Spirits Packaging: The Complete FAQ Guide In 2025

The demand for sustainable, quality, and resilient packaging is growing day by day especially for liquids. Similar is the case with spirits which are too in need of effective packaging to retain its quality and freshness for large span of time. Are you also interested in the spirits packaging? If yes! We welcome you to this detailed FAQ guide about spirits packaging.

Spirits packaging not only extend the shelf life of spirits, but it also gives you an opportunity to take your favorite spirits with you on outing and anywhere you want without any fear to be wasted or degraded. Not only that, spirits packaging also has other aspects to be discovered including the vast range of packaging options, machinery, labeling, and troubleshooting etc. So, let's uncover these all, in one go!

1.What Is Meant By Spirits Packaging?

Various spirits bottles-Picture Courtesy: packagingoftheworld.com

You may not be unfamiliar to the alcoholic drinks commonly admired in your surrounding such as whiskey, vodka, rum, and gin etc. All these drinks are simply referred as spirits which are made from the distillation of various fruits, grains, and other materials.

These spirits are free flowing liquids and having high acidic nature due to which their preservation is done quite responsibly. This process of preserving spirits is known as spirits packaging which involves using resilient packaging options such as bottles, cans, and bags etc.

Spirits packaging greatly contributes to the protection of spirits against environmental hazards and wastage during transit. It also extends the spirits shelf life, promote convenience in their handling, and most prominently allow manufactures to get their brands recognition across the globe.

2.Enlist The Vary Advantages Associated With Spirits Packaging?

Packaging is inevitable for the preservation of spirits. But it holds in it several attributes which can be used for making your business more lucrative. Some of these benefits are as follows:

Extend Shelf Life

Spirits bottles on shelves-Picture Courtesy: thebudgetsavvybride.com

The quality and taste of premium spirits can be better retained by packing them in safe and hygienic packages such as glass bottles, metallic cans, and flexible pouches. This ultimately give your spirits better environment to sustain for large span of time.

Reduce Waste

Spirit can-Picture Courtesy: davidlineton.com

Packing spirits in impermeable packages provide high degree of protection to the inside content. It reduces the possible evaporation and oxidation of spirits as a result the products safely reaches to consumers.

Easy Handling

Spirit can opening-Picture Courtesy: drinkolipop.com

Handling of hard and solid objects without packaging is somehow possible, however, applying same theory on liquids can result in mere wastage. Therefore, using resilient spirits packaging such as spout bags, bag in box, and bottles enable consumers to enjoy their favorite spirits wherever they want.

Get Market Appeal

Branded spirit bottle and spirit filled glass-Picture Courtesy: fordmedialab.com

Another advantage of spirits packaging on part of manufacturers is to get market appeal by presenting their spirits in innovative design packages and labeling to attract the targeted consumers.

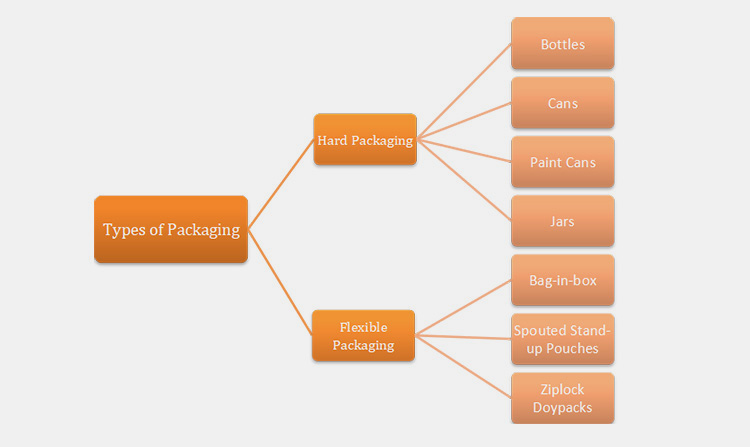

3.Explain In Detail Each Packaging Option Which Can Be Utilized For Spirits Packaging?

Choosing right type of package for your spirits is a critical task as consumers are looking towards flexible and easy to handle packages. Moreover, it also represents the quality of your goods. Therefore, we have highlighted for you the vary options which can be employed for spirits packaging:

Bottles

Spirits glass bottles-Picture Courtesy: eoddistillery.com

Bottles are the most used packaging option for spirits. They are commonly made up of durable glass, and rarely of plastic. Looking towards the changing trends in spirits packaging, now bottles are formed in unique shapes and sizes. Ergo, using them will help your spirit get noticed on the shelf.

Cans

Spirits cans-Picture Courtesy: foodbev.com

Another type of container which you can use for storing your spirits is can. Cans are made from aluminum or metal with high resistance to moisture, light, and air. They are highly compact, which keep your spirits intact and fresh till last sip.

Paint Cans

Spirits in paint cans-Picture Courtesy: packagingoftheworld

Paint cans are large size containers with a handle to carry and strong lid to cover. Even a single paint can is enough to hold up to 2 liters of spirit. Therefore, such cans may also be used for delivering large volume of spirits.

Jars

Glass spirit jars-Picture Courtesy: Walmart.com

Jars are transparent fancy containers which can be used for premium spirits. They are free from leaching and temperature transitions which makes them perfect for the retaining the freshness of spirits.

Bag-in-Box

Spirit dispensing from Bag-in-box to glass-Picture Courtesy: packagingoftheworld

Bag-in-box is yet another flexible package which is made up of combination of a plastic spirit bag packed in corrugated box for providing additional safety. They are available in small to large size. Mostly, such type of packaging is beneficial for parties, concerts, and amusement parts where consumers may get entertained by filling their cups directly from spirit bag with a single push button.

Spouted Stand-up Pouches

Spouted spirit standup pouch presentation idea-Picture Courtesy: rhubarbar.com

Among flexible spirit packaging, standup spouted pouches are the most notable. They stand upright with a spout at upper side which helps in quick dispensing of spirits. Users may simply twist the spout and start sipping spirit from pack without bothering for a cup or glass.

Ziplock Doy packs

Various ziplock spirits doypacks-Picture Courtesy: etsy.com

Ziplock doypacks are made from versatile plastic such as PET and PE with optional aluminum foil for additional protection. They are having ziplock seal which can be opened and closed for multiple times. These packaging also allows users to consume their spirits by using straw.

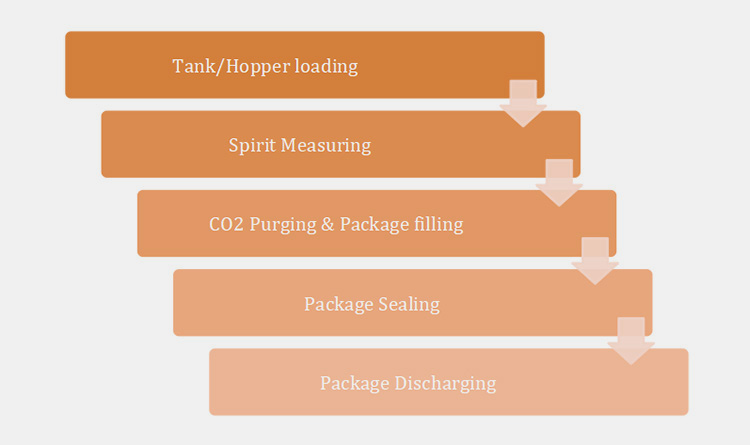

4.What Are The General Working Principles Of Spirits Packaging?

Generally, spirits packaging is a simple process which consists of few steps. However, each step is significant in making the spirits packaging effective. These are described below:

Tank/Hopper Loading

Red spirit in large volume-Picture Courtesy: www.behance.net

Tank is the reservoir of a machine where the spirit is loaded before starting operation. From the tank spirit is forwarded to the filling stations of machine.

Spirits Measuring

In second step, the precise measuring of spirits take place which is the important part in spirits packaging. This mechanism is used for measuring the desired volume of spirits with the help of weighing system fitted in machine.

CO2 Purging & Package Filling

Spirits bottles filling process-Picture Courtesy: istockphoto.com

This part involves the purging of packages especially for canned spirits. It is carried out by intermittently releasing CO2 gas from machine into packages to complete eliminate the presence of oxygen and hydrogen. After that, the required amount of spirit is filled in the packs with the help of filling nozzles. Here, multiple filling heads are usually used to boost the productivity and efficiency of spirits packaging.

Package Sealing

Spirits bottle sealing process-Picture Courtesy: istockphoto.com

Once the product is filled in various packages, they undergo the sealing process. This sealing process involves heat, vacuum or pressure sealing methods. In this way plastic bags, pouches, glass bottles, and cans are sealed.

Package Discharging

Spirits bottles discharging-Picture Courtesy: istockphoto.com

After sealing, the product is discharged from the machine for further processing which includes the labelling and packing. Package discharging can be done with the help of robotic arms or any other mechanism such as conveyor belt that can move the finished packages for further processing.

5.Which Machines Are Used For Spirits Packaging?

Several machines can be employed for spirits packaging. The detailed description about each type of machine has been given below:

According to Automation

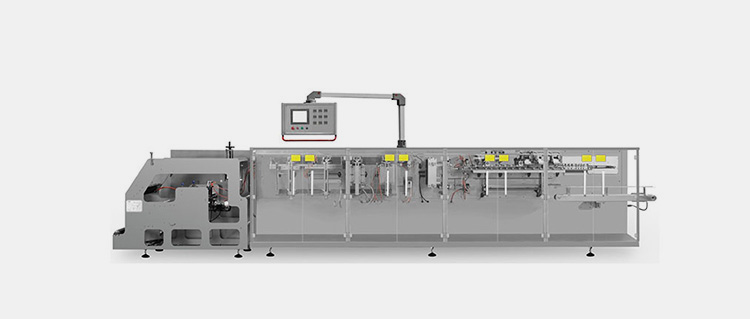

Fully Automatic Spirits Packaging Machine

Fully Automatic Spirits Packaging Machine

In fully automatic spirit packaging machine the empty bottles are loaded on machines, followed by the automatic filling and final packaging of each bottle. It involves less human interaction to increase the production rate. Due to its high production rate, it can be used at large scale industry. Its automation makes it more precise and effective for use.

Semi-Automatic Spirits Packaging Machine

Semi-automatic spirits packaging machine-Allpack

Semi-Automatic spirits packaging machines are much more efficient and quicker than manual machines. The parameters of filling packages are manually controlled by the operator for precise filling. It offers automatic weighing and filling of packages to enhance productivity.

Manual Spirits Packaging Machine

Manual Spirits Packaging Machine-Allpack

In this machine a human operator is required for the packing process. The operator must load the container onto the machine and must set the parameters for the filling. Manual spirit packaging machines can be used for the production at a small rate where the operator wants to customize the product.

According to Design

Rotary Spirits Packaging Machine

Rotary spirits packaging machine-Picture Courtesy: zjweichi.net

Rotary spirits packaging machine is a complex structure equipment employed to aid the large scale industries in their regular task completion. Although, the machine has similar purpose of filling various containers and bags with spirits, but its production efficiency is quite higher than any other type of machine. It is due to the multiple filling stations fixed on a rotary turntable that maximize the speed of spirits packaging.

Inline Spirits Packaging Machine

Inline spirits packaging machine-Picture Courtesy: asgmachinery.com

Inline spirits packaging machine is linear type machine with the conveyor belt capacity to allow only one bottle pass through it for filling purposes. However, the machine is more precise, stable, and easy to handle. By following a sequential order during operation, the machine is excellent in detecting empty bottles or defected bottles etc.

According to Head

Single Head Spirits Packaging Machine

Single head spirits packaging machine-Allpack

This single head spirits filling machine by Allpack has a magnetic pump system through which it fills containers. The machine comes with a single alone filling nozzle which can at a time fill each bottle, can, or pouch. This machine is semi-automatic in autoionization. It is highly compact and cost-effective for small businesses.

Dual Head Spirits Packaging Machine

Double head spirits packaging machine-Allpack

Double head spirits packaging machine is available in tabletop format and is semi-automatic technology. Here, the user may place cans, bottles, and bags with ziplock and spouts etc. The machine is precise, compact, and easy to operate with zero tolerance on working stability.

Multi head Spirits Packaging Machine

Multi head spirits packaging machine-directindustry.com

Multi head spirits packaging machine is an extensive and more composite machine with 6-12 filling nozzles. Such type of machines are carrying great advantage for large to extra large manufacturing firms where workload is high on regular basis. Hence, when the machine completes a single phase, it fills up to 12 bottles in the same single run contributing to high production, low energy consumption, and time saving.

According to Packages

Can Spirits Packaging Machine

Cans spirits packaging machine-Picture Courtesy: pestopack.com

The machine is specifically tailored to meet the needs of spirits can packaging. By adopting simple operational procedure, the machine takes empty cans from conveyor belt and filling the measured spirits into them. Similarly, the filled cans are discharged from machine for further processing like sealing and labeling etc.

Bottles/ Jars Spirits Packaging Machine

Bottles/ Jar spirits packaging machine-Picture Courtesy: polsinelli.it

This machine by Allpack is resilient enough to cope up with any type of small to large bottles, paint cans, and jars etc. Several components including stainless steel body, adjustable tooling system, conveying unit, control system, storage tank, and filling nozzles make up the assembly of the machine. Its working procedure starts from detecting container, passing them through measuring, filling, and ultimately ended by discharging these containers.

Bag-in-box Spirits Packaging Machine

Bag-in-box spirits packaging machine-Picture Courtesy: liquibox.com

Bag-in-box spirits packaging machine is the most ergonomic machine designed with distinct features to carry out the function of bag-in-box packaging simultaneously. It intelligently forms the bag from double layered plastic film with a fitment and start filling the bag with spirits through filling nozzles. After the bag get filled, machine close the attached fitment and convey it towards the box packing where corrugated card boards box is formed and filled with a packed bag.

Spouted Pouch Spirits Packaging Machines

Spouted pouch spirits packaging machine-Allpack

Spouted pouch spirits packaging machine is used for supplying the pouches with accurate amount of spirits. The machine is designed with ergonomic features through which the operator set commands in the machine and in turn it starts forming a pouch, fill it with spirits, and infuse a spout to pouch opening. The pouch is then sealed via heat sealing and discharged by the machine.

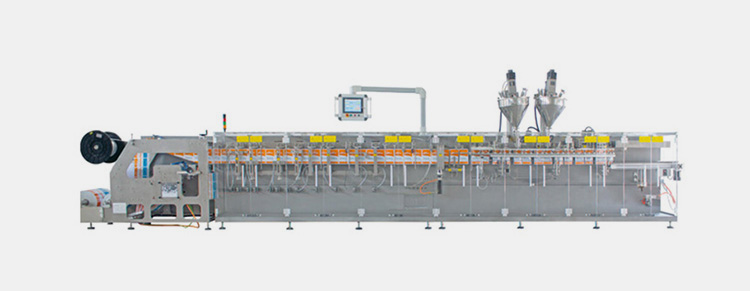

Ziplock Doypack Spirits Packaging Machine

Ziplock Doypacks Packaging Machine-Allpack

This machine is available in horizontal structure with capacity to perform multiple tasks. It begins the process by forming doypacks from a film roll and filling it with spirits. The pouches are then tightly sealed via ziplock and get out of the machine for further processing like secondary packaging etc.

6.Describe The Various Types Of Information Provided Through Spirits Packaging?

Spirits packaging is a mean to deliver useful information about the company and product to users. Hence, the important information which every spirits package should have in common are as under:

Spirit glass bottle labeling-Picture Courtesy: dribbble.com

Brand Name

Brand name is the name given to any type of spirit package produced by specialized factory. It may be the actual name of the company, or a logo given to spirit packages. Brand Name helps consumers to pick the spirit bottle which they know and trust for a longer period.

Product Name

Product name is the actual name of content present inside the bags or bottles. For instance, whiskey, rum, and vodka etc. The product name is a very crucial thing that needs a must mention on package for getting quick attention by the shoppers.

Ingredients Used

Commonly, ingredients used in spirits are not mentioned on their bottles, however, reputable spirits suppliers want their consumers to be fully aware of each component used in spirits making. It is also done for the purpose of attaining customer satisfaction.

Company Information

Company information include the location, contact information, and certifications accredited to the company. Together, such information is helpful for building the reputation of your company in the eyes of buyers.

Expiry Date

Expiration date is a useful data that is and must be present over all types of spirits packages to enable the users about product validity.

Allergens

Allergens refers to specified ingredients such as eggs, milk, gelatin, and yeast etc., which are not good for people who are on any sort of abstinence. Thus, mentioning allergens can protect the users from health hazards.

Bar Code

With the advancement in technology, spirits tracking is now commonly done on mobile phones and computer devices. In this way, the bar code which consists of parallel lines and few digits disclose the important information about product.

7.What Are The Future Trends For Spirits Packaging?

Multiple spirits cans-Picture Courtesy: packaginginspiration.com

The spirits packaging market size has exceeded the worth of 50.14 billion USD in 2022 and is expected to grow rapidly by increasing its market value up to 74.94 billing USD by 2032. It shows the importance of spirits packaging industry on one hand, while consumers preferences on the other.

Similarly, the future trends for spirits packaging encompasses several factors such as the use of more environmentally friendly packaging, consumers proclivities towards using convenient on-the-go packaging, and the changing dynamics of the packaging world which pushes manufacturers to adopt innovative technology for their brand promotion through spirits packaging.

Environmentally friendly spirit card boards bottle-Picture Courtesy: designerpeople.com

These factors ultimately create a better room for using light weighted and biodegradable packaging options such as those derived from plant sources. Moreover, the demand for customized spirits packaging is also gaining momentum which in turn ask for spirits packaging machinery equipped with more resilient features to cope up with the required targets.

8.What Are The Prominent Quality Standards Spirits Packaging Should Meet With?

FDA headquarters-Picture Courtesy: today.uconn.edu

Processing hygienic and sustainable spirits packaging is the prerequisite for healthy and safe spirits life. Hence, to achieve this objective certain quality standards are established among which Food & Drugs Administration is the prominent one. It has established certain rules for spirits packaging whose fulfilment can lead to healthy spirits packaging.

Besides that, International Organization for Standardization (ISO) is another agency working on states level to make sure the machines which process spirits packaging are made from fully protected and antibacterial materials.

In addition, Good Manufacturing Practices (GMP) is formed to examine whether the spirits manufacturing equipment are meeting the needs or not. Similarly, the entrepreneurs who wish to sell their spirits packaging machines in Europe are bound to meet the European Union quality standards.

9.Troubleshoot The Common Problems Faced During Spirits Packaging?

During spirits packaging you may confront some of the challenging problems, which if not resolved timely, can waste your spirits. Hence, to know their troubleshooting, consider the table below:

| No | Problem | Causes | Solution | Pictures |

| 1 | Leakage | It is the most common problem that often occurs due to inappropriate sealing or hole in the spirits bags, pouches containers. | It can be fixed by checking the sealing station for clarity in jaws debris and pollution. Along with that, the sealing pressure and heat may be adjusted to make sure that sealing formed is tamper. |

Leaked spirits bottles-Picture Courtesy: www.behance.com |

| 2 | Over filling | It occurs due to the unstable placement of spirits packaging machine which or detection problem | Locate the machine on smooth surface and examine the machine detector if polluted with debris |

Spirits overfilling presentation idea-Picture Courtesy: fontsinuse.com |

| 3 | Bottles shaking during process | It is due to the incompatibility between bottles size and the size of conveyor | Here, it is important to modify the conveyor width in accordance with the bottles |

Lose conveyer belt-Picture Courtesy: bwpackaging.com |

| 4 | False Sealing | False sealing badly affects the spirits quality and result in spirits wastage. It happens when the sealing jaws are too heated or cold | It can be solved by keeping the temperature of sealing jaws at moderate level, so, that the bags would remain strong to resist pressure |

False spirit can seam-Picture Courtesy: pictestudio.com |

10.Which Factors Must Be Considered For Attaining Excellent Spirits Packaging?

Reaching the top-level packaging is every manufacturer's dream. It requires certain potential steps which must be taken in right direction such as:

Sustainable Packaging

Sustainable spirits bottles-Picture Courtesy: foodnavigator.com

Selecting right type of packaging material should be your top priority. In this way, opting for eco-friendly packages such as biodegradable paper, recyclable plastic, and cans are good options. It will reduce the environmental impact of packaging on one hand, while cut the cost of packaging on the other.

On the go Solutions

Spirit doypack dispensing spirit in glass-Picture Courtesy: packagingoftheworld.com

With every passing day, people are becoming busier and that's where the need of ready to take spirits packaging come into use. Hence, designing your spirits packaging in a way that facilitate fast, and convenient handling will ultimately increase the demand for your products.

Advertisement

Spirit bottle with label for branding-Picture Courtesy: paperspecs.com

Labeling play a very instrumental role in shaping your business success. If you use it for advertising your products by designing them with eye-catching colors, traditional pictures, and appetite packaging, they will surely be a mesmerizing factor for every spirits's lover who comes across your spirits packages.

Conclusion

To sum up, spirits packaging is essential for the quality retention, marketing and retailing of spirits. They can be delivered in range of alluring and versatile packaging options such as bags, bottles, and cans etc., by using the multitude of spirits packaging machines available for them. Not only that, but the growing boost in spirits packaging market can also turn the fate of your business. By using our wide range spirits packaging machines, you can make a difference in your production. So, don't make a delay in taking right decision, and feel free to ask us any question that arises in your mind regarding spirits packaging. We will be glad to help you out!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide