Stick Packaging Machine VS Sachet Machine

All kinds of products require packaging, and now there are various types of packaging available. Diversified packaging can beautify products and attract customer interest in purchasing. Are you often attracted by the diversified packaging? Among them, stick packaging and sachet are widely used, and we often see them in various occasions.

Both stick packaging machines and sachet machines are common packaging machines, but what is the difference between them? Do you want to know more information about stick packaging machines and sachet machines? So, let’s start to explore these two kinds of machine!

1.What Is Stick Packaging Machine VS Sachet Machine?

To begin with, in order to learn the basic knowledge about stick packaging machine and sachet machine, let’s discuss the definition of them.

Stick Packaging Machine

Allpack Stick Packaging Machine

A stick packaging machine is a kind of device with multiple functions, which can achieve automatic small-doze automatic flexible packaging.

This kind of machine is commonly applied in a lot of industries. They usually use PLC program control and touch human-machine interface, combined with servo system drive, to ensure the accuracy and stability of the packaging process.

Sachet machine

Allpack Sachet Machine

The sachet machine is an automated equipment, which is mainly used for accurately measuring and packaging materials such as liquids, powders and particles into small bags. This type of machine is widely used in industries such as food, medicine, and chemical engineering, which can improve production efficiency and ensure packaging quality.

2.What Are the Applied Industries of Stick Packaging Machine VS Sachet Machine?

Have you often seen stick packaging and sachets in supermarkets? For example, you must have seen instant coffee with stick packaging before. To be honest, the stick packaging machine and sachet machine are applied in various industries. Then, let’s explore them one by one!

Chemical Industry

Desiccants - Sourced: widgetco

As is known to all, chemical products need to be packaged and sealed in a sterile environment. The stick packaging machine and sachet machine can flexibly develop packaging plans to meet the packaging requirements of chemical products, ensuring product hygiene and safety.

The stick packaging machine and sachet machine can package desiccants, pesticides, and other products.

Food Industry

Dove Chocolate - Sourced: facts.net

The stick packaging machine and sachet machine have the capability to efficiently package a wide array of food products, ranging from chocolate and coffee to biscuits and more. These foods usually need to be easy to carry and store, and small bag packaging can well meet this demand.

Pharmaceutical industry

Pharmaceutical Sachet - Sourced: formika

The stick packaging machine and sachet machine can adjust packaging parameters according to the properties and needs of different drugs, such as packaging materials, sealing temperature, packaging speed, etc. These machines are suitable for packaging various forms of drugs such as powder and tablets.

The stick packaging machine and sachet machine ensure accurate drug dosage and reduce errors through precise measurement and packaging techniques.

Cosmetic industry

Cosmetics Sachet - Sourced: freepik

The stick packaging machine and sachet machine have extensive applications in the cosmetics industry, offering significant advantages that bring numerous conveniences and benefits to the sector.

The packaging form is convenient to carry, easy to store, and can enhance the overall aesthetics of the product. In terms of cosmetics, an aesthetically pleasing packaging design can effectively capture the attention of potential consumers.

In a word, after continuous optimization and adjustment, the stick packaging machine and sachet machine are now suitable for various materials and widely used in various industries, improving the safety and aesthetics of products.

3.What Is the Difference Between Stick Packaging Machine and Sachet Machine?

The distinction between stick packaging machines and sachet packaging machines is often blurred due to their numerous similarities, causing confusion for many. Next, I will introduce the differences between them.

Appearance

Stick Packaging Machine VS Sachet Machine

As you can see, the stick packaging machine and the sachet machine have many similarities in appearance. They all have hopper, control panel, filling device, etc.

Nonetheless, the stick packaging machine incorporates a sleek and compact design that caters specifically to the requirements of lengthy stick packaging. The design of sachet machines may be more diverse to accommodate sachet of different sizes and shapes.

Packaging format

Packaging Format - Sourced: musgravemarketplace.ie

The packaging formats produced by these two packaging machines are different. The product packaging produced by the stick packaging machine is slender and long, generally with back sealing.

However, the packaging produced by sachet machines is wider than that of stick packaging, usually with 4 side or 3 side sealing.

4.What Material Do the Stick Packaging Machine VS Sachet Machine Adopt?

You have eaten ketchup, and drink milk powder with stick package or sachet. Whether it is stick packaging machine or sachet machine, they use a wide range of materials.

Powder

Milk Powder - Sourced: bcdairy.ca

The stick packaging machine and sachet machine are particularly suitable for powdered materials such as coffee powder, milk powder, seasoning powder, pharmaceutical powder, sugar, desiccants, etc. They are often disposable products, which is convenient to carry.

Granule

Chewing Gum - Sourced: candywarehouse

Having you eaten chewing gums? Some are packaged with sachet or stick packaging. Moreover, both stick packaging machines and sachet machines can package granular items like candies, grains, and nuts.

Liquid

Ketchup - Sourced: foodandwine

Have you ever eaten fried chips or fried chicken with ketchup? Do you pay attention to the packaging of ketchup? To be honest, in addition to ketchup, the stick packaging machines and sachet machines are also suitable for packaging many liquid materials, such as soy sauce, vinegar, milk, soy milk, beverages, etc.

5.What Are Advantages of Stick Packaging Machine VS Sachet Machine?

Do you know the advantages of stick packaging machine and sachet machine? Their advantages are reflected in the following aspects:

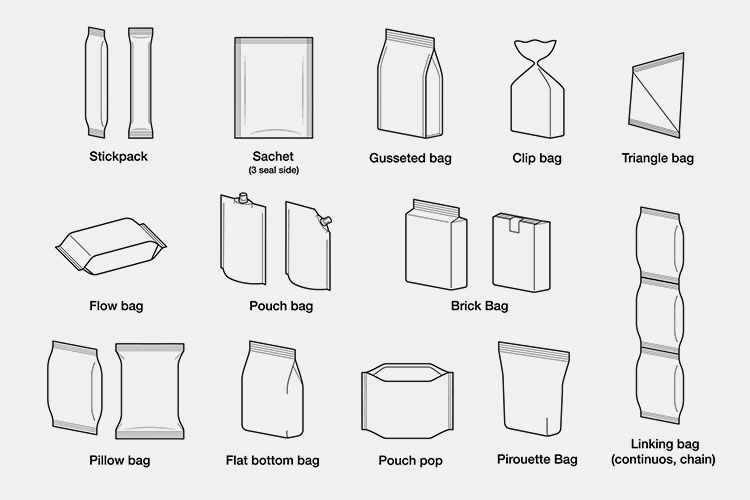

Diverse bag types

Diverse Bag Types - Sourced: xmlinkcn

Stick packaging machines and sachet machines can adapt to products of different shapes and sizes, with a variety of packaging sealing types including back sealing, straight cutting, 3 side sealing, and 4 side sealing.

High degree of automation

In today’s world, fully automatic stick packaging machines and sachet machines are usually equipped with automated control systems, which can automatically complete a series of packaging processes such as measuring, filling, and sealing.

Accurate measurement

Accurate Measurement - Sourced: javatpoint

Utilizing advanced measurement technology, stick packaging and sachet machines guarantee precise and uniform weight or quantity for every packaged product. This accuracy not only minimizes material waste but also enhances material utilization efficiency.

High production efficiency

The two kinds of machines adopt automated operations and reduce manual intervention, improve production efficiency, and lower production costs.

Cost saving

Cost Saving - Sourced: digitaldealer

The use of stick packaging machines and sachet machines can significantly reduce labor costs and save expenses for companies. This device can achieve continuous operation, reduce production interruptions and waiting time, and further reduce costs.

6.What Are the Main Parts of the Stick Packaging Machine VS Sachet Machine?

Do you know the main parts of the stick packaging machine and sachet machine? Let’s move on to this section.

Stick Packaging Machine

The Main Parts of Stick Packaging Machine

| Filling device | It is used for temporary storage of materials to be filled, ensuring the continuity of the filling process. |

| Pouch forming | It is mainly responsible for shaping packaging materials (such as film, paper, etc.) into packaging containers or bags that meet product requirements through certain processes and mechanisms. |

| PLC | As the core device of the control system, PLC is mainly responsible for controlling the logical operations of the entire packaging process. Through pre-set programs, PLC can accurately control the various execution mechanisms of the packaging machine. |

| Seal (vertical seal and horizontal seal) | During the packaging process, vertical and horizontal sealing (horizontal edge sealing) are combined to jointly complete the sealing work of the packaging bag. The sealing quality directly affects the sealing, aesthetics, and service life of packaging bags. |

| Multi lane filling | Filling is a core process in packaging machinery, mainly responsible for filling liquid, granular or powdered materials into packaging containers in predetermined quantities. |

Sachet

The Main Parts of Sachet Machine

| Roll film

|

Roll film is one of the indispensable parts in the automated packaging process. According to the different materials, there are various types of film rolls, such as PVC shrink film rolls, PE rolls, PET protective films, etc. |

| Hopper

|

A hopper is a device used for storing and conveying materials, ensuring that the materials can be continuously and stably supplied to the packaging machine. |

| Filling volume adjustment | Filling volume adjustment is to ensure the accuracy and efficiency of product filling. During the adjustment process, attention should be paid to the interaction and coordination of various components to ensure the stability of the entire system. |

| Bag former

|

The bag former uses high temperature, high pressure and other processes for sealing, printing and other subsequent processing to meet the packaging needs of different industries. |

| Packaging control panel | The main functions of the control panel include setting packaging parameters (such as bag size, inflation rate, etc.), monitoring equipment status (such as running speed, fault information, etc.), and performing necessary operational controls (such as starting, stopping, pausing, etc.). |

| Upper heat sealing | By heating, the contact surface of the packaging material reaches a molten state, and then it is bonded together under pressure to achieve sealing. This process requires control of heating temperature, pressure, and time to ensure the quality of sealing. |

7.What Technology Do Stick Packaging Machine VS Sachet Machine Adopt?

The importance of technology is self-evident, as it plays a crucial role in the entire packaging machine. Let’s explore the packaging technology used by the stick packaging machine and sachet machine.

Technology - Sourced: standards.org.au

The stick packaging machine and the sachet machine adopt two kind of technology: Vertical Form Fill Seal (VFFS) and Horizontal Form Fill Seal (HFFS).

Vertical Form Fill Seal

VFFS usually refers to a packaging technology that package materials (such as plastic film or paper) in a vertical direction. This technology is commonly used to manufacture various vertical packaging bags, and is particularly suitable for dry products such as sugar, grains, etc.

Horizontal Form Fill Seal

HFFS is another packaging technology in which the packaging material is formed horizontally, filled with items, and sealed.

8.The Market of Stick Packaging Machine VS Sachet Machine

You must be curious about the market situation of these stick packaging machine and sachet machine, as detailed in the following analysis.

Market Drivers

Consumer Demand for Stick Packaging and Sachet - Sourced: slimstock

With the increase in consumer demand, industries such as food, medicine, and daily chemicals has provided a broad market space for the packaging machinery industry. The increasing demand for packaging machinery in these industries has driven the growth of the stick packaging and sachet machine market.

Owing to the convenience and distinctive features of stick packaging and sachets, the demand for machines that produce these formats is steadily rising among consumers.

Market Restraint

Stick packaging and sachet may be affected by moisture, which can shorten the shelf life of the product. In addition, some drugs also require sterile packaging, which poses a great challenge to ordinary packaging. Therefore, companies need to ensure product quality based on product requirements.

Market Opportunity

Market Opportunity - Sourced: okcredit.in

At present, the stick packaging machine and sachet machine have undergone significant advancements in incorporating sensors, controllers, and human-machine interfaces. These sophisticated integration enable precision monitoring and seamless automatic adjustments throughout the packaging process, thereby enhancing the overall stability and quality of the packaging operation.

For example, intelligent control systems can automatically adjust equipment parameters to meet different packaging requirements, while achieving fault self diagnosis and early warning, reducing downtime.

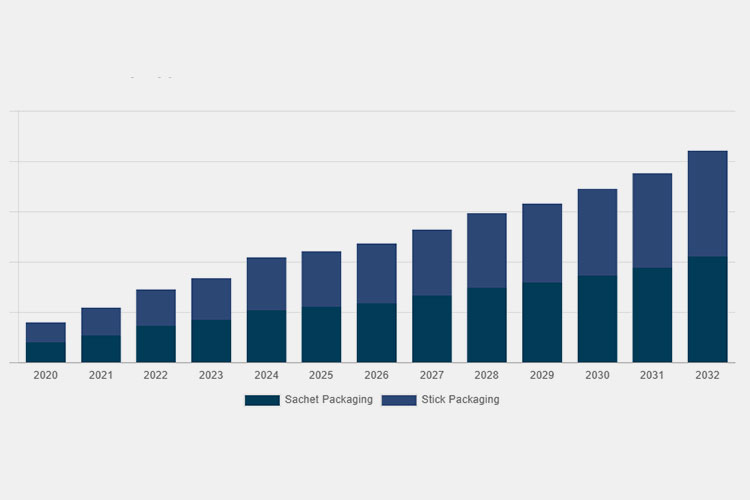

Market of Stick Packaging and Sachet - Sourced: straitsresearch

Based on the figure above, the market share of stick packaging and sachet is similar. In 2023, the market size for stick packaging and sachet machines globally exceeds USD 500 million. It can be seen that the market environment for these two machines is relatively good.

9.Which One is Better? Stick Packaging Machine VS Sachet Machine?

Which packaging machine do you want to choose? There is no good or bad distinction between these two types of machines. Your choice depends on your needs. When you selecting a suitable packaging machine, you requires considering many factors.

Product features

Different Packaging Forms - Sourced: visionhunters

As the picture showed above, there are many packaging forms. So, you should consider the packaging forms of the product, such as stick packaging, sachet, etc., to ensure that the selected packaging machine supports these packaging forms.

You should determine the size range of the product, such as length, width, height, etc., in order to select the appropriate packaging machinery.

Besides, you should pay attention to the weight range of the product and ensure that the packaging machine can handle the required weight of the product.

Price

Before selecting a packaging machine, the first step is to determine your budget range. This will help you quickly screen out devices that meet budget requirements and avoid unnecessary waste.

You should keep in mind that don’t just pursue low prices, but consider the cost-effectiveness of the equipment. Equipment with high cost-effectiveness usually performs well in terms of performance, quality, and after-sales service.

Visit the manufacturer and machine

Visit the Manufacturer and Machine - Sourced: auroratextile

If possible, you can try to conduct on-site inspections at the equipment manufacturer to understand the production environment, manufacturing process, and quality control of the equipment.

You can try to bring samples for machine testing as much as possible to ensure that the equipment can meet its actual production needs.

In addition, you can pay attention to observing and evaluating the performance and stability of the equipment during actual operation.

Conclusion

After reading this article, do you have a general understanding of stick packaging machines and sachet machine? If you want to know more information about how to choose a packaging machine, you can contact Allpack and we will provide you best service.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours