What is the Difference between a Stick Pack and a Sachet?

What is the Difference between a Stick Pack and a Sachet?

In modern society, product packaging is not only to protect products, but also the key to conveying brand image and attracting consumers. More and more customers are choosing to purchase single use products with stick packs or sachets. Both are widely used in various industries, such as food, agriculture, and pharmaceuticals.

The two packaging forms occupy a place in the market due to its portability and diversity. Because of their similarities, many customers often confuse them.

What is the difference between a stick pack and a sachet? I think you must have thought about such a question. Today, let’s explore their differences.

1.What Is a Stick Pack and a Sachet?

As we all know, the stick pack and sachet have many common points. You must have many questions about them. Let me first introduce to you the definition of two kinds of packaging.

Stick Pack

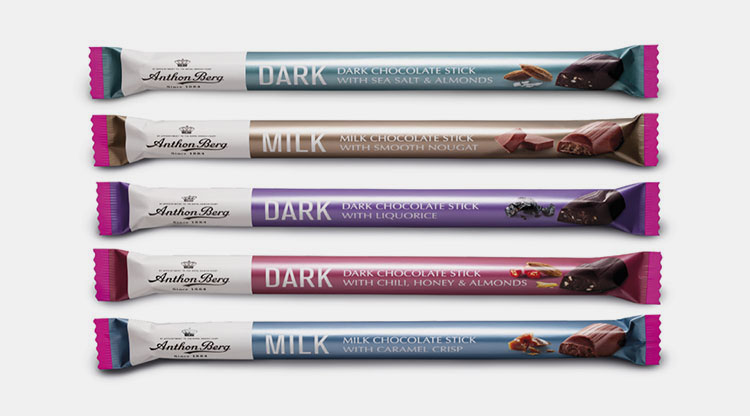

Stick Pack - Sourced: blackcoffeeroastingco

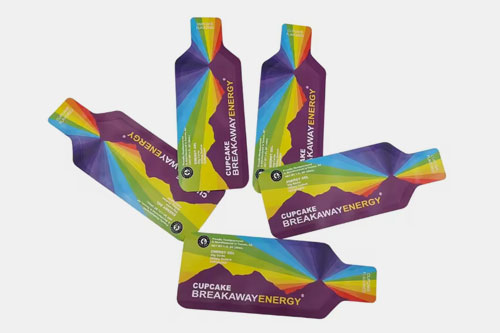

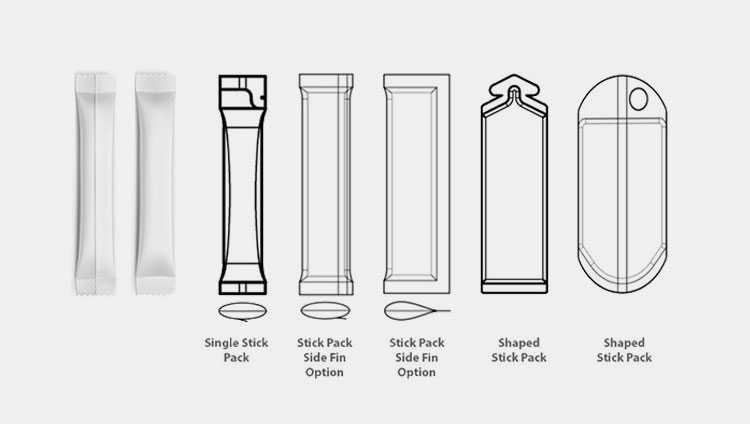

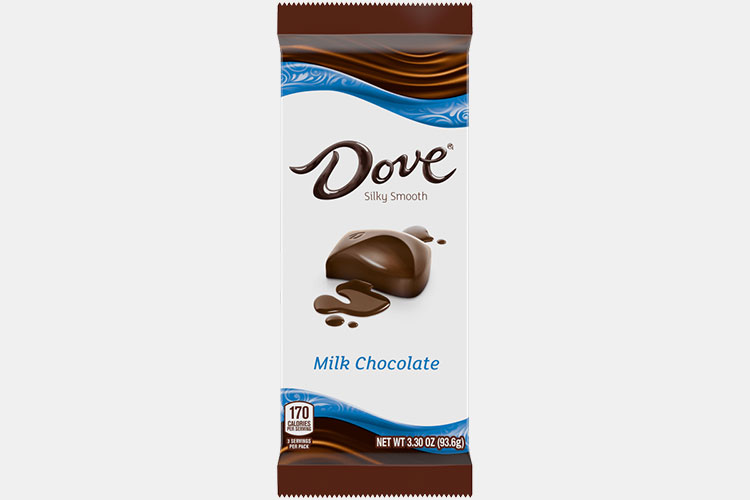

Stick packs, also known as stick packaging, are a kind of long and narrow packaging. This kind of packaging is mainly used for single servings of liquids, powders, and granules.

Sachet

Sachet - Sourced: fifoplus

A sachet refers to a tiny container within little material. The sachet is usually wider than a stick pack. A variety of products are applied as single doses using these compact, light-weight packaging.

2.What Are the Applied Industries of Stick Packsand Sachets?

Believe it or not, you must have seen many stick packs and sachets in your daily life. These two kind of packaging are widely used in a lot of industries, such as food, pharmaceutical, cosmetic, agriculture, and chemistry.

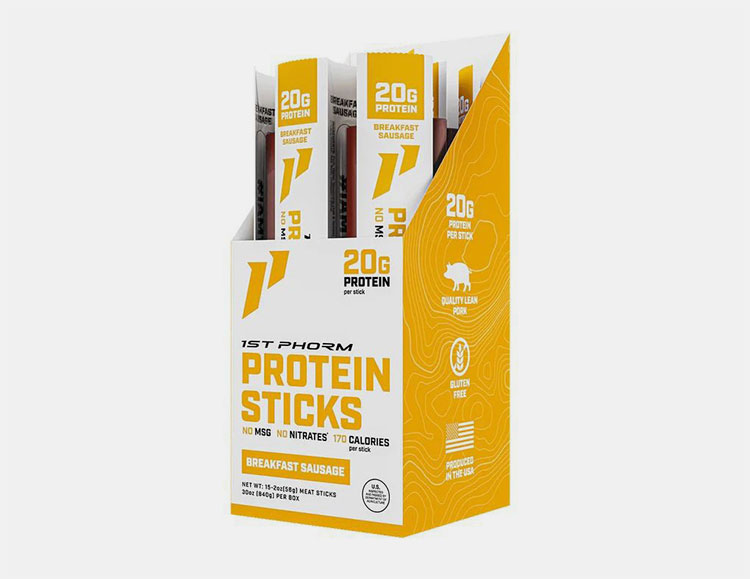

Food industry

Coffee Stick Pack & Sachet - Sourced: nicejugsmk & pandemanila

In the food industry, whether it is brewed coffee, fruit juice, or health products, stick packs and sachets can provide precise weight control while ensuring the sealing and clean of food.

Pharmaceutical industry

Pharmaceutical Sachet - Sourced: webpackaging.

Having you seen the pills with stick packs and sachets? These two kinds of packages are widely used in the pharmaceutical industry, especially suitable for tablets, capsules, suppositories, pills, cold granules, etc.

This packaging form has such advantages as light weight, and easy portability. It has good protection for the packaging material and meets the special packaging requirements of drugs and health products.

Cosmetic industry

Cosmetics Sachet - Sourced: linkedin

The stick pack and sachet design of cosmetics usually reflect the high-end and luxurious feeling of the product, attracting the attention of consumers. At the same time, the two kinds of packaging also facilitate consumers to control usage, and keep the product fresh.

This type of packaging not only meets consumer demands for simplicity of use but also improves the product’s sales attractiveness. It is also comfortable to carry.

Agricultural industry

Vegetable Seeds - Sourced: lowes

Stick pack and sachet are widely used in the agricultural field, and with their unique characteristics and advantages, they provide great convenience for agricultural production, storage, transportation, and sales. Small bag packaging is widely used in the packaging of agricultural products, such as vegetable seeds and grains.

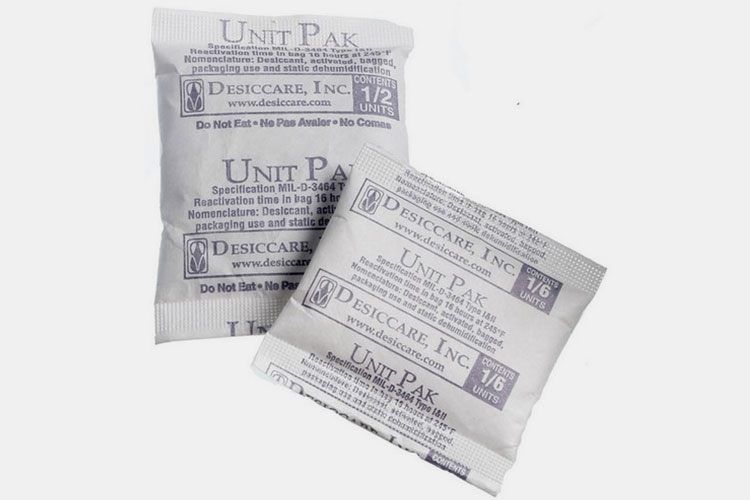

Chemical industry

Desiccant - Sourced: edcosupply

Stick pack and sachet are widely used in the chemical industry, and its unique design and functionality make it an ideal choice for packaging many chemical products.

Due to their good sealing characteristics, stick pack and sachet are particularly suitable for packaging such chemicals as chemical reagents, catalysts, and desiccants, making it convenient for users to use and manage.

3.What Is the Difference between a Stick Pack and a Sachet?

After knowing the basic information of a stick pack and a sachet, you will find that they have many things in common. However, it is precisely because of their similarities that many people are easily confused. Do you know their difference? Let’s move to study their differences.

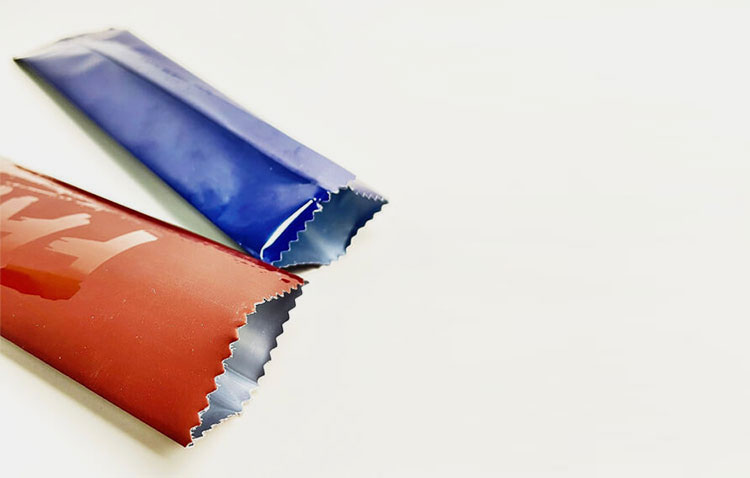

Form

The Form of A Stick Pack and A Sachet - Sourced: yellowimages

The stick pack have a long and narrow design. And it has many bag styles, such as straight cutting, round, serrated, and diamond.

However, the sachet is wider than the stick pack, usually with 3 or 4 side sealing.

Capacity

The capacity which can be packaged in the stick pack and sachet are different. In terms of powder, the stick pack can accommodate several grams of powder. In terms of liquid, the stick pack can accommodate 1 to 60 milliliters.

In terms of powder, the sachets can package several grams of powder. In terms of liquid, the stick pack can package 1 to 10 milliliters of liquid, far less than stick pack. This capacity is very suitable for single servings of lotion or shampoo.

Cost

Cost - Sourced: mckenzielake

To be honest, stick packs are often more expensive than sachets, because of their distinct shape, such as diverse cutting types what we have discussed in the above. Stick packs, on the other hand, provide a few benefits over sachets.

4.What Materials Can Be Packaged in a Stick Pack and a Sachet?

Stick pack and sachet are a kind of flexible and practical packaging form that is suitable for various types of materials. The following describes in detail the materials that can be packaged in stick pack, especially liquid, granule, and powder:

Liquid

Tomato Sauce - Sourced: mcdonalds

Stick pack and sachet are particularly suitable for liquid materials, such as beverages, condiments, sauces, milk, etc.

This packaging form can effectively prevent liquid leakage and is convenient for consumers to carry and use. Through appropriate material selection and structural design, stick pack and sachet can ensure the stability and safety of liquid materials during storage and transportation.

Granule

Coffee Granule - Sourced: mashed

Products such as coffee granules, candy granules, and grain granules are also suitable for using stick pack and sachet.

Stick pack and sachet can neatly package granular materials in bags to prevent material form being scattered or moisturized. Meanwhile, by controlling the size and shape of the packaging bag, it can be ensured that the amount of granules taken each time is accurate and convenient.

Powder

Seasoning Powder - Sourced: lowcarb-nocarb

Milk powder, coffee powder, seasoning powder are also common materials in stick pack and sachet. Stick pack and sachet can keep the powder dry and hygienic, and prevent moisture or contamination.

By precise packaging control, it is possible to ensure the accurate amount of powder in each bag, making it convenient for consumers to use according to their personal needs.

5.What Is the Advantages of a Stick Pack and a Sachet?

Advantages - Sourced: opening

When you go out, would you try to bring stick pack or sachet of products? The portability of two kinds of packaging forms will reduce the burden of travel. To be honest, the advantages of a stick pack and a sachet are more than this.

Convenience and portability

The stick pack and sachet are compact and are easy to carry, and especially suitable for business trips or travel.

For some special drugs, such as children’s drugs, they can be designed in unique shapes to increase children’s willingness to take drugs.

Good sealing

Good Sealing - Sourced: newfoodmagazine

Stick packs and sachets have good sealing properties, which can completely prevent moisture and oxygen from entering, and ensure the effectiveness and safety of drugs or other products.

High precision

Stick packs and sachets can be filled quantitatively with high precision, with a minimum capacity of 0.3g, suitable for products with strict dosage requirements.

Good protection

PET - Sourced: pakpackages

PET and other materials are used in stick pack and sachet. PET material has the characteristics of being lightweight and sturdy, making it easy to carry and use, while also having good impact resistance.

In addition, PET material is easy to process into various shapes and sizes of products, suitable for large-scale production. It also has a good barrier effect on gases and water, which can effectively prevent the oxidation and deterioration of food, beverages, and other items.

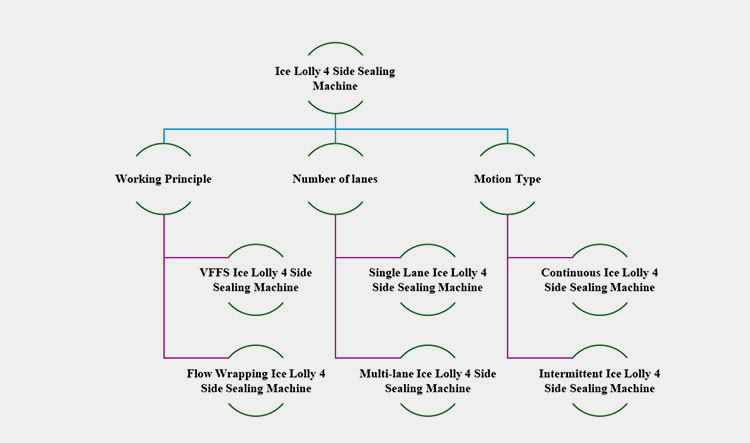

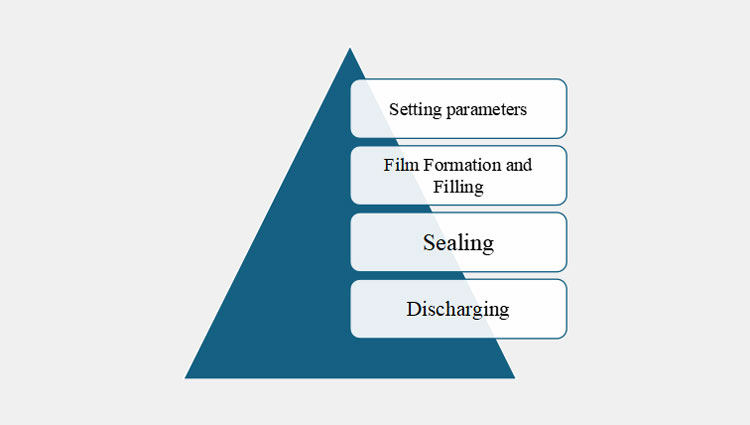

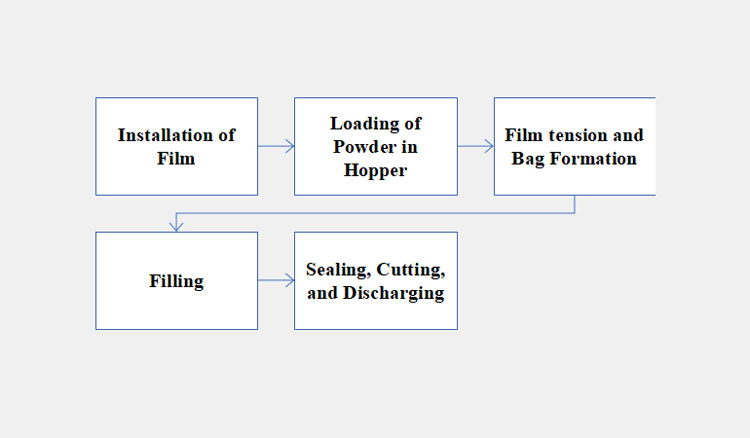

6.What Are the Machines for Producing Stick Packs and Sachets?

Do you know the machines for producing stick packs and sachets? Let’s take a look at these two kinds of packaging machines.

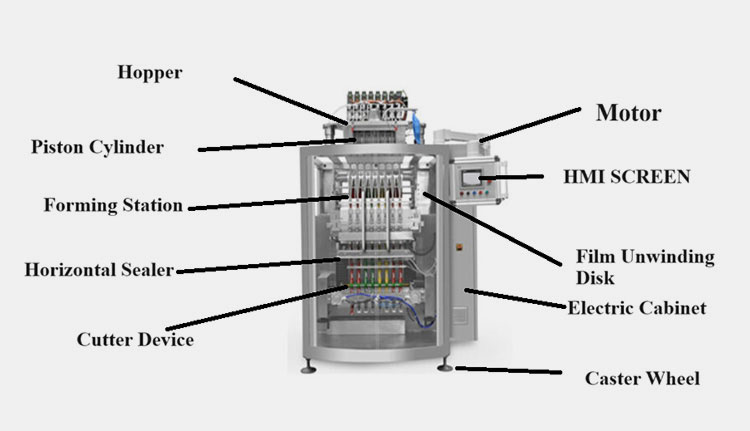

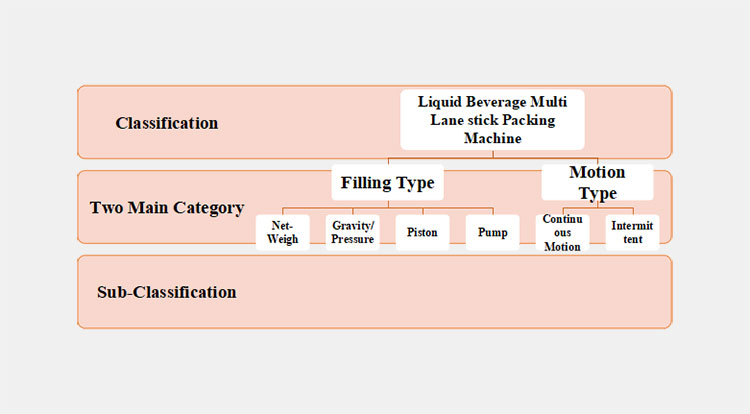

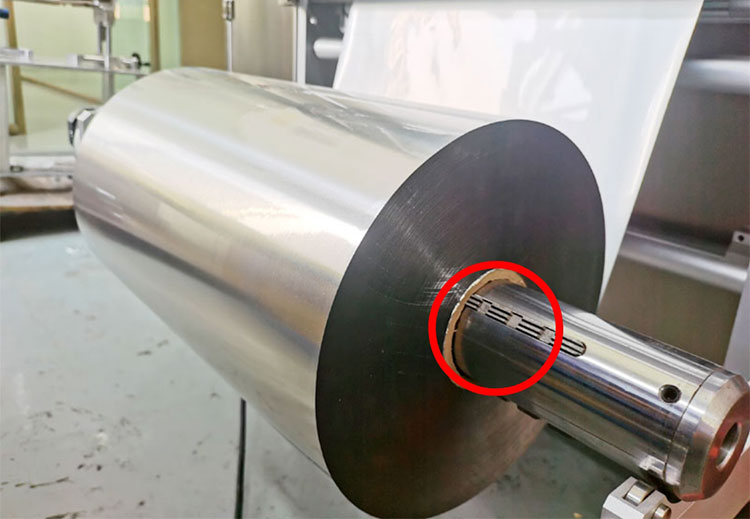

- Stick pack machine

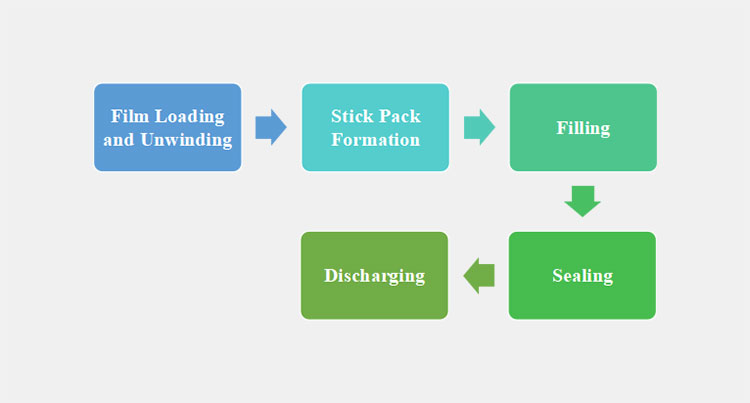

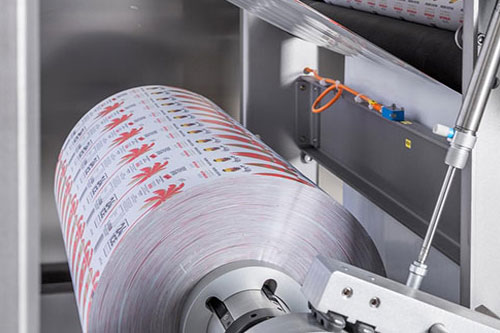

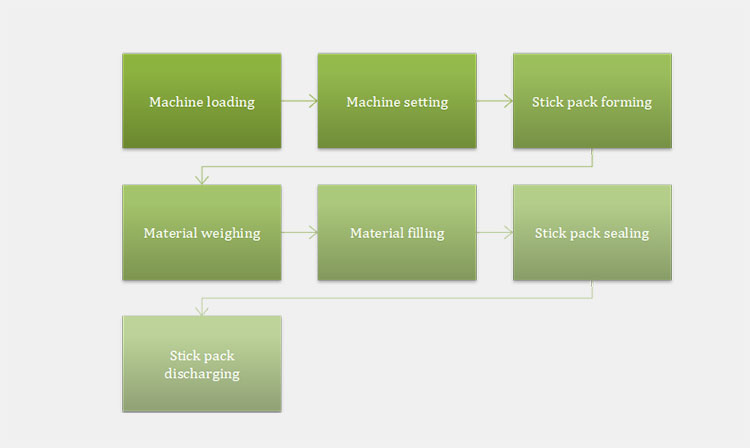

A stick pack machine is a machine, which was used for packaging of powder, liquid and granular materials. The stick pack machine has the characteristics of fast speed, high accuracy, and wide applicability. Next, I will introduce two types: multi-lane stick pack machine and single lane stick pack machine.

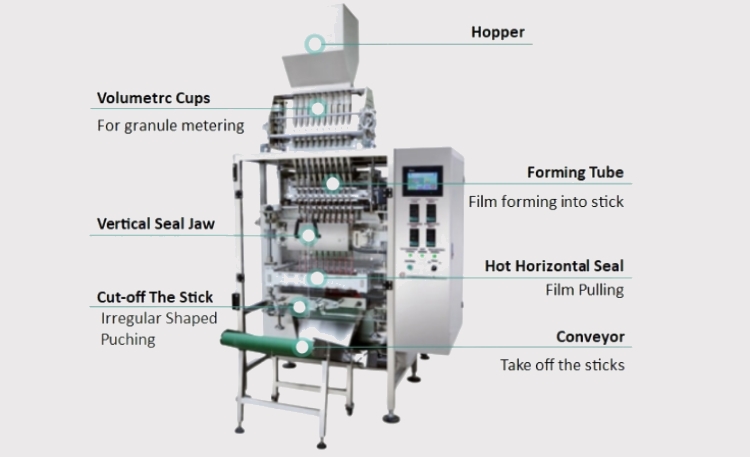

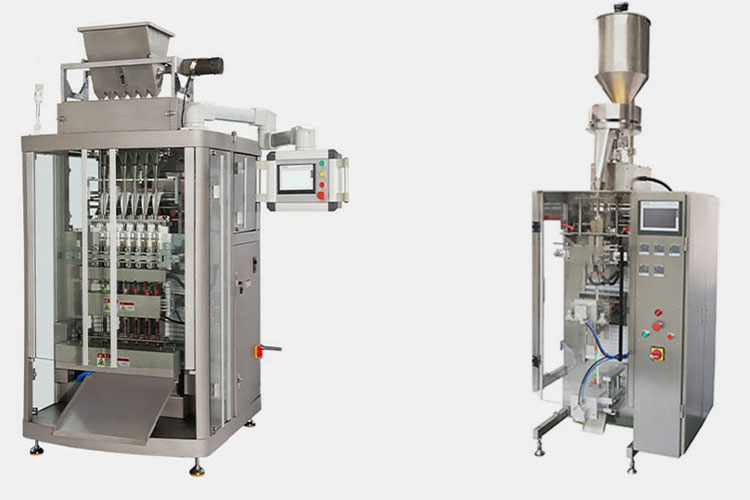

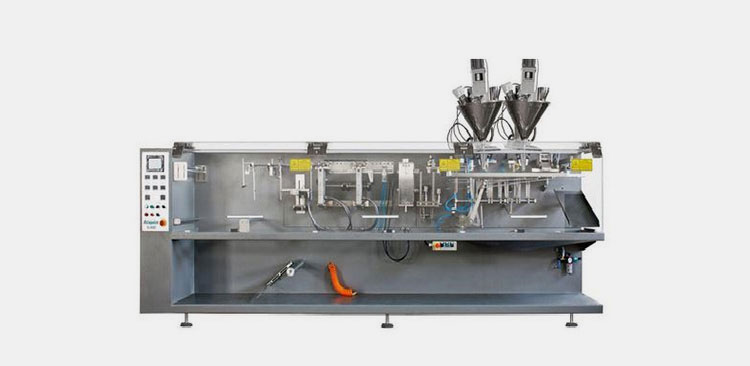

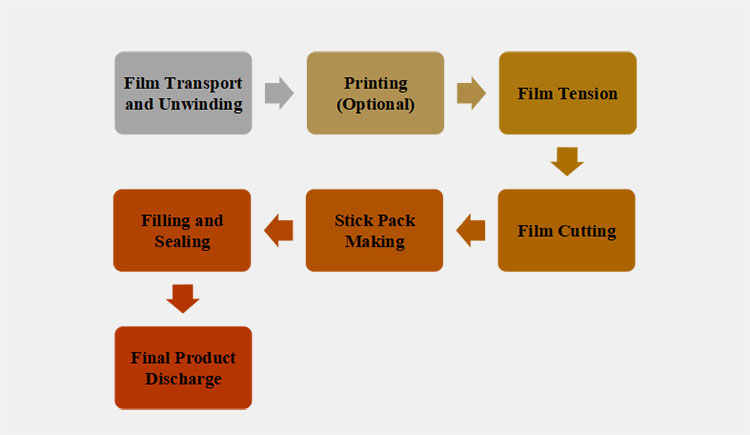

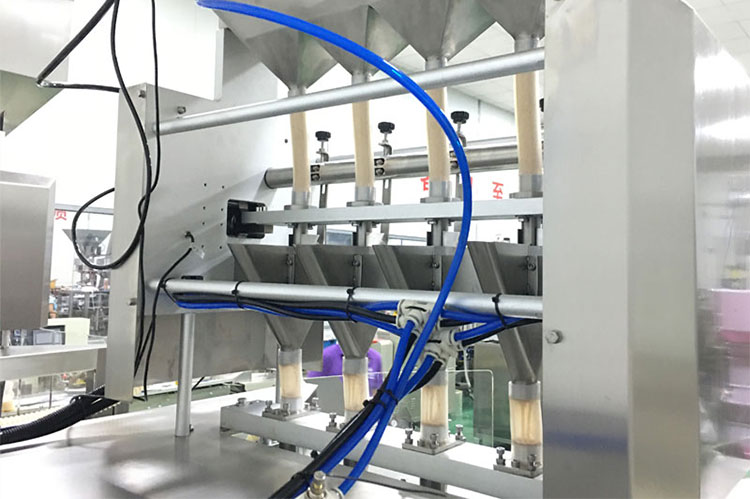

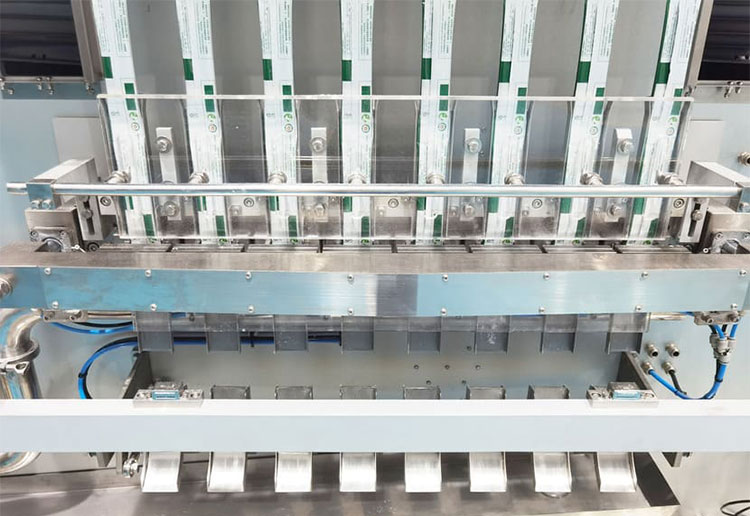

Multi-lane stick pack machine

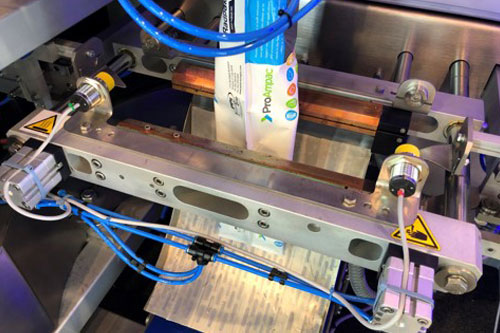

Allpack Multi-lane Stick Pack Machine

The multi-lane stick pack machine can pack 2, 4, or 8 lanes of materials simultaneously. It fills materials into multiple independent packaging bags through feeding devices and forming molds, and then undergoes sealing, cutting and other processes to form multiple parallel rows of stick packaging products.

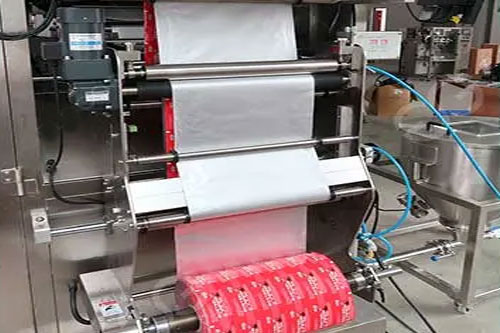

Single lane stick pack machine

Allpack Single Lane Stick Pack Machine

A single lane stick machine is a mechanical device, which can only package one lane of material at a time. It usually only has one feeding device and one molding mold, which fills the material into a single packaging bag, and after sealing, cutting and other processes, forms a single row of stick packaging products.

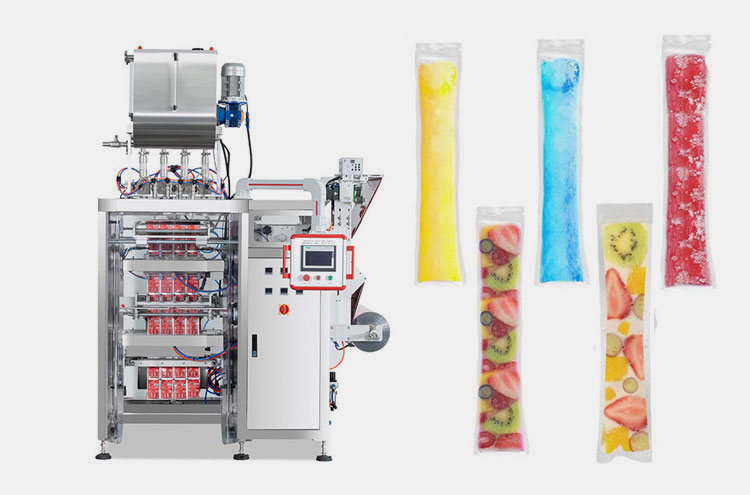

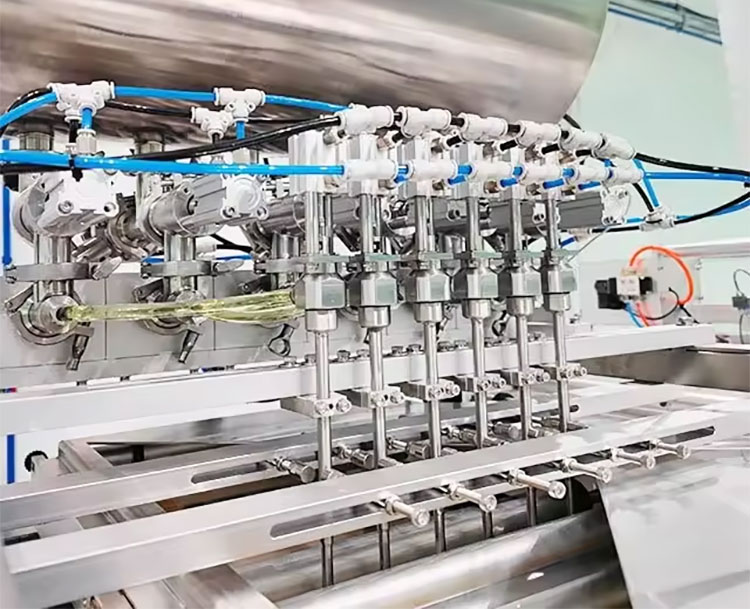

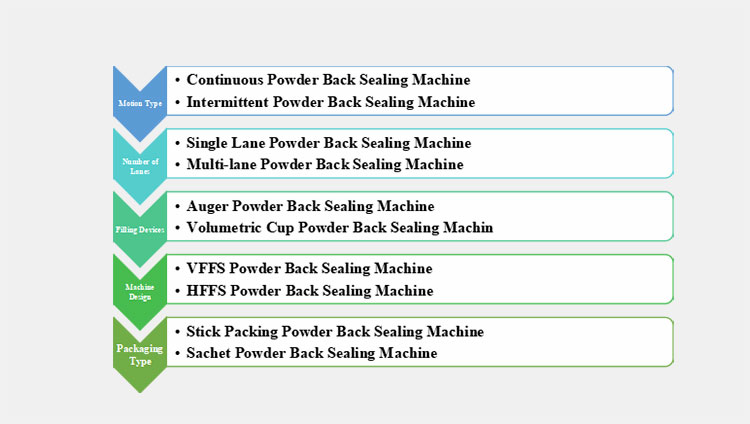

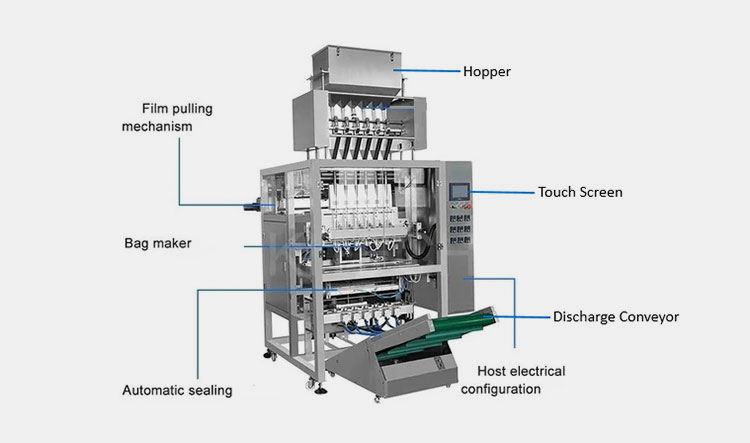

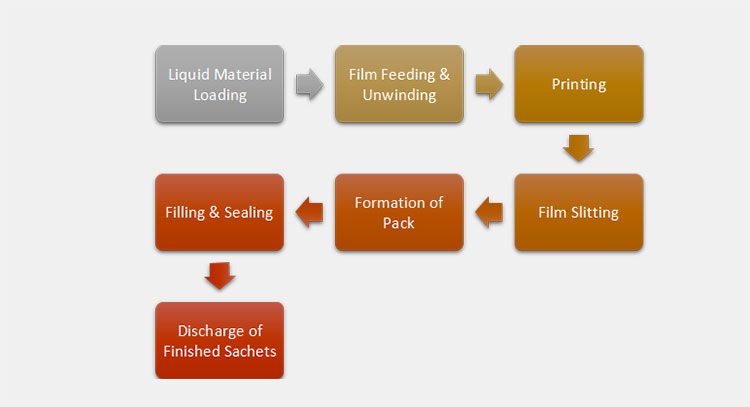

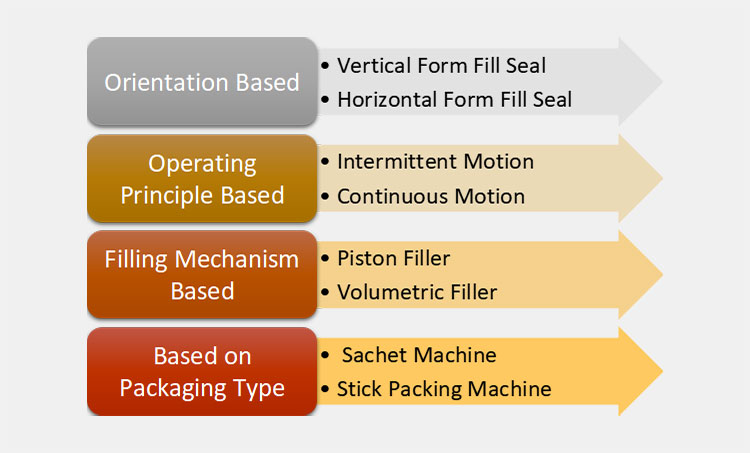

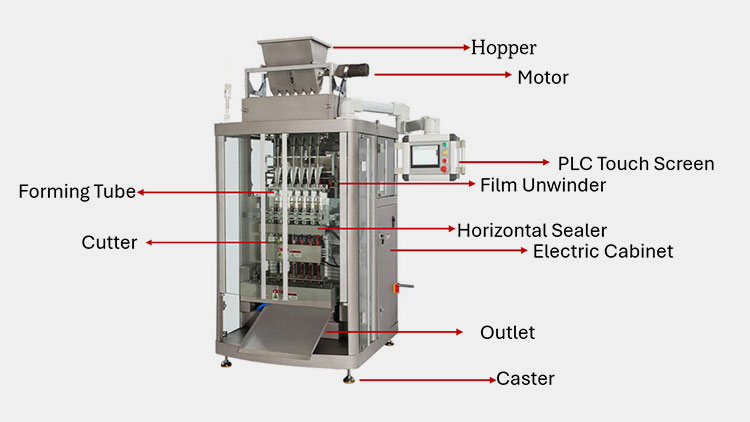

- Sachet pack machine

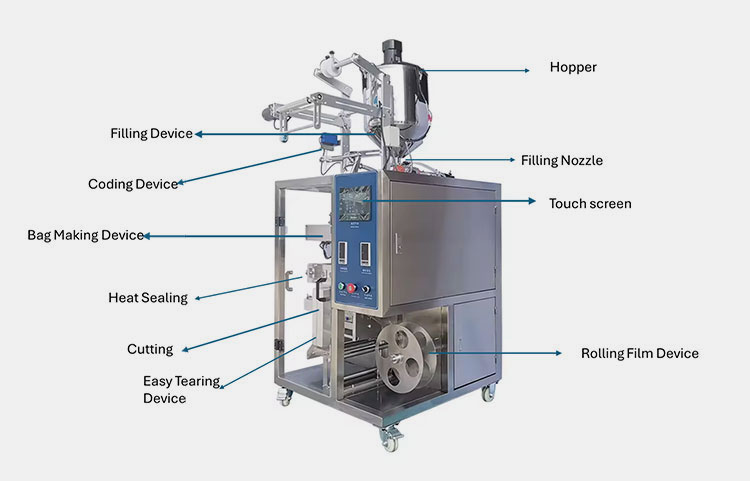

A sachet pack machine is a equipment specifically designed for packaging items into small bags and sealing them. The small bag packaging machine can package various items (such as food, medicine, cosmetics, etc.) into independent small bags and ensure the sealing of the items inside the bags.

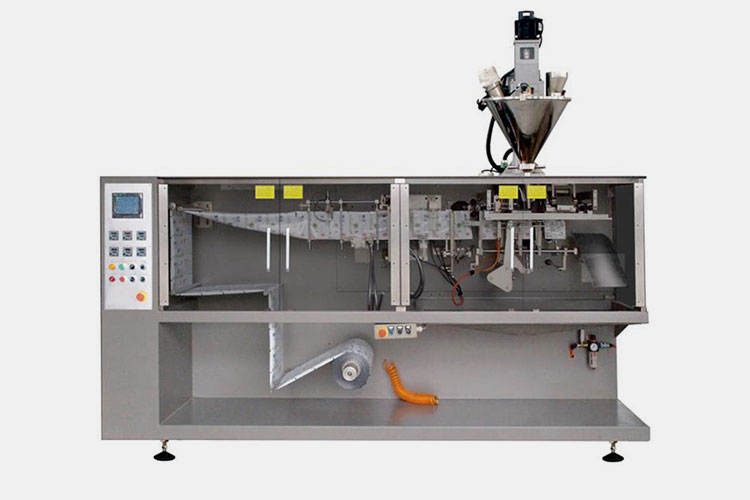

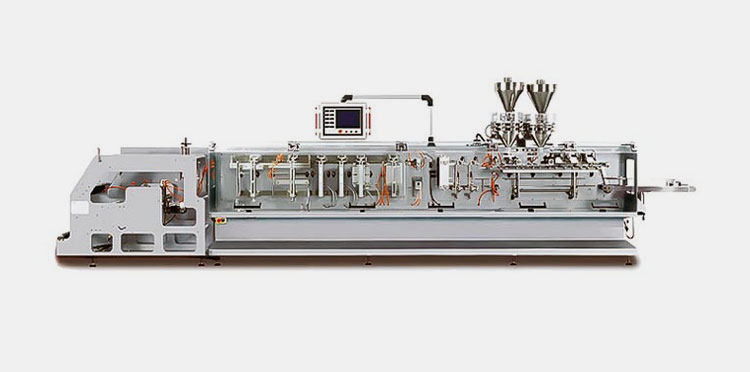

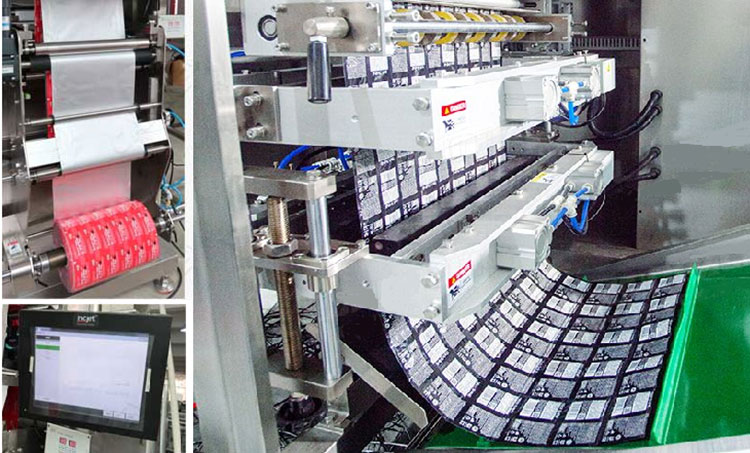

Horizontal sachet pack machine

Allpack Horizontal Sachet Pack Machine

The horizontal sachet pack machine is a composite film automatic packaging machine independently developed for the diversity of packaging materials and the adaptability of packaging bag types. It adopts a horizontal fully automatic bag making, filling, and sealing form.

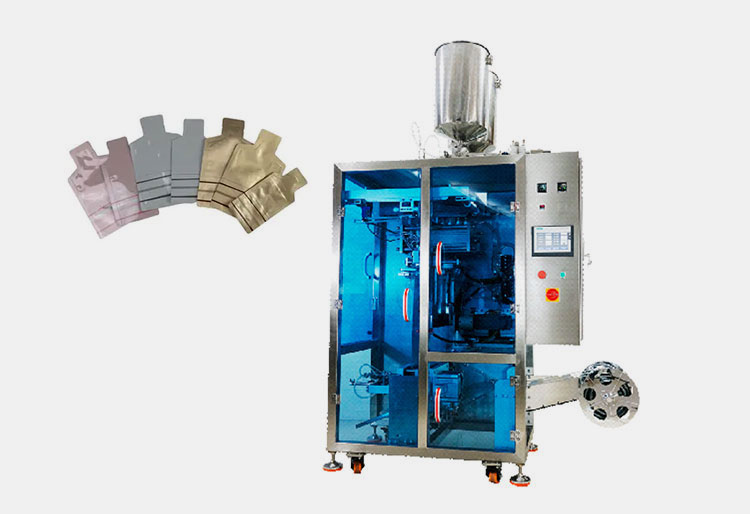

Vertical sachet pack machine

Vertical Sachet Pack Machine - Sourced: samfull.net

The vertical sachet pack machine is an automated packaging equipment, the body is vertical to the ground and the top is facing upwards. It is mainly used for various operations, such as filling, sealing, and labeling packaging bags, and it can automatically detect, count, and weigh during the packaging process.

In a word, both kinds of pack machines have many advantages. If you use a stick pack machine or sachet machine, it will bring you many benefits. The specific details are as follows:

High precision quantitative filling

The sick pack machine and sachet pack machine adopts fully automatic packaging, which can achieve high-precision quantitative filling of materials such as drugs and food.

High efficiency

High Efficiency - Sourced: solitaireconsulting

The sick pack machine and sachet pack machine typically have fast packaging speeds and can quickly complete the packaging of large quantities of materials, greatly improving production efficiency. This high efficiency meets the requirements of modern industry for production speed.

Cost savings

Cost Savings - Sourced: cashflowinventory

The packaging form used by sick pack machine and sachet pack machine is more economical, which can save manufacturers and sellers 35% of costs.

Conclusion

What is the difference between a stick pack and a sachet? You must have your own answer. The decision between stick packs and sachets will ultimately come down to your own requirements. If you want to know more information about a stick pack and a sachet, you can contact to Allpack at any time.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

What is the Difference between a Stick Pack and a Sachet? Read More »

Powder- Sourced: eminenceorganics

Powder- Sourced: eminenceorganics