Spice Bottle Filling Machine: The Complete Buying Guide In 2025

Don’t you think spice filling process is the most challenging task? Yes of course, this is because of spicy texture, intolerant to your sinus, irritant to eyes and more. Beside this, entrapping moisture, clumping, and other related factors are really tricky to manage during filling process.

So, what should be the solution? The spice bottle filling machine is the right answer to many questions. Planning to invest in? Please go through this blog for useful content related to the machine.

Let’s get into it!

1.What is a Spice Bottle Filling Machine?

Spice Bottle Filling Machine

A spice bottle filling machine is a specialized equipment that is utilized to fill raw or ground spices in their specialized packaging bottles to keep them as fresh as possible for a longer time till it reaches you.

This machine is capable of automating the procedure of filling spices by considering precise and accurate quantity of product into each bottle and is commonly used to improve quality and enhance your brand.

2.How is Spice Bottle Filling Machine Significant?

Transparent & Beautiful Glass Spices Bottles

A spice bottle filling machine offers several benefits to customers, for example:

Well- Controlled Environment

Promising Spice Bottle Filling Machine

A spice bottling filling machine provides well controlled working conditions for handling spices as it doesn’t allow its involvement in the air and reduces risk of irritation to technicians or inducing respiratory issues such as uncontrolled sneezing when breathing.

High Automated Processes

Spice Bottle Filling Machine

Sometimes, manual handling to spices become troublesome to you due to high labor and delays in filling time. A spice bottle filling machine is available with various automation and has ability to deal with various production capacities that ultimately bring fast production and workflow.

A Compact Unit

Spice bottle filling machine with compact structure

There are various spice bottle filling machines that are featured with enclosed and compact units to protect outer environment from exposure to spice particles as it liberates and more likelihood to cause skin, eyes, and other relatable problems to workers. The machine is offering safe and protective work processes.

No Worry to Spillage

Spices filled bottles- picture courtesy: gorillascales

With spice bottle filling machine, you can enjoy precise and accurate properties with no chances of product spillage or its distribution.

Easy Cleaning

A Stainless Steel Structure Ensure Easy Cleaning

A stainless-steel made-up body structure of spice bottle filling machine is specially designed to allow you an easy cleaning and potentially safe due to high quality standards and hygiene maintenance.

3.What are the Major Uses of Spice Bottle Filling Machine?

Industrial Prepared Spices Shaker Bottle Set

Despite using a spice bottle filling machine for filling spices, there are many other uses linked to this machine in various other fields as well. We’ve designed industrial applications below:

Food Industry

Spices bottles are demanding items in routinely cooking

Maintaining quality, flavor, hygiene and exact ratio of food products, a spice bottle filling machine is used in food industry, this includes a flours, rice, sugar, and other raw products such as wheat, grains, pulses, etc., this machine is mandatory to bring streamline manufacturing processes on its best way.

Pharmaceutical Industry

Powder used in pharmaceutical industry- Picture Courtesy: dehum

In pharmaceutical industry, you can observe filling and packaging departments installed with spice bottle filling machine for packaging of medications that are powdery in nature, such as instant oral digestive complications sachet (risek, bicarb powder), topical antibiotic powders (cicatrin), and injectables such as painkillers, antibiotics or Oral IV powders, etc. needs a spice bottle filling machine for its safe and sterile packaging under regulatory compliance.

Chemical Industry

Powder used in chemical industry- Picture Courtesy: russellfinex

In chemical industry, dealing with potential hazardous compounds is pretty common, for example powder involved in buffer, acidic and alkaline salts, some organic and inorganic salt, etc.

A spice bottle filling machine ensures promising filling to make you safe with direct handling of chemicals, also it minimises chances of inaccuracies.

Cosmetic Industry

Powder used in cosmetics industry

In cosmetics industries, there are various products that are manufactured in powder form for example blush on, eye shadows, face powder, dusting powder ,etc.

A spice bottle filling machine ensures filling of these products with beautiful presentation without any chances of error.

Agricultural Industry

Fertilizer Powder for Plants

In agriculture industry, you have seen various products such as pesticides, insecticides, animal feeds, energising boosters, crop inducers, or various plants fertilisers etc. All these mentioned products are packed by using spice bottle filling machine respectively to supply them directly to farmers.

Detergent Industry

Detergent Powders used for laundry

A spice bottle filling machine is frequently used in the utilisation filling and packaging of products employed in house cleaning such as detergents, cleaning powders, anti mould powders, laundry powders, dish washing powders, carpet cleaners, and much more.

Construction Industry

Powder used in ceramic industry-Picture Courtesy: scmgeurope

Construction industry is involved with products that are powdery in nature , for example, cements, paints, adhesives, binders, fillers, and others. This machine ensures fast and safe filling of materials used in construction processes.

Nutraceutical Industry

Nutraceutical Powders in Bottles

Nowadays, people are more focused about concerning health and wellbeing. The uses of spice bottle filling machine in nutraceutical industry showing high demand and is used for the filling of products, such as protein powders, infant powder (milk formulas), cereals, vitamins, trace elements, various enzymes, etc. So, a spice bottle filling machine is capable of dozing these nutritional supplements in their individual bottles effectively.

Pet/Veterinary Industry

Veterinary Industry Application

In pet or veterinary industry, whether it is animal feed, or animal health related medicines, a spice bottle filling machine is used for their packaging.

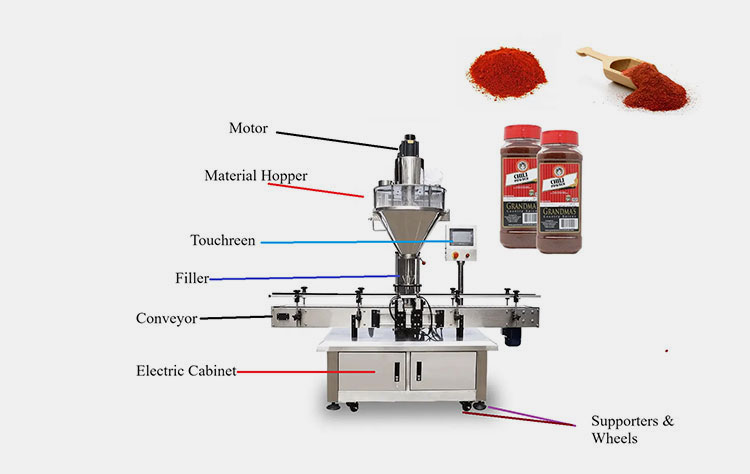

4.What are the Parts of Spice Bottle Filling Machine?

To describe parts of spice bottling machine, please see below illustration and description for understanding.

Spice Bottle Filling Machine

Motor

A motor which serves as a driving component of the machine, you can simply consider it as a powerhouse of equipment. Its functions include, drawing, filling of spices, conversion of electrical energy into mechanical energy, and running of entire machine i.e., speed, filling rate, entrance and discharging or bottles etc.,

Hopper

Hopper is responsible for holding and storage of spices. it is mostly designed at top of the machine that allows a control and a uniform flow of powder in the downward direction for a flexible filling of spices.

Touch Screen

All necessary directions, and process protocols can be entered into the machine by using a touchscreen interface. Also, it allows operator to watch the process, maintain, and troubleshoot the machine. By using the screen, you can also regulate the procedure, such as, speed of process, filing concentration, process memory, integration of machine, notifications, emergency alerts, etc.,

Filling Head

Whether powder or liquid spice, the filling head is responsible for accurate dispensing of product inside bottle with regulated speed. The point to be noted, for powder spices, an auger is responsible for countering granular, free flowing and non-free flowing products.

Conveyor

This component plays an essential role in every machine it supplies bottles inside the machine and subject them directly to filler and ensuring a consistent and smooth workflow due to its regulated speed. Once spice bottles are filled, a conveyor moves them to another machine and brings next batch of empty bottles.

Electric Cabinet

Machine basic electrical components, wires, plugs, connections are enclosed in a electrical cabinet for a safe running of machine.

Supporters and Wheels

With supporters and wheel, a spice bottle filling machine is capable of moving from one place to another. These parts of machine ensure stability and helps in adjusting position when integrating them with other units.

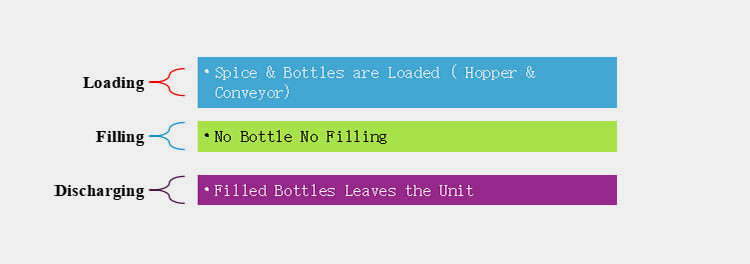

5.What is Working of the Spice Bottle Filling Machine?

The working principle of bottle spice filling machine is comprised of the following steps:

Spice & Bottle Loading

Loading Of Spices and Bottles

The machine is designed to fill spice into bottles that should be loaded using a storage hopper which infeed the product into each bottle upon its presence. Similarly, in automatic spice bottle filling machine, an oriented or upright positioned set of bottles are transported into the machine with the help of conveyor.

Spice Filling

Filling of spice in bottles

The filling process is based on particular machine’s designs; a spice bottle filling machine is commonly facilitated with an auger unit that upon agitating auger screw, dispenses a precise quantity of spice into each present bottle ensuring filling up to desired level.

The filling process can be vacuum based or gravimetric, the basic selection can be done by considering type of spice texture and its flow ratio.

Discharge

Discharging Of Spice Bottles

Once spice bottles are filled, they’re transported toward the next phase of packaging and brings next empty set of bottles. The machine features with sharp detector system where principle of no bottle, no filling is followed.

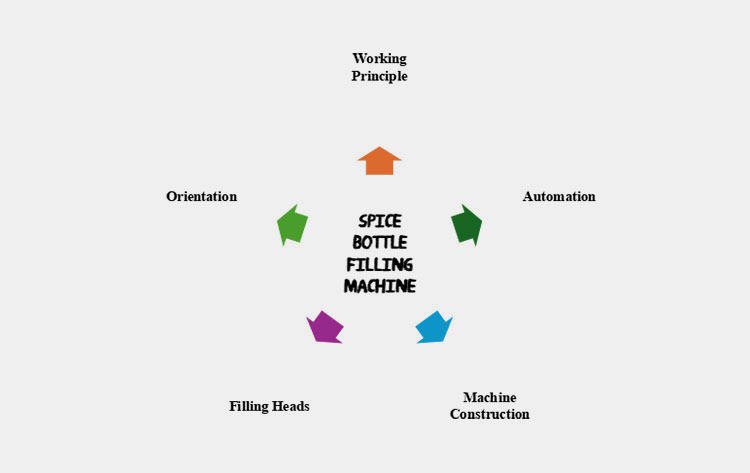

6.What are the Types of Spice Bottle Filling Machine?

A spice bottle filling machine has various advance types. Although the machine is conventional, but with rising demand and awareness, bioengineering has well-executed new features in every coming model. Let’s see them one by one.

Classification Of Spice Bottle Filling Machine

Based on the Working Principle

With different features, every specific spice bottle filling machine offers some different working principles such as:

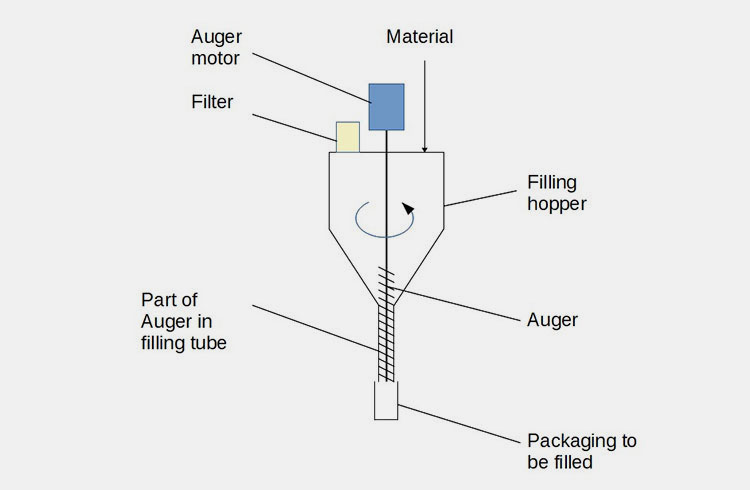

Auger Fillers

Mechanism of auger spice bottle filling machine

Auger filler is used to fill spice with a very fine texture or simply known as free-flowing spice. This machine is composed of main parts like auger drive, agitation blades, and auger screw. All of these parts play important role in the dispensing of spices with a tremendous result.

Inside View of Auger Drive

Upon driving of auger drive, a uniform flow of spices goes down toward filling nozzle, in the meantime; an agitation blade helps in the de-aeration and uniformity of the spice by removing and breakage of lump produced during the process and draw free-flowing consistency of spice inside the bottle.

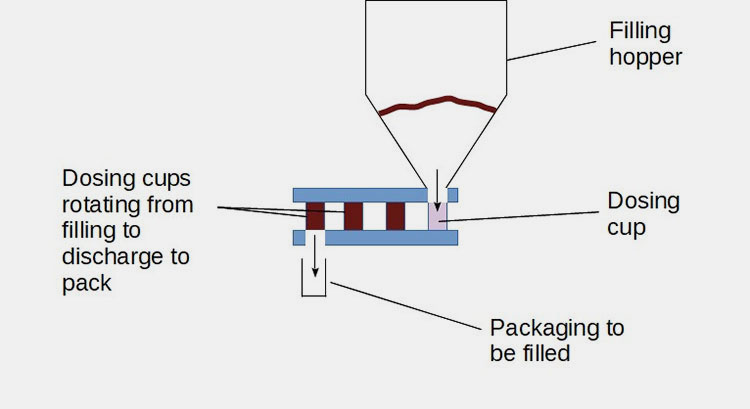

Volumetric Fillers

Mechanism Of Volumetric Spice Bottle Filling Machine

A volumetric spice bottle filling machine is more precise and accurate as compared to auge filler as its basic design is composed of a cup which is also known as a dosing cup.

A structural view of a volumetric spice bottle filling machine- Picture courtesy: All-Fill UK

Upon rotation of plates, a cup is filled with spice and make an adjustable requirement of volume. As compared to auger filler, a volumetric filler is a type of passive filling means it passes through two mediums, i.e. hopper to cup then to bottle. this is commonly used for filling spice required in a smaller volume.

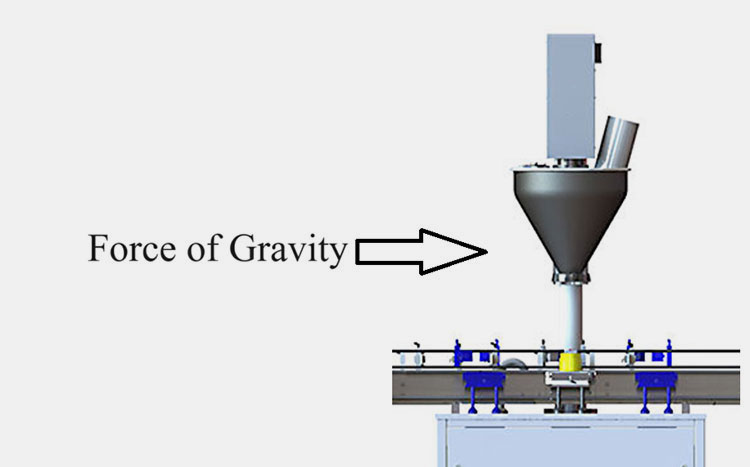

Gravity Fillers

Gravity Spice Bottle Filling Machine

As its name shows, the flow of spices from hopper till nozzle take place by a force of gravity. The machine is ideal to fill spices with a very small and accurate volume. This machine is a good solution to avoid extra expenditure on costly techniques and brings the process in a very flexible way. The machine allows filling in a faster cycle time and with a greater dosing precision.

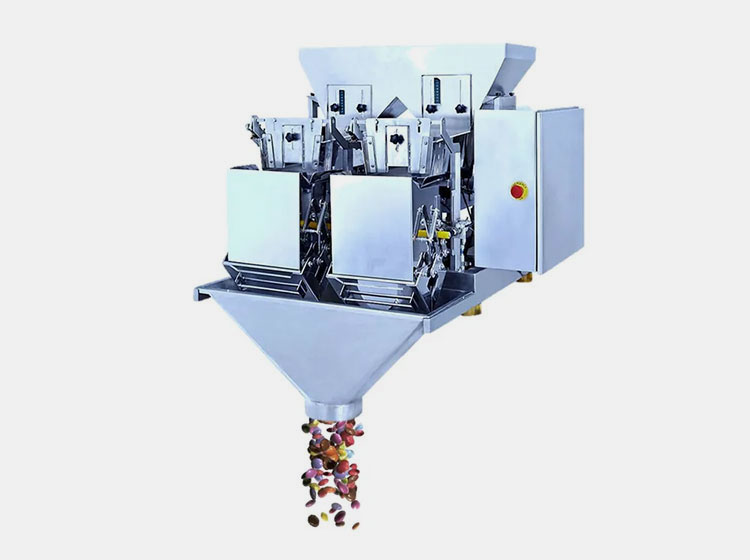

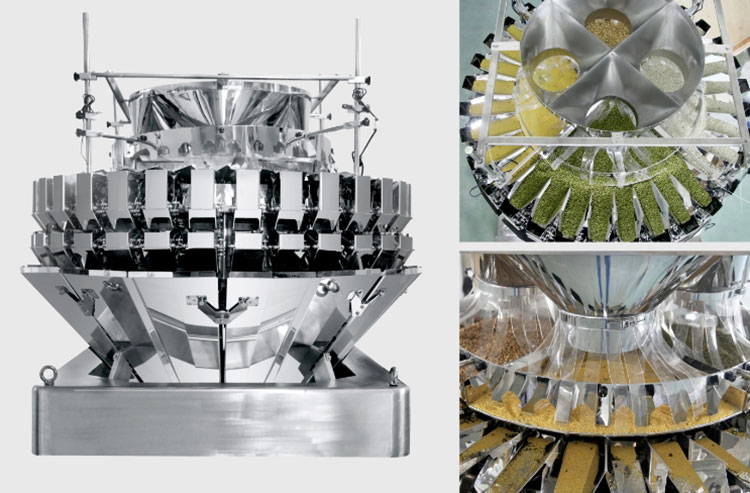

Weight-based Fillers

Weight-based Spice Bottle Filling Machine

Embarking on journey with weight-based spice bottle filling machine, this machine is only based on filling of weight alone. The central function is to load spice and detect quantity or concentration of spice in grams or kilograms and release spices into each bottle using funnel ensuring each bottle is filled with exact amount of spice as required.

Automation Level

Machine with high automation is always in demand to save your time and energy. Similarly, a spice bottle filling machine is also presented with three broad automations such as:

Manual Spice Bottle Filling Machine

Manual Spice Bottle Filling Machine

A very simple and handy tool to fill spices in an economical way.

Besides, from flexible operation, this machine is easy to transport or move due to compact and smaller size.

This machine is basically used in small production sites.

To use a manual spice bottle filling machine, you need to pour, push, release and remove the filled bottle by yourself.

Machine itself is a promising tool in dispensing un-spreadable spice and composed filling.

Here, you will need a constant working, monitoring, and little technical expertise to bring quality outcomes.

Semi-Automatic Spice Bottle Filling Machine

Allpack Semi- Automatic Spice Bottle Filling Machine

This machine is more advanced than manual spice bottle filling machine as here you don’t need to put extra working on the machine.

With this equipment, you can fill hundreds of bottles per hour as machine is presented with greater mechanical output.

Here, you need to load spices, and bottle, once it is filled with machine, you can remove filled bottle and place new one to repeat the process.

Due to this characteristic, you can use this machine to run small to medium production batches easily.

Automatic Spice Bottle Filling Machine

Automatic Spice Bottle Filling Machine

An automatic spice bottle filling machine is a complete solution with high promising throughput as from loading till discharging entire working is done by the machine itself.

You can achieve thousands of spice bottle filling processes in one hour.

The machine is able to detect the presence of bottle and starts filling; if there’s no bottle- no spice filling.

Along with greater automation, machine is capable of integrate with other equipment of production line to bring smooth working in your manufacturing vicinity. You do not need to monitor the process constantly and run the machine for a longer time.

That’s why, for large-size production, this is a good filling solution.

Machine Construction

A spice bottle filling machine is made up of following two construction types such as:

Vacuum Spice Bottle Filling Machine

Vacuum Spice Bottle Filling Machine- picture Courtesy: JBT

This machine is an enclosed equipment that features vacuum suction for drawing of spices from hopper till bottle.

Due to this major property, you can employ this equipment in the running of those spice that are prone to react with external environment and forms lumps. Simply, to keep your environment protected against dust of spice and reaction to oxygen with your product, this machine is ideal.

Opened Spice Bottle Filling Machine

An opened Spice Bottle Filling Machine

A commonly used machine, which is available in two automations such as semi and automatic. This machine is featured with an opened structure allowing user with simple working. Machine is also featured with anti-dust device to conserve formation of dust while procedure and keep workplace safe from spice particles.

Filling Heads

A spice bottle filling machine is featured with various filling heads. Such as:

Single-Head Spice Bottle Filling Machine

Allpack Spice Bottle Filling Machine

This machine is available in high automation and featured with single filling head for filling of spices. You can use this equipment when dealing with moderate filling and packaging process.

Multi- Head Spice Bottle Filling Machine

Multi head Spice Bottle Filling Machine

In a limited time, you can enjoy and boost your spice bottle filling process by using a multi-head spice bottle filling machine that is featured with more than a single filling head to deal with packaging bottles simultaneously.

Orientation

A spice bottle filling machine filling direction is followed by two ways- such as:

Rotary Spice Bottle Filling Machine

Allpack Rotary Spice Bottle Filling Machine

This is a compact and fast filling solution where bottles come in contact with filler and leave the unit once treated using a circular or rotation direction. This machine is basically used where limited installation space matters and require high filling capacity.

Linear Spice Bottle Filling Machine

Allpack Linear Spice Bottle Filling Machine

With machine feeding in and leaving of bottles are taken place using a linear or direct fashion. This machine is flexible to integrate and giving you greater and precise filling results with broad applications.

7.What Other Units are Integrated with Spice Bottle Filling Machine?

Bottle Unscrambler

Allpack High Tech Automatic Bottle Unscrambler

A bottle unscrambler is a specialized machine that is used for the automatic feeding of an oriented bottle in a spice bottle filling machine. This machine basically works by picking bottles from a bin and placing them in an upright position. An optimized time observed is 200 to 300 bottles per minute. The machine structure includes HMI, air pressure and vacuum, bottle fallen sensors, hopper sensors and vibratory plate to bring the following tasks effectively.

Capper

Allpack Cap Screwed Machine

After spice filling, a capper is used for securing bottles that are worked by direct or rotary way. This machine is suitable for giving greater throughput which is roughly noted as hundreds of bottles per minute. Due to its small and compact footprint, this machine is widely used in various packaging companies. The capping process can take place by using screw on cap, snap on cap, pressure pump, or push method.

Induction Sealer

Allpack Induction Sealer for Spice Bottles

A highly effective machine that improves the quality and security of spices by offering tamper evident packaging with no chances of leakage. The cap has an inner lining that melts upon contacting with induction sealer as it emit high frequency electro-magnet waves to induce the melting of inner foil. Once it is cooled, a firm sealing is produced that can keep spices fresh and intact for a longer time.

Labeler

Allpack Labeler for Spice Bottles

Labelers with top/bottom side, wrap-around, front & back, shrink sleeves and many other types are available in the market that offers integration with spice bottle filling machine to bring desirable labeling. Machine is capable of working with applying multi-purpose system, means can be applied using pressure sensitive label, hot-melt glue, cold-pressing and various other mechanisms to give effortless and diverse results with user’s satisfaction.

8.What Different Material Types does a Spice Bottle Filling Machine fill?

A spice bottle filling machine is a flexible machine that is used to deal with spices available in various textures and forms. For example:

Dry Crushed/ Ground Spice

Dry Ground powder spices bottle

The machine features an auger filler which is ideal to fill free-flowing or ground spices. Using an auger agitator, you can enjoy a smooth filling of spices with no stress of clumping or aggregation during filling process. You can fill seasonal spices, crushed herbs, or blended spices using a spice bottle filling machine.

Granular Spices

Dried chili flakes- picture courtesy: epicurious

You have seen various spices available in granular forms as well as in flakes. For example, chili flakes, onion flakes, etc., or granulated garlic, coriander granules, etc. can be filled by using a spice bottle filling machine.

Seed Spices

Seed Spice Bottle

There are various spices available in seed forms such as cumin seed, mustard seed, star anis, and other dried seeds can be filled in bottles using spice bottle filling machine.

Whole Spices

Whole spices- picture courtesy: naturalfoodseries

There are various spices that are on sale as a whole, for example, cloves, red chili, cinnamon, or black pepper etc., you can apply a spice bottle filling machine for treating these products to bring a specialized packaging.

Powder Extracts

Cinnamon powder extract spice bottle- picture courtesy: Savory spice

There are major portions of spices that are grounded and powdered after extraction to bring high aroma and flavor into your cuisine. A spice bottle filling machine is a suitable machine to extract spice into each respective bottle.

9.Is a Bottle Spice Bottle Filling Machine Suitable for Pouches?

Spice Pouches

Yes, there are certain machines that are particularly designed for dispensing spices in bottles as well as other packaging types such as pouches, bags, cans etc.

A spice bottle filling machine is featured with PLC which is capable of controlling and regulating the system depending upon the material type to bring an efficient operation. Now you can run and enjoy working carrying bottles and pouches as filling material and make a trustworthy choice for your production line.

This option is suitable for dealing bottles and pouches of various sizes and shapes, this equipment promises for a consistent and effective filling of process.

10.How is Spice Dust Emission reduced by spice bottle filling machine?

Every manufacturing industry uses a spice bottle filling machine for filling and packaging their product. However tolerating spice dust emission is not possible when it comes to regular and astringent working. The machine is a feature with certain factors to control spice dust emission. Such as:

| De-Dusting Rings |

The specialized rings are used to control spice dust emission in the air and offer clean working conditions to workers. This addition is high in demand where sensitive and irritant products are dealt with filling |

| Vacuum Conveying

|

By utilizing a vacuum conveying system control over a generation of spice mess by picking and sucking of spice particles that ultimately cleans the air as spice dust stays inside the system. |

| Central Dust Collection by Inducing Negative Pressure |

Due to dust collector, a centralized collection of spice is taken, this is because machine is featured with induction of negative pressure that pick particles from surrounding offering safe and reduced dust emissions. |

| Smart Spice Dosing |

The unit is helpful in measuring and filling of spices without spreading of spices everywhere by keeping an intact and smart dosing including pneumatic dose conveying, screw unit, and others. |

11.What are the Technical Problems and Solutions of Spice Bottle Filling Machine?

Like any other industrial machine, a spice bottle filling machine also encounters some technical problems. However, don’t worry- for every problem there’s an easy solution. Check below to find some basic issues with solutions.

Spice Bottles with inconsistent Filling

Inaccurate filling spice bottle

Problem

- Nature and texture of spice may develop this problem, for example, non-free flowing spice possible clumps during filling due to adherence.

- Speed of flow rate may lead to inconsistencies.

- Non-maintenance and non-cleaning for a longer time

Solution

- Assess the texture of spice, determine its flowability ratio, consider machines featuring vacuum mechanism to achieve effective and uniform filling.

- Calibration of machine may solve inconsistencies.

- Proper cleaning and maintenance of the machine can prevent irregularities in filling of spices in bottles.

Clogging of Spices

Clogging bottles spices- picture courtesy: soundhealthandlastingwealth

Problem

Clogging of spices may be caused by due to various reasons such as potential characteristics of spices, some spices are prone to pick excessive content of moisture, may produce caky-ness, reduced flowability, etc., which is more prone cause clogging in the machine.

Solution

- Use spice bottle filling machine designed with vibratory feeders, screw agitator, and various nozzle designs promoting anti-clogging flow of powders.

- Ensure there is no overloading of spices fed inside the machine to prevent uneven flowing of spices.

- Use de-aerator and pre-condition parameters to avoid aggregation during filling.

Leakage of Spice from Bottle

Leakage of spice bottles

Problem

A simple and very typical cause of the leakage of spices from bottles is due to the generation of dust.

Solution

To avoid this problem, dust aspirators must be installed in the machine or use a machine featuring dust controlling properties. For example, vacuum filling, enclosed structure, de-dust rings, or other units.

Bottle Jamming

Spice Bottle Jamming

Problem

Bottle orientation and proper flow towards the filling nozzle failed due to blockage or interruption.

Solution

Adjust the setting and velocity of the moving conveyor.

Check the integrated unit (bottle unscrambler) as it supplies uniform and oriented bottles toward the machine.

Conclusion

We hope this post will be interesting to understand about different types of spice bottle filling machines and relevant topics. Nevertheless, a spice bottle filling machine is a significant equipment used broadly in filling and packaging industries as it meets high quality standards with secure working. Still, if you have queries in mind, we suggest contacting our experts to get a response. Also, if you’re wishing to see our spice bottle filling machine line- we will welcome to connect us to explore various categories involved in spice bottle filling and understand how this particular machine can help to boost your business and meet market demands. Please message us now to enjoy your new journey with Allpack.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide