Spice Filling Machine: The Complete Buying Guide in 2025

Did you know that spices not only impart flavour to food but is also used for medicinal and preservation purposes? Today, spices are filled in stylish and tough containers to increase their shelf life. Spice filling machine is increasingly employed in the spice industry for filling spices in wide-ranging packaging containers. It is an extraordinary solution that provides an absolute answer to all spice filling problems.

It is known for its accurate and spill-free filling. Planning to add this handy machine to your production line, then go through this guide to discover its important features.

1.What is Meant by the Spice Filling Machine?

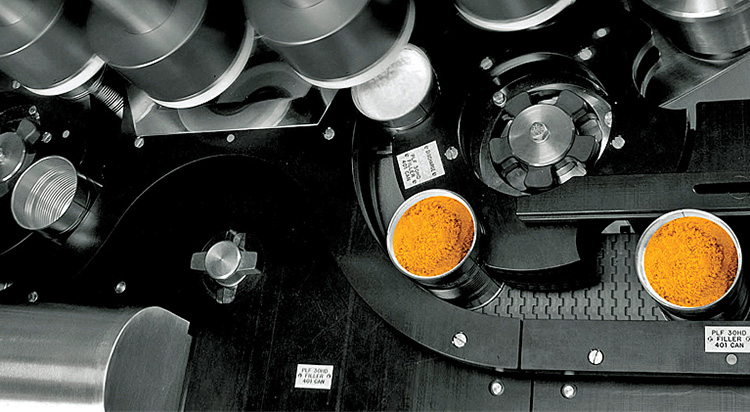

Spice Filling Machine- Picture Courtesy: FILLING AND SEAMING MACHINE

This machine is meant for filling different volumes of spices like cardamom, red chilli, black pepper, cloves, cumin, garlic, and many more into tough and sturdy containers like pouches, bottles, jars, tins, etc. This machine is offered with various kinds of filling systems that assist in filling precise quantities of spices inside the packaging.

Moreover, the spice filling machine has a prime importance in preserving the shelf-life of the spices and it also prepares spices for shipment and transportation by packaging them. Due to spice filling machine, there is consistency in every batch.

2.How a Spice Filling Machine Prove as an Advantageous Equipment for Production Lines?

Spice Filling Machine

Manual labour is time-consuming and tedious requiring, a great deal of caution which is why manufacturers use a spice filling machine. Some useful advantages that spice filling machine brings to production lines are discussed below:

Quick Filling

Quick Filling by Spice Filling Machine- Picture Courtesy: Accutek Packaging Equipment

One of the major pros of a spice filling machine is its efficiency and speed. Manufacturers process large numbers of batches per day where one batch has hundreds of spice containers. This is where the spice filling machine has proven its importance. It can fill tons of spice containers within no time due to its automated and computerized systems.

Less Error Rate in Filling

Precision with Spice Filling Machine- Picture Courtesy: Packaging News

Underfilling and overfilling cause huge trouble for manufacturers often, leading to product wastage and recall. Hence, a spice filling machine is employed in the production line because it has consistency in every fill. Precision and accuracy are guaranteed by using a spice filling machine due to its weight-checking sensors and PLC units.

No Contamination

Spice Filling Machine- Picture Courtesy: Landpack Packing

The spice filling machine is manufactured using a stainless stain that provides hygienic construction. Furthermore, this machine is designed by keeping in mind GMP guidelines. Thus, safety and security in spice filling are ensured by this machine. Due to this, there is zero risk of cross-contamination and microbial growth.

Flexibility and Versatility

Flexibility in Spice Container Processing- Picture Courtesy: Trend Hunter

Spice filling machine is designed in such a way as to easily accommodate a variety of packaging containers. It is a flexible and versatile piece of equipment, handling not only present packaging requirements but also can process evolving future packaging needs.

Ease of Handling

Ease of Handling in Spice Filling Machine- Picture Courtesy: JBT Corporation

This machine comes with components that are easily disassembled and reassembled which offer quick and fast changeovers, cleaning and maintenance. Besides this, HMI present in the spice filling machine is the ideal way to set up and control filling processes.

3.Where a Spice Filling Machine Has Found its Use?

Spice filling machine has multiple uses in various industries due to its automation and precision. It is the need of every industry that fills and packages various kinds of powders. Its industrial uses are detailed below:

Food Industry

Spice Filling Machine in Food Industry- Picture Courtesy: World Brand Design Society

It is a big industry that increasingly uses the spice filling machine for packaging different kinds of food powders and granules, for instance, spices, salt, sugar, fruit and vegetables chucks, chips, pulses, grains, etc. Spice filling machine is important in the food industry because of its hygienic fill.

Chemical Industry

Spice Filling Machine in Chemical Industry- Picture Courtesy: Bold Brand

Different types of household and laboratory chemicals are in the form of fine particles, thus spice filling machine is employed in the chemical industry for dosing of such chemicals in bottles and jars. Some chemicals are expensive therefore, spice filling machine is a significant part of the chemical industry as it does not waste chemicals while filling.

Agriculture Industry

Spice Filling Machine in Agriculture Industry- Picture Courtesy: Bold Brand

Various kinds of agriculture products such as fertilizers, pesticides, and herbicides come as granular feeds, so to load these products inside the containers, a spice filling machine is usually employed. It is popular in the agriculture industry due to its exact filling.

Pharmaceutical and Nutraceutical Industry

Spice Filling Machine in Pharmaceutical and Nutraceutical Industry- Picture Courtesy: Dieline

Spice filling machine is a part of the pharmaceutical and nutraceutical industry and is used for dosing accurate quantities of different medicinal, herbal, and nutraceutical supplement powders in rigid and flexible packaging such as bottles and pouches.

Cosmetic Industry

Spice Filling Machine in Cosmetic Industry

Beauty powders are typically filled inside elegant and stylish containers by the spice filling machine. It can dose both fine powders and grainy powders in bottles, tubes, jars, and pouches. In the cosmetic industry, this equipment is employed for filling face powders, blushes, face masks, and whitening powders in different packaging.

4.What are the Components of Spice Filling Machine?

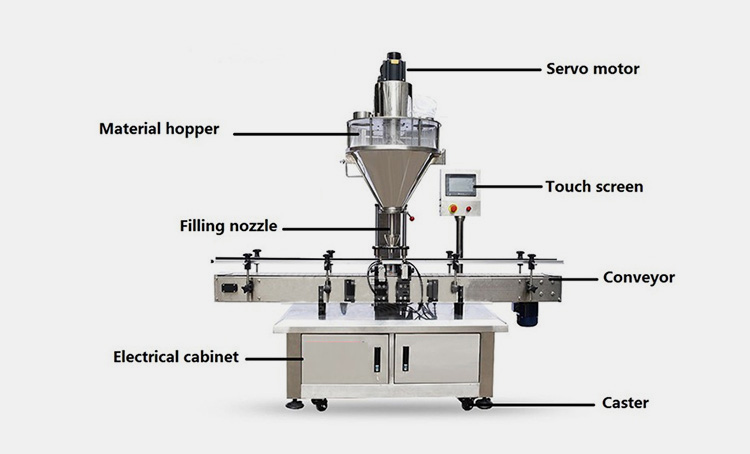

Spice filling machine consists of various advanced components that work in synchronization to regulate the spice-filling process. A detailed account of these components is discussed below for your information.

Parts of Spice Filling Machine- Picture Courtesy: SZHX Machine

| Material Hopper | It is the conical-shaped part typically found at the upper portion of the equipment. Its function is to store large quantities of spices for convenient and uninterpreted filling. It passes the spices to the filling devices once, the filling operation begins. |

| Filling Nozzles | These are the cylindrical devices and are part of the filling devices. Spices are drawn into filling nozzles by the vibration and rotation of the filling devices. Sometimes, spice powder is moved into the filling nozzle via pressure. These filling nozzles are used for dosing the correct amount of spices in the containers. |

| Electric Cabinet | Different kinds of relays, switches, circuit breakers, cables, and wires for controlling the movement of different parts of spice filling machine are present inside the explosion-proof electric cabinet. This cabinet is made with reinforced material to provide safety. |

| Caster | It is the part that supports as well as directs wheels for movement. Due to the displacement of the caster, the wheel rotates for moving the wheel. It helps in easier portability. |

| Conveyor | This part is lined with different types of rollers, chains, or drive belts for the transport of the conveyors. The conveyors support the containers and guide them to different stations of the machine. The operators typically load the bottles and jars at fixed intervals on conveyors for filling spices. |

| Touch Screen | It is an intuitive and smart touch screen for quick changes in filling parameters. The touch screen is an HMI that stores data recipes for quick changeovers. |

| Servo motor | The motor is employed for converting electric energy into mechanical energy and these parts assist in the movement of conveyors, rotating of filling devices, and other parts. It is the powerhouse of the spice filling machine. |

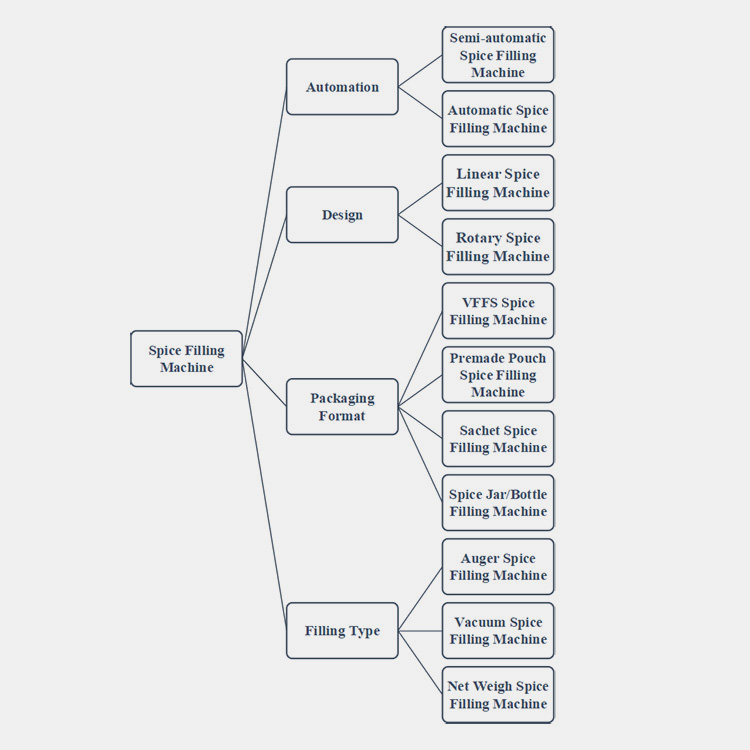

5.How to Classify Spice Filling Machine?

With the evolution of technology, different models of spice filling machines are developed every day that cater to diverse kinds of spices. These machines usually differ in their design, automation, type of fill, and packaging format.

A complete detail of the classification of a spice filling machine is penned below for your understanding.

Classification Depending Upon Automation

There are two kinds of spice filling machines when categorised depending upon automation.

Semi-automatic Spice Filling Machine

Semi-automatic Spice Filling Machine

It is a compact machine serving small and medium-sized businesses that do not involve bulk volume spice packaging. In this machine type, operators have to perform the job of loading and removing spice containers from the machine. However, a semi-automatic spice filling machine usually doses spice containers independently. It is typically a portable unit and requires a small space for its installation.

Automatic Spice Filling Machine

Automatic Spice Filling Machine- Picture Courtesy: iiitl.ac.in

As the name suggests, it is a completely automated unit capable of executing every spice fill process itself. This machine is integrated with infeed units that load containers for spice filling and filled containers are collected inside the discharge bins. Advanced sensors and rejection systems assist in quick and accurate filling in the automatic spice filling machine. This machine is a large unit, requiring more space and is fairly pricey; however, this machine speeds up production and can process large batches.

Classification Depending Upon Design

Based on the design, there are two kinds of spice filling machines.

Linear Spice Filling Machine

Linear Spice Filling Machine

This machine is available in straight-line configuration usually in L, Z or U styles. Linear spice filling machine has conveyors for transporting different kinds of container like jar, bottles, or tins for the filling station. This machine has one or multiple heads for spice filling, but the processing capacity of this equipment is slow because conveyors stop when a container is being filled, thus it cannot fill multiple containers consecutively.

Rotary Spice Filling Machine

Rotary Spice Filling Machine- Picture Courtesy: Brightwin

It is a larger-sized machine that has a rotary design. It is offered with a star wheel or turn table that gives this machine its name. This star wheel has numerous filling nozzles that allow it to fill multiple containers consecutively, resulting in higher productivity than its linear counterpart. Rotary spice filling machine dose spices without pausing. It is difficult to clean and maintain such a unit; moreover, it requires a special setup for its integration with other machines.

Classification Depending Upon Packaging Format

There are four classes of spice filling machines when classified depending upon the type of packaging format.

VFFS Spice Filling Machine

VFFS Spice Filling Machine

It is a widely popular spice filling machine that forms, fills and seals pouches in the vertical direction. It has a vertical configuration where forming units are located at the top of the machine, hence it has a smaller footprint. The packaging film holder is placed at the bottom part of the machine. The film passing over the rollers, goes to the top where the handy forming station shapes the film into pouches. This machine can process pouches of any shape and size and thus is well-liked by the brands in the spice industry.

Premade Pouch Spice Filling Machine

Premade Pouch Spice Filling Machine- Picture Courtesy: HonorPack

This machine is flexible equipment that can process diverse kinds of pouches, such as gusset, flat bottom, standup, doypack, and many more. It uses preformed pouches instead of packaging film to fill spices hence, is a lot faster than the VFFS spice filling machine. Furthermore, it packages zipper pouches, euro slot pouches, and window pouches.

Sachet Spice Filling Machine

Sachet Spice Filling Machine

It has a similar design configuration and identical working principle as that of the VFFS spice filling machine. However, rather than filling large bags, it fills small sachets usually having a single serving of spices. This machine seals sachet at 3 or 4 sides and is popular for packaging economic spice sachets.

Spice Jar/Bottle Filling Machine

Spice Jar/Bottle Filling Machine

It is an essential part of the spice industry and is employed in the production line for filling rigid containers, for instance, tins, bottles or, jars. This equipment is provided with conveyors which assist in the transportation of different kinds of spice packaging containers. This machine is available in both linear as well as rotary configurations. This machine has an HMI touchscreen that allows it to easily adjust program parameters.

Classification Depending Upon Filling Type

Depending upon the type of filling devices, there are three kinds of spice filling machines.

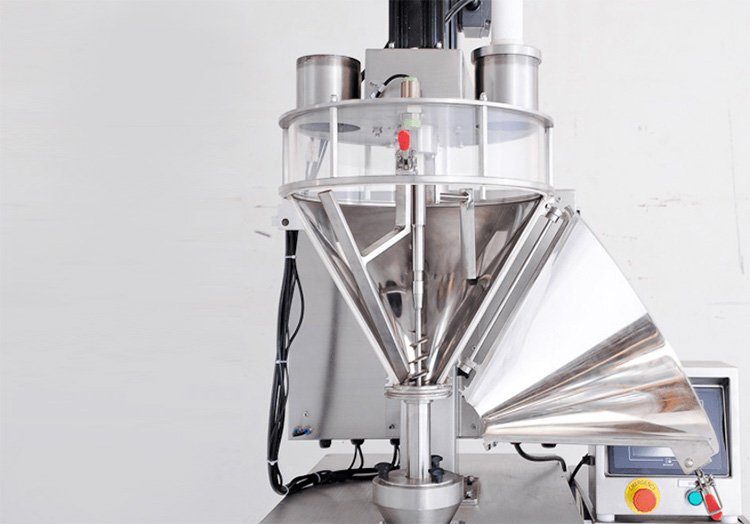

Auger Spice Filling Machine

Auger Spice Filling Machine

It is one of the most common machines for filling dry powders and granules such as spices. This machine has hopper, auger screws, and tubes. Spice filling usually takes place with the rotation of auger screws. It has metering sensors that accurately monitor the volume of spices passing through the auger. A feedback system is employed to micro-adjust filling accuracy by counting the number of pulses produced by the rotation of screws.

Vacuum Spice Filling Machine

Vacuum Spice Filling Machine- Picture Courtesy: JBT Corporation

This machine is designed without the auger hence is employed for gentle and delicate filling of spices that could lose their structural integrity and flavor due to the movement of an auger. The spices are filled inside the container via gravitational force and pressure. These products are moved to the funnel from the hopper and then they gradually flow into containers using pressure. The biggest advantage of using such a machine for spice filling is that there is no dust production while dosing.

Net Weigh Spice Filling Machine

Net Weigh Spice Filling Machine- Picture Courtesy: Weighpack

This machine is extra sensitive and can accurately dose small quantities of spices, such as 1 gram in containers. It uses weight-checking systems that correctly measure the weight of spices flowing into containers. It has a compact construction and consists of a V-shaped dribble pan. The spices are dispensed inside the container due to vibrations of the plates.

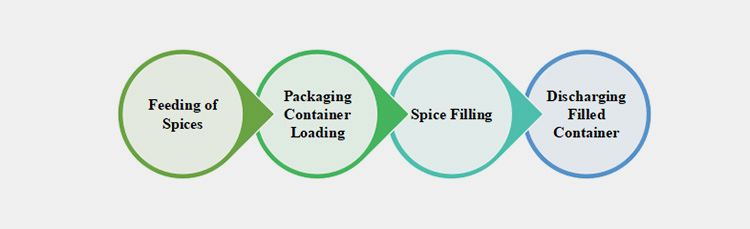

6.What are the Working Stages of a Spice Filling Machine?

As precision is required in spice filling, each working step is carried out at the predetermined time to acquire harmony in the movement of each machine component. There are four main working stages of a spice filling machine such as:

Feeding of Spices

Spice Loading- Picture Courtesy: All-Fill Inc.

At the beginning of spice filling, bulk loads of spices are loaded inside the infeed tank by the operators or other machines. The spices are transported to the hopper from the infeed tank via pipes and a vacuum system.

Packaging Container Loading

Container Loading- Picture Courtesy: BellatRx Inc.

Packaging containers such as bottles, jars, or tins are placed on the conveyors while in the premade pouch spice filling machine, empty bags are placed inside the bag magazine. In the VFFS spice filling machine, the packaging film is loaded on the packaging film holder.

Spice Filling

Spice Filling- Picture Courtesy: Linkedin

When a pouch, jar, bottle or other packaging container is detected under the filling nozzle by the sensor, it transmits a signal to the PLC unit. This computerized system in turn gives a signal to the hopper to start filling. The spices from the hopper flow into filling devices from where by rotation, vibration, or pressure, they flow into filling nozzles. ultimately, spices are dispensed inside containers.

Discharging Filled Container

Discharging Spice Containers- Picture Courtesy: All-Fill Inc.

After filling the preprogrammed quantity of spices inside the container, the bottle or jars are moved to the capping and labelling section while flexible spice pouches are sealed by sealing jaws and dropped down from the chute into a collection area.

7.What are the Technical Problems and Solutions of a Spice Filling Machine?

Spice Filling Problems and Solutions-Picture Courtesy: Santa Cruz

Many of the technical issues that you will find below are actually the most common underlying complications that you faced when working with spice filling machine. As spices are very sensitive to human therefore to resolve these problems immediately is paramount important.

Spice Clogging in the Hopper of Spice Filling Machine

Spice Filling Machine-Picture Courtesy:Paxicom Group

You commonly observe the seamless flow of spices from the filling head of the machine but when you pour bulk of product in the filling heads, this would results in the clogging or jamming of the filling product in the hopper which results in the irregular pattern of flowability and variations of results.

How to solve?

To keep the hopper of spice filling machine in a proper slop orientation of hopper can solve this problem in fact it wont allow this problem to be occurred. Secondly, by applying an agitator is another useful way to keep this problem away from the filling process. Thirdly, using vibratory or shaking hopper also helps in improving the flowability of the powder spices efficiently.

Variation in Weight during the Spice Filling Procedure

Spice Filling Machine

As you know the spice filling process is commonly taken placed in a volumetric measurement. Simply, sometime you can face problem in volumetric measurement by dosing system instead of accurate or constant weight.

This is mostly occurred due to wrong adjustments or setting of the spice dosing by cup dozers. Secondly it is occurred due to weight control variation or irregular filling due to non-free flowing spices powders.

How to Solve?

To counteract this problem, you can adjust the formulation first; this is done by addition of flowing agents that helps in easy flowing of the spices or reduce the cohesiveness. Secondly, you can add an agitator system in the hopper that helps in the flowability rate of the spices. Keep leveling the machine’s settings with time, it helps you in the controlling of filling process.

Leakages of Spices from pack

Leakages of Spices from pack

This is another commonly occurring problem where spice powder is sticking at the level of sealing edges which can lead to failure in proper sealing and cause leakage and spillage of the product. For perishable spices this type of product must be avoided to reduce loss.

How to solve

This problem can be avoided by control dust formation. A dust aspirator unit must be installed or find equipment with dust aspirator can help you in the troubleshooting of this problem.

Inaccurate Filling of Spice Powders

Inaccuracy Problems in Spice Filling Method- Picture Courtesy: Berrihealth

This is the common problem where you can meet with an inaccuracy filling problem to deliver spices.

How to Solve

To solve this problem correct the setting by calibrate the equipment. Clean and maintain the machine with cleaning the filling nozzles, hopper, etc., Inspect the obstruction in the auger and reset the machine to ensure promising activities of powder flow.

8.What is the Maintenance Schedule of Spice Filling Machine?

The regular maintenance of spice filling machine is integral for quality life

The regular maintenance schedule for spice filling machine is essentially significant to extend lifespan of the spice filling machine. The mentioned below tips are useful to maintain the equipment.

Cleaning of Residue Spices Pile Up

This is one of the primary step you should not ignore. The regular cleaning must be done to keep quality of filling materials and the machine as intact.

Lubrication of Movable Parts

Weekly lubrication of moving components such as auger filler, driving unit, or components of conveyor must be greased appropriately to ensure smooth operability.

Calibration and Adjustment & Regular Inspection

Always conduct the regular inspection and calibration of the machine to maintain the accuracy and filling characteristics. Correct or replace the worn out components and loose connections.

Conclusion

The spice filling machine is one of the integral units in the spice packaging line. Unparalleled precision filling is the major plus point of this equipment. It automates production lines with high speed which is a main issue with manual spice fill. Investing in this machine brings a high return on investment. So, to buy the best-quality spice filling machine, visit our Allpack website where we provide ultimate solutions at discounted rates.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide