Shampoo 4 Side Sealing Packing Machine:The Complete Buying Guide In 2025

Why shampoo 4 side sealing packing is important and brings greater business value?

Let me tell you an easy explanation! When you’re traveling, you want to feel like a bird, carefree about your stuff and want to enjoy every single minute. But it is not possible when you’re stuck with various clutters or worry about materials leakage or loss. A shampoo packing is way more significant this way as it is lightweight and essential to keep you hygienic and beautiful.

A minimalist approach and easy-to-carry shampoo packing is now demonstrated with high production demand which is fulfilled by shampoo 4 side sealing packing machine. This is a successful machine carrying a popular strategy of packing, so why do you ignore this equipment?

There are certain amazing benefits and broader applications hooked to this machine that you will love to read. Keep reading this post to find out how a shampoo 4 side sealing packing machine can skyrocket your business with astonishing features.

1.What is Shampoo 4 Side Sealing Packing Machine?

Shampoo 4 Side Sealing Packing Machine

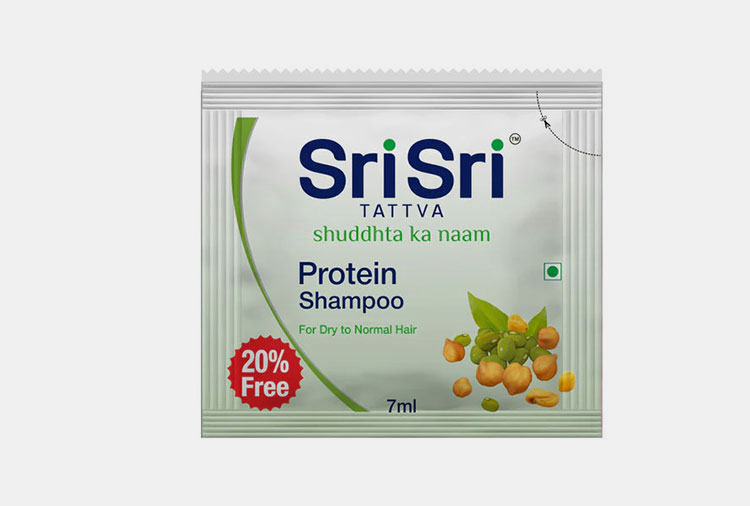

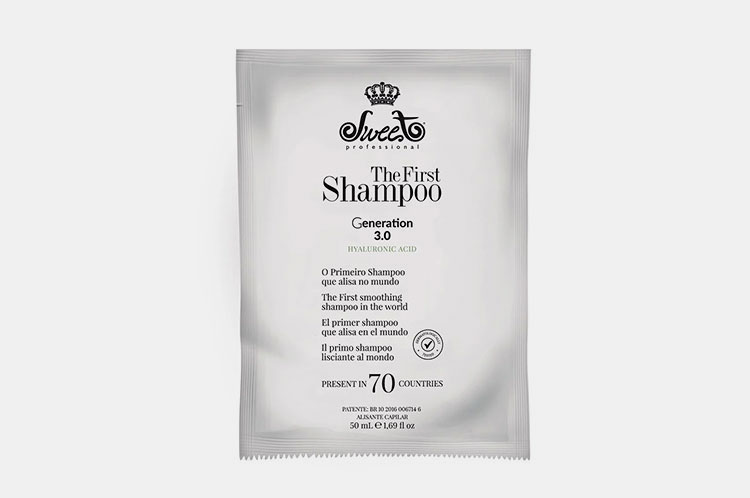

This is a machine that is particularly designed to automate the filling and packing of shampoo formulation into small individual and single-use packaging. When it comes to knowing about 4 side sealing packing, it directly refers to a sachet or stick pack.

This machine shows a broad classification depending upon the type of demand from the consumer. Shampoo packing is an ever-growing field that is catered by shampoo 4 side sealing packing machine conveniently making high value of your brand and improving your product look.

Due to pocket and user friendly properties, this is considered a promising tool that accurately fills shampoo into each pack which helps you enhance attractiveness and quality and ensures freshness and preservation of shampoo.

2.Why Do You Need Shampoo 4 Side Sealing Packing Machine?

Benefits of shampoo 4 side sealing packing machine

There are plenty of benefits a shampoo 4 side sealing packing machine offers to you. Those benefits are mentioned below

Transportation

Flexible transportation

A shampoo 4 side sealing packing machine has a few essential benefits for businesses and retailers as it provides customized shelf space design. This means that shampoo can be filled with its slender 4 side sealing design with desirable volume. Compared with bottles, shampoo packs are easy to carry, and transport, and high quantity material can be adjusted in the secondary packaging or boxes minimizing unwanted packaging burden needed for transportation.

Easily Customizable

Customization

A shampoo 4 side sealing packing machine helps in presenting easily customizable packaging styles to demonstrate your identity and branding. This is included with sealing, opening, and cutting styles. There are various benefits too which include greater aesthetics and blurb related to your business. Additionally, the machine is highly versatile to provide a greater range of products packing that’s why it is demanded well in the field of packing industries.

Long shelf life

Greater protection

A shampoo 4 side sealing packing machine provides preservation of product to remain fresh long time. It is due to offering three features, reducing the chances of oxidation, protecting your formulation against climatic factors, and keeping it safe against leakage., these qualities can help extend the shelf life of your product for long periods of time.

Environmentally Friendly

Eco friendly

This is proven that shampoo 4 side sealing packing has more innovative packing and leaves a reduced carbon footprint with amazing flexible formatting and styles.

Therefore, a shampoo 4 side sealing packing machine plays a significant role in offering environmentally friendly packing with greater storage space and ease of transportation.

Special Film Barriers

High film barrier properties

The shampoo 4 side sealing packing machine is friendly to run a special film barrier that combats against the interaction of light, oxygen, and humidity with your product offering an extra care layer to maintain your product quality.

Distinctiveness

Distinct packing

Shampoos mostly do not feature unique packaging besides standard bottles, but a shampoo 4 side sealing packing machine is coming up with something unusual that makes your product distinctive from your competitors. You can obtain a large window flex when using this machine.

Branding

Boost your brand

Attractive shampoo 4 side sealing packing enables your customers to communicate more so you can convey important information and messages via flexible vibrant packaging. This is all possible with a shampoo 4 side sealing packing machine.

3.How does a shampoo 4 side sealing packing machine process?

Process flow of shampoo 4 side sealing packing machine

There are the following steps which describe the working process of the shampoo 4 side sealing packing machine.

Shampoo Loading

Shampoo Loading

This is the initial step of the working procedure is involving with secure loading of the shampoo material into the machine’s hopper. This section is significant as it provides a material reservoir for the entire process by offering a flexible and smooth supply of the shampoo packing procedure. Once you carefully load the material; you will be ensured and notified by the machine for effective operation ahead. This is a critical step that you must be attentive to as it is a kind of foundation for coming next stages of the packing which ensures your appropriate and correct amount of shampoo is delivered.

Film Loading

Film Loading

Now your attention goes toward loading and adjustment of the film onto the equipment. This is also a critical process step because the correct loading of the film helps you ensure that the whole process is precise and correct. A shampoo packing film is fed carefully around the equipped supporting cords and supports to allow ease of movement for the following stages of the operation., for example, film formation till finishing. If it is loaded well, you can get an ideal packing for sure with optimal presentation.

Film Formation

Film Formation Steps

It the time to switch on the machine and load the information you require; the machine is now ready to undergo the process of film formation where a film wraps around the tube former to acquire the shape of packing you need. This is an essential step that is carefully performed by the machine to prepare a consistent and uniform pack with smooth and equal edges. Once it is accomplished; a set of vertical heating bars punch the longitudinal side of the pack to secure the edges and create a firm bond. A horizontal heating bar is responsible for cross-sectional sealing on one side of the pack and allowing the top side to open.

Filling

Filling of shampoo

Keep in mind that film formation and filling are kind of simultaneous stages where the open side of the pack is left for the filling of an optimized concentration of the shampoo. The machine's high-measuring system controls the correct volume of shampoo dipping into each packet.

A precise amount of the shampoo is filled inside the pack accurately with reduced chances of wastage or leakage maintaining overall uniformity.

Sealing

Sealing

This is another adjunct process step which is ensuring that shampoo packing has to be hermetically sealed by a horizontal heating bar on the upper edge. A strong binding layer is applied to the left portion ensuring now your packing is ready for further processing steps. Keep in mind that now shampoo is properly secure and safe; this means that product freshness and fragrance are intact till you open it for usage.

Cutting

Cutting

After the formation, filling, and sealing of the shampoo 4 side sealing packing; it is the time to separate each pack from the final film roll. This is efficiently performed by the sharp set of knives. The cutting of the film is neatly done without any irregular edges or abrasions to maintain the quality of the pack for your branding and marketing. This is now almost the final step which is allowing the pack for discharge.

Finishing

Ready Product

Many machines are now available that offer with control checking option or the final weighing of the shampoo 4 side sealing packing to ensure that the prepared sample is as accurate as claimed on its packing. This mainly involves weighing each pack, if it is incorrect send it back to the rejection section.

4.What are the different kinds of shampoo 4 side sealing packing machine?

A shampoo 4 side sealing packing machine is not a single machine but there are various available types of equipment that provide this task. The classification of the shampoo 4 side sealing packing machine is mentioned below:

Working Direction

Depending on working direction the shampoo 4 side sealing packing machine is categorised into the following:

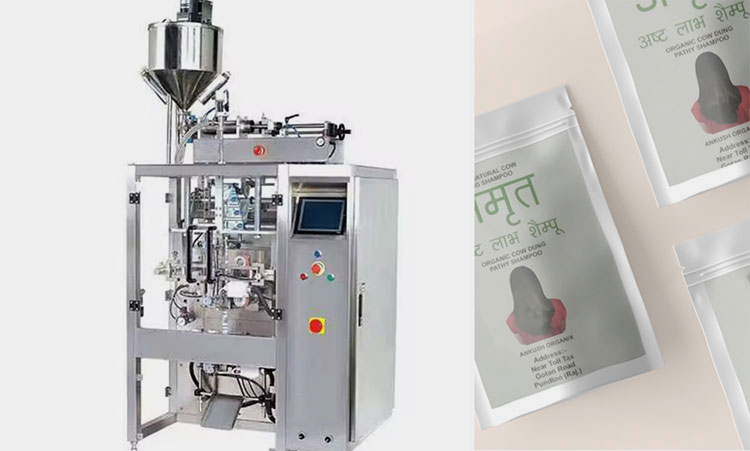

Vertical Form Fill Seal (VFFS) Shampoo Packing Machine

Vertical Form Fill Seal (VFFS) Shampoo Packing Machine

This is a super fast and easy solution that is capable of shampoo packing by forming, filling, sealing, and cutting the pack. Believe me, this small machine is providing a promising 4 side sealing packing for your production batches. This is mainly known for its compact size and offering working with high automation.

Working Principle

As the name suggests, the structural feature and working steps of the shampoo 4 side sealing packing machine are based on the vertical format. Once you load the film, a vertical forming tube ensures the shape formation, followed by filling, sealing, and other work steps in a vertical and straight manner. This machine offers a continuous flow of work with a smooth operating setting. This is the reason behind its high success among shampoo manufacturers across the globe.

Horizontal Form Fill Seal (HFFS) Shampoo Packing Machine

Horizontal Form Fill Seal (HFFS) Shampoo Packing Machine

This is another sophisticated innovation to create 4 side sealing packing for shampoo as it ensures an accurate and precise filling method to its consumers. Likewise, other machines, HFFS is also composed of multiple procedure units which include formation, filling, sealing, and further processing steps such as cutting, weighing, discharging, etc.,

Working Principle

The working principle of the HFFS shampoo 4 side sealing packing machine is composed of various series steps., for example, a film roll unwinds and allows it to roll around the tube former to acquire the shape of the pack. An optimized volume of shampoo is introduced by the machine into the already created pack with a subsequent series of sealing which is included in vertical and horizontal sealing packing systems. The final cutting and discharging take place once shampoo is filled into each pack.

Filler Type

Based on the filler type, a shampoo 4 side sealing packing is categorized into the following:

Piston Shampoo 4 Side Sealing Packing Machine

Piston shampoo 4 side sealing packing machine

Piston shampoo 4 side sealing packing machine is very important as it facilitates the machine to measure and deliver the premium quantity of viscous shampoo volume into each prepared packing.

This is well understood that the viscosity of shampoo is comparatively much higher than regular liquids. Therefore, to meet this challenge a piston shampoo 4 side sealing packing machine is used by manufacturing industries to ensure each pack is excellently filled and marketed.

Working Principle

As mentioned above, it is also following the same standard mechanism where a film and shampoo content is self-loaded into the machine. A piston shampoo 4 side sealing packing machine is capable of forming, filling, sealing, and cutting packs with an accurate filling of shampoo followed by 4 sides sealing of continuous packing film.

Pump Shampoo 4 Side Sealing Packing Machine

Pump Shampoo Packing Machine

This is a unique featured machine that is designed for dispensing highly viscous materials such as shampoo or related products into packs. A pump is responsible for pumping out the shampoo accurately as it creates pressure inside the filler ultimately ensuring speeding up the filling process without any obstruction.

Working Principle

Shampoo from the hopper is sucked by the pump filler which is accurately measured and dispensed into the formed pack by the machine and filled into each pack respectively. Once it is filled, a cutting knife separates the pack from the packing chain.

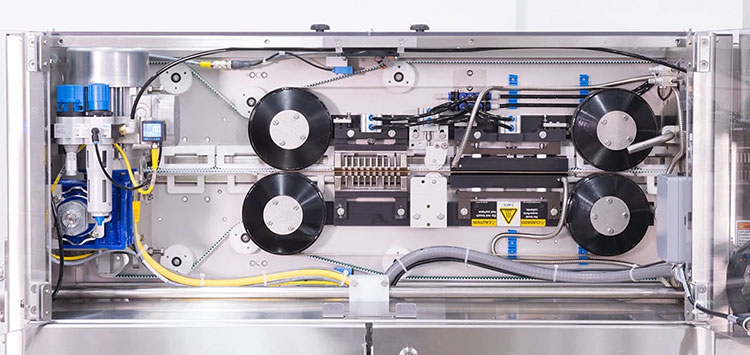

5.What are the Important Parts of Shampoo 4 Side Sealing Packing Machine?

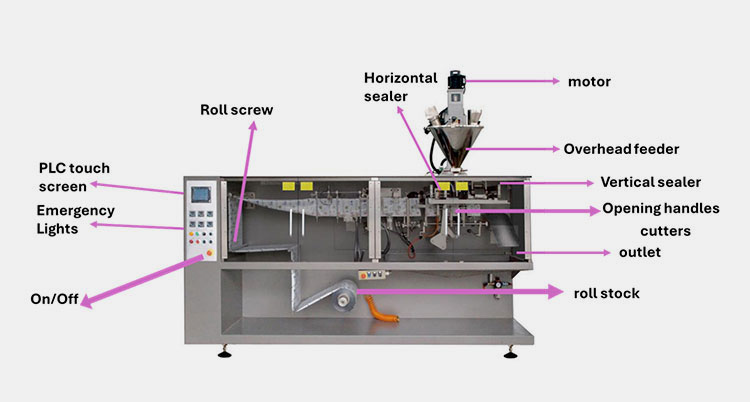

Allpack horizontal shampoo 4 side sealing packing machine

Motor

For smooth operation of pack making, filling, movement of products, and other components, there’s a master unit that sends orders to them, known as a motor. It is responsible for transmitting the power to the entire machinery and like a powerhouse.

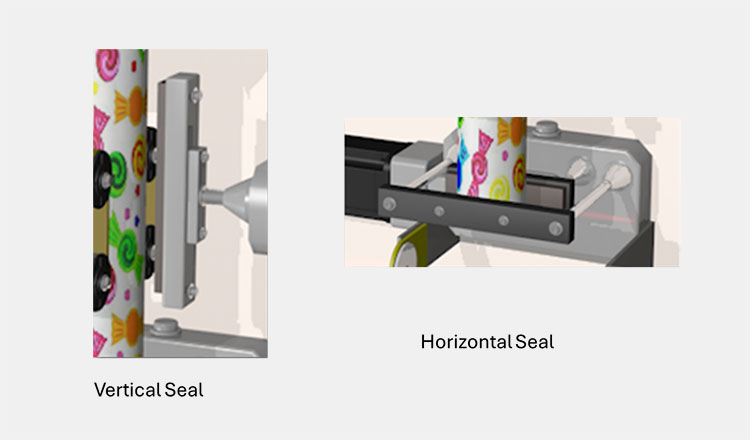

Horizontal Sealer

This is a cross-sectional heated bar that is used to punch the shampoo pack to bind firmly around its edges in a horizontal manner. This is another promising and leading unit of the machine that assures sealing around two sides of the shampoo pack.

Roll Screw

This is a kind of film roll supporter., it allows an optimized portion of the film required by the system by gently w at a very controlledled rate. The purpose of this unit is to prevent uncertain situations such as jamming, wrinkling, or inconsistent packing.

Overhead Feeder

A correct volume of shampoo is filled inside the 4 side sealing packing when it is released from the overhead feeder. This is the most important part of the machine which serves as a storage unit for the filling product. Different machines have different overhead feeders, such as single, dual head, or more depending on the type of production you’re dealing with, for small it is fine to carry one overhead feeder, if you are having large processing, you can select more than one overhead feeder machine.

Vertical Sealer

The sealing process is not completed if a vertical sealer is not devised. This hot sealing bar is mainly utilized to bind the edges of the pack vertically and completes the four side sealing packing. After the shampoo filling, a vertical sealer also helps in the final closing of the pack by punching a single bar on the left or open section of the pack. Thus, it assures you that the final packaging is now safe against leakage or cross-contamination.

Opening Handles

Stuck with a problem? Just push the opening handles to get access to the machine. This is also useful for maintenance or replacement of tools inside. It is a new feature that is not very common in various machines but yes, it is an emerging technique implemented in shampoo 4 side sealing packing machine for improving the operation.

Cutters

Cutters, trimmers, or cutting knives., this is considered important units of the shampoo 4 side sealing packing machine as they ensure the finished product is evening separated from the rest of the packing and ready to move for final production steps.

Outlet

Once the shampoo packing is done by the machine it is effectively moved out of the machine with the help of an outlet which is mostly situated just below or in the middle of the machine.

Roll Stock

This unit is responsible for hooking the film roll and allows flexible unwinding of the roll through the process during the formation of the packing without any unwanted interruption.

PLC Touch Screen

A modern feature of the machine which serves as a control panel that allows you to add important and necessary parameters by clicking on the touchscreen. It makes you experience an easy and efficient performance of the machine.

Emergency Lights

If there’s any uncertainty during work, these emergency lights blow on and alert you to take immediate action. Mostly machines stop working to halt the operation and make you and the environment pretty safe. While some machines alter or notify before any damage ultimately ensuring safe working.

On/Off Switch

For starting or stopping the machine., you can control it by using switch on and off buttons.

6.What are the cutting options of Shampoo 4 side sealing packing machine?

When it comes to the cutting options for shampoo packing machines, there are three main choices: chain cutting, straight cut, and zigzag cut.

Chain Cutting

Chain of shampoo 4 side sealing packing

For wholesale distribution and high marketplaces, the shampoo 4 side sealing packing machine has chain chain-cutting option which is commonly accompanied by having series of connected shampoo packs. This kind of cutting is of high value as it allows to separation of packs by gently pushing against the chain and picking the number of packs as per their needs.

Straight Cut

Straight cut by shampoo 4 side sealing packing machine

This is a standard cutting method that allows the individual cutting of the pack once it is finalized. It is mainly employed for the broad spectrum of product filling and packing such as shampoo, conditioners, detergents, etc.,

Zigzag Cut

Zigzag cut

This is another commonly used cutting pattern for shampoo packing that can be provided by a shampoo 4 side sealing packing machine effectively. This is mainly done by using a zigzag cutting die that forms serrated edges which helps easy separation, and enhances visual appearance.

7.What are the Applicable Markets for shampoo 4 side sealing packing machine?

It won’t be surprising to know several available options for shampoo 4 side sealing packing machine across the huge spectrum of manufacturing industries. This machine is capable of catering to different types and states of product. Come on and check what is your area of interest!

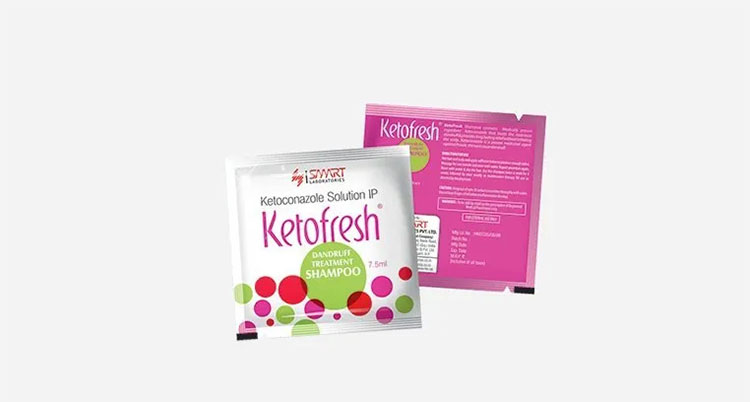

Pharmaceutical Industry

Pharmaceutical Packing

Is shampoo 4 side sealing packing machine right for your drugs? Of course, yes! It has a diversified construction and is capable of taking care of your value asset in your medicinal manufacturing sector. You are welcome to use this machine if you’re dealing with packing syrups, lotions, ointments, creams, etc. A shampoo 4 side sealing packing is a cost-effective and very safe option for running the critical packing of products with 100% hygiene properties.

Food Industry

Food Industry

How to maintain long-term freshness of your food products? A shampoo 4 side sealing packing machine is an absolute answer for you. This is not only a time-saving machine, but it provides greater packing properties to keep the quality and preserve the food items for final marketing. In the food industry, you can mainly use it to pack sauces, condiments, such as kinds of ketchup, purees, and various other products such as mayonnaise, ghee, etc., this unmatchable machine promises you that food product is packed with precise filling and without leave any option of leakage or cross-contamination.

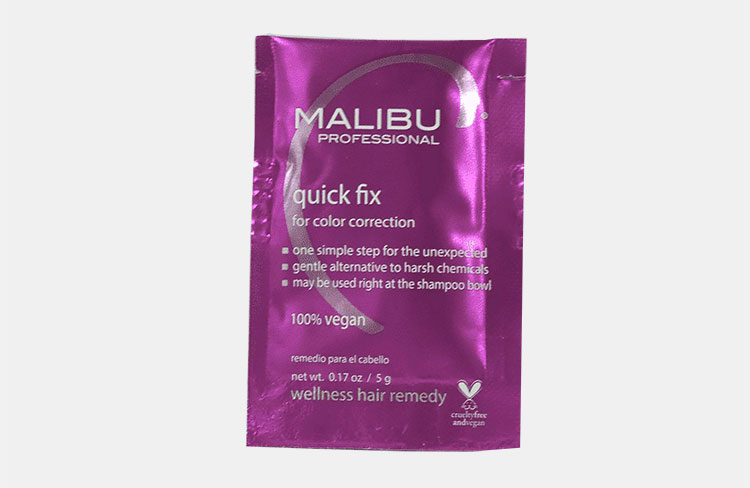

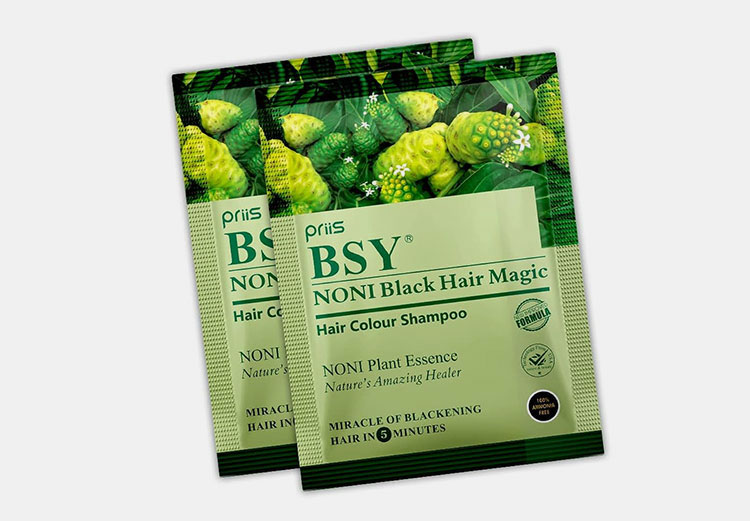

Cosmetics and Personal Care Industry

Cosmetics products

Traditionally, you have seen bottles and jars for cosmetics packaging! The world has changed, trends have changed, and your needs have changed!

A shampoo 4 side sealing packing machine is a great way to secure and enhance your product’s market value simply by critical filling with securing your product's unwanted wastage.

There are various products that are subjected to this machine for packing related to the cosmetic industry. For instance, face lotions, cleansing masks, hand lotions, eye creams,. Etc., the most common application of this machine is preparing 4 side sealing sachet for marketing purposes when you’re launching a new item in the market. This is because it is mostly required for single-serve applications.

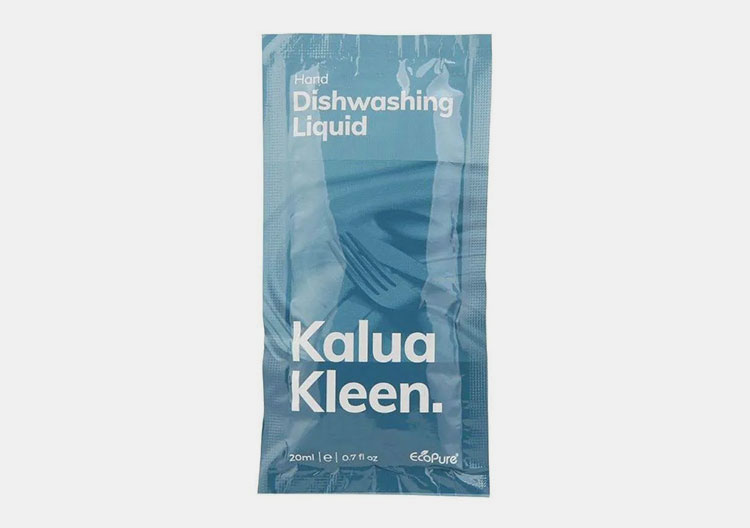

Household and Cleaning Industry

Household products

Now getting household cleaning products is very easy! If you have children in your house then single-serve products are pretty safe to use. That’s why a shampoo 4 side sealing packing machine is showing significant demand in this area of manufacturing. Not just because, it offers safe, secure, leak-proof, etc packing but it ensures that customers' lives and loved ones are safe too. You can pack products such as shiners, anti-fungal solvents, fabric softeners, dishwashing liquids, body washes, hand washes, disinfectants like hand sanitizers, etc.

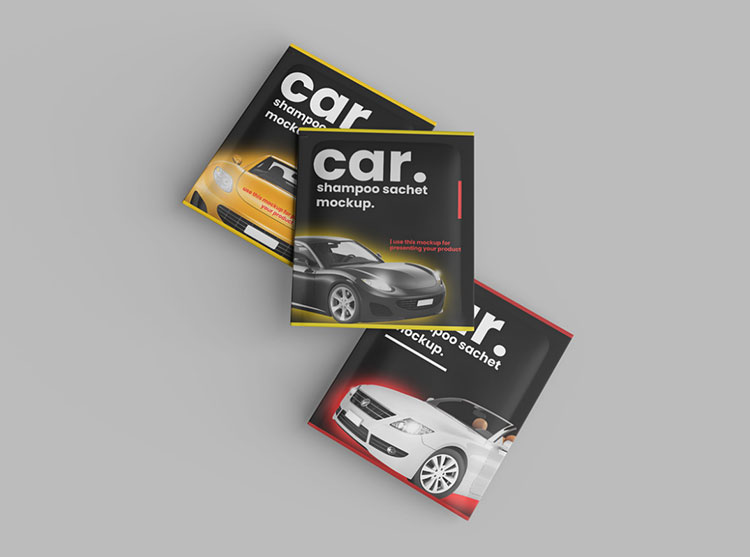

Automotive Industry

Automotive Industry

Elevate your automotive products by using a shampoo 4 side sealing packing machine! a flexible packing option for your products such as car washes, grease, lubricants, waxes, polishes, and related products., A durable machine that promises to prevent expensive liquids during the filling and packing process.

Packaging of liquid industrial chemicals such as solvents, degreasers, and cleaning agents.

Packaging of liquid adhesives, sealants, and coatings.

8.What are the materials compatible with the shampoo 4 side sealing packing machine?

It is not about the game of shampoo packing only! But If you have a shampoo 4-side sealing machine it will be very surprising for you as to how versatile and dynamic it can be! These machines can fill and seal various products, not just liquids. Let’s explore other products you could pack with a 4-side sealing machine.

Liquids

Liquids

These machines are therefore capable of handling other liquids like lotions, creams, liquid soaps, and even sanitizers without any problem. You can utilize it in the manufacture of sauces, syrups, juice, and other beverages. The machine's filling and sealing parts are built to be safe for food grade products.

Powders

Powders

It’s not about liquids. These machines can also work with powders. Think of coffee, tea, protein, spices, and milk powders for the formers. It’s all about ensuring the filling mechanism is suited to the specific product’s characteristics.

Granules

Granules

Various products that are presented in the granular state can also be cater by this machine., for example, grains, salts, condiments, this is the one stop solution which ultimately won’t disappoint any of you; the single machine is the master packing several products so you can enjoy your fruitful investment when buying a shampoo 4 side sealing packing machine.

9.What is standard volume of packing using shampoo 4 side sealing packing machine?

Volume of shampoo 4 side sealing packing

The normal size of shampoo pack with a 4-side sealing machine varies, however these machines are designed to handle packing ranging from tiny to medium in size. They can frequently fill sachets ranging from a few millilitres to 100 millilitres or more, depending on the product and the sachet's intended use.

Usually, sachets that are used once contain between 10 and 20 millilitres product.

For those looking for slightly bigger options, these machines can handle pouches with 50 to 100 millilitres which are great for small retail packs or subscription boxes.

This way, whatever the product may be (shampoo, lotion, or even shower gel), you can adjust the volume to fit the needs of your target consumers.

10.How to clean & maintain the shampoo 4 side sealing packing machine?

Shampoo 4 side sealing packing machine

Maintaining and caring for a 4-side sealing machine for shampoo in good working order is crucial to guarantee that the equipment performs effectively and safely, especially when utilized for packaging personal care goods.

To ensure that shampoo 4 side sealing packing is 100% cleaned, here's a step-by-step guide to completing the cleaning process. Doing cleaning and maintenance on a regular basis will make the machine last longer so that the quality and safety of the product will remain intact.

Clean the internal parts of the machine which is involved in flow of shampoo by using vigorous hot water. Clean the external parts of the machine by dry cloth.

Look at moving parts, seals and connections to find wear and tear.

Lubricate parts where necessary and replace any worn out parts to avoid the situation where the machine breaks down.

Check electrical parts for indications of damage or overheating. By executing these steps, you will be able to make sure that your shampoo 4-side sealing machine will be working properly.

11.What are the challenges with the shampoo 4 side sealing packing machine?

A shampoo 4 side sealing packing machine is an absolute solution for the packing era. However, there are a few minor challenges you may encounter when running the process. For example,

How do you fill shampoo with varying viscosities?

Shampoo viscosities determination

There are variations in viscosities in shampoo and other products such as creams and pastes which makes the packing process difficult whilst also it requires a punch to fill thicker substances.

In the worst cases, adding a new formulation to your production range may necessitate a new machine.

For this reason, you must pick a methodology of positive displacement. It mainly helps you in the flexible filling which is mainly driven by using mechanical piston filler. It is an option you can integrate into the shampoo filling line to get the controllable filling to your line.

How do you deal with the complex shrinking of the film?

Shampoo 4 side sealing pack wrinkling

In the cosmetic industry, negating aesthetics can affect your brand! When using a shampoo 4 side sealing packing machine you come to with useless shrinkage of the film that wastage your product and as well as your efforts.

This problem can be tackled by opting for an optimized temperature for sealing the film. – allowing the fine tune-up of the screw and film adjusters can save you from suffering this problem. Today, robotic technology can also help you adjust the machine by calibrating and knowing the progress using a PLC unit.

How to Prevent Film Jamming?

Jamming of the film- Picture Courtesy: Syntegon

The jamming of the film can dramatically stop the entire running process—it is necessary to maintain the issue by selecting the right material for packing that flexibly shows compatibility with your machine. You can deal with the problem by re-adjusting the film using the proper technique of setting the film around winders, rollers, and supporters. Run the test to assess if a problem is solved.

12.What is the impact of shampoo 4 side sealing packing machine on your business?

This is a very interesting thing you called it ‘packing economy’. I hope you’ve not heard about it before. The shampoo 4 side sealing packing machine is all about producing small and tiny packets which is almost super handy and allows all categories of people to enjoy a portion of the product at affordable prices. There are certain significant points related to this machine which impact on your business!

Small Product High Purchase

Improved production and value

A shampoo 4 side sealing packing machine provides packing of small products, on the other hand, it profits you more as it can gain popularity and more access among consumers even with high and low-budget shopping places. This is because it offers great accessibility to everyone and increases your profitability.

Modern & Rural Sector Market

High market

Isn’t amazing how a shampoo 4 side sealing packing machine shows a high market not only in modern markets but also in rural areas? According to our experience, the rural areas mostly prefer small packs and show more demand. This is all because of the affordability and simplicity of the product. If you buy this machine; we guarantee you high business value around every marketplace.

Environmental Benefits

Eco-friendly

A packet formed by shampoo 4 side sealing packing machine is not only a better option for your wallet but also eco-friendly. This is beneficial to create less waste comparatively when considering large packing options. Today, in first-world countries, this option is mostly preferred as it reduces the potion and landfills.

Expansion of Profit

Gateway to communicate with your customers

Today everyone is using 4 side sealing pack to get in touch with consumers. It is the basic version where you can write something or enhance a product by adding more vibrant colors on a pack to attain high consumer attention and ultimately profit.

Conclusion

Filling and packing shampoo are nevertheless a challenging task! Many of you don’t think too much about its packing. Having general knowledge about its packing and knowing the right equipment can certainly improve your profit margin and brand. You shouldn’t be worried about the matter when Allpack is here. Choose us first before selecting the machine. We have an extensive 5-star machinery profile with excellent customer service reviews. Remember, selecting the right machine can change your business fate., if you’re looking to buy shampoo 4 side sealing packing machine or require a consultation then We would love to hear from you. Please don’t hesitate to contact us now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide