Soup Packaging: The Complete FAQ Guide In 2025

The hustle and bustle of everyday life often leave us with little time to enjoy the colors of life. But what if you get the innovative means to fulfill your desires especially those of appetite? Definitely you will rush for having them! Similarly, soup packaging is one of the advanced techniques which has been used to make your favorite and delicious soup all time available to you.

Are you eager to know about it? What actually soup packaging is, its various benefits, resilient packaging formats, the machines required for its processing and much more? So, let us show you this comprehensive FAQ Guide on Soup Packaging, which will enable you to get the importance of soup packaging. Also, you can use it for uplifting your business. So, let's get started!

1.What Is Meant By Soup Packaging?

Various soup filled cups- Picture Courtesy: worldbranddesign.com

Soup packaging simply refers to storage and preservation of both cooked and uncooked soup in various types of packages. These packages involve rigid and flexible packaging such as bottles, mason jars, pouches, cups, and many others.

The primary purpose of soup packaging is to provide safe means for delivering readymade soups, promoting convenience of food handling, and ensuring high protection to soup quality. Apart from this, certain other aspects such as labeling, sealing, and material used for soup packages comes under the category of soup packaging which greatly contribute to manufacturers' communication with consumers.

2.Why Soup Packaging Is Important - Explain The Benefits?

Soup packaging is the need of modern day for both consumers and manufacturers and the product itself. Let's, have a look towards various benefits soup packaging is offering!

Food Safety

User checking kraft paper soup tub for leakage- Picture Courtesy: sunkea.com

Undoubtedly, soup packaging is paramount for the safety of soup against environmental, chemical, and biological contaminants etc., by creating strong and protective barrier around content. Also, soup packaging reduces content waste and leakage that may occur especially during transit.

Extend Shelf Life

Number of canned soup containers on shelves- Picture Courtesy: eatthis.com

Soups are normally made in homes on the spot because they get deteriorate when kept for longer. However, the trialblazing of soup packaging has solved this conundrum. Now, soups can be stored for months without worrying about their spoilage.

Promote Convenience

Small soup and noddles filled cups with benefits

As soups are often liquid and meant to be microwaved before serving, thus, soup packaging provides convenient handling for liquids. For instance, you can take a pack of soup for traveling and directly consume it from pack.

Brand Promotion

Innovative soup powder pack

By employing customized packaging for your soup, attractive labeling for visualization, and using innovative and eco-friendly material, you can better distinguish your soups in market. Therefore, an increase in demand will give you more chances to expand your business.

Customer Satisfaction

Woman opening soup cup- Picture Courtesy: Behance

People are becoming more concerned about knowing product information, validity, and quality which can be only communicated to them through labeling, a crucial part of soup packaging. Hence, it paves the way for building trust in customers regarding your goods.

3.Which Type Of Soups Can Be Delivered Through Soup Packaging?

You will be amazed after knowing that how broad the variety of soups people are enjoying across the globe. Also, you must be familiar with all of these if you want to become a successful businessman and expand the sales. These are as follows:

Bisque Soups

Bisque soup- Picture Courtesy: nospoonnecessary.com

Bisque Soups are creamy and thick in nature. Their origin can be traced in France where people used to make soup from seafood and shellfish such as lobster, shrimp, or crab. Hence, bisque soups are now favored around the globe and particularly in Europe.

Consomme Soups

Consomme soup- Picture Courtesy: thespruceeats.com

Consomme soups are clear soups which are made after boiling meat with onion, celery, and carrots etc., in water. However, after cooking, the boiled ingredients are removed out through filtration and the obtained liquid is called consomme soup.

Broth or Stock Soups

Broth soup in plate- Picture Courtesy: popsugar.com

Broth or stock soups are most consumed soups in Asia. They are characterized by being free flowing obtained from chicken, fish, or meat and simmered with vegetables and spices.

Chowder Soups

Chowder soup- Picture Courtesy: wordpress.com

Chowder is a type of soup that contains seafood along with certain vegetables such as onion, potatoes, and carrots etc. Cream or milk is added into soup for thickening and most importantly, unlike consomme soups, chowder soups have chunks. Chowder soup is a great source of rich diet that include all the vitamins, proteins, and fats your body must have.

Cold Soup

Cucumber cold soup- Picture Courtesy: cookingcloset.com

Are you wondering after reading the term Cold with soup? Probably yes! But cold soups exist and are also famous in some regions like Spain, Korea, China, and few other countries. Similarly, its name varies from country to country, however, it refers to the same soup recipe which is made after quickly processing vegetables and fruits. Cold soups give refreshing sensation by replenishing the fluids we often loose during summers. Hence, cold soups are popularly consumed in hot season.

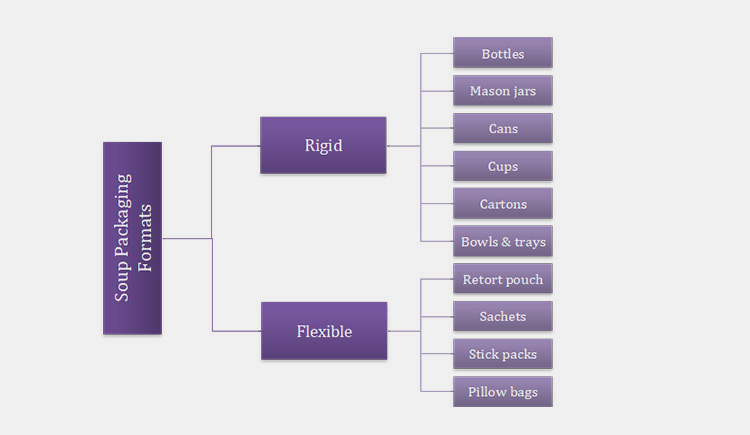

4.Describe The Various Soup Packaging Formats?

In the realm of soup packaging, you will be amazed how extensive is the line. Have a look towards the soup packaging formats which we have classified for your ease!

Rigid Packaging

Rigid packaging encompasses all types of packages with high resistance to pressure. They provide great support in terms of maintaining structural integrity and stability of content. Following are the popular rigid packaging options used for soup packaging:

Bottles

Chilled gazpacho soup bottles- Picture Courtesy: tiogazpacho.com

Bottles are rigid and durable packaging containers frequently made from plastic, glass, and in some cases metal. As bottles are easy to open due to cap and can be used for consuming soups directly without requiring any tools, most of the manufacturers used to deliver their clear liquid soups and cold soups in bottles.

Mason Jars

Mason jars filled with chicken soup- Picture Courtesy: freshpreserving.com

Mason jars come under the category of glass jars due to being chic and holding high inert properties that resist the entrance of microbes into soup and thus ensures protection to its taste, color, and aroma. Glass mason jars are fancy packages which are best for preservation of soups. Despite being heavyweighted and expensive, reputable companies used to deliver their soup in mason jars to attract shoppers.

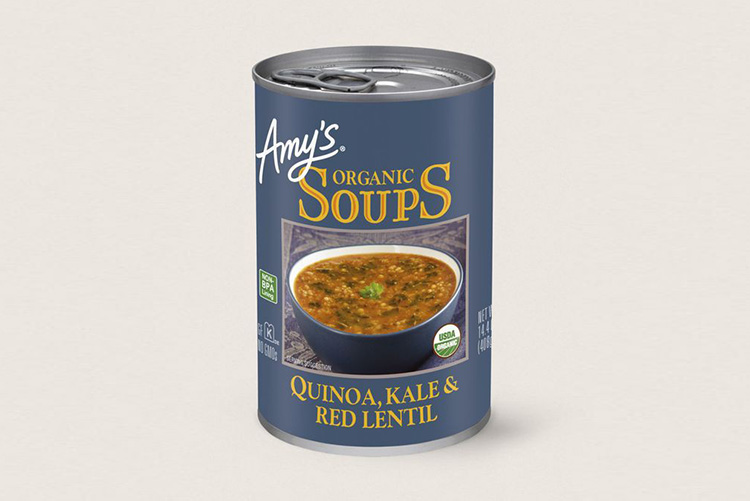

Cans

Organic soup can- Picture Courtesy: Amy's Kitchen

Cans are metal containers made from thin metal or tin layer. They are highly compact, corrosion resistant, and made with strong barrier properties particularly against light. Therefore, you will see the chunky and creamy soups made by quality brands often displayed on shelves in cans.

Cups

Tomato soup cup- Picture Courtesy: Dieline

Soup cups are commonly seen in restaurants and cafes on the roadside for serving single person prepared soup. These cups highly resemble glass with having a lid that strictly adhere to the cup mouth. Hence, you can use cups of various sizes for packaging your freshly made soups.

Cartons

Drinkable soup cartons- Picture Courtesy: Packaging of the World

Cartons can be better described as containers made from the combination of paper, plastic, and foil lined inside. They are having rectangular shape. These cartons are also called aseptic packaging as they are bacterial free and make soups shelf-stable until they are opened by consumers. Hence, you can pack cold soups, soup broths, and consomme soups in cartons.

Bowls & Trays

Plastic food trays

Bowls and trays made up of plastic may also be used for packaging soups such as thick soups and chowder soups. Such type of soup packaging containers are used in super markets to provide buyers with preserved soups having clear display.

Flexible Packaging

Flexible packaging refers to the packaging which can be easily customized and mold into any shape. They are aften made from paper, plastic, and aluminum etc. Some of the prominent flexible soup packaging include following:

Retort Pouch

Carrot & lentil soup retort pouch- Picture Courtesy: Packaging of the World

Retort pouch is a form of stand-up pouch that is made up of several layers comprising aluminum, film, and plastic. These pouches are strong enough to resist light, pressure, and temperature. Therefore, broth and stock soups are mostly packed in retort pouches with hermetic sealing or recloseable spouts.

Sachets

Soup sachet back and front- Picture Courtesy: akimmelnik.com

Sachets are known for their three or four sealed sides which adds into the product safety. They are of square or slightly rectangular shape made from flexible plastic in combination with aluminum. If you want cheap but effective way of packaging your small amount of soup, then sachets are all time favorable.

Stick Packs

Various soup stick packs- Picture Courtesy: stanbranding.com

Stick packs are long narrow bags made up of plastic. They are perfect for single serving of soup. Apart from this, packaging your soup in stick pack helps your products reach far regions where people do not afford large expensive soup packed containers.

Pillow Bags

Pee soup pillow bag- Picture Courtesy: designerpeople.com

Pillow bags look like pillow, and they have larger space to hold any kind of soup inside them. This flexible type of soup package facilitates the convenient delivery of soup while taking care of soup quality and consumers' pockets.

5.Differentiate Between Dried Soup And Liquid Soup Along With Their Packaging?

Most of the people get confused and thus mix dried soup with that of liquid soup. However, these two terms as well as types of soups are different from each other, therefore, their packaging also vary. In this way, the table below will be helpful:

| No | Factors | Dried Soup & Packaging | Liquid Soup & Packaging |

| 1 | Definition | Dried soup refers to soup mixes which consist of powders and several other ingredients. Dried soup is cooked and then dried for making instant soup, thus, it is available in form of powder or granules. | While as, liquid soups are readymade soups. They are available in liquid and creamy form such as soup broth, cold soups, and chowder soups etc. |

| 2 | Packaging | Dried soup packaging is mostly done in flexible packaging such as pouches, bags, sachets, and stick packs etc. | In contrast, liquid soup packaging is extensive and available in both rigid and flexible packaging like bottles, cans, cartons, and pouches. |

| 3 | Usage method | Dried soups are meant to be mixed with water and let it reach the boiling point after which it can be served. | In turn, liquid soups do not require further processing and are ready to be consumed directly from package or served after microwaving. |

| 4 | Packaging process | Its method of packaging is simple and easy. | However, liquid soup packaging requires more efforts and responsible packaging to avoid waste due to spillage. |

| 5 | Machines used | Machine used for dried soup packaging include VFFS machine, HFFS machine, stick packaging machine, and pouch packaging machine. | Contrary to that, liquid soup packaging machine line is broader encompassing separate filling, capping, and sealing machines. |

Knorr instant soup mix powder sachet- Picture Courtesy: My Africa Caribbean |

Various soup filled cups- Picture Courtesy: Behance |

6.What Are The General Steps Adopted For Soup Packaging?

Soup packaging is carried out by using several machines depending on the type of packaging you employ such as rigid packaging or flexible packaging. Hence, the process of packaging may be variant from one another in several aspects. However, the below description is about general steps which almost every type of package follow. Consider these:

Soup Weighing

Although, soup preparation and its loading into hopper of the soup packaging machine are prerequisites of soup packaging, the weighing step will be directly followed by them. Once, machine is loaded with sufficient volume of prepared soup, the machine will be assigned with task to process it. Hence, the first phase will be weighing the soup as per operator demands which are fixed in machine.

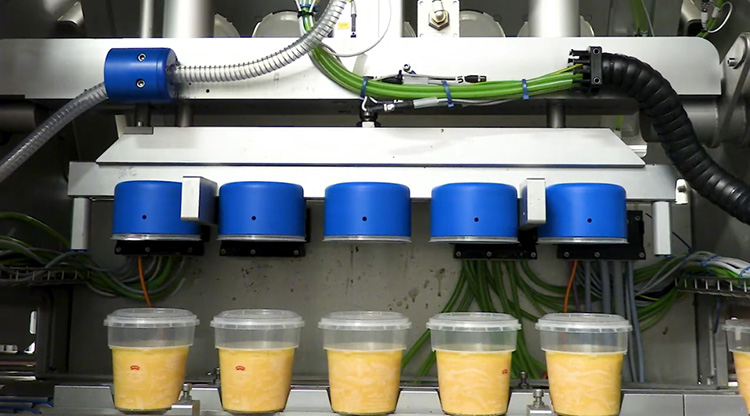

Soup Filling

Soup cups filling process- Sealpac UK & Partners

Moving forward, the precisely weighed volume of soup will be filled into containers. This process is carried out via nozzles. It is crucial to mention here that multiple types of filling machines are used having distinct techniques to handle soups of various viscosities. For instance, piston filling machine is used for thick creamy soups like bisque Soups, cold soups, and chowder soups. While as, soup broth and consomme soups will be effectively filled by gravity filling machine.

Package Sealing

Soup cups capping process- Picture Courtesy: Sealpac UK & Partners

Indeed, the most significant phase where soup filled containers get sealed. This step includes the application of caps and lids over cups and bottles respectively. Afterwards, these caps and lids are tightly sealed to the containers through pressure or screwing. There are other types of soup packages like cans, cartons, and flexible pouches whose sealing is accomplished by different techniques like can sealing and heat sealing etc.

Package Labeling

Soup can labeling- Picture Courtesy: Sealpac UK & Partners

When soup containers get sealed, they are passed through a labeling process where adhesive labels are applied over them. This step of labeling includes package labeling for only bottles, jars, and cups which are not already labeled, while as, necessary coding such as date of expiration for all types of rigid to flexible packaging.

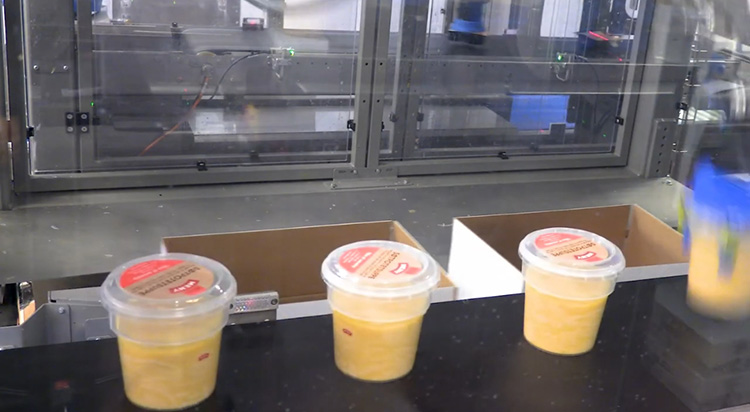

Package Discharging

Discharging of packed soup cups- Picture Courtesy: Sealpac UK & Partners

Finally, after packages underwent filling, capping, sealing, and labeling, the discharging of packed containers is achieved. All soup packed containers are discharged through conveyor belt after which further steps of cartoning and stacking are carried out for their effective delivery.

7.What Machines Are Required For Soup Packaging?

Multiple types of machines are there to be employed for soup packaging. Some prominent among them are described below:

Soup Sachet Packaging Machine

Soup sachet packaging machine

Soup sachet packaging machine is automatic machine used to pack all kinds of thick and viscous soups in sachets by creating stringent sealing on 3 or 4 sides of the pack.

Components

The structure of soup sachet packaging machine consists of a feed hopper, film roll, bag forming structure, control panel, date coder, vertical sealing heating block, film pulling structure, filling nozzle, horizontal sealing heating block, and bag buffer board.

Working Principles

The machine start working by pulling film from roll and turning it into sachet with the help of bag forming structure. Likewise, the formation of sachet is done by creating vertical sealing on single or dual sides while horizontal sealing on the bottom. Here, precise dosage of soup is filled into sachet after which another horizontal sealing is created on the top of sachet to close the opening and sachet is discharged by machine.

Premade Pouch Filling Machine

Horizontal Premade Pouch filling machine- Allpack

This premade pouch filling machine by Allpack is a topnotch machine designed with innovative technology to meet the advance needs of soup packaging. It is effective enough to fill all types of clear, creamy, and chowder soups into premade pouches. It can also perform the same function for filling sauces, honey, and creams etc.

Components

Several essential components together make the assembly of premade pouch filling machine. These include a stainless-steel main frame, hopper, motor, filling nozzle, control board, empty pouch magazine, bag supply device, bag opening device, coding device, heating sealer, and discharge chute.

Working Principles

The process gets start with bag supply device taking premade empty pouch from magazine and supplying it to machine. Here, the coding of pouch gets done after which it is opened, filled with soup, sealed with heat, and ultimately discharged by the machine.

Soup Cup & Bowl Filling Sealing Machine

Soup cup & bowl filling sealing machine

This is another type of soup packaging machine particularly designed to cope with the complexities of handling cups and bowls. It has multiple features which make it perform dual functions of cup filling and sealing as well. It is best suitable for all types of clear and thick soups packaging.

Components

The machine is composed of a complex body, container holder, hopper, filling nozzles, film roll, conveyor belt, control cabinet, touch screen display, sealing mechanism, data printer, and film cutter etc.

Working Principles

It follows sequential order for carrying out the packaging of cups and bowls. Firstly, the machine automatically drops down the cups from holder onto conveyor belt which are then taken for filling. Secondly, the machine automatically weighs precise volume of soup and fill in the cups. Thirdly, it dispenses the film onto filled cups, cut the film, and tightly seal cups once or twice to ensure leak proof sealing. Finally, after coding, all the packed cups are taken out of machine via conveyor belt.

Soup Bottle Filling Machine

Soup bottle filling machine

Soup bottle filling machine is a sophisticated machine configured with advance features to fulfill the demand of soup bottle filling. It can be used for small to large bottles, cans, and jars which are meant to be filled with soup. Besides that, this automatic machine can be also integrated with auxiliary machines to make a production line.

Components

Stainless steel body, transfer pump, hopper, filling nozzles, conveyor belt, control cabinet, alarm light, PLC control panel, and automatic detection system are the few important components of soup bottle filling machine.

Working Principles

The machine operates on the principle of pressure filling. When bottles are delivered to filling station through conveyor belt, the sensor detect the presence of bottles after which accurate dosage of soup is delivered into the bottles. After getting filled, all the bottles are removed out of machine via guide rail.

8.Can You Explain The Production Line For Soup Packaging?

Production line for soup packaging involves all the machines which work together in the formation of finished soup packaging. Below provided example of production is applicable to all types of bottles, jars, and cartons with caps as a sealing mean. It consists of following machines:

Liquid filling Line- Picture Courtesy: Union Machinery

Bottle Unscrambler

Bottle unscrambler is a machine that is used to unscramble the mixed bottles and provide the bottle filling machine with aligned bottles. It consists of a large hopper, stainless body, control system, and conveyor belt. Similarly, it takes the bottles from hopper, align them, and move them forward via conveyor.

Bottle Filling Machine

Bottle filling machine is an automatic machine that is integrated into the production line for undertaking most critical task of bottle filling. Hence, by making in use its various components the machine weigh soup, fill into bottles, and discharge the bottles through moving belt.

Capping Machine

When bottles get filled, they need proper sealing, hence, capping machine is used to secure caps over jars, cartons, and bottles. After that, the caps are tightly sealed over packages through screwing.

Labeling Machine

Labeling machine is another equipment that is part of soup packaging production line. It is used to apply adhesive or sticker labels around soup bottles, jars, and cups. Therefore, the machine is made up of key components, to perform the desired task, such as human machine interface, label plate, label pulling structure, electric system, and application sponge etc.

Shrink Wrapping Machine

Shrink wrapping machine is another machine that is necessary for soup packaging. It is made up of several parts with the help of which soup bottles and jars are covered in plastic wrap, passed through heat, and get shrunk tightly.

9.Highlight The Role Of Labeling In Soup Packaging?

Tomato soup sachet

Labeling is the core component of soup packaging whose absence, otherwise, can leave you with minimal benefits that can be attained through soup packaging. Below description about soup packaging labeling will help you know its significance:

Product Identification

It is the labeling that represents the content laying inside package. Hence, it provides a mean to visualize your soup packaging so, that, it can be easily identified on market shelves.

Enhance Charm

Most of the time, people get confused when choosing same product provided by different companies. Here arises the importance of enticing and alluring labeling which will push the user to go for picking your charming pack of soup.

Communication

The term soup is vast enough that there are multiple types of soup which are now available in market. How will one get to know about the type of soup one is looking for? Definitely through labeling! The labeling of soup packaging will demonstrate whether it is liquid soup, dried soup, or cold soup.

Product Information

Soup pouch presentation idea- Picture Courtesy: designerpeople.com

The ultimate end of soup packaging labeling is to describe the soup. It will hold certain information about soup such as:

Ingredients:Various ingredients used in making soup.

Nutrition Chart:Breaks down the nutritional benefits of soup such as calories, fats, proteins, and vitamins etc.

Validity:Date of manufacturing and expiration of soup.

Batch No & Bar Code:A tracing designation consisting various numerals and machine-readable bars.

Company Information

Finally, the basic information about company such as its name, location, contact no, and most importantly the quality certifications are displayed over soup packaging labeling.

10.What Are The Eco-friendly Solutions For Soup Packaging?

Plastic is one of the most detrimental objects that is degrading the environmental sustainability by creating water and soil pollution. The reasons vary from harming marine life to restricting plants growth, landfills, and many others. Hence, the packaging world is more concerned about introducing biodegradable, compostable, and recyclable packaging options for soup packaging.

Besides the myriad of soup packaging formats discussed above which also include unsustainable ones, let's discover what are eco-friendly soup packaging options:

Paper Packages

Paper soup cups with lids

Paper is the most environmentally beneficial packaging material which is both suitable for your soups and ecosystem. There are multiple industries producing resilient packages for soups and also you can made by yourself. These packages are strong enough to resist soup leakage and restrict humidity from getting into soup. Some of the prominent paper soup containers include cups, trays, and boxes etc.

Plant Based Packages

Eco-friendly food packed tray- Picture Courtesy: kreafolk.com

The common example of plant-based packages is bagasse containers. These are made from the residues of sugarcane, which left after extracting juice. Bagasse containers are 100% compostable, hence, there is no harm done to ecosystem. You may find range of options for soup packages like boxes, cups, and cartons etc.

11.What Is The Leak Test For Soup Packaging?

The leak test for soup packaging can be defined as a testing that provides information about whether the container holding soup is fully protected and tightly sealed or leaking. It thus remarkably helps you in fulfilling the quality control regulations as well as reducing the possible risk of food damage and your brand reputation. In this way, example below will provide you a valuable insight regarding soup packaging leak test:

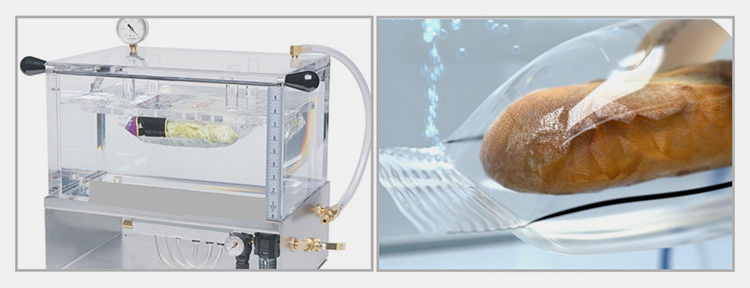

Vacuum Leak Test

Pack Veck Leak Detector- Picture Courtesy: L Hong To Rtai

Vacuum leak test is one of the most notable tests that has been carried out in packaging world for long. It basically aims at identifying the leak in container through employing the technique of vacuum, where a package or container is kept inside the water filled chamber and air pressure is produced. With the help of electric sensor and air pressure gauge not only the leak is found but also its location.

Conclusion

The bottom line is that soup packaging is a practice carried out in restaurants, industries, and even in home kitchens. That's why, vigilant ways are now available to take on for effective soup packaging that paves way for food storage, fulfilling consumers' demands, and ultimately business promotion. So, now the turn is yours! Are you ready for it? If yes! Then let us know your demand and we will be glad to present you an outstanding line of Allpack's machines for soup packaging which are made with sophisticated technology and quality tools. For further information please contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide