Small Bottle Labeling Machine: The Complete Buying Guide In 2025

Labeling small bottles is often like a conundrum which requires accuracy as well as safety. However, it is not possible for a user to label hundred and thousands of bottles manually while ensuring precision and efficiency. Therefore, small bottle labeling machine by Allpack is particularly designed for absolving this tiresome job on part of user.

This small bottle labeling machine is intelligent enough to take the entire mechanism of bottle labeling on its part while following the exact commands settled by operator. Equipped with range of astonishing features this machine is suitable for industries with diverse backgrounds. Do you also want to get rid of the false and slow labeling? If yes! Then don't miss reading this informative review which is holding striking solutions to all of your conundrums!

1.What Is A Small Bottle Labeling Machine?

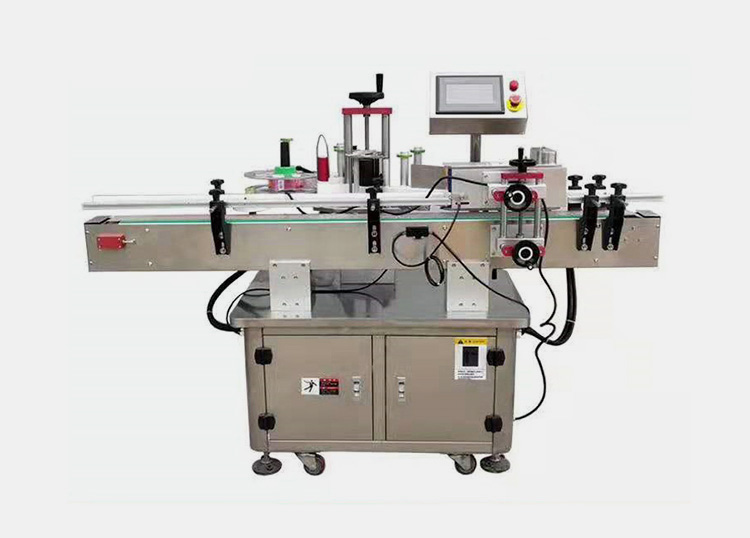

Allpack Small Bottle Labeling Machine

Small bottle labeling machine as the name suggests, is an electrical machine structured for the labeling of small bottles, tubes and vials etc. This machine had been equipped with ergonomic features of automatic detection system, PLC control system and fast stable parts changeover as per bottle requirement. By using these attributes, the machine effectively apply adhesive sticker labels over bottles.

2.What Are The Benefits Of Using A Small Bottle Labeling Machine?

Small bottle labeling machine has been made with ergonomic features which ultimately give substantial benefits to the user and his business. Some of these essential attributes are enumerated below:

Easy to Configure

HMI configuration-Picture Courtesy: technopack

This small bottle labeling machine is developed with intuitive operating interface and PLC controller which together makes the machine extremely easy to configure. Moreover, by using this feature, you could have multitude of choices available to use such as storing multiple setting at the same time and using many software programs etc.

Advance Features

Small bottle labeling machine is tailored with ergonomic features of checking missing labels, ejecting bottles and fast converting from two side labeling mode to wrap around labeling makes the machine to excel the labeling.

High Output

Small bottle labeling machine is proficient in labeling up to 50 bottles per minute. This indicates the efficiency and capability of machine to withstand bulk containers and label them in fast pace.

Stable Performance

Bottles getting labeled in small bottle labeling machine-Picture Courtesy: Direct Industry

Small bottle labeling machine is compact and durable with all components working in harmony and leading to the stable performance where labeling of small bottles get exceptional quality precise labels.

Diversity Of Labeling

Various size bottles with different labels-Picture Courtesy: Mckenzieking Design

Small bottle labeling machine can handle bottles of diverse shapes as well as sizes. In essence, ampoules, vials, canisters, plastic bottles and many other types of bottles can be labeled by using this machine.

3.Which Type Of Labels Does A Small Bottle Labeling Machine Process?

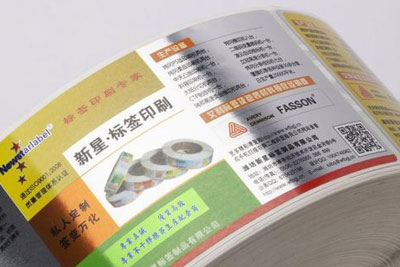

Labels not only give your products an identification rather it helps your customers know the quality of your packaging by analyzing how durable they are to last longer. Therefore, underlying types of labels will help you know the various types of labeling processed by this machine and which is more suitable:

| No | Type | Description | Sample |

| 1 | Waterproof Labels | All types of plastic labels including white plastic, vinyl, holographic and transparent plastic labels are highly resistant to oil and water. These labels are cost-effective but not eco-friendly. |

Plastic labels-Picture Courtesy: Etsy |

| 2 | Paper Labels | Paper labels are cheap in price, and they are also eco-friendly due to their fast decomposition. Hence, paper labels of all categories including white paper, Avon classic, and black vellum paper labels are to be run by this machine. |

Labeling idea-Picture Courtesy: Etsy |

| 3 | Laminate Labels | Laminate labels are the combination of printed label and a protective layer over it to add extra protection against moisture, temperature and light. Thus, gloss laminate, matte laminate, and UV resistant laminate labels are perfect for bottles requiring extra protection. |

Multiple labels-Picture Courtesy: Linxprint |

| 4 | Foil Labels | Foil Labels are made from metallic aluminum material with smooth shiny outlook and strong texture. These labels have adhesive back and can be applied by this machine. |

Sticker label roll-Picture Courtesy: Xinzing label |

4.Which Bottles Are Supported By A Small Bottle Labeling Machine?

The modern technology has added ergonomic features to this small bottle labeling machine to better meet the diverse needs on part of labeling eclectic bottles. Similarly, it is versatile enough to support bottles with ranging material as well as shape including:

Glass Bottles & Vials

Labels on glass bottles-Picture Courtesy: Behance

Although glass bottles and vials are slippery and sterile, a small bottle labeling machine has foam rolling shafts to tackle this issue by preserving the protection of glass bottles.

Plastic Bottles

Labels on plastic bottles-Picture Courtesy: world brand design society

Plastic bottles are lightweight and affordable due to which most of the food items, cosmetics and drugs are packed. In this way, a small bottle labeling machine can be used for their labeling.

Bottles with respect to material

Cans

Pack of labeled cans-Picture Courtesy: Commarts.com

Cans is the most notable example of metal bottles which are used for holding goods and materials. These bottles too are eligible to be labeled by this machine.

Bottles with respect to Shape

Round

Kids gummy bottles-Picture Courtesy: Behance

As round bottles are more comfortable to hold and having big vertical space, these bottles are commonly used for packaging and can be labeled by small bottle labeling machine.

Square

Tomato ketchup bottle-Picture Courtesy: world brand design

Labeling square bottles is a difficult task to do, however, there is a separate category in small bottle labeling machine which is particularly designed to undertake this task for square bottles.

Triangular

Triangular bottles with colorful labels-Picture Courtesy: Dieline

Manufacturers who want to give their products unique and catchy look often opt for triangular bottles. Now, there is no need to worry about the labeling of such beautiful bottles, as this precise small bottle labeling machine is able to do that task effortlessly.

Flat

Perfume bottle and box-Picture Courtesy: Aime Skincare

Most of the cosmetics and food items including perfumes, cream, and ketchup etc., are packed in small flat bottles for easy carrying especially during traveling. Therefore, it can label flat shape bottles.

5.What Do You Know About The Working Principles Of A Small Bottle Labeling Machine?

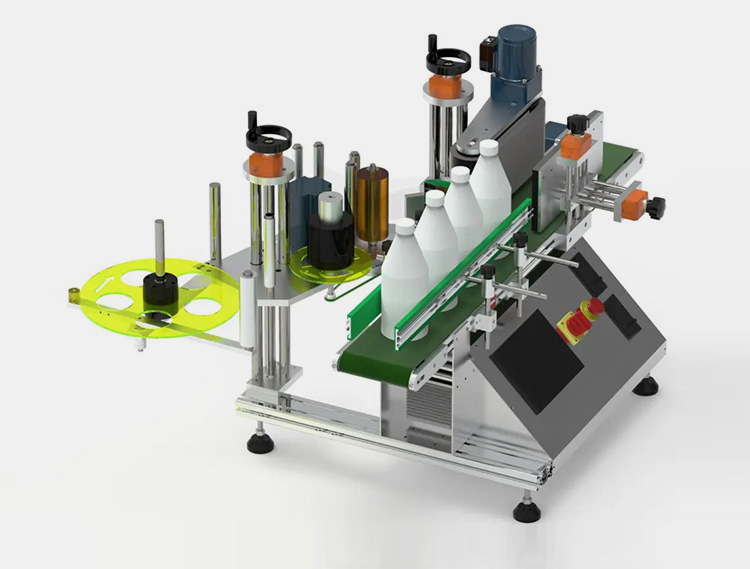

The operation of a small bottle labeling machine is based on particular working principles which we have provided in underlying steps:

Initial Step

Operator fixing parameters on HMI-Picture Courtesy: technopack

Firstly, the working principles of small bottle labeling machine begin with operator setting of machine where basic parameters for label distance, conveyor speed, frequency of rolling shafts and the label applicator is fixed.

Second Step

Bottles on conveyor belt-Picture Courtesy: Joreshtech

Secondly, the machine has to be loaded with a feed roller (labels) and bottles. The feeding of bottles may be done automatically if the machine is integrated with other machines.

Third Step

Thirdly, the machine is now fully ready to be started. The operator will press power button which will ultimately result in the pulling of label through rolling shafts on one hand and mobilization of bottles through conveyor on the other. In this step, the electric eye detects the gap between each label and send message to control system.

Fourth Step

Bottle labeling-Picture Courtesy: Herma

Fourthly, when bottles will reach to the labeling station, the label applicator will apply labels over them in a tidy manner. Similarly, the rolling shafts will swiftly move around the bottles to make sure the labels are accurately adhered to the bottles.

Final Step

Labeld ketchup bottles on conveyor belt-Picture Courtesy: Shamesh Automation

Finally, the labeled bottles will be automatically ejected by machine or manually taken out by operator.

6.Describe The Components Of A Small Bottle Labeling Machine?

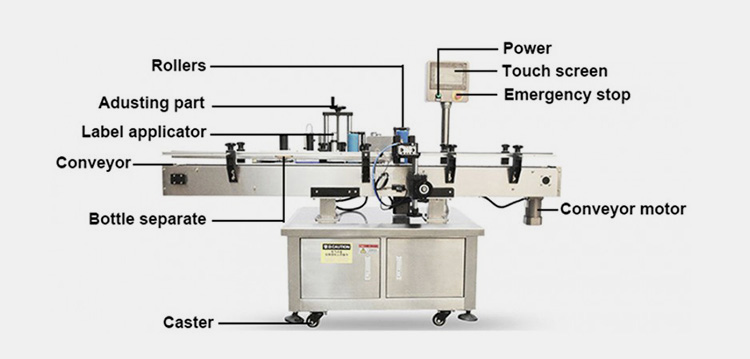

Structure of small bottle labeling machine-Picture Courtesy: SZHX Machine

A small bottle labeling machine is made up of small to complex tools which are described below:

Touch Screen

Touch screen is a display in the small bottle labeling machine which allows the operator to fix the commands into machine control system according to which the machine will be executed.

Power

Power button is the unit in machine which is used to turn on or off the machine.

Emergency Stop

Emergency stop is large size highly visible button located on the front of machine. Its red color enables user to swiftly shut down the machine in case any mishap happen.

Conveyor Motor

Conveyor motor is integrated into machine to power conveyor for transportation in a synchronized manner.

Rollers

There are multiple rollers designed in this small bottle labeling machine. These can be divided into following two:

Feed Roller: Feed roller holds over it the bulk of labels and supply the machine with labels during operation by the constant revolution of label plate.

Shaft Rollers: One pair of shaft rollers is located near the feed roller in order to pull the labels from it and feed them to label applicator. While as, other pair of shaft rollers is placed to the opposite side of label application to help achieve wrap around labeling.

Adjusting Part

It helps in the adjustment of mainframe by changing its height according to bottle size.

Label Applicator

This part of machine is designed to apply the sticker labels over bottles when they pass through it.

Conveyor

Conveyor is a flat belt fitted in Automatic small bottle labeling machine to pass the bottles through labeling phase.

Bottle Separate

Bottle separate device is located at the edge of indeed conveyor which maintains the gap between two bottles when they move onto conveyor belt for labeling. It thus helps to avoid bottle overlapping.

Casters

Casters are also called wheels which are attached to the bottom side of the small bottle labeling machine and assist in its movement.

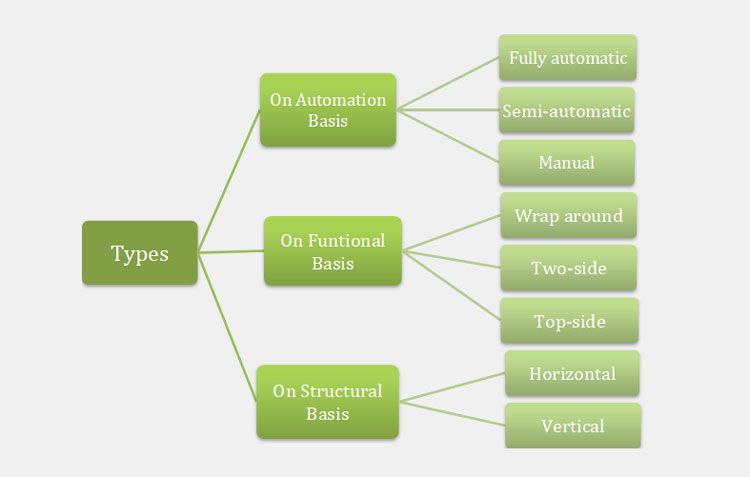

7.Enlist The Different Types Of A Small Bottle Labeling Machine?

Small bottle labeling machine can be fundamentally divided into two categories which are explained below in detail:

Fully Automatic Small Bottle Labeling Machine

Fully automatic small bottle labeling machine-Picture Courtesy: Herma

Fully automatic small bottle labeling machine is topnotch equipment with integrated features of PLC control system, electric detection system, automatic adjustment to the change in bottle dimension as well as the bottle separation for safe labeling. It fully relieves the user from any sort of interaction with machine and carry on its way towards stable, efficient and clean labeling. Every industry having huge production volume on daily basis can better take advantage of this efficacious equipment without any restriction on the field such as cosmetic industry, chemical industry, food industry and medical industry etc.

Semi-Automatic Small Bottle Labeling Machine

Allpack Semi automatic small bottle labeling machine

Semi-automatic small bottle labeling machine is an electronic device which is suitable for running medium range production. Unlike fully automatic machine, this machine requires an operator to initiate the operation. In addition, the bottles are loaded onto machine and discharged by it manually and rest process of taking labels from roller and applying over bottles is done automatically. It has small footprint with modest price which any mediocre business can afford to purchase.

Manual Small Bottle Labeling Machine

Allpack manual/handheld small bottle labeling machine

Manual small bottle labeling machine is available in market to facilitate the small batch or home based businesses in meeting their needs of tidy labeling. This machine is most handy, affordable and requires less space to place as a result of which you can take it anywhere you want. You have to simply put the feed roller in the fixed area and start applying labels over bottle with the convenience of your hands.

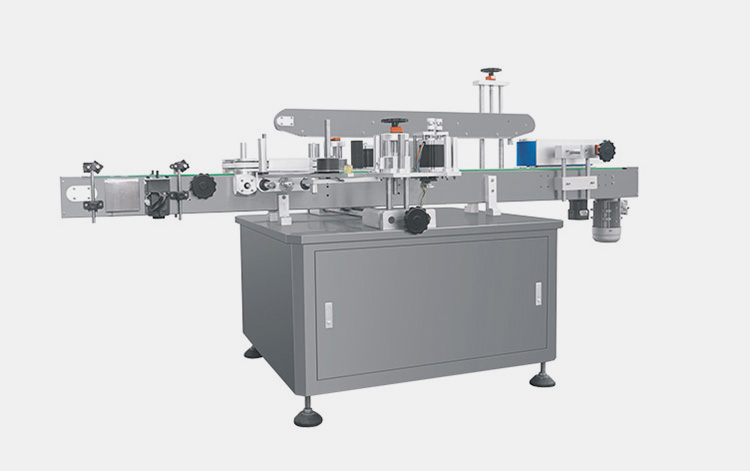

Wrap Around Small Bottle Labeling Machine

Allpack Wrap around small bottle labeling machine

Wrap around small bottle labeling machine has been brought into the field to provide bottles with wrap around labels. It takes the labels from feed roller and cut them into individual labels as per distance or detection system fixed in the machine and apply over bottles. It primarily aims at encircling the bottles with one label on all sides. Most of the vials and round bottles are labeled with wrap around labels. Therefore, wrap around small bottle labeling machine are effective where multiple information is printed over single label.

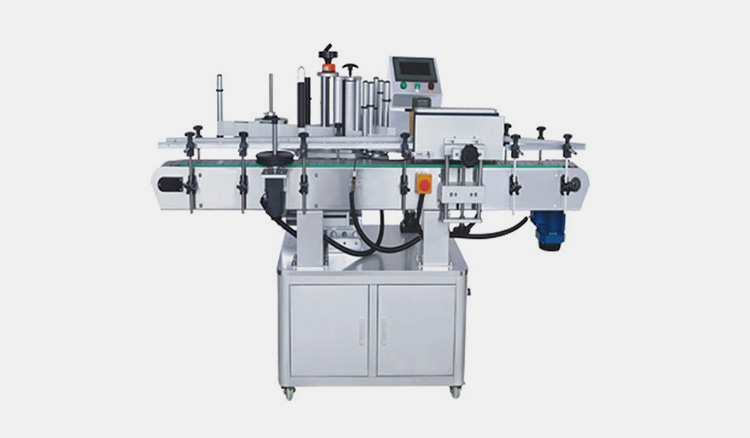

Two-Side Small Bottle Labeling Machine

Two-side small bottle labeling machine-Picture Courtesy: Gosunm

Two-side small bottle labeling machine is employed to deal with the double sides labeling of each bottle. The difference is of feed roller which are two in this machine. The rolling shafts on both side of the conveyor take labels and apply over opposite sides of bottle. Products such as perfumes, talcum powder and sauces are labeled by using this machine due to their presence in flat bottles.

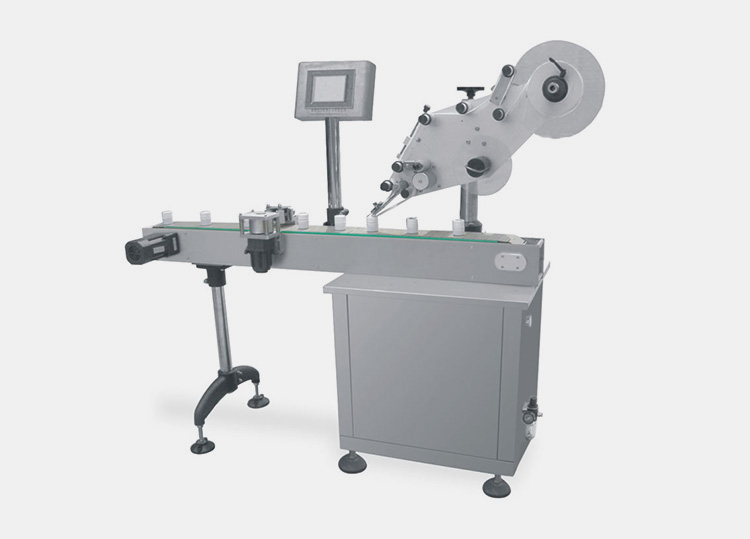

Top-Side Small Bottle Labeling Machine

Top-side small bottle labeling machine-Picture Courtesy: Allpack

Most of the innovative bottles we see on the market shelves grab our attention due to the appealing top-side labels. This is the result of an advance top-side small bottle labeling machine which effectively label every type of small bottles with beautiful labels. This machine has single feed roller on top side which dispenses labels over the top of each bottle passing under the label applicator. Hence, you can use this machine for making your little bottles more catchy.

Horizontal Small Bottle Labeling Machine

Allpack Horizontal small bottle labeling machine

Horizontal small bottle labeling machine is especially designed for small size bottles, tubes and vials which have poor stability to stand. Therefore, this machine is perfect to label these round shape small bottles by taking them from hopper via plastic movable mold roller. The moving roller fall the bottles onto soft conveyor rail and take these bottles to labeling. After reaching under the label applicator, the labeling wheel apply labels over individual bottles and the belt press labels for good results. Hence, this effective small bottle labeling machine is safe to use for small and sterile bottles.

Vertical Small Bottle Labeling Machine

Allpack Vertical small bottle labeling machine

Vertical small bottle labeling machine is used for full or partial labeling of bottles with eclectic shapes and sizes. It labels the bottle which are standing on the conveyor and mobilized towards label applicator. Therefore, it is suitable for every industry including cosmetic, food and chemical etc.

8.Differentiate Between Several Types Of A Small Bottle Labeling Machine?

Below tables will resolve your queries by clearly marking differences among several types of small bottle labeling machine. After understanding these differences you will be able to choose right machine. Let's begin with it:

On The Basis Of Automation

| No | Factors | Fully Automatic Small Bottle Labeling Machine | Semi-Automatic Small Bottle Labeling Machine | Manual Small Bottle Labeling Machine |

| 1 | Nature | Fully automatic, based on independent regulation of mechanism | Semi-automatic in nature with compulsory operator intervention | It is totally manual and is fully dependent on user |

| 2 | Structure | Complicated and large structure with multiple parts | Precise in structure, larger than manual and smaller than fully automatic machine | Smallest compare to both the fully automatic and semi-automatic machine |

| 3 | Operation | Started, regulated and ended by machine | Started by operator, regulated by machine and ended by user | Entirely carried out by the operator |

| 4 | Speed | Extra efficient | Mediocre | Slow |

| 5 | Cost | Expensive | Cost-effective | Cheap |

| 6 | Application | Large scale industries | Medium level enterprises | Home based businesses or retail market etc. |

| 7 | Machine |

Fully automatic small bottle labeling machine-Picture Courtesy: Vkpack |

Semi-automatic small bottle labeling machine-Picture Courtesy: direct industry |

Manual small bottle labeling machine-Picture Courtesy: jetcitylabel.com |

On The Basis Of Function

| No | Factors | Wrap Around Small Bottle Labeling Machine | Two-side Small Bottle Labeling Machine | Top-side Small Bottle Labeling Machine |

| 1 | Function | To encircle the bottle with single label on all sides | To apply two labels over single bottle | To apply single label over the cap of bottle |

| 2 | Feed Roller | One | Two | One |

| 3 | Label Applicator | On one side with multiple rolling shafts on opposite side | On two sides of the conveyor | Only on the top side of conveyor |

| 4 | Application | Round, triangular and square bottles | Flat, rectangular and square bottles | Round, triangular and square bottles |

| 5 | Sample |

Jam bottle labeling idea-Picture by: Vector stock |

Front & back label on juice bottle-Picture by: packaging of the world |

Hand cream jars-Picture Courtesy: Behance |

On The Basis Of Structure

| No | Factors | Horizontal Small Labeling Machine | Vertical Small Labeling Machine |

| 1 | Structure | It is vertical in structure with parts including label roller, applicator, hopper and label pressing device positioned in vertical form | It is horizontal by structure with label applicator, feed roller and label pulling mechanism placed in horizontal parallel form |

| 2 | Process | It takes the bottles from hopper and apply labels through upside down label applicator | The bottles reach to labeling station via conveyor where labeling wheel provide them with labels from right, left or both sides |

| 3 | Label Applicator | Only one | One or two |

| 4 | Application | Round vials, ampoules and plastic tubes | All shapes plastic, glass and metal bottles |

| 5 | Machine |

Aipak Horizontal small bottle labeling machine |

Vertical small bottle labeling machine-Picture by: Technopack |

9.Explain The Applications Of A Small Bottle Labeling Machine?

Small bottle labeling machine has broad range of applications in small to large manufacturing sectors which are shown below:

Medical Sector

Capsule bottles-Picture Courtesy: Nutrafol

In medical sector, tablets, syrups, injection water and vaccines etc. are packed in small bottles and vials which need to be properly labeled. For this purpose, a small bottle labeling machine is the first choice of every industry that comes under the category of medical sector.

Food Sector

Juice bottles-Picture Courtesy: 365detox

Small bottle labeling machine has good demand in food sector where products like sauces, sweets, beverages and condiments are supplied in plastic and glass bottles. These bottles are labeled with attractive labels via small bottle labeling machine.

Cosmetic Sector

Different sized cosmetic bottles/jars-Picture Courtesy: Etsy

While using daily personal care and beauty products, such as shampoo, lotion, hand wash and perfumes etc., you may have observed informative labels over these bottles. Indeed, this is the result of effective small bottle labeling machine.

Chemical Sector

Chemical filled glass test tubes-Picture Courtesy: Compoundchem

Chemicals in their vary forms need to be properly labeled to aware the users about warning and usage method etc. Hence, this small bottle labeling machine can be used to labels all the bottles containing chemicals and associated items.

Oil & Lubrication Sector

Lubricant bottle-Picture Courtesy: BMR

Every mechanical machine even the small bottle labeling machine itself require lubrication for stable performance. Here, it is worthy to mention that lubricating these complex movable parts can be only done via small bottles containing lubrication oil. Thus, this small bottle labeling machine has also great significance in the relevant sector.

10.Which Type Of Information Is Provided On The Labels Processed By A Small Bottle Labeling Machine?

This question carries great significance for manufacturers who want to make their customers well-informed about their products as well as additional information related to them. In this way, underlying points can be helpful:

Product Name

Labeling idea-Picture Courtesy: Behance

Product name is the most prominent element which must be clearly manifested over label alongside brand name. It is crucial to use such fonts for labels which can easily show that the product is for adults or kids.

Brand Name

Brand name is the important part of any label as it provides manufacturers an opportunity to let customer identify their products. Hence, it is the must-have of any label and is displayed on its front side.

Ingredients

Label information-Picture Courtesy: Etsy

Reputable brands are well known for their sincere production due to which consumers expect from them to give complete information about the ingredients used in items. Therefore, a portion of label is dedicated to hold ingredients.

Nutrition Chart

Nutrition chart sample-Picture Courtesy: Karen jolyn

In case the label is of food product or medicines, it will contain nutrition chart that will elicit the percentage of nutrition and thus, allow consumers about daily nutritional intake.

Usage & Warning

Things like syrups or heavy food which can be taken by both adults and kids should properly display the daily usage for both entities. In addition, warning against allergy may be seen over it.

Date Of Expiration

Expiray date label-Picture Courtesy: famouscampaigns.com

Date of expiration is the obligatory information which every label must have. It simply enlightens the users to consume product before it lost the essence.

11.Which Other Machines Can Be Integrated With A Small Bottle Labeling Machine?

This small bottle labeling machine is well-equipped to support the direct connection of other machines with it for establishing a full scale automatic production facility. These machines include the following:

Bottle Unscrambler

Aipak Bottle Unscrambler

Bottle unscrambler is an innovative machine resulted from the combination of mechanical and electrical energy. It is designed to facilitate the packaging of large industries by automatically positioning bottles onto conveyor belt for processing.

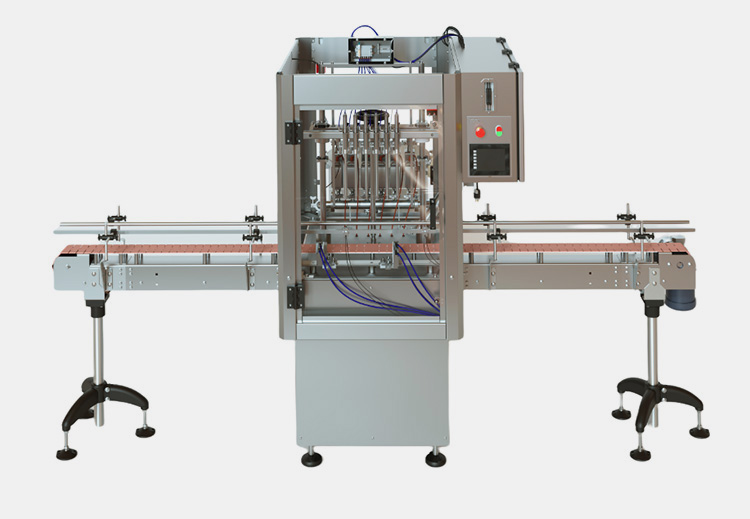

Liquid Filling Machine

Liquid filling machine-Picture Courtesy: Acasi Machinery Inc

Liquid filling machine is made with advance features to accommodate a wide range of free flowing and viscous liquids into small bottles. It uses multiple hoses and nozzles to fill up to 120 bottles per minute. Hence, this machine is an integral part of the production line in correspondence with small bottle labeling machine.

Tablet Counting Machine

Aipak Tablet Counting Machine

As the bottles processed by small bottle labeling machine, may contain tablets, capsules or candies, first they should be properly counted. To attain this objective, tablet counting machine is integrated to the main production line which by using detection system automatically count and fill the desired amount of tablets into bottles.

Desiccant Inserting Machine

Allpack Desiccant Inserting Machine

Desiccant inserting machine is tailored to feed the bottles with silica bags. These desiccant bags functions as oxygen absorbers and remove the possible risk of humidity inside bottles. It takes the long strip of desiccant from feed roller and put it into bottles one by one after cutting it into individual desiccant bags.

Bottle Capping Machine

Allpack Bottle Capping Machine

Bottle capping machine is the vital equipment employed to apply the plastic or metal thread lids over filled bottles. While capping, the machine ensures safety and serenity to preserve the hygiene of material and avoid cap damage.

Induction Sealing Machine

Allpack Induction Sealing Machine

Another machine in the production line includes induction sealing machine. This machine is designed with electromagnetic radiation feature through which it creates heat and melt down the heating material attached to bottle cap. It eventually sticks the aluminum foil to the mouth of bottle resulting in tamper-proof sealing.

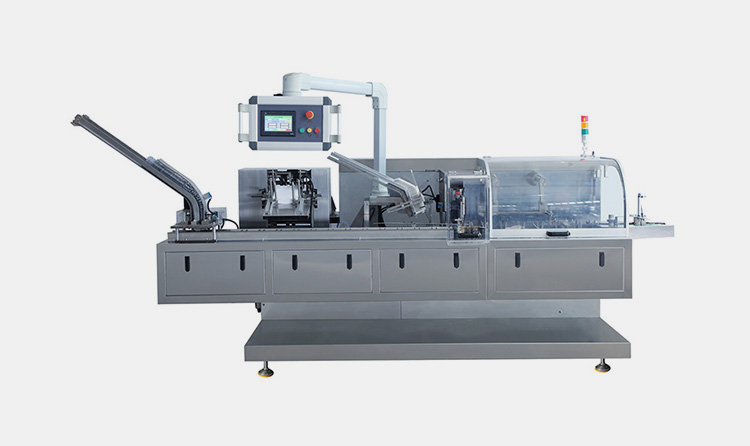

Cartoning Machine

Aipak Cartoning Machine

Cartoning machine also known as cartoner is a device used to pack the bottles into cardboard cartons. It picks up the blank carton, transform into original rectangular shape and put the bottle into it. The carton is then closed via flaps of machine. This entire process of cartoning bottle is carried out by the machine automatically.

12.What Is The Preventive Maintenance Of A Small Bottle Labeling Machine?

Preventive maintenance board-Picture Courtesy: depositphotos.com

It is necessary to keep the small bottle labeling machine clean and maintained for attaining excellent results and smooth performance. Following are the tips in this regard:

Regular Cleaning: Keep the machine clean on regular basis to avoid poor labeling caused by dirt and pollution.

Properly Set Up Machine: Take care of the machine setting before and after operation by checking internal parameters setting and examining external parts.

Use of Quality Labels: Use quality labels to make best use of this brilliant machine and give unique look to your bottles.

Lubricating Parts: Do not forgive to lubricate movable parts of machine for slippery and fast running.

13.What Are The Troubleshooting Of A Small Bottle Labeling Machine?

The underlying remedies can better help you to tackle the sudden problems faced when operating a small bottle labeling machine:

| No | Problem | Reason | Troubleshooting | Picture |

| 1 | Machine fails to produce label | When there is problem in electric sensor the machine stop producing labels | Adjust the position of electric sensor and make sure the sensitivity setting of electric eye is altered after putting new label roller |

Problematic label applicator-Picture Courtesy: Herma |

| 2 | Problem of labeling deviation | Either the bottle holding device is loose or the standard applicator is skewed | Tight the screws of bottle holder and make sure the stripping device is located on standard place |

Bottle holder and label applicator marked with red circle-Picture Courtesy: Herma |

| 3 | The quality of labeling is poor due to bubble appearance | It occurs when the bottle is dusty or the labeling wheel is unparallel to bottle | Keep the bottles and environment free of dust and adjust the labeling wheel by making it parallel to bottle |

Sequential bottle labeling-Picture Courtesy: direct industry |

| 4 | The motor keeps rotating | There may be problem with sensor detection or the speed of motor is too fast | Check the sensor for correct working and also reduce the speed of motor |

Small bottle labeling machine with red encircled label feed motor-Picture Courtesy: Herma |

14.How To Get The Best Small Bottle Labeling Machine?

To get the best small bottle labeling machine you need to be cautious and must consider certain questions among which important ones are discussed below:

Production Range

Multiple herbal liquid bottles-Picture Courtesy: Ly Labo

Have you measured the current range of your production? Are you able to categorize your production either into small scale, medium scale, or large scale? If yes! Then you are just one step away from picking the best machine which will definitely work for meeting your desired throughput by being manual, semi-automatic and fully automatic small bottle labeling machine.

Resilience

Row of large to small glass bottles-Picture Courtesy: Gardenista

If you have different types of bottles in size as well as shape then the machine is meant to be flexible in its function. For instance, a more resilient small bottle labeling machine will be perfectly able to label round, square and any other irregular shape bottles without any parts changeover.

Cost

Cost is an undeniable factor for most of the consumers whenever they intend to make a purchase, and it is crucial to do so. Hence, your preference should be to get quality equipment while keeping in view its price which will ultimately depict your rational decision.

Features

You are going to make your packaging more attractive and unique in the vast market of choice. In this case, it becomes obligatory to have quality equipment integrated with broad spectrum of features for precise working. Therefore, you can check the features of machine from diverse aspects.

Customer Support

Customer service-Picture Courtesy: revechat.com

Do you want to have support of the vendor in case you find any difficulty in operating machine or want to change any part? Definitely you would! Thus, never overlook the availability of customer support on part of supplier.

Conclusion

To conclude, we hope that this article has been helpful in resolving your queries about small bottle labeling machine. The significance and demand of this machine is gaining momentum after every passing day as manufacturers want to beautify their labeling by using this machine. If you are also desiring the same for your business, Allpack as an extensive line of small bottle labeling machine which perfectly complement your needs. For further information please contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide