Sterilization Vs Pasteurization:What Are The Difference?

Have you ever wondered the sanitary of your food, medicines and drink? If you have the conscious of taking the qualified products, then you may know sterilization and pasteurization. This two are the irreplaceable way for proving your products quality and sanitary. So how much you know about this two disinfection method.

What are the difference between sterilization and pasteurization? How much you know about this two type? Where are they applied? What are their disinfecting manner? Here you may have the comprehensive understanding about sterilization and pasteurization. Come on and have a reading!

1.What Is Sterilization And Pasteurization?

Sterilization and pasteurization are two frequently used disinfecting method for us. How to determine them? Check this.

Sterilization

Sterilization-Sourced:outsource

Sterilization adopts the thermal processing to eliminate the various bacteria. As bacteria cannot survive in the high temperature, the sterilization can clear up the affecting bacteria and leave the products away from the affect of bacteria. Usually, it can prolong the shelf life of products for several months.

Pasteurization

Pasteurization-Sourced:finamac

Pasteurization also applied the heat treatment for the products preserve. Instead of eliminating the whole bacteria, it creates the environment which benefits some bacteria and hurt other bacteria. The saved bacteria will benefit the products save and resist the pollutants for products.

2.Why You Need Sterilization And Pasteurization?

Why you need sterilization and pasteurization? The sterilization and pasteurization are two important factors for your products saving. And here are the reasons.

Products quality

Products Quality-Sourced:amautoclave

Sterilization and pasteurization are the methods which help prove the products quality and inhibit the microbe or other affecting bacteria. It decreases the possibility of deterioration and makes the products of great state for you.

Longer shelf life

Longer Shelf Life-Sourced:cpdonline

Sterilization and pasteurization can prolong the shelf life of products as it eliminates the active bacteria and makes the great protection of the pollution. It can store longer and have the shelf life longer too.

Sanitary prove

Sanitary Prove-Sourced:terrafoodtech

The heating process of sterilization and pasteurization can eliminates the affecting bacteria. The clean and bacteria free products with little affecting of pollutants can have the sanitary proved better.

3.The Common Types Of Sterilization And Pasteurization

For sterilization and pasteurization, there may be various types and methods for each. And here are the common types of sterilization and pasteurization.

Sterilization

Ultra-High-Temperature (UHT) Sterilization

Ultra High Temperature Sterilizer-Sourced:fruitprocessingmachine

Ultra high temperature sterilization means to make the sterilization by exposing the products to high temperature with a short period. It makes sure the aseptic condition of products before it is opened.

Retort Sterilization

Retort sterilizer-Sourced:retorts

Retort sterilization is the sterilization which can be applied in home. After placing the products in the container, you can then boiled it in high temperature. With high temperature and high pressure, it can be sterilized. The common use of it can be found in can production.

Cold physical sterilization

Bacterial Filters-Sourced:qmedicalindustries

Cold physical sterilization involves the sterilization with bacterial filters and radiation. You may apply the non-ionizing ultraviolet radiation, ultrasound and ionizing rays for sterilization use. The strong penetrating of the radiation makes the long shelf life of products.

Chemical sterilization

Chemical Sterilization-Sourced:pharmacyscope

There are various chemical products for chemical sterilization. And you may apply phenol derivatives, aldehydes, alcohols, oxidants, surfactants, guanidine compounds, acids and bases for chemical sterilization.

Pasteurization

Short Time/High Temperature (HTST) pasteurization

HTST Pasteurizer-Sourced:csidesigns

Short Time/High Temperature (HTST) pasteurization is one of the most common pasteurization process which means to make the high temperature in short period. There is strict standard in the this process.

Ultra-high temperature (UHT) pasteurization

UHT Pasteurizer-Sourced:wikipedia

Ultra-high temperature (UHT) pasteurization means to heating the material in high temperature. The temperature is usually around 63°C. You may have almost all bacteria killed in this high temperature.

Low-temperaturelong-time (LTLT) pasteurization

LTLT Pasteurizer-Sourced:foodtechinfo

In contrary with make the pasteurization under high temperature, LTLT pasteurization refers to kill bacteria in low temperature and long time. You should usually take 30 minutes to make the pasteurization. And its affect is great.

4.Sterilization Vs Pasteurization, What Are The Difference?

What are the difference between sterilization and pasteurization? Can you make the casual interchange? Here is the detailed difference.

Sterilization Vs Pasteurization

| Sterilization | Pasteurization | |

| Storing temperature | Products from sterilization can be stored in the higher temperature. | Products from pasteurization should be stored in fridge for the microbe inhibiting. |

| Organoleptic properties | The high temperature of sterilization may in some way affect the flavor and decrease the nutrition. | The low temperature of pasteurization contains the nutrition and favor of products. |

| Shelf life | Products of sterilization can be stored longer as it has all microbe and bacteria destroyed. And the shelf life is usually 4 months. | Products of pasteurization has shorter shelf life compared with sterilization. The leaving bacteria required the low temperature to be saved suitably. |

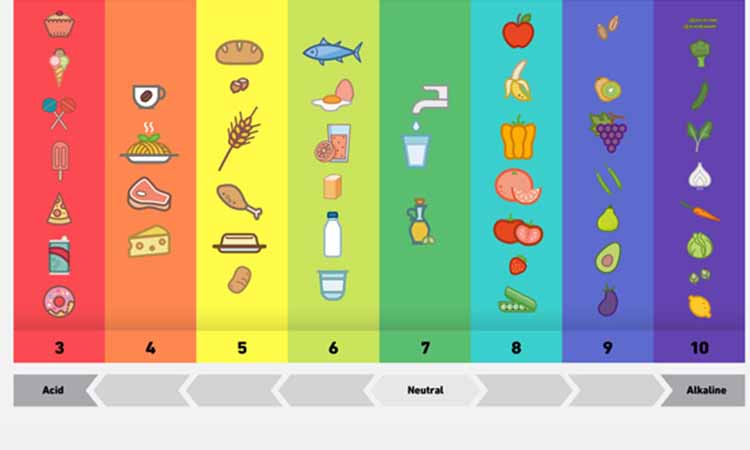

| Food PH and acidity | Food PH and acidity affect in many way the disinfecting manner. The food with higher PH and acidity required the sterilization which usually gives the high temperature. | Food PH and acidity which is neutral or acid may be better cared with pasteurization which makes the low temperature dealing. |

| Microbe destroy | Sterilization destroyed all types of microbes to make the complete sterility environment. | Pasteurization killed the affecting microbes and left some beneficial one alone. |

| Industry application | Sterilization can be widely used in laboratory equipment, pharmaceutical industry, dietary industry, can industry and dentist industry and so on. | Pasteurization is usually applied in food industry, drink industry, dietary industry and so on. |

| Equipment applying | Sterilization usually applied tubular heat exchangers and plate heat exchangers for its disinfecting equipment. | Pasteurization usually applies plate heat exchangers and tubular heat exchangers as its disinfecting equipment. |

| Cost | Sterilization equipment costs more compared with pasteurization equipment and it consumes more in disinfecting process. | Pasteurization makes less expense in equipment and energy consuming. |

| Environment affect | As sterilization consumes more in energy, it has larger environment affect for world. | Pasteurization consumes less and is thus more friendly to environment. |

5.How DoesSterilization And Pasteurization Work?

How does sterilization and pasteurization work? Here is the working process of sterilization and pasteurization.

Sterilization working

Sterilization Working-Sourced:lso-inc

As the many types of germs and microbes have the different heat resisting ability, sterilization adopts the strong heating process to eliminate the all bacteria. The high temperature of sterilization changes the structure of microorganisms and makes damage to microbe’s important parts. At the main time, the nutrition and flavor may change in the process.

Pasteurization working

Pasteurization Working-Sourced:brewersassociation

Pasteurization makes the same process as sterilization. Pasteurization applies the precisely moderated temperature and the strict time combination to eliminate the microbe or germs which may lead the spoiling of products and stay the microbes which maintain the nutrition and special flavor of food.

6.What AreAdvantages And Disadvantages Of Sterilization And Pasteurization?

What are the advantages of sterilization and pasteurization? Of course, they benefit your products in a comprehensive way. Their advantages and disadvantages are also different.

Advantages And Disadvantages-Sourced:communityinfest

| Advantages | Disadvantages | |

| Sterilization | The sterilization products can be saved for more than 4 months without the fridge conserving. | The high temperature of sterilization may destroy the fragrance, taste and nutrition. Your products may have the |

| Pasteurization | The pasteurization won’t have taste or fragrance changed too much. And the products can maintain its foremost state. | The shelf life of pasteurized products is shorter and you should save it in fridge. With spores not delete in the state, the products may have features change later. |

7.Where Sterilization And PasteurizationAre Frequently Used?

Where can sterilization and pasteurization be frequently used? They are mostly applied in food industry, and you may find the common products as follow.

Drink

Drink-Sourced:anticoro-babik

For the various fruits drink and beer, the sterilization and pasteurization are two common methods which can be applied in the process. They can help prolong the life and maintain cleaning of the two.

Can food

Can Food-Sourced:glassmania

Can food is the representative sterilized products. For fish food, vegetable food, tomato food and many other can, you can apply sterilization for the can food and prolong the shelf life of this products.

Jam

Jam-Sourced:sairem

The jam has also the various kinds and you can also apply the sterilization for the disinfecting. You can also get the home made sterilization manner for your home made jams.

Milk and its derivatives

Milk And Its Derivatives-Sourced:nutritionistandreadelseppia

For milk and its derivatives like cheese, yoghurt and various dairy products, the pasteurization is the preferred sterilizing manner. Your milf and dairy products will get better save and sterilized this way.

Wine

Wine-Sourced:wikipedia

You may find your various wine, alcoholic drink and beer have all experienced pasteurization process. After the processing, it may be stayed longer and can have its flavor and taste maintained.

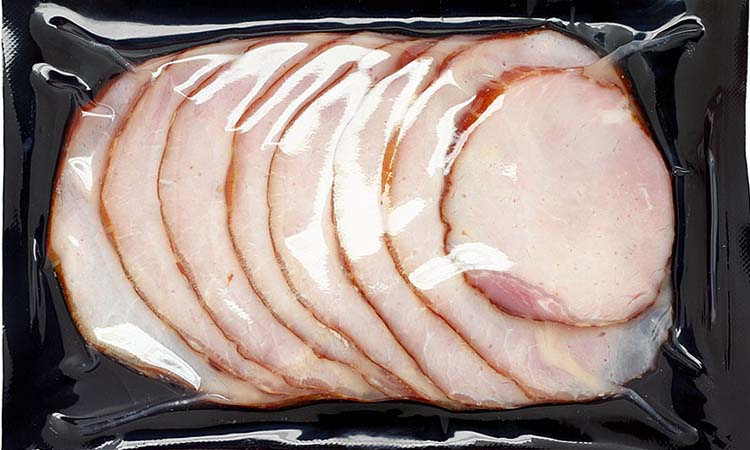

Meat

Meat-Sourced:provisioneronline

Meat is the important food for food industry. And sterilization is the irreplaceable parts for meat dealing. You may adopt the various sterilization and pasteurization method for the meat dealing.

Medical equipment

Medical Equipment-Sourced:allstatesmed

For pharmaceutical industry and laboratory equipment, there are high standard on sanitary. And pasteurization is the great way to deal with medical instruments, drugs, labware and so on.

8.What EquipmentAre Applied In The Sterilization And Pasteurization Work?

What equipment are applied in the sterilization and pasteurization work? Here are the some equipment for its use.

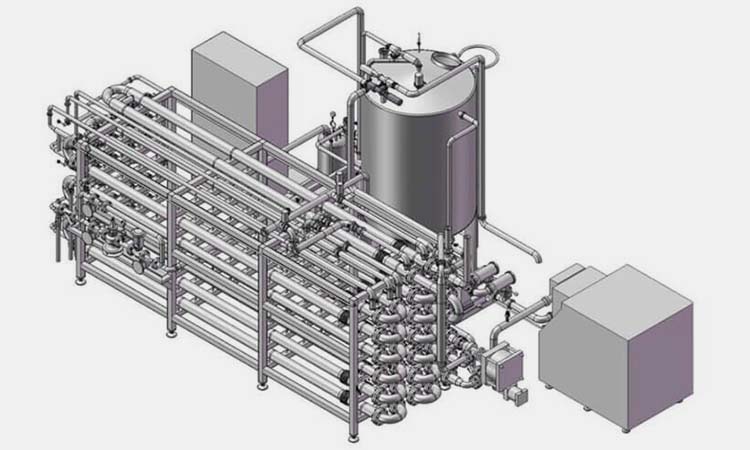

Sterilization

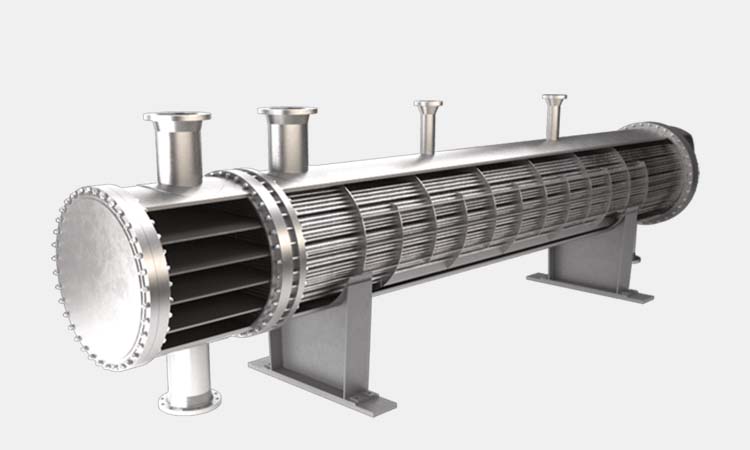

Heat exchanger

Heat Exchanger-Sourced:syncquip

Here are tubular heat exchanger and plate heat exchanger as the representative sterilizing methods. As sterilization applied the heat processing frequently, the two methods are essential.

Autoclaves or retorts

Autoclaves Or Retorts-Sourced:allpax

Autoclaves or retorts are used to make food processing and sterilized food to meat the standard. It has the various type and you may get one according to your need. It makes the sterilization with steam.

Pressure cookers

Pressure Cooker-Sourced:making

Pressure cooker is the equipment which deal with various products with high pressure. It is the equipment frequently applied in sterilization or cooking. And there are various pressure cooker type or you to choose.

Pasteurization

Pasteurization vats or tanks

lPasteurization Vats-Sourced:libertyviewcreamery

Pasteurization vats and tanks are the professional sterilization equipment for sterilization applying. The equipment is composed by the fragile and precise parts for the smooth and deep pasteurization.

Heat exchanger

Heat Exchanger-Sourced:aager

Heat exchanger is typical equipment which is used for the liquid like milk pasteurization. It makes the heat exchange between liquid and hot water which makes the qualified pasteurization.

9.How To Choose Your SuitableDisinfecting Manner?

The two disinfecting manner of sterilization and pasteurization, which one you should select. As the two are totally different, here is the way for you to choose your suitable disinfecting manner.

According to your products

According To Your Products-Sourced:recipes

What is your products? Can your products benefit from the refrigerating? The choose of your disinfecting type should conform to the products biggest feature. And your sterilization manner should maintain its nutrition and taste in the large sphere.

According to the PH of food

According To The PH Of Food-Sourced:technologynetworks

Products of different PH has different request on disinfecting manner. For food with the neutral PH, you should give its disinfecting with the temperature above 100ºC. And for food with the acid PH, you would better to make the sterilization below 100ºC.

According to container type

According To Container Type-Sourced:houseofcans

The container you applied can help you decide the disinfecting manner. There are glasses can and plastic container for you to choose. There are different container lid for sterilization and pasteurization. And for sterilization lid, it can usually withstand the temperature below 100ºC, and for pasteurization lid, the temperature can go above 100ºC.

According to shelf life

According To Shelf Life-Sourced:chapeltonboard

The products shelf life of sterilization and pasteurization are also different. For sterilized products, it can have the shelf life of more than four months. And for the pasteurized products, you would better to consume it in two or three weeks. It has the shorter shelf life.

10.What Are The Suitable Packaging Of Sterilization And Pasteurization?

Are you in the confuse of getting the suitable packaging of sterilization and pasteurization. Here are some typical packaging for sterilization and pasteurization.

Plastic packaging

Plastic Packaging-Sourced:arka

For plastic packaging, there are polyvinylidene chloride, polyvinyl chloride and polypropylene for you to choose. There are different permeability of different plastic packaging material and you may get the suitable one according to your products type.

Glasses packaging

Glasses Packaging-Sourced:feemio

Glasses packaging is also the welcomed packaging type for sterilization and pasteurization. You may find its widely application in can food packaging. There are soup, pickles, preserves and so much food which apply glasses packaging for the better conserving and displaying.

Metal packaging

Metal Packaging-Sourced:campdenbri

Metal packaging is usually applied in food and pharmaceutical industry. It can stand the various disinfecting method and makes the great taking of meat, fruits, vegetables and so much products.

11.What You Should Pay Attention To InSterilization And Pasteurization Process?

The sterilization and pasteurization make so much benefits to our health and convenience. What you should pay attention to in sterilization and pasteurization. Here are some tips.

Nutrition loss

Nutrition Loss-Sourced:balancenutrition

Sterilization and pasteurization may lead the nutrition loss as the high temperature may lead the nutrition change. For the food or product which cannot have nutrition and favor change, you would better to apply the sterilization and pasteurization with low temperature.

Fermentation unstable

Fermentation Unstable-Sourced:fermentingforfoodies

Pasteurization breaks down the bacteria for fermentation. For food with rich sugar like honey and beer, the leak of relative fermentation disinfecting may accelerate the spoiling of food.

Bacteria and flora developing

Bacteria And Flora Developing-Sourced:thoughtco

Unlike sterilization, pasteurization leaves some bacteria and flora. While in high temperature, the bacteria and flora keep developing and make the terrible affecting for food conserving.

Suitable maintaining

Suitable Maintaining-Sourced:nycfoodpolicy

For products of pasteurization, you should pay attention to its conserving manner. The low temperature can withstand the developing of bacteria which may lead the spoiling and so on.

12.Are There Other Disinfecting MethodBesides Sterilization And Pasteurization?

Are there other disinfecting method besides sterilization and pasteurization for disinfecting manner. You may check here for the relative advice.

Chemical preservation

Chemical Preservation-Sourced:hotelmariahilf

Chemical preservation is used to retard of hinder of the microbe and bacterial. And in this way, the food can be better preserved. There are natural food constitutes and chemical compounds for chemical preservation. You may find sugar, salt, wine, ascorbic acid, sulfur dioxide, sulfites and so on for chemical preservation use.

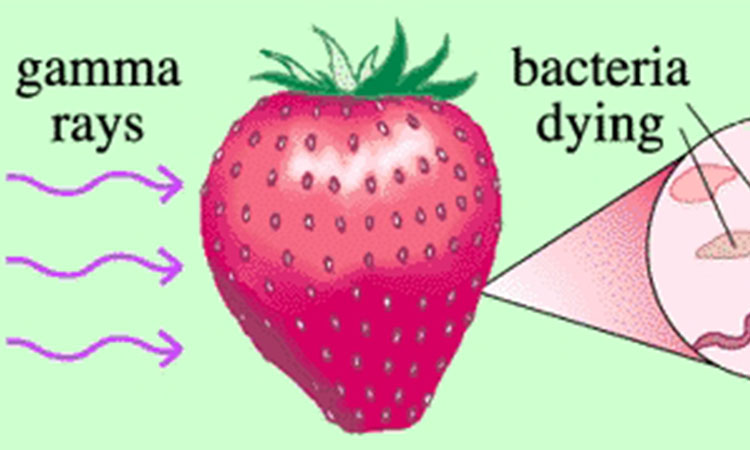

Irradiation

Irradiation-Sourced:teachnlearnchem

Irradiation is frequently used in food industry. X-rays and gamma rays of food irradiation can help destroy the molecule, bacteria, molds and pests. All in all, it is useful and efficient in dealing with food problem.

Lyophilization

Lyophilization-Sourced:vandrunenfarms

Lyophilizer applied the moist steam under pressure to make the sterilizing and lyophilizing. The process is just like high pressure sterilization. And the freeze dried food can better stored and has the longer shelf life.

Conclusion

What are the differences of sterilization and pasteurization? Here is the comprehensive answers. The two disinfecting manner help you so much in the various industry. And if you have any problems or questions about sterilization and pasteurization, you may just contact ALLPAK.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide