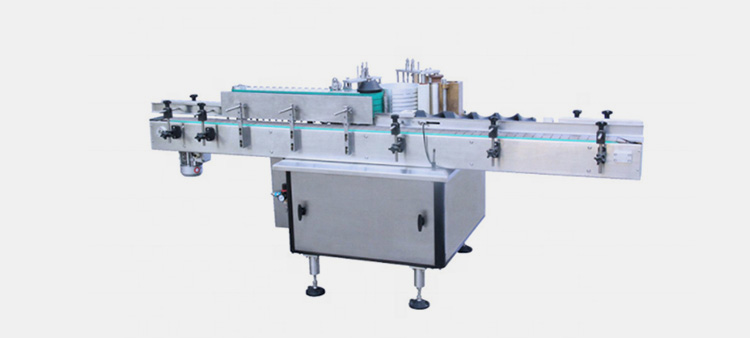

Linear Sticker Labeling Machine

This type of sticker labeling machine has a straight line or L shaped design configuration. The conveyor systems in this machine transport packaging containers one by one through the labeling station. The production speed of this machine is slow than its rotary counterpart because conveyor pause while container labeling is in process.

Rotary Sticker Labeling Machine

Picture Courtesy: Cosmetic Equipment

This machine has rotary table or star wheel where multiple labeling heads are present for simultaneous container labeling. The star wheel rotates to label multiple containers in a given time. This rotary sticker labeling machine is ideal for larger production because of its fast speed and high label processing.

Based on Automation

Three types of sticker labeling machines are present in market when classified on automation level.

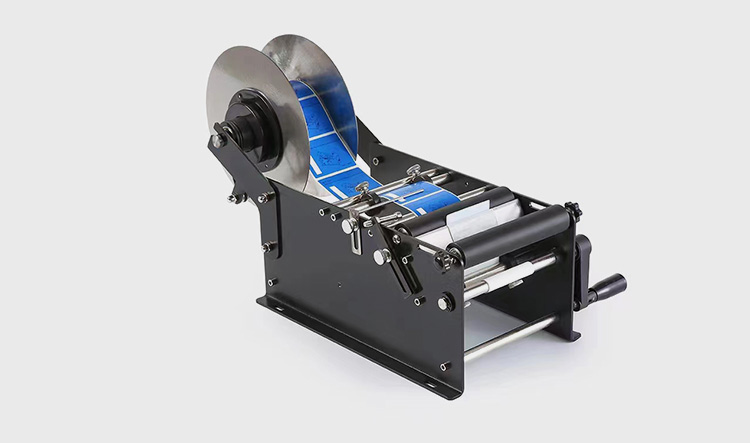

Manual Sticker Labeling Machine

Manual Sticker Labeling Machine

It is a simple device needing high human intervention. Label roll is manually loaded on the unwind disk. Labeling head and other components are adjusted and aligned by operator in this equipment. Containers are placed under labeling head one by one for labeling. This machine is popular in home-based industry due its easy operation and low cost.

Semi-automatic Sticker Labeling Machine

Semi-automatic Sticker Labeling Machine

An ideal solution for small and medium scale industries as this machine process thousands of packaging containers per hour. Operator simply have to load and unload containers while this equipment is capable of carrying out labeling functions independently. Semi-automatic sticker labeling machine has compact construction and is accommodated in small space.

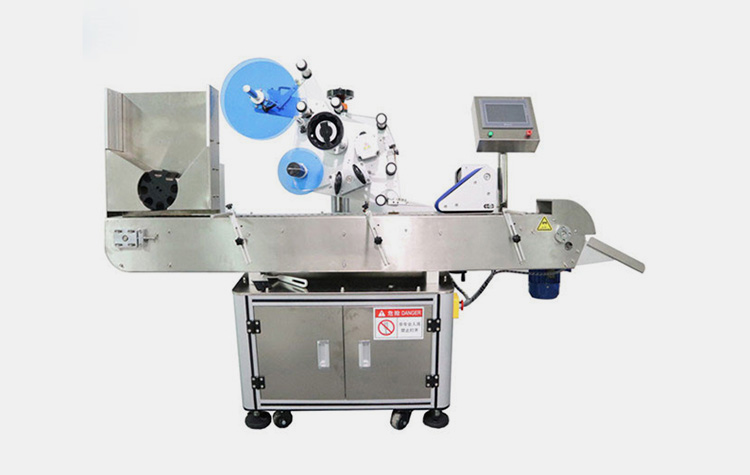

Automatic Sticker Labeling Machine

Automatic Sticker Labeling Machine

This type of sticker labeling machine requires minimal human assistance and operate as an independent unit. Operator just have to set labeling format on the touch screen. This machine operates at higher speeds and is easily integrated into production plants. It has automatic sensors, PLC systems, and alarms for fast and safe labeling.

Based on Adhesive Characteristics

Three types of sticker labeling machines are available depending upon adhesive characteristics.

Wet Glue Sticker Labeling Machine

Wet Glue Sticker Labeling Machine

Wet or cold glue is type of adhesive that is employed by this sticker labeling machine for container labeling. This machine is typically employed for labeling over products that are not thermos-sensitive and also for aesthetic labeling because it applies thin glue layer. It is effective for hard-to-peel labeling on glass, tin, and plastic containers.

Hot Melt Glue Sticker Labeling Machine

Hot Melt Glue Sticker Labeling Machine- Picture Courtesy: Higee

This type of machine uses hot melt glue for labeling purposes. Glue applicator in this machine melts glue at high temperature and then put this glue on back labels. It uses precut paper, foil, or label film and has the advantage of lower glue consumption. It is usually employed for wrap-around heat resistant labeling.

Self-Adhesive Sticker Labeling Machine

Self-Adhesive Sticker Labeling Machine- Picture Courtesy: ibc machine

Rather than using hot or cold glue, this machine uses labels that self-adhesive. It is also known as pressure-sensitive sticker labeling machine as it applies sticky labels on containers using pressure. It can process containers with different shapes and sizes such as square, round or oval, etc.

Based on Label Position

On basis of label positioning, there are four categories of sticker labeling machine.

Three Roller Positioning Sticker Labeling Machine

Three Roller Positioning Sticker Labeling Machine- Picture Courtesy: vkpak

As name suggest, this machine has three rollers that assist in precise positioning of labels over packaging. These rollers prevent misorientation and crumpling of labels. It is mostly employed for accurate and fast labeling of curved objects.

Wrap-around Sticker Labeling Machine

Wrap-around Sticker Labeling Machine

This machine work best with round containers and cover them at centre fully or partially. Wrap-around sticker labeling machine easily handles long labels and apply them perfectly without any positioning error.

Double Side Sticker Labeling Machine

Double Side Sticker Labeling Machine- Picture Courtesy: Pacific Inline Filling, Filler

It is also known as front and back sticker labeling machine since it applies labels at front and back panel of packaging objects. It handles every shaped container whether oval or rectangular, square or cylindrical. This equipment usually uses pre-glue stickers to create strong and durable bond with containers.

Flat Top Sticker Labeling Machine

Flat Top Sticker Labeling Machine- Picture Courtesy: Higee

For one side labeling flat objects such as pouches, bags, boxes, cardboard cartons, etc, flat top sticker labeling machine is employed in industries. It can be offered with printers for printing bar codes, dates, and batch numbers on packaging. Moreover, it has benefit of superior quality labeling without air bubbles or crinkles.

Based on Printing

There are two kinds of sticker labeling machine when classified on the basis of printing.

Preprinted Sticker Labeling Machine

Preprinted Sticker Labeling Machine

It is a simple machine without any printers and usually uses custom-made film label rolls for gluing stickers on the exterior of packaging. It can label one or two sides of containers or can be used as a wrap-around sticker labeling machine. This equipment has fewer components and is easily to maintain.

Print & Apply Sticker Labeling Machine

Print & Apply Sticker Labeling Machine- Picture Courtesy: Labeling Machine

This machine is customized with printers and is utilized for directly printing labels and applying them to objects. It has UV inks and thermal transfer printer for printing high-definition graphic labels and barcodes on film or paper. Moreover, it has high-speed label applicator for steady label application.

Based on Orientation

There exist two categories of sticker labeling machine when classified based on orientation.

Vertical Sticker Labeling Machine

Vertical Sticker Labeling Machine- Picture Courtesy: Sharp Pharma Machinery

This machine sticks labels in the vertical direction over product packaging such as lip-gloss, eye liner, ampules, vials, and tubes. It is ideal for creating a smooth and elegant finishing over products. Usually, this machine is employed for aesthetic purposes in pharmaceutical, food, and cosmetic industry.

Horizontal Sticker Labeling Machine

Horizontal Sticker Labeling Machine- Picture Courtesy: vkpak

This machine has glue applicator and label applicator for applying labels horizontally over products. It is suitable for accurately labeling flat containers like boxes or cartons or on bottles. Moreover, this machine applies self-adhesive, thermal transfer, and wet glue labels. It operates at high speed for consistent labeling.

Based on Packaging Type

There are three different kinds of sticker labeling machine when classified depending upon packaging type.

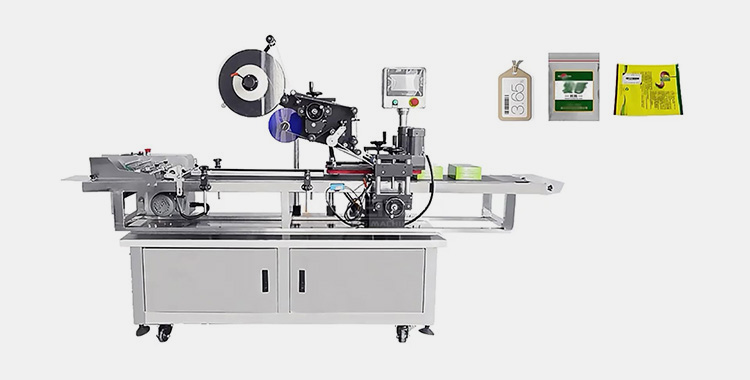

Pouch Sticker Labeling Machine

Pouch Sticker Labeling Machine

Pouch packaging is gaining immense recognition in packaging world. So, special pouch sticker labeling machine is developed that deals with flat or standup pouches, zipper pouches, sachets, or stick packs. This machine normally applies double-sided labels on pouches with minimal error rate.

Carton Sticker Labeling Machine

Carton Sticker Labeling Machine- Picture Courtesy: vkpak

This machine adheres both preprinted as well as machine printed labels at the front, back, top, and bottom sides of cartons or other tertiary packaging for tracking, tracing, scanning, and storing, and identifying products during transportation. It sticks firm and durable labels that withstand rough handling while shipment.

Bottle Sticker Labeling Machine

Bottle Sticker Labeling Machine

Automatic bottle sticker labeling machine are equipped with fast controls and highly accurate sensors for labeling bottles and jars having shapes such as round, cylindrical, hexagonal, square, oval, and also atypical shaped bottles. This machine has low error rate thus is preferred by food, pharmaceutical, nutraceutical, beverage, and chemical industries.

6.What Are the Components Of Sticker Labeling Machine?

Some important components of sticker labeling machine are listed below:

| Touch Screen HMI | It is a touch sensitive HMI display screen which facilitates the programming of machine operation. Users can modify labeling settings on this smart and intuitive touch screen interface. |

| Electric Cabinet | It is an enclosure where different kinds of relays, switches, knobs, buttons, wires, etc are present for smooth running of sticker labeling machine. This is usually made with fire-proof and explosion-proof material to prevent electric accidents. |

| Labeling Positioning Photoelectric | It is an extreme sensitive sensor that automatically detects the direction and placement of labels. Light beam is employed by these sensors for accurately placing labels on moving containers. |

| Label Recycle | It is like a label rewind system as it can be employed for rewinding the label back into roll once no container is detected on the conveyor. |

| Unwind Rollers | They are different types of rollers that are essential in in unspooling labels from the label rolls. These rollers are normally located at the top or start of the sticker labeling machine and play important role in label feed. |

| Labeling Head Adjusting Mechanism | This component is responsible for manually or automatically altering the height of labeling head. This mechanism consists of hand wheel or level for manual adjustment. It aids in accuracy and consistency of labeling process. |

| Product Conveyor | Conveyors are the transport systems that carries product containers across the sticker labeling machine. These conveyors are powered by motors or hydraulic cylinders for movement. They increase the productivity of sticker labeling machine by rapidly transporting containers across labeling station. |

| Label Unwind Disk | It is a rotating plate having holes or slots for passing labels. It is powered by motors which facilitates its rotation. This component aids in unwinding of labels from roll and ensures smooth and steady label feed. |

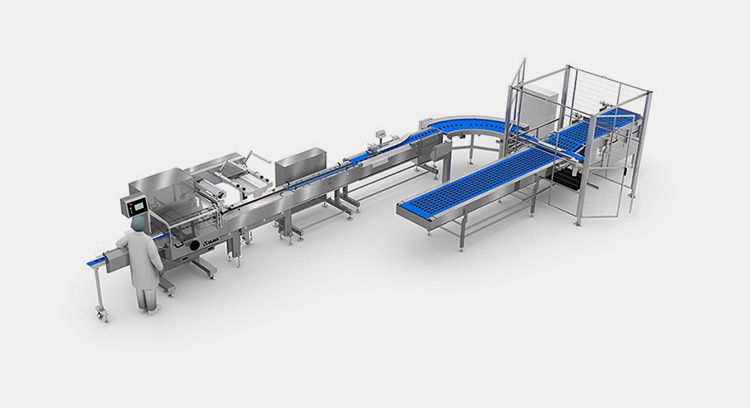

7.What Is the Complete Production Line Of The Sticker Labeling Machine?

A good label always creates a great impression on customers. Sticker labeling machine is useful instrument that aids in standing out of products among crowd. But this machine is often integrated with other machine to create unique packaging results. The order of machine in production line of sticker labeling machine is listed below:

| Bottle Unscrambling Machine

Picture Courtesy: HG Molenaar |

This machine aligns bulk amount of containers in proper standing position on the conveyors systems. The containers are typically loaded in the random order inside the hopper but this machine collects containers for their proper orientation. |

| Filling Machine

|

This machine utilizes several kinds of filling systems such as auger fillers, volumetric fillers for precise loading different kinds of products inside the containers. |

| Capping Machine

Picture Courtesy: Asset Packaging Machine |

For preventing product leakage and spillage, capping machine are normally employed in production lines. It uses servo motors and capping heads for seurely fixing caps or lids on the opening of containers. |

| Induction Cap Sealing Machine

Picture Courtesy: Industry Plaza |

It is often employed for creating hermatic seal bwteen cap and opening of container. Heating create electromagnetic field for melting and bonding foil with container. This form premanent seal that reduces tampering risk. |

| Cartoning Machine

Picture Courtesy: Shineben Machinery |

It is a tertiery packaging machine that has carton errector for errecting carton and product loader for automatically packaging products inside the carton. This machine usually packs bulk quantities of product packaging inside the secure box for convinent shipment. |

8.How To Clean and Maintain A Sticker Labeling Machine?

Cleaning and maintaining a sticker labeling machine ensure its long and healthy operational life. So clean and do preventive maintenance regularly to avoid dust accumulation that causes problems in longer run. Here are some cleaning and maintenance tips for your learning.

| Cleaning of Sticker Labeling Machine | Maintenance of Sticker Labeling Machine |

| Before washing any part of sticker labeling machine, first remove any powdered products or label materials from the machine with the help of brush.

Then use lint-free cloth to remove dust or debris from the surface of the machine. Dissemble the machine parts. Use mild detergent and water mixture to thoroughly wash the equipment for removing sticky product or left-over glue. Use brush and detergent solution to fully clean hard to reach parts. Use air blowers or direct sunlight to completely dry dismantled components before reassembling them. |

Examine sticker labeling machine on the daily basis for defects or damage to any component. Repair or replace any worn-out or defective part.

Check the alignment and configuration of rollers, labeling head, conveyors, and unwinding disk on the weekly basis. Lubricate the moving parts as well as different nuts and bolts weekly. Check working order of sensors correctly on weekly basis. Examine loose cables and other electric connections monthly. Check level of oil in gear box on the monthly basis. If level of oil is low then top it up. |

9.What Are the Major Technical Problems And Solutions Of Sticker Labeling Machine?

Technical problems in sticker labeling machine are the major source of headache and stress for businesses because they could cause a lot of money and time. However, these problems are easily resolved by training operators. Below is the list of some major technical problems and their solutions.

Tearing of Labels

| Probable Cause | Solution | Picture |

| This problem could arise due to incorrect tension or sharp edges of the labels.

It also occurs due to debris buildup on rollers. |

Adjust the settings of labeling procedure to ensure that tension is either not too tight or not too loose. Secondly make ensure that labels do not have any sharp point. Clean the rollers thoroughly before start of labeling process. |

Picture Courtesy: Design & Paper |

Flagging or Bulging of Labels

| Probable Cause | Solution | Picture |

| This problem could arise because of incompatible label size. If labels have big size or does not design according to curvature of container. This could cause label slumping or swelling. | Redesign your labels keeping in mind dimensions of your packaging container. |

Picture Courtesy: Food Navigator Asia |

Air Bubbles in Labels

| Probable Cause | Solution | Picture |

| When container is manufactured using lower quality glass then this results in rigid glass containers having minute peaks and valleys. This rough surface of container traps air upon label application resulting in visible air bubbles. | This problem is avoided by using containers manufactured with appropriate materials. |

Picture Courtesy: Label & Litho |

Labels Jamming the Labeling Head

| Probable Cause | Solution | Picture |

| On high temperature, glue on labels become soft and oozy resulting in strain in removing labels from roll. Moreover, these gluey labels also block label head. | Maintain accurate temperature as recommended by label manufacturer during labeling process as well as storage of labels. |

Picture Courtesy: Aligned |

Labels Do Not Stick Properly to Containers

| Probable Cause | Solution | Picture |

| If tension in the film is not accurate this could result in peeling off of labels. Moreover, if labeling head is not properly aligned this could lead to non-stickiness of labels. Another possible reason is defective in die strike. | Adjust the tension in the film. Properly configure labeling head. Replace damaged die strike.

|

Picture Courtesy: Wizard Label |

10.What Is the Factor That Must Be Considered When Purchasing A Sticker Labeling Machine?

Purchase of sticker labeling machine is a big investment that could have zero return if no planning is put into buying process. Several factors should be considered to purchase right kind of sticker labeling machine that is completely compatible with your production line.

Determine Your Production Efficiency

Picture Courtesy: BellatRx

Before going for purchase first look into production efficiency of your production line. If you are processing hundreds of thousand products per day then it is best that you buy automatic sticker labeling machines as it can label thousands of containers per hour. This will speed up your production.

Access Installation Space

Picture Courtesy: Lab Packaging

Measure the plant space that will accommodate your future sticker labeling machine. This will give you an idea about the size of sticker labeling machine. This is important as installing large machine in overcrowded space can negatively impact packaging process.

Evaluate Your Existing Machines

Picture Courtesy: ULMA Packaging

Before buying sticker labeling machine, access your existing instrumentation and determine what kind of sticker labeling machine will work best with your production line. This will help in easy integration of your purchased system.

Look into Container and Label Types

Different Labeling Formats

Determine your container shape and manufacturing material. As not all kinds of labels are suitable for every container material-glass, plastic or metal. If you are dealing with unusual shaped containers then select that machine that is capable of handling said shaped container.

Prioritize Advance Machine Controls

Picture Courtesy: Nevatio Engineering

Go for sticker labeling machine that is equipped with state-of-the-art technology and computerized controls. This machine would have ease of usage and latest alarm sensor systems to assist in safety and accuracy of production systems.

Conclusion

Labeling has significant important in every industry for product recognition. Thus, sticker labeling machine is a wide-ranging and adaptable solution that boost high accuracy and lower labeling error rate. This increases your product sale by visually pleasing labeling. Allpack is a brand best known for its excellent quality labeling turnkey solutions and ever-ready customer support. We are offering cutting-edge sticker labeling machine with best price range. Contact us on our helpline if interested in purchase.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide