Snack Packaging: The Complete FAQ Guide In 2025

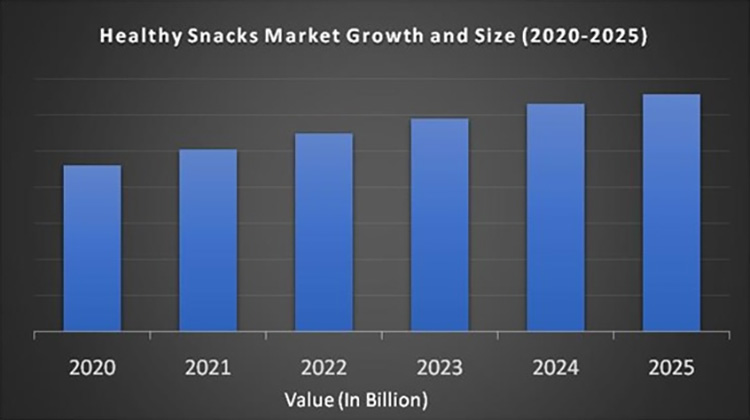

The usage of snacks has increased by 80% in the last 10 years. Snacks are becoming more popular among all age groups. Industries are also now focused on the mass production of snacks. Snack packaging on the other hand holds significant importance in attracting customer’s attraction.

This FAQ guide will help you to understand what snack packaging methods are and what their advantages are. What types of snacks are packed in different packaging materials and why it is necessary to have different types of packaging machine. To answer all your queries Allpack is providing you with this detailed guide. So let us get started!

1. What Is Snack Packaging?

Snack packaging is the practice of preparing and packaging small portions of food that is to be eaten as snacks throughout the day. Nuts, fruits, granola bars, and other healthy options available these as are used as snacks. The purpose of snack packing is to have a convenient, nutritious option as and when required, rather than resorting to food that becomes an unhealthy choice in the future. Balanced diet is also a unique feature that snack packaging provides.

2. Why Do Snacks Need To Be Packaged?

Snack packaging provides a number of benefits to its buyer. Snacks are packaged because of the following reasons

- Material Freshness

The material that is packaged lasts for a longer period and its freshness remains the same until it is used. It protects it from the air, moisture, and other elements that can cause contamination. Also, the safety of the material is provided by the packaging material.

- Ease in Convenience

Snacks that are Packaged make it easy for people to take with them whether they are moving, traveling, going to school, or a party. Snacks can also be used when an individual is just running errands.

- Material Safety

Packaging can help in preventing contamination and protect consumers from harmful substances. Metal and plastic package is made up of durable materials and resists the entrance of microbes. They perform with high efficiency when it comes to providing moisture-proofing products.

- Ease in Material Transportation

Packaging of snacks makes it easy for both manufacturers and suppliers to transport and store snacks throughout the globe. Bulk quantities of snacks can be transported in a single go.

- Environment Friendly

The packaging is environmentally friendly and does not release any type of harmful gas or toxic material that can affect the atmosphere. The packaging materials that is recyclable or biodegradable, which works in favor of the environment.

3. What Are The Types Of Snacks That Are Mostly Packaged?

Some of the snacks that are mostly packaged and used globally are

- Jerky Products

Meat products also need quality packaging to remain fresh even if it gets stored for a longer period. Packaging of meat and beef jerks blocks the entrance of moisture to extend product shelf life. Meat is packed in bags, pouches, and cans as per the requirement for retention to environmental influence.

- Dried Fruits

Dried fruits are also grown naturally to provide a healthy living to human life. But when they are kept for a longer period in open atmosphere, direct environmental affects their pureness. Dry fruits can be not effective if their natural pureness gets affected. Therefore, dry fruits are easy to access and appealing when it comes to their packaging.

- Daily Snacks

Daily snacks like chips, popcorn, cheese balls, biscuits and others also require efficient packaging to keep them alive for a longer period. This packaging can enhance their expiry time and secures material freshness throughout its packaging duration.

4.What Are The Methods To Pack Snacks?

- Snack Packaging Machines

There are several types of snacks packaging machines, including:

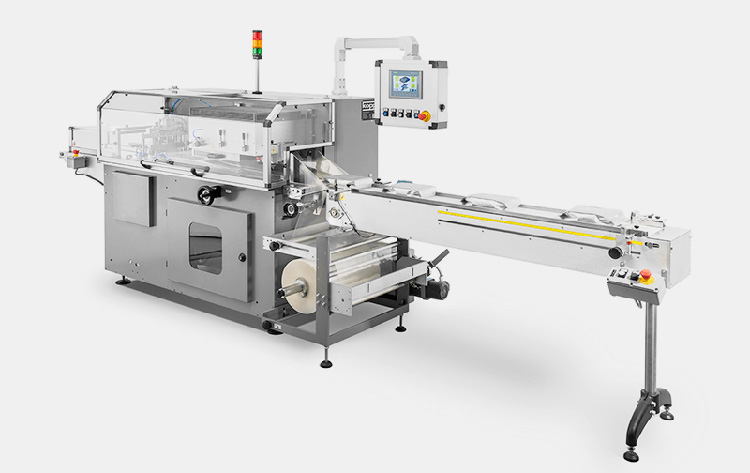

Flow Wrap Machine

Flow-wrapped of snacks in a film is conducted in a flow-wrap machine. In its continuous roll of material is folded and sealed around the product.

Working Principle of a Flow-Wrap Machine

- Initially snacks are loaded onto the conveyor belt and transported to the flow wrap machines operation.

- The wrapping material is unwound from rollers and fed into the machine.

- Both the wrapping material and product combines in the main system and the flow wrap material gets wrapped around the snacks.

- Edges of flow wrapped material are heated and sealed to create a tempered a secured packaging.

- The final packaged snacks are taken out of the machine with the help of exit conveyors.

Vacuum Packaging Machine

Snacks are also packaged using a vacuum packaging machine. The machine gets all air from the bag and then sealing is performed. The sealing prevents oxidation which helps in extending the life of the snacks.

Working Principle of a Vacuum Packaging Machine

- Snacks that are to be packaged are placed in bags that are made of a special material that holds the ability to withstand vacuum processes.

- After that open end of the bag is inserted into the vacuum chamber of the machine.

- As the air is removed from the chamber, it creates a vacuum inside the bag. In the end, the open end of the bag is sealed which prevents air from entering the product.

Vertical Form Fill Seal Machine (VFFS)

A VFFS is also used to provide efficient and quality packaging of snacks. These are used in many industries due to their high compatibility and applications

Working Principle of a VFFS

- Initially the snacks are loaded into the hopper that is present at the top of the machine.

- A roller that holds flexible packaging material like film or foil loads the material onto the machine and fed continuously.

- Packaging materials are formed into a tube by a set of forming shoulders.

- The tubes that are to contain snacks are filled with the product from the hopper.

- The filled tube of snacks is sealed at the bottom to create a complete packaging

- In the end the product is sealed and is cut to a specified length.

Horizontal Form Fill Seal Machine (HFFS)

A HFFS has all forming, filling, and sealing methods incorporated in horizontal orientation. Precise way packaging of snacks is carried in a HFFS.

Working Principle of a HFFS

- A HFFS has a roller of the flexible packaging material of film or foil which further loads it onto the machine system by a continuous movement of rollers.

- After that, the packaging material is formed into a tube by a set of forming shoulders.

- The tubes are filled with the snacks using a filling system.

- The filled tube is then sealed at the top and bottom to create a package, and then the sealed package is cut to a specified length.

Multi-Head Weigher

This machine is used to measure and fill the product into the bag. Multiple heads are weighted and filled with snacks to ensure accurate and efficient packaging.

Working Principle of a Multi-Head Weigher

- A multi-head weigher holds the snack material in its hopper which is further fed to the system.

- Snacks are then distributed across multiple weighing heads, typically using a vibratory feeder.

- Attached each weighing head uses a set of load cells to accurately weigh the product.

- The multi-head weigher uses advanced algorithms to determine the optimal combination of weights from the different weighing heads to reach the desired target weight.

- Accurately weighed snacks are then dispensed into a bag or other container and sealed.

Snack Packaging Bags

- Bag Type Packaging

Following is the bag type packaging done using a snack packaging machine

- Pouch Style Packaging

Flexible and soft packaging of snacks are done in bags and pouches. The bags and pouches are mostly made up of plastic and paper material that can easily be manipulated without any hindrance. The snack product remains secure in bags and pouches and are easy too remote from one place to another.

- Can or Jar Style Packaging

Aluminum, tin, steel, paper and glass cans are packed using s snack packaging material. Safe and contamination-free products are packed in these materials. Although paper cans can be affected by the environment with each passing day this is why glass and metal ones are preferred the most.

- Sachet Style Packaging

Sachets are typically made of plastic or foil and are sealed to keep the contents fresh. They are often used for items like candy, nuts, and small packets of condiments or seasoning. Sachets are easy to carry and consume. The packaging helps the product to remain fresh.

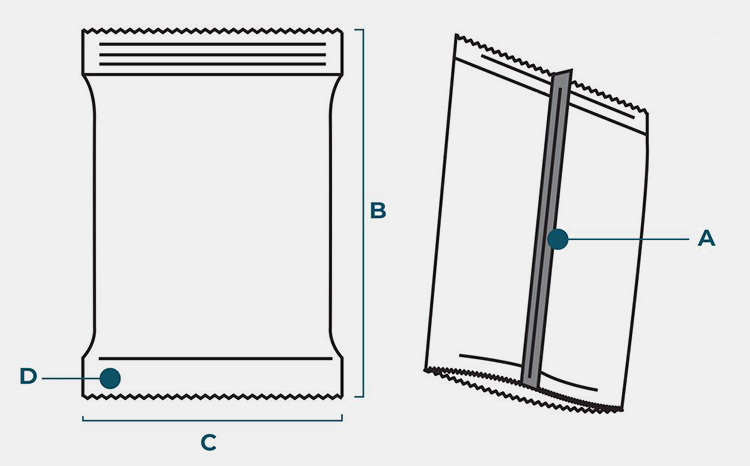

Bag Sealing Type

Bags are sealed in dual, three-sided and even quad sides. Each packaging requires a specific type of sealing method depending upon its application and usage. Some types of bag seal packaging are

- Three-Sided Sealing

Three-sided sealing of snacks is an economical way of packaging that allows large room for material accommodation. The case is easy to pack and provides convenient styling of bags.

- Corner Seal

A corner seal is a packaging way of snacks in which the edges of bags are sealed in a way that V-shaped or triangular corners are created. The corner seal supports in the preservation of snacks and maintains their freshness. This type of seal provides airtight protection that resists the entrance of environmental factors like dust, microbes, bacteria and moisture.

- Stand-up Pouch

Stand-up pouches are designed in a way that the packaging looks in a stand upright manner. Bottom of the pouch has gusset and the top in sealed to make a triangle or rectangle shape. This design grants snacks to look attractive to customers when placed in retail stores. Pouches made up of paper, plastic or laminations are more likely to be used to make reusable stand-up pouches. Cereals, chips, and granola are ideally packed in these pouches.

- Zipper Bag

Reusable or resealable bags mostly come under the header of zipper bag. Snacks that are packed in zippered close bags are designed in a way that they can be opened and reclosed easily. Snacks can easily be used multiple times without having any effect to the freshness or purity of snacks. Airtight zippered sealed bags can easily prevent the entrance of contaminant influence. Crackers, chips, dried fruits and nuts are conveniently packaged in these bags

- Back Sealing

Back sealing methods involved bottom and back sealing of packages to maintain product quality. Food products are more precisely packed in these back-sealed bags and remain contamination free for a longer period.

- Top Seal Doy

As the name states, “Top” defines the design of packaging that is performed at the top of the bag and “Doy” stands for the round-shaped sealing that is done by sealing and folding of the top part. This type of packaging also provides airtight sealing to maintain the freshness of snacks.

- Quad Sealing

Gusseted side collapsing in a quad type seal packaging gives a huge room for product differentiation and placement. They are done in both standup and lay down type style and are one of the unique sealing methods of bags,

5. What Are The Different Types Of Packaging Materials Used To Pack Snacks?

Snacks are packed in several types of packaging materials. Some of them are

- Paper

Paper materials can be used in flow-wrap and VFFS machines to create paper or cardboard-based packaging of snacks. These materials are biodegradable and compostable. This feature makes them an environment friendly and keeps the snacks healthy.

- Glass

Snacks like nuts, dried fruits, and candies and others are packaged in glass jars and bottles. They can be sealed afterward with metal or plastic lid. As glass is a good barrier to light, moisture and air therefore it is popular packaging material for dry and high-value products.

- Biodegradable Material

Number of plant-based materials such as corn starch and sugarcane are packaged with snacks in them. The material can be eco-friendly packaging for snacks. These materials are biodegradable, and compostable and can be used in flow-wrap, VFFS and HFFS machines.

- Composite Material

Composite materials are made from multi-layer of plastic and paper. The packaging material provides a good barrier to air, light and moisture and becomes environment friendly in all aspect.

- Plastic Films

Plastic materials including polyethylene (PE), polyvinylchloride (PVC), polypropylene (PP), and nylon can be used in vacuum packaging and flow-wrap machines. These films are light weighted, flexible and stops the entrance of oxygen and moisture which directly extends the product life of the snack.

- Metal Material

Metal cans and tins are one of the safest materials in which snacks can be packaged. The metal material can be used for packaging of snacks like nuts, popcorn, and chocolate. Metal provides a good barrier to light and moisture, but is heavy in weight as compared to other snack packaging materials.

6. What Are The Differences Between Bag Snack Packaging And Can Snack Packaging?

Bag snack packaging and can snack packaging can be distinguished on following parameters

- Material Cost

Bags type snack packaging are typically less expensive because the material used in these packages is extremely low.

Whereas can snack packaging holds greater production costs as the can material is bit expensive and not all can afford it.

- Packaging Material

Bags snack packaging is made up of flexible films such as polyethylene or polypropylene.

In can snack packaging mostly metals such as aluminum or steel are used to provide greater material safety.

- Material Shelf Life

Can snack packaging products longer their shelf life because the airtight sealing provides a greater barrier on the entrance to air and light?

In bag snacks, packaging environmental conditions can enter after a certain period of time that can reduce product life.

- Barrier Properties

Bags snacks packaged are often made with a laminated structure that provides a barrier to moisture, light, and air.

While can snacks packaging is made of metal which is a good barrier to moisture, light, and air.

- Size and shape

Snacks that are packaged in bags are more flexible in terms of size and shape as they can be made in a variety of sizes and shapes to fit different snacks and according to the production needs.

Can snacks packaging on the other hand have typical cylindrical shape and limited in same size options?

- Recyclability

Metal cans are more easily recyclable and can be re used easily.

Bags snacks packaging are made up of plastic or paper and may not be easily recyclable.

7.Why do Different Snacks Need Different Types Of Packaging Method?

All snacks have different chemical and environmental features. Each of them is different from the other. Each material uses different type of packaging method due to following reasons.

- Nature of Snacks

Some snacks, such as potato chips and crackers are brittle and can be easily broken. Therefore, they require packaging that provides a barrier to protect them from being crushed. Other snacks, such as nuts and dried fruits may require packaging that provides a barrier to moisture and oxygen to extend their shelf life.

- Shelf Life of Snacks

Snacks with a shorter shelf-life spanlike fresh baked goods require packaging that is designed to keep them fresh for a shorter period. Vacuum packaging or modified atmosphere packaging is highly suitable for this.

Snacks with a longer shelf life, such as chocolate require packaging that is designed to keep them fresh for a longer period. Therefore they are packed in metal cans or glass jars.

- Size and Shape of Snack

Some snacks, such as popcorn or cereal come in larger sizes and shapes. Therefore, they

require packaging that can accommodate these sizes and shapes, such as bags or boxes.

Other snacks, such as candy or chocolate, come in smaller sizes and shapes, so they may require packaging that is designed to hold multiple items, such as a translucent plastic container with a lid.

- Target Market Size

Different types of packaging can be used to target different market segments or to create a specific brand image. For example, eco-friendly packaging materials may be used to target environmentally conscious consumers, while sleek and modern packaging may be used to appeal to a younger demographic.

8. What Are The Common Factors That Should Be Considered Before Packaging Snacks?

- Preferences Of Consumers

The most important factor that should be considered before packaging snacks is to do proper research and development on what the consumer in demanding. The packaging of snacks should also be done accordingly to increase the rate of consumption.

- Size And Weight Of Package

Particular sized product should be placed in the materials that can bear its weight. Putting heavier weighted snacks in paper or plastic packaging can damage the material while production or procurement.

- Sustainability Of Product

Sustainability of snacks is the ability to counter environmental impact and increase snacks purity for longer period by using modern techniques. Sustainability actually is the mission to meet the positive impact of environmental, economical and social influence.

- Barrier Protection

It is important to understand the barrier protection factor of snack packaging as environmental influence can directly affect the freshness and quality of snacks. It is important to consider the oxygen, light, gas and moisture transmission rate before packaging of a particular snack in its packaging material.

- Warnings And Alerts

The manufacturer should clearly mention all the warnings and alerts on the packaging material related to use of snacks. It will allow the consumer to get all the information related to the snacks product. Also mentioned expiry date on packaging can help the consumer to use the material within its shelf life.

Conclusion

Due to the availability of different types of snack products, it is always difficult decision select the right type of packaging for each. We Allpack provide you complete guidance regarding snack packaging and its advantages. Feel free to ask if any query remains in your mind. Our customer supports is available 24/7 or visit our website http://www.allpackchina.com/.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide