Stick Packaging Machine: The Complete Buying Guide in 2025

When selecting a product, are you attracted by its fine and beautiful packaging? Usually, exquisite packaging can immediately capture customers’ attention and prompt them to learn more about the product. The stick packaging is widely used in many industries because of its exquisite appearance, fine sealing, and portability.

However, in the face of a wide range of stick packaging machine on the market, how to buy a suitable equipment for you production needs has become a big problem. Do you want to buy good quality products at affordable prices? Are you looking for a complete buying guide for a stick packaging machine? The following article will give you some help.

1.The Development of Packaging.

Have you ever been curious about how the packaging we see in our daily lives has evolved step by step to this day? The development of packaging goes through several stages, which include primitive packaging, industrial packaging, and modern packaging.

Primitive packaging stage:

Leave Packaging - Sourced: forbes

It can be traced back to ancient times, people used leaves, shells and animal skins as packaging materials. This type of packaging is simple and easy to obtain, and it is still used in certain places and on specific occasions today.

Industrial packaging stage:

Cardboard Box - Sourced: wikipedia

Stick Packaging

The Industrial Revolution witnessed the changes in packaging. The packaging industry is gradually developing and more diverse packaging forms have emerged, including stick packaging, cardboard boxes, and corrugated paper.

Modern packaging stage:

Recyclable Packaging - Sourced: europlas

Environmental protection and sustainable development have become important development directions in the packaging industry, which led to a shift towards more sustainable packaging solutions, including biodegradable materials, recyclable plastics, and composite packaging.

2.What Is a Stick Packaging Machine?

Allpack Stick Packaging Machine

Just as its name implies, the stick packaging machine is a machine that can produce stick packaging, also called the stick pack machine. The stick packaging machine is typically used for packaging powders, granules, or liquids.

3.What Are the Benefits of the Stick Packaging Machine?

If you use a stick packaging machine in your company, it will bring you many benefits. The details are as follows.

- Cost-effective

Cost-effective - Sourced: retroshirtz

Due to its high degree of automation, the stick packaging machine can save a lot of labor and time costs.

- High-speed/efficiency

Efficiency - Sourced: filecenter

By adopting advanced technologies, the stick packaging machine has a faster packaging speed. Currently, the production of packaging machines can approach 120-240 bags per minute, greatly exceeding the production of handmade products.

- High-precision

The stick packaging machine adopts electronic weighing technology, which can achieve high-precision measurement and packaging. In this way, it ensures that the weight and volume of each packaged product meet the preset standards, thus improving the quality and consistency of the product.

4.Which Industry Needs the Stick Packaging Machine?

Nowadays, various stick packaging can be seen everywhere in our lives. The stick packaging machine has been applied to multiple industries, such as food, pharmaceuticals, cosmetics, healthcare and agriculture.

Food Industry

Coffee Stick Packaging - Sourced: shopblends

It can be seen everywhere that many foods adopt stick packaging. Stick packaging machines are widely used in the food industry, mainly used to produce single-use products, including:

- sugar

- coffee

- ice cream

- honey

- tomato sauce

- milk

Pharmaceutical Industry

Cold Granules

For the convenience of carrying and using, stick packaging machines are used for small-dose pharmaceuticals, mainly including:

- cold granules

- anti-inflammatory granules

- Chinese medicine granules

These pharmaceuticals need to be measured accurately and packaged in sealed packages to ensure the effectiveness and safety of the pharmaceuticals.

Cosmetic Industry

Cosmetic Stick Packaging - Sourced: glamour

In the cosmetics industry, stick packaging machines are mainly used for small packaging products. As the stick packaging machine can provide portable and convenient packaging solutions, it is suitable for packaging a variety cosmetics with small doses, including:

- shampoo

- conditioner

- lotion

- cream

- facial cleanser

This form of packaging is not only convenient to carry, but also helps to enhance the sales appeal of the product and meet the consumer’s demand for ease of use.

Healthcare Industry

Powdered Protein - Sourced: bestbodiesforlife

With people’s concern for health, the healthcare industry has gradually emerged. Today, the stick packaging machine can produce many packaging for healthcare products, including:

- powdered protein

- vitamins, enzyme

- probiotics

These products often need to be accurately measured and packaged to ensure that each serving meets the specified nutritional content.

Agricultural Industry

Vegetable Seeds - Sourced: learningwithexperts

The stick packaging machine plays a significant role in the agricultural field, and can produce various packaging for agricultural products, including:

- vegetable seeds

- pesticide

- herbicide

5.What Are the Parts of a Stick Packaging Machine?

The Parts of Allpack Multi-lane Stick Packing Machine

The normal operation of a stick packaging machine requires many parts. When you study the parts of the stick packaging machine, you will find that they are not only the crystallization of technology, but also a symbol of wisdom. The specific parts are shown in the following figure.

Filling device

The main function of the filling device is to store the materials to be packaged. During the production process, the device needs to ensure that materials can be stably supplied to other parts of the packaging machine, so as to ensure the smooth packaging process.

Pouch forming

Pouch forming

The main function of pouch forming is to transform the material into the required shape and size of the packaging, and adjust the parameters of the forming system, such as the shape and size of the forming plate.

During the process of material entering the forming system, it is usually necessary to undergo heating treatment to soften or melt the material for better processing and forming.

Servo pouch pulling

Through the precise servo motor and controller, the precise control of each parts of the packaging machine is realized.

Vertical seal

In the manufacturing process, the packaging material is unfolded and cut along its length to form a series of stick materials with equal width. By vertical cutting, packaging bags with variable length but fixed width can be obtained.

Horizontal seal

During the manufacturing process, the vertically cut stick material is transported to the cutting area and cut horizontally to form a certain length of packaging bag.

Multi lane filling

It can simultaneously process and fill multiple lanes of packaging materials to produce stick packaging simultaneously. This design significantly improves packaging efficiency and allows for faster processing of large quantities of products.

PLC control system

Programmable logic controller, used to achieve complex control logic and automated operations. There is a machine interface on the control panel, which allows the operators to monitor and adjust various parameters, such as filling quantity, sealing temperature and speed.

6.What Is the Working Principle of a Stick Packaging Machine?

Are you curious about the working principle of stick packaging machine? Let’s reveal the details behind it.

Working Principle of the Stick Packaging Machine

Material supply

Powder - Sourced: canadianpreparedness

The materials (including powder, liquid and granules) are automatically, and uniformly transported to the predetermined position of the packaging machine through a feeding system (such as a vibrating disc and screw feeder).

Measurement and filling

After the material reaches the predetermined position, the packaging machine measures the material through precise measuring devices (such as electronic scales and volumetric meters) to ensure that the amount of material in each packaging unit meets the preset requirements.

After the measurement is completed, the material will be automatically filled into the prepared packaging material.

Sealing and Forming

After filling is completed, the packaging machine will automatically seal the packaging material. This usually involves different sealing techniques such as heat sealing, cold sealing, ultrasonic sealing, depending on the packaging material and product characteristics.

And then, the stick packaging machine shapes the packaging material into a predetermined stick shape through forming devices (such as forming plates and forming wheels).

Cutting and output

The formed stick packaging will be cut into individual packaging units through cutting devices (such as rotary knives and hot cutting knives.). These packaging units will be automatically transported to the output area.

7.What Are the Different Types of the Stick Packaging Machine?

Based on different classification methods, the stick packaging machine will be divided into several types. The specific type are shown in the table below.

| Classification Method | Type |

| Product line | single-lane stick packaging machine |

| multi-lane stick packaging machine | |

| Level of Automation | semi-automatic stick packaging machine |

| fully automatic stick packaging machine |

(1)product line

- Single-lane stick packaging machine

Allpack Single-lane Stick Packaging Machine

A single-lane stick packaging machine is simple in design and has only one lane for the packaging process. It is suitable for small-batch production or packaging processes that require manual intervention.

- Multi-lane stick packaging machine

Allpack Multi-lane Stick Packaging Machine

A multi-lane stick packaging machine adopts a multi-lane design, which can be 2 lanes, 4 lanes, 6 lanes, or even 12 lanes. Each lane can complete the packaging process independently. This type of packaging machine greatly improves productivity and reduces the need for manual labor, making it suitable for mass production.

(2)level of automation

- Semi-automatic stick packaging machine

Semi-automatic Stick Packaging Machine

A semi-automatic stick packaging machine is a kind of mechanical equipment used for product packaging, which combines automation technology with manual operation to achieve partial automation of the packaging process.

- Fully automatic stick packaging machine

Fully Automatic Stick Packaging Machine

The fully automated stick packaging machine requires almost no manual intervention throughout the entire packaging process and is used for continuous, high-speed, and precise packaging of various products.

8.Which Filler Can Be Used for the Stick Packaging Machine?

Liquid filler

Liquid Filler

Liquid fillers are usually used for filling liquid products into packaging, such as water, fruit juice, oil, honey and other substances. There are many types of liquid fillers and each is suitable for different types of liquids.

Auger filler

Auger Filler

Auger fillers are used to measure and dispense the product into packaging with high precision. Auger fillers are often used in the packaging of products like spices, flour, coffee, pharmaceutical powders, and powdered chemicals.

Granule filler

Granule Filler

Granule fillers are designed specifically for filling granular materials into packaging. These fillers are often used in industries that deal with products such as grains, seeds, nuts, granulated sugar, salt, and similar products.

9.What the Types of Bags Will the Stick Packaging Machine Create?

You must have seen many types of bags. According to the different needs of customers, the stick packaging machine can create many types of bags.

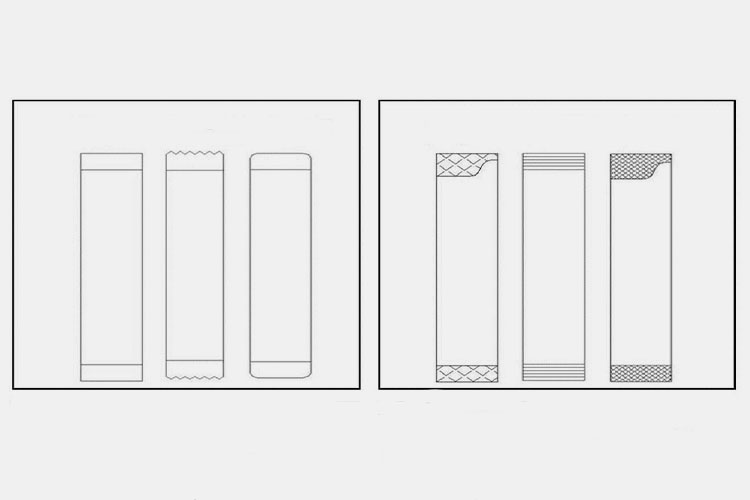

The Types of Bags - Sourced: vikingmasek

Cut type options

- Straight cuts:This shape has the advantages of low cost and high efficiency, but it is not suitable for products with high sealing requirements because of its relatively poor sealing performance.

- Serrated:The serrated shape of the stick packaging increases the sealing strength of the packaging and has a unique appearance

- Round:It is a kind of widely used stick packaging, characterized by the use of a round design in the sealing part, which not only has aesthetic appeal but also ensures the sealing and safety of the product.

Seal type options

- Diamond:The use of a diamond-shaped structure for sealing provides a unique appearance and appeal to the product.

- Serrated:This design is widely used in the packaging industry, as the stick shape has good elasticity and can better adapt to different shapes and sizes of products.

- Micro-diamond:This shape is similar to a diamond shape, but has better sealing than a diamond shape.

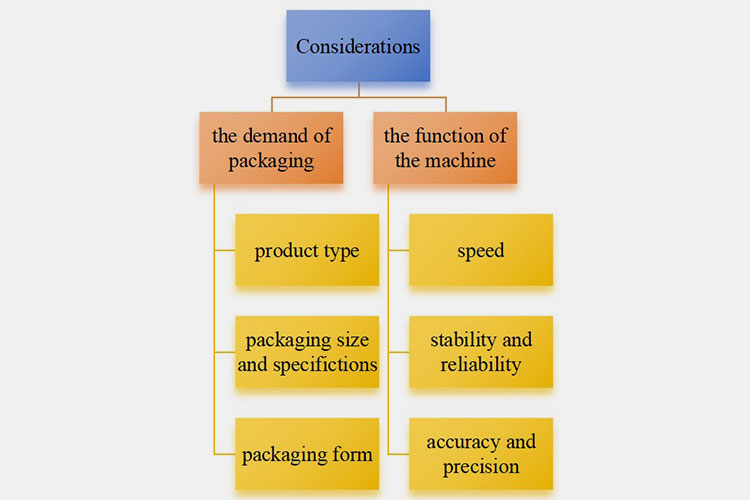

10.What Should You Consider When Buying a Stick Packaging Machine?

After understanding the basic knowledge of the stick packaging machine, you must be in a dilemma when facing the machines varied considerably in quality. The following will introduce some considerations for you when you choose a stick packaging machine.

What Should You Consider? - Sourced: inc

(1)The demand of packaging

- Product type:Determiningthe product type to be packaged, such as food, medicine and cosmetics. Different types of products may have different requirements for packaging machines.

- Packaging size and specifications:Determiningthe size and shape of the products to be packaged, so as to select the appropriate packaging machine model.

- Packing form: Determining the packaging, which will affect the configuration of the packaging machine.

(2)The function of the machine

- Speed:Selecting suitable packaging speed according to production.

- Stability and reliability: Consideringthe stability and reliability of a stick packaging machineto avoid frequent failures affecting production.

- Accuracy and precision: Ensuringthat the packaging machine can accurately complete the packaging process, such as sealingand cutting.

Considerations of Buying a Stick Packing Machine

11.How to Choose Reliable Stick Packing Machine Manufactures?

At present, there are more and more stick packaging machine manufacturers. To be honest, choosing a right manufacturer is like finding a reliable partner, which directly affects the quality of products and the competitiveness of the enterprise.

A wise choice can not only ensure the stable operation of the business, but also bring long-term development momentum to the enterprise. When choosing a reliable manufacturer, you should consider several factors, including their strength, reputation, and after-sales service.

The strength and reputation of manufactures

Reliable Manufacturer - Sourced: manusis4

A reliable stick packaging machine manufacturer usually has a certain production scale, technical strength, and rich industry experience. You can evaluate the strength of the manufacturer by checking their official website, visiting the factory, and learning about customer cases.

After-sales service

After-sales Service - Sourced: responsive.io

After-sales service is a vital factor that cannot be ignored when you choose a reliable stick packing machine manufacturer. A reliable manufacturer should provide comprehensive after-sales service, including equipment installation, training, and maintenance.

When choosing a manufacturer, you can learn about their after-sales service policy, service response time, and customer feedback.

12.How to Maintain and Repair a Stick Packing Machine?

If you don’t operate the stick packaging appropriately, you will cause many problems , so the following will introduce some common problems and solutions.

Maintain and Repair of a Stick Packing Machine - Sourced: gocodes

Problem 1: Packaging material cannot be delivered or stuck properly

Solutions:

(1)You can check whether the feeding device is blocked or damaged, and clean or replace it in time;

(2)You can adjust the tension of the feeding device to ensure smooth feeding of packaging materials;

(3)You can check whether the specifications and quality of packaging materials meet the requirements, and avoid using materials that do not meet the standards.

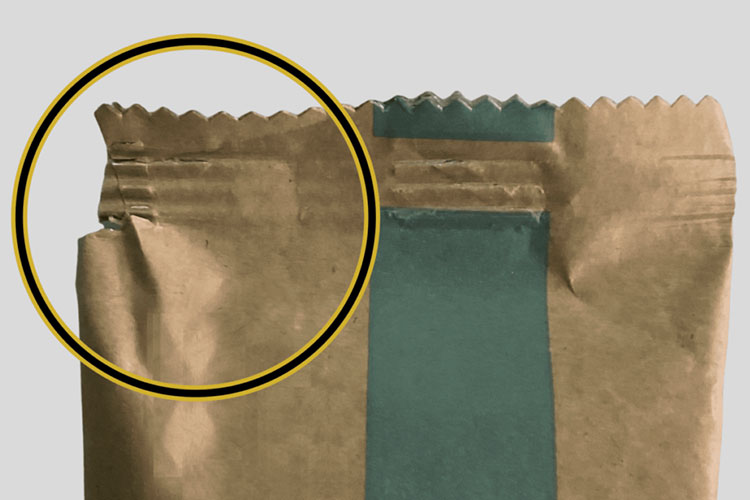

Problem 2: Poor sealing or material leakage

Poor Sealing -Sourced: greenercorp

Solutions:

(1)You can check whether the pressure of the sealing device is sufficient, and increase the pressure appropriately can improve the sealing quality;

(2)You can check whether the sealing device is damaged or worn, and replace the worn parts in time;

(3)You can check whether the packaging materials are flat, because uneven materials can cause poor sealing.

Problem 3: Unstable machine operation or noise generation

The Noise of Machine - Sourced: justrite

Solutions:

(1)You can clean the dust and debris inside the machine and keep it clean;

(2)You can check whether the transmission components are worn or damaged, and replace the worn components in time;

(3)You can check whether the motor and reducer are working normally.

Problem 4: No response or abnormal display on the touch screen

Solutions:

(1)You can check whether the power supply and connection wires of the touch screen are normal, and ensure that the touch screen is powered on normally;

(2)You can restart the touch screen or packaging machine to see if it can be restored to normal;

(3)You can check whether the settings and parameters of the touch screen are correct, and adjust them promptly if there are any errors.

If all the above methods are ineffective, you may need replace the touch screen or contact professional personnel for repair.

13.The Future of the Stick Packaging Machine.

The future development prospects of stick packaging machines look quite optimistic, which is mainly due to several important trends and factors.

- Intelligent development

Intelligent Development - Sourced: elearningindustry

With the advancement of technology, stick packaging machines will increasingly integrate technologies such as automation, IoT, and AI. The application of these technologies will achieve automation, tracking, and monitoring of the production process, thereby improving production efficiency, reducing labor costs, and optimizing product quality.

- Innovation and upgrading

In order to meet the needs of different industries, manufacturers of stick packaging machines will continue to innovate and upgrade. This includes the development of new packaging materials, improvement of mechanical structures, and optimization of the control systems.

- Market demand growth

Food Stick Packaging

With the development of the global economy and the increase in consumer demand, the rapid development of industries such as food and beverage, pharmaceuticals, cosmetics will bring broad market space to the stick packaging machine market.

Especially in emerging markets and developing countries, with the improvement of people’s living standards and changes in consumer attitudes, the demand for packaging machinery will continue to grow.

Conclusion

After looking through this article, have you gained something about the stick packaging machine? If you have any questions, Allpack are available 24/7 to provide more detailed information about the stick packaging machines for you.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you within 24 hours.