Single Lane Special Shapes Bag Powder Packing Machine: The Complete Buying Guide In 2025

Are you captivated and attracted by special shaped powdered bags?

Uniqueness and creativity matter a great deal in attracting customers. A single lane special shapes bag powder packing machine is an innovative tool that aims to produce aesthetically packed yet high-quality special-shape powder bags.

It transforms the production capacity of your business and is a remarkable product packaging device that upholds the powder's integrity, quality, and essence.

Do you want to acquire maximum benefits from your investment? For this, you must have detailed knowledge of the single lane special shape bag powder packing machine. So, buckle up for the informative ride.

1.Define Single Lane Special Shapes Bag Powder Packing Machine.

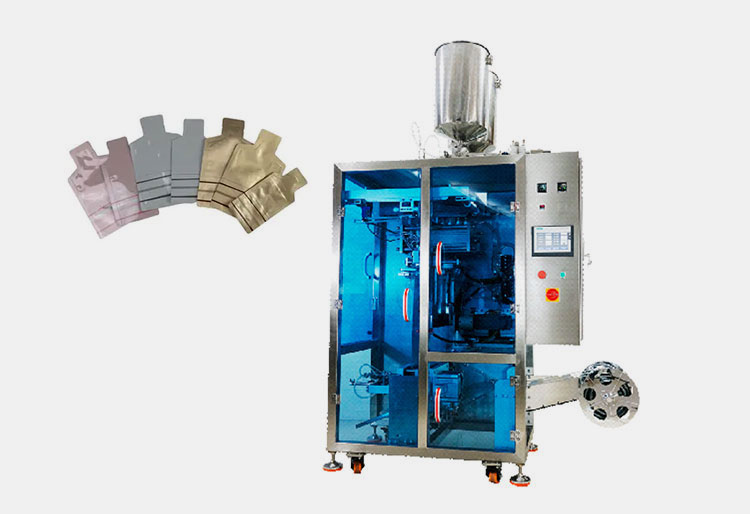

Single Lane Special Shapes Bag Powder Packing Machine

A single lane special shapes bag powder packing machine is constructed to fill powders in unique and nontypical shape bags. This machine creates bags with nonstandard shapes other than rectangular and square.

It typically consists of a single lane for forming, filling, and sealing bags. Single-lane special shapes bag powder packing machine has accurate control over different packaging operations.

2.Enlist the Benefits of Single Lane Special Shapes Bag Powder Packing Machine.

Picture courtesy: aeroflex

A single lane special shapes bag powder packing machine is utilized in both small- and large-scale productions because of its high speed and automation Now let's discuss some important benefits of a single lane special shape bag powder packing machine.

Production Efficiency

Production Efficiency of Single Lane Special Shapes Bag Powder Packing Machine- Picture Courtesy: prohory

This machine has far more efficiency than manual labor. Human operators generally take a long to package one bag which leads to slow and long production. But single lane special shapes bag powder packing machine is faster and can easily fulfill the high demand for powdered products.

Accuracy and Precision

Accuracy and Precision

Accuracy and precision are important in the manufacturing process and the powder packaging line is no exception to the rule. A single lane special shapes bag powder packing machine has a fill precision in every processing batch because there are no fill differences with this machine. Also, with its automated control, it produces special shape bags with far more accuracy.

Versatility

Versatility of Single Lane Special Shapes Bag Powder Packing Machine

Yes, versatility and flexibility are some of the biggest advantages of a single lane special shape bag powder packing machine. This machine produces any kind of special shape bags, as it is customized to produce everything under the sun bags. It is adaptable to every type of special shape with just a change in some key settings.

Branding

Branding – Picture Courtesy: Polynova

Special shapes bags play a very important role in the image building of the brand. Therefore, a single lane special shapes bag powder packing machine is best for branding because it outputs customized patterned bags. These bags tempt customers to buy the powdered products, therefore, they provide an edge to the brand over its competitors.

Compact Machine

Compact Machine- Picture Courtesy: kenhigh

This machine constitutes a single lane that’s why it has a compact and durable construction and occupies a smaller place in the industries. It is composed of quality parts and is easily installed and moved to any place you want. Many manufacturers prefer this machine's compact footprint.

3.In What Industries Is Single Lane Special Shapes Bag Powder Packing Machine Used?

Since a single lane special shapes bag powder packing machine processes wide varieties of powder, so, due to its adaptability, this machine is applicable in a wide range of industries such as:

Pharmaceutical Industry

Pharmaceutical Powders- picture courtesy: stocking up

This important machine is increasingly found in the pharmaceutical industry where drug powders are routinely processed. It packs different types of pharmaceutical powders like emulsion powders, topical powders, and, oral preparations.

Nutraceutical Powders

Nutraceutical Powders- Picture Courtesy: Bow pack

This all-rounder solution is also found in the nutraceutical industry where its hygienic processing has great value. A single lane special shapes bag powder packing machine is utilized in the nutraceutical industry for loading vitamins, minerals, protein, energy, and various other supplement powders.

Food Industry

Food Powders- Picture Courtesy: hj packaging

The food industry is the primary application of the single lane special shapes bag powder packing machine. Effective operation and accurate filling are what make this machine popular in the food industry. It packs different types of sugar, seasoning, salt, and chili powders into irregular shape bags.

Beverage Industry

Beverage Powders- Picture Courtesy: flexpack

This industry vastly processes and packs quick drink mixes in powdered forms. Therefore, a single lane special shapes bag powder packing machine dispenses different kinds of beverage powders like tea, coffee, drink mixes, hydration powders, etc into beautifully shaped sachets or stick packs.

Cosmetic Industry

Cosmetic Powders

A single lane special shapes bag powder packing machine is also employed in the competitive cosmetic industry. Some common cosmetic powders packed by this machine are hair dye, face masks, facial powders, blushes, etc. These special shape bags increase the value of items.

Pet Industry

Pet Health Powders- Picture Courtesy: Foodpack

A single lane special shapes bag powder packing machine packs different kinds of powder pet treats and powder nutritional supplements in creative shape bags. This machine creates convenience and preserves the freshness of pet powder products.

4.What are the Types of Single Lane Special Shapes Bag Powder Packing Machine?

There exist multiple types of single lane special shapes bag powder packing machines in the industries. These types differ in their packaging format and filling devices. These machines are discussed in detail below:

According to the Filling Devices

Auger Single Lane Special Shapes Bag Powder Packing Machine

Auger Single Lane Special Shapes Bag Powder Packing Machine

This type of single lane special shape bag powder packing machine is commonly seen in the industries because of its straightforward and convenient powder dispensing. It is equipped with a closed auger filling device that aids in contamination-free powder loading. It consists of auger screws, auger heads, and auger plates, filling nozzles.

Working Principle

The auger screws rotate the auger devices from moving the powders down the funnel auger device into the filling nozzles. These nozzles gradually load the powders into the special shape bags.

Volumetric Cup Single Lane Special Shapes Bag Powder Packing Machine

Volumetric Cup Single Lane Special Shapes Bag Powder Packing Machine

It is used for dispensing powdery materials into special-shaped bags. It is widely used in the industries because it is synonymous with accurate filling. Agitators are present alongside the volumetric cups in some types of volumetric cup single lane special shapes powder packing machines.

Working Principle

A calibrated syringe is used for measuring the powders loaded in each volumetric cup. Once a correct volume is obtained, it is dispensed inside the cups at increasingly high speed. For these cups, the powders are moved to the filling nozzles and ultimately in the special shape bags.

According to the Packaging Format

Sachet Single Lane Special Shapes Bag Powder Packing Machine

Sachet Single Lane Special Shapes Bag Powder Packing Machine- Picture Courtesy: Shanghai Fubo Packaging Machinery Co., Ltd.

This machine is quite popular in industries because it creates convenient and easy-to-carry sachets that are helpful in an on-the-go lifestyle. It has a modular design with a simple working principle. It creates special shape sachets that engross and fascinate the customers.

Working Principle

At the start of the packaging operation, the packaging film located on the film mounting rack is unwound and carried on toward the forming station. A special shape sachet is formed by the forming tube. The filling and top sealing are performed by integrated filling devices and horizontal sealers.

Stick Pack Single Lane Special Shapes Bag Powder Packing Machine

Stick Pack Single Lane Special Shapes Bag Powder Packing Machine- Picture Courtesy: Landpack Packing Machine

It forms, fills, and seals irregular special shape stick packs. This machine is on the smaller end of the spectrum due to which it has a compact design. It has greater output capacity and accuracy.

Working Principle

It begins its work with the unwinding film and this film track to nip rollers, dancer arm, and forming tube sequentially. The film is shaped into special shape stick packs via folding and sealing. Vertical sealers and forming collars create special shape stick packs with their unique design. Next, powders are loaded into stick packs and then top sealing jaws fuse top edges. Specialized blades cut down unequal sides to create a smooth and aesthetically pleasing look and feel.

VFFS Single Lane Special Shapes Bag Powder Packing Machine

VFFS Single Lane Special Shapes Bag Powder Packing Machine

In this type of single lane special shapes bag powder packing machine, the packaging process occurs in the vertical direction meaning the powders are dispensed in the top hopper and the finished bags go out of the machine from the bottom. Due to vertical operation, it has a smaller footprint.

Working Principle

Initially, the film is fed on the rolling devices from where the film is unwound and goes to the forming station. Here, it is a special-shaped pouch is created with the forming collar and vertical sealer. After filling the powders, the top sealing is performed by the horizontal sealer. Cutters cut the edges and create a smooth finish.

5.What are the Working Steps of the Single Lane Special Shapes Bag Powder Packing Machine?

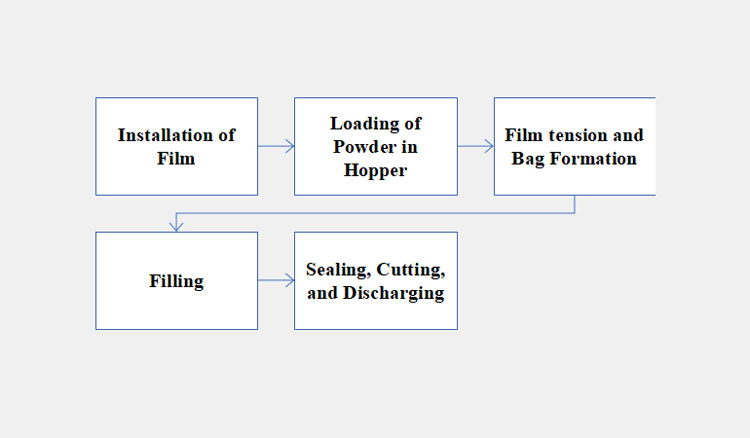

A single lane special shapes bag powder packing machine follows a sequential series of steps. These working steps are straightforward and are given below:

| Step | Description | Image |

| Installation of Film | In the initial phase, feeding and installation of film material occur at its corresponding station. For this, the operator loads the film material on the mounting rack. This film is tightly fitted on the unwinding disk and passed over the series of rollers. |

Installation of Film |

| Loading of Powder in Hopper | The hopper is filled with a bulk volume of powders for the continuous filling operation. Also, the feed tank is connected to the hopper to supply an automatic and nonstop amount of powder to the hopper. |  |

| Film Tension and Bag Formation | The film travels over nip rollers and the dancer’s arm. From rollers, the film travels to the forming tube, where it is given an appropriate shape using forming collars and cutter. |  |

| Filling | After shaping, the filling nozzles take powders from the filling devices, where the powder is dispensed from the hopper. In the next step, the powder is loaded into the special shape bag. The filling nozzles are the significant component of the single lane special shapes bag powder packing machine that feeds exact volumes of the powder in special shape bags. |

Filling- Picture Courtesy: penglaipacking |

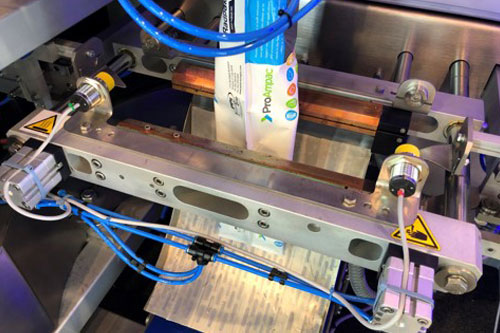

| Sealing, Cutting, and Discharging | The next step is top sealing of the special shape bag which is performed by the horizontal sealing jaws. Cutting and separation of bags take place by the cutters. Finally, the separated bags are discharged from the machine. |

Sealing, Cutting, Discharging- Picture Courtesy: Engilico |

6.What Components Constitute the Single Lane Special Shapes Bag Powder Packing Machine?

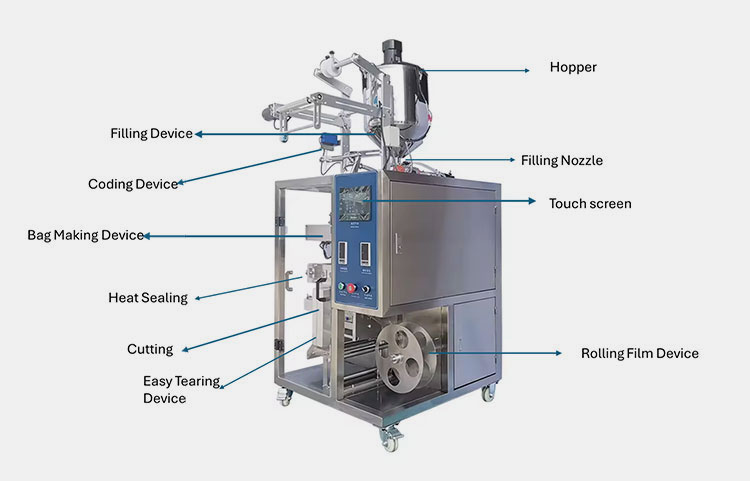

Different components constitute the single lane special shapes bag powder packing machine. Some of the components are described below:

Parts of Single Lane Special Shapes Bag Powder Packing Machine

| Parts | Description |

| Hopper | It is a large container in which large quantities of powder supply are stored. A hopper is a rectangular, conical, or triangular-shaped unit that is essential for continuous powder feeding. |

| Filling Device | The filling device plays a significant role in measuring accurate quantities of the powders and depositing them in the filling nozzle. |

| Coding Device | It is a printing device that codes batch numbers, bar codes, and expiry dates on the packaging film. |

| Touch Screen | It is the intelligent and interactive part of the machine. With this touch screen, operators can supervise the machine by programming and inputting different program parameters. Packaging operation is controlled through touch touchscreen interface. |

| Bag Making Device | The bag-making device in the forming or shaping tube that confers different shapes to the bags. |

| Heat Sealing | There are two heat sealing parts- vertical sealers and horizontal sealers. The vertical sealers are responsible for sealing the sides or edges of the special shape bags. The top and bottom part of the special shape pouch is sealed by the horizontal sealer. These heat sealers are essential in hermetically sealing the bags while protecting them against environmental agents and other containers. |

| Filling Nozzle | It is a tube-like device and is connected to the filling devices. Its job is to load the fixed quantities of powders in the special shape bags. |

| Rolling Film Device | It is also called a mounting rack and is a film-holding device. It is an essential component used for unwinding the film by its rotation. |

| Easy Tear Device | It is an ultrasonic or mechanical instrument that is present in the single lane special shapes bag powder packing machine and forms a small cut on the side of special shape bags. This cut is used for easily opening the packaging container. |

7.What are the Special Shapes Bags Produced by the Single Lane Special Shapes Bag Powder Packing Machine?

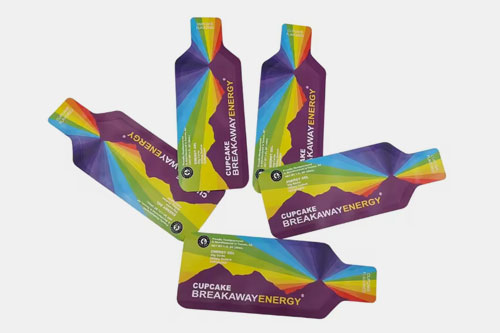

A broad range of special shape bags are produced by the single lane special shapes bag powder packing machine. These creatively design bags go a long way in attracting and engaging customers. Here is the list of some special shapes produced by the single lane bag powder packing machine.

| Bottle Shape Bag

|

These bags resemble bottles with wider bases and narrow tops. It is the most common special shape bag. Bottle-shaped bags are typically used for holding drink mixes and juice powders. |

| Oval Shape Bags

|

This bag has a silky and modern look due to its smooth oval shape. It is excellent for packing gourmet powders, premium cosmetic powders, and supplement powders. |

| Heart Shape Bag

|

These bags have a unique heart shape and are usually used for storing powders during the holiday season and special occasions. |

| Circular Shape Bags

|

These have a round shape with no corners. Circular-shaped bags are used for storing cosmetic powders. |

| Irregular Shaped Bag

|

Irregular shape bags have no distinct shapes and are employed for holding supplements and food powders. |

| Fruit Shaped Bags

|

These bags are like fruits. These can be found in apple, mango, pear, and, banana shapes. These are used for storing drink mixes. |

| Eye Drop Bottle Shape Bag

Picture Courtesy; Biocrown |

These bags have unique eye-drop bottle shapes. It is easy to tear and powder is easily poured out. Eye drop bottle-shaped bags are used for storing healthcare powders. |

| Pyramid Shape Bag

Picture Courtesy: Hotel Suppliers |

These have three-dimensional triangular shapes. It is used in hotel settings for storing different powders like salts, sugar, sweeteners, etc. |

8.How to Maintain the Single Lane Special Shapes Bag Powder Packing Machine?

Maintaining Single Lane Special Shapes Bag Powder Packing Machine

Maintaining a single lane special shapes bag powder packing machine ensures its longevity and efficiency. Here is the maintenance schedule to increase the uptime of the single lane special shapes bag powder packing machine.

| Daily Maintenance | To remove any powder residue, use a soft brush or compressed air and gently wipe out the machine frame and sealing jaws. |

| Weekly Maintenance | Dismantle different parts like hopper, sealing jaws, and filling nozzles and meticulously clean them with mild detergent water solution.

Examine different parts like gear, bear, and chain for damage. Oil these components using specified lubricants. |

| Monthly Maintenance | Check the working order of electric switches, wiring, and other connections. Replace them if needed and fix the positioning of the forming tube, sealing jaws, and cutting blades. |

| Periodic Maintenance | Check and replace different parts periodically to ensure smooth working efficiency of single lane special shapes bag powder packing machine. |

9.Single Lane Special Shapes Bag Powder Packing Machine- What are Technical Faults and Their Solutions?

Sometimes there are inconsistencies in the packaging operation due to technical faults in the single lane special shape bag powder packing machine. It can have determinantal effects on the production. Hence, it is better to learn about these problems and their solutions. Some of the technical faults and their solutions are given below:

Incorrect Film Tracking

The film has poor tracking, as a result, incorrect shape bags are formed.

| Cause | Solution | Picture |

| Inaccurate film tension

There is a defect in the sensors, There are mechanical obstructions in the path of the film. |

Verify that film tension settings are according to the manufacturer's guidelines.

Routinely examine and calibrate the film sensors. Check the film path and remove any hindrance present on this path for consistent film movement. |

Weak or Inconsistent Seal

The packaging bags are improperly sealed, leading to gaps in seals or weak seals.

| Causes | Solution | Picture |

| Poor sealing temperature, pressure, and short dwell time.

Dirty sealing jaws Defects in heating elements |

Adjust the settings of temperature, pressure, and dwell time. These should be adequate to form strong sealing.

Clean the dirty sealing jaws. Repair or replace the heating elements. |

Picture Courtesy: Samfull Packing Machine |

Variation in the Bag Shape

The shapes of the bags are irregular and not according to the desired input.

| Causes | Solution | Picture |

| Damaged forming collars.

Forming tubes are not in line with the film feed. |

Repair or replace damaged or old forming tubes.

Change the alignment of the forming tube so that it is in line with the film feed. |

|

Filling Variations

Under and overfilling of the special shape bags because of the inaccurate amount of powder in the bag.

| Causes | Solution | Picture |

| Out-of-calibration filling instruments.

Poor powder flow. |

Regularly check and calibrate the filling devices.

The powder should be free-flowing and should not clump together. This free-flowing powder will have a consistent flow. Otherwise, consider adding anticaking agents to avoid clumping. |

|

10.How To Choose Ideal Single Lane Special Shapes Bag Powder Packing Machine?

Purchasing a single lane special shapes bag powder packing machine is a hectic and overwhelming decision because there exists a multitude of instrumentation in the market. We have made your purchasing simpler by stating some essential consideration points that will help you in your purchase.

Production Speed

Production Speed- Picture Courtesy: comctl.rtaf.mi.th

It is essential to examine the speed of the single lane special shapes bag powder packing machine. This is because there are different types of solutions found in the market, each having its specified speed. The speed is also dependent upon the bag shape and powder being processed. Elaborate shapes take more time while simple ones take less time. Also, the processing speed is slow with non-free-flowing powders.

Type of Bag Shapes

Type of Bag- Picture Courtesy: OK Packaging

Ensure that your intended machine can process the shapes of bags you need. Also, this machine should process a variety of shapes to accommodate your future needs.

Powder Fill Precision

Powder Fill Precision

It is essential to have a high rate of powder fill precision, as it translates into minimal product wastage and high and consistent packaging quality. Check the filling accuracy of the machine by testing it on-site and ensure the filling quality conditions are fulfilled.

Competence

Competence

Always go for the equipment designed with durable, corrosion-resistant, food-grade, and high-quality materials. When choosing the equipment, it is recommended to purchase the device with the highest customer reviews as it is a failsafe way to ensure equipment delivers high-quality performance.

Conclusion

The powder packaging industry is continuously evolving because of the addition of versatile and multi-purpose machines. Out of this, a single lane special shapes bag powder packing machine is the latest and handy invention that is useful for brand recognition. This machine is known in the market because of its unwavering creativity and top-notch convenience. Learning about working principles, structure, and other components is a must for taking maximum advantage of this convenient creation. So, make sure that you thoroughly read this informative guide. For more queries, please message us now. We, Allpack are here to provide the best guidance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide