Semi Automatic Gummy Machine: The Complete Buying Guide in 2025

Having a limited budget but unlimited aims for gummy production? You’re at the right place!

Sweet, colorful, and enticing gummies are everyone’s favorite. In the previous few years, the gummy candies production has progressively improved that turned into million million-dollar business. Indeed, this is not complicated to achieve the goal of producing gummy making as you have bunch of available options that offering pretty easy production of gummies professionally.

Today we’ve brought an informative blog that will assist you in executing your dreams exactly the way you want. Come on, Find the below article and look how our experts have added significant input about semi-automatic gummy machine and its impact on your business.

1.What are gummies? Why is its demand progressing?

The gummy candies are sweet and sugary treat that has a bit hard external layer with softer and chewy inside. As the name suggests, a gummy has a superb gummy texture than any candy you’ve experienced so far. This is all because of the involvement of the main ingredient ‘gelatin’ which enhances an elasticity when you chew it. The stretching of gummy is almost like a rubber band.

By the exact definition; the gummies the formed by a gelatin and sugar. Today, gummy market is extremely competitive and progressing for certain reasons. The gummies are high in demand among children as a treat. Side by side, gummies are manufactured in medicinal industries. Also, athletes or health-conscious people prefer them to consume as a health supplement. These all requirements are turned into an astringent supply scale in the market. To meet the flexible supply various companies and businesses are more likely to focus on making gummy. This is predicted that its business will give rise to CAGR of 6.5% total in between 2023 to 2033 which is approximately 7352.3 million dollars business in the competitive market.

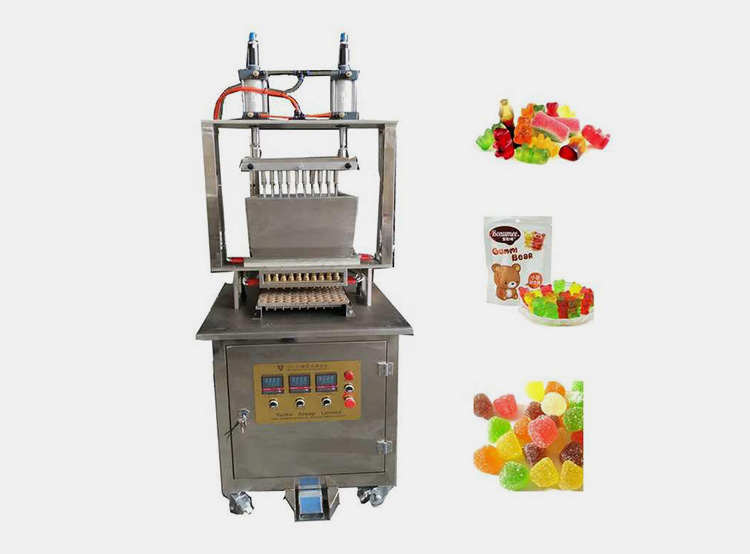

2.What Is A Semi Automatic Gummy Machine?

Semi Automatic Gummy Machine- Picture Courtesy: Aipak Pharma

A semi- automatic gummy machine is the most popular and competitive addition in the gummy making world that can accomplish the formation of gummy candies effectively. If you’re worried about its construction and working, then you’ll surprise to know this robust machine is extremely useful in making gummies batches without needing so many workers and tiresome operation.

But the machine is preferable in running small to moderate production companies as it can ranges hundreds to thousands gummy production in the few hours. Thus, this is an ideal machine for you featuring a simple structure that we have talked below. As it names shows, machine is working automatically but requiring human intervention in fixing mold and removing it from the machine. although other tasks can be operated by the machine itself.

3.Where a semi automatic gummy machine is used?

A semi automatic gummy machine is a versatile equipment used broadly in the large industrial sector as it offers you unlimited benefits in the term of productivity and business. Let's find the fields semi automatic gummy machine industrial applications helps you in sustaining skyrocketing your high market.

Nutraceutical industry

The role of semi automatic gummy machine in the nutraceutical industry- Picture Industry: Nutraingredients

Today, the first world countries such as America, Europe, Australia, etc., depicting high market rate and with more demands of nutraceutical products prepared in the form of gummies. Such as vitamins, protein supplements, enzymes, minerals, trace elements, etc., The manufacturing industries opt semi automatic gummy machine to fast productivity in a cost economical way to meet their requirement.

Confectionery Industry

Semi automatic gummy machine In Confectionery Industry- Picture Courtesy: Nutra-Organic

An enticing gummy with various shapes and colors has boosted the demand for the gummy market. The semi automatic gummy machine is a prime equipment used in the confectionery industry in the formation of candies, gummies, jellies and other relative products that has improved the significance of the machine worldwide.

Pharmaceutical Industry

Semi automatic gummy machine In Pharmaceutical Industry- Picture Courtesy: Holland

Of course, this is not new to know that semi automatic gummy machine is now the most significant preference of pharmaceutical manufacturers in the making of pharmaceuticals items such as medicines used in the treatment of subsiding the pain, or antioxidants, an anti inflammatory medicines, depression reducing medicines etc,. side the side, making of cannabis is also most commonly manufactured in the controlled department of pharma industries needs semi automatic gummy machine to professionally produce gummy items.

Cosmetic Industry

The Semi automatic gummy machine in the cosmetic industry- Picture Courtesy: Nutraorganic

You have seen many visual appealing cosmetic products that are brought to the market in the form of gummies. For example, have you seen colorful and vibrant soaps? Yes they, are molded and shaped with semi automatic gummy machine. Also various skin related products such as manicure and pedicure items with the same machine.

Veterinary Industry

The use of semi automatic gummy machine in the veterinary industry-Picture Courtesy: Dalmatian

In the veterinary industry, the semi automatic gummy machine is gaining demand for the formation of gummy vitamins, gummy therapeutic medicines, etc in the various shapes such as bones, teeth, claws, etc., to attract the attention of your pet and improve the compliance.

Stationery Industry

The semi automatic machine uses in stationery industry

The semi automatic gummy machine has a high role in the formation of stationery items such as pen’s topper, rubbers, decorative tools, sharpeners, etc. hence, you can see this robust machine offer various benefits in this sector and having high market value.

4.How beneficial a semi automatic gummy machine is?

Semi automatic gummy machine

The semi automatic gummy machine is offering various benefits to its users such as:

First Class Operation

Perfect Operation of semi automatic gummy machine

Never underestimated semi automatic gummy machine over automatic machine. this robust and simple machine is a giant player offer high and fast operation with easy operating keys.

Better Hygiene

The safest and Finest property of semi automatic gummy machine

The makeup of this machine has acquired stainless steel 306. This machine is quite easier to clean and maintain. Hence the production of gummies are entirely safe and without any risk of contamination.

Cost Effective

Cost economical solution semi automatic gummy machine

The semi automatic gummy machine is a compact and cost economical solution for making small to medium production batches fastly. This is indeed a cost effective solution for those consumers who are running production batches holding a limited budget plans.

No Working Fatigue

Easy operation with no fatigue

The semi automatic gummy machine is a one stop solution of making superb variety of gummies batches without requiring constant handling. You just need to set the mold and remove them manually once you put in the required setting. So user don’t feel tiredness during the working.

Bespoke Production

A semi automatic gummy machine can make gummies with various shapes and sizes

Whether making gummy bears, gummy candies, or making various shapes, sizes, bi-colored, and tri-colored products; the semi automatic gummy machine is an ideal machine to make all you wish to bring in your production line.

High Quality Production Batches

The finest outcome you get with semi automatic gummy machine

The semi automatic gummy machine is an excellent machine that helps you in the formation of high quality, uniform, and highly finished products. So you don’t need to worry if you’re purchasing this machine and worried about achieving the products.

No Chances of Cross- Contamination

100% pure and high quality results by semi automatic gummy machine

The semi automatic gummy machine is cleaned by using highly advanced method CIP and SIP system; in a nutshell, you can get an amazingly perfect machine by clearing the unwanted particles that can cause the chances of cross-contamination.

5.What is the composition of a semi automatic gummy machine?

A semi automatic gummy making machine is undoubtedly comprised of the simplest components. Please check below the following parts and their structures that will help you to understand the machine.

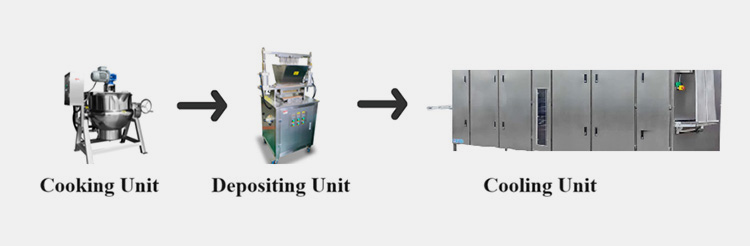

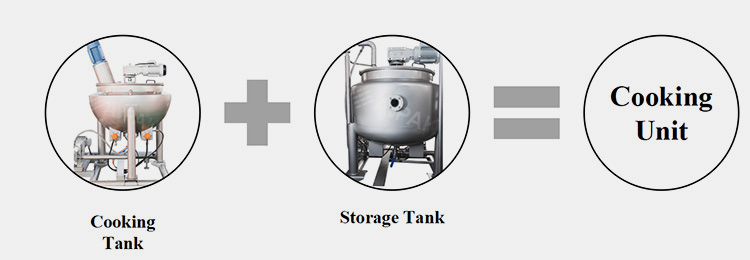

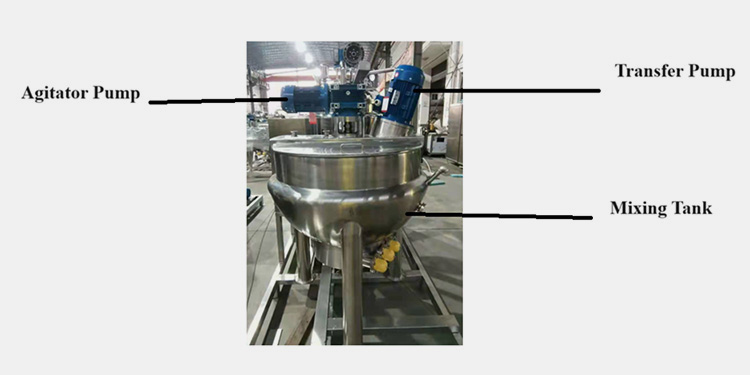

A Cooking Unit

This unit is comprised of two important components; a cooking tank and storage tank. In the working principle you have observed that gummy making process is all about the game of melting. Yes, for that a specialized cooking system is used to dissolve the raw ingredients. Once the material is dissolved completely it is stored in the storage tank for sometime till it is required for the next unit.

Parts

Cooking Tank

| Agitator Pump | An agitator motor is a simple mechanical device that is equipped with upper part of the cooking unit. As it names shows, this motor is highly significant in inducing the mixing and dissolving of the ingredients present inside the tank. |

| Transfer Pump | This is an assistance tool that allows the development of the pressure required for movement of the impellers inside the tank for proper mixing of the ingredients to make a uniform slurry with define distribution of mixing particles. Without agitation pump, this would be certainly impossible to attain a perfect gummy solution. Moreover, an agitator pump that converts electrical force into mechanical force swiftly helps you empty the tank to transfer slurry into the next gummy making unit without any hurdle, or time and product wastage. |

| Mixing Tank | This is a large tank which is capable of holding raw ingredients slurry up to 100 liters, means you can cook and store the large volume solution before producing gummy bears. Remember, the volume adjustment of the mixing tank varies from brand to brand. The machine is featured with temperature and water regulation sensors that notifies and modulate automatically. Due to high shear emulsification property, the mixing and cooking of the ingredients are achieved as you dreamt for. The internal clearance of slurry can be achieved by presence of mechanical scrapers. As its body is made up of stainless- steel 306 with three layers thermal insulators, so it ensures promising temperature maintain capability. |

| Heating Pipe | The double jacketed cooking unit is equipped with heating pipes meant to induce the flow of heat into the tank for dissolving and melting of the ingredients. |

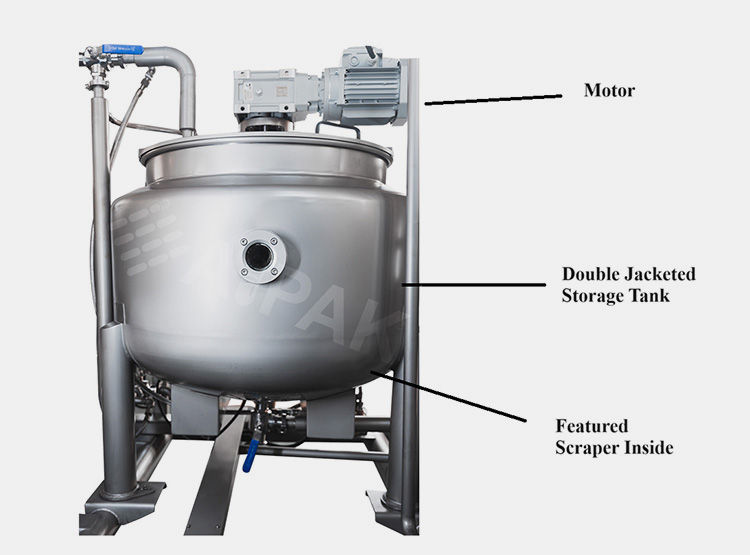

Storage Tank

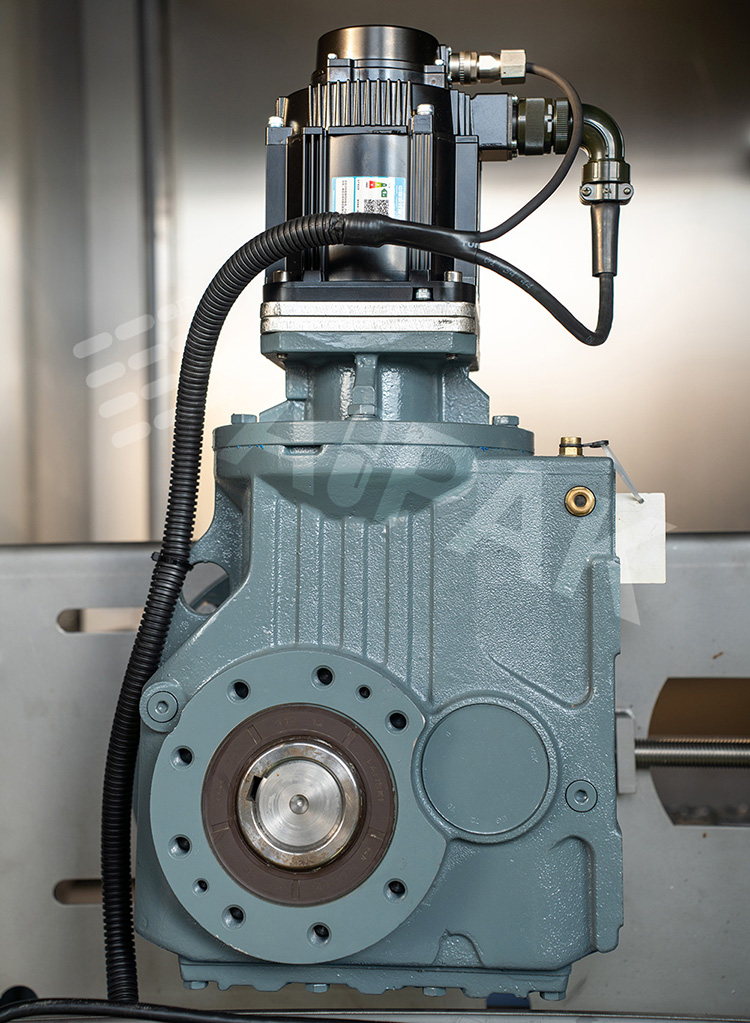

| Motor | This is equipped at the top part of the machine involved with running of agitator to maintain the homogeneity of the slurry inside. |

| Double Jacketed Storage Tank | A double jacketed storage tank meant to conserve or hold the heated solution as required for the longer time. |

| Featured Scraper Inside | The mechanical scraper inside helps in the evacuation of the tank with maximum possible cleaning inside. |

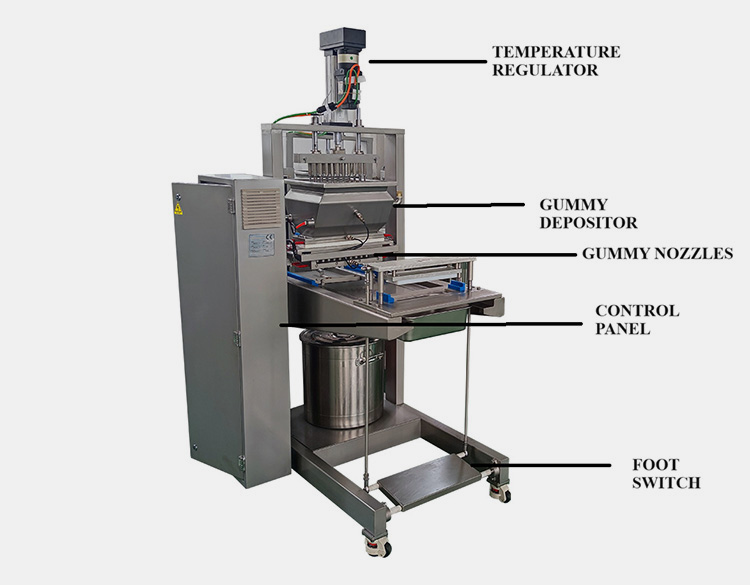

Depositing Unit

This is an independent unit meant to give a particular and assigned shape to gummies as you want. You can consider this unit as a major part of your gummy making process. What main parts a depositing unit is comprised of; you will let it know below.

The parts semi automatic gummy machine

Depositing Hopper

The depositing hopper is meant to hold or accumulate the amount of syrup required for gummy formation. The semi automatic gummy machine is composed of this unit that allows the particular concentration of solution into each depositing cavities. This is an important part of the machine which ensure neat and cleaned work process and ease flowability of slurry via force of gravity.

Temperature Regulators

Certainly, in this phase machine the gummy deposition process is timely and fast. Plus, the semi automatic gummy machine is accompanied by temperature sensors that notifies the user if the temperature becomes too lowers and making unfavorable conditions for ideal working.

Gummy Nozzles

The semi automatic gummy machine’s are designed with a set of gummy nozzles that are independent and individual in the term of operation and giving exact amount of gummy syrup into mold without worrying for wastage and septic condition. The machine is able to configure the particular concentration itself so user has to input the required protocol once prior to initiate the working.

Control Panel

The semi automatic gummy machine is featured with controlled keys that helps in running, setting the timing, temperature, and other important tasks.

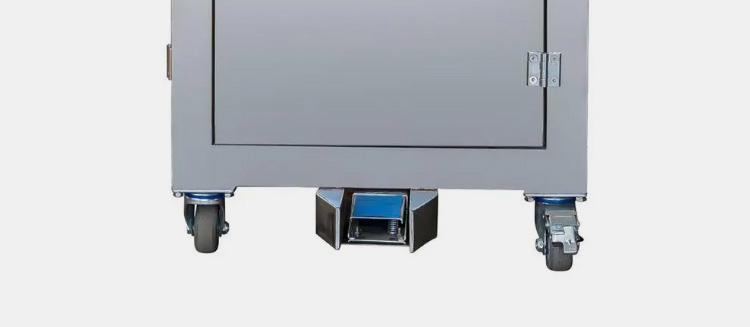

Foot Switch

This is kind of a conventional way to operate the machine, the machine basically relies on air pressure switch to immediate shutting down of the unit when there’s any accidental or unwanted mishaps takes place. You don’t need to rush but simply press the unit and everything will be in the order.

Cooling Unit

This is the basic unit of gummy making machine where molds are exposed to cooling temperature in order to acquire the designated shape. The machine is simple in structure with a defined set of units inside giving amazing and excellent treat in the form of gummies.

Cooling Pump

A cooling pump is the prime unit of a cooling tunnel which is meant to produce and maintain the cooling temperature inside the tunnel.

Cooling Chamber

This looks like a narrow but a wider cabinet which is closed by doors to maintain the temperature and avoid the external factors to enter inside the machine. The machine is constructed with the set of doors to easily access the required unit. The cooling chamber is designed with tiers which is used to place the mold for the certain temperature till it solidifies.

Opening Handle

The cooling tunnel is opened and closed firmly by help of designed handles. These handles are like usual doors handles, you just need to twist them when opening or closing them.

Transmission Chain

As it names suggest, it is equipped with movable chain panel which is able to hold the depositing mold. The responsibility of the transmission chain is to transport gummy mold from semi-automatic gummy machine to cooling tunnel easily.

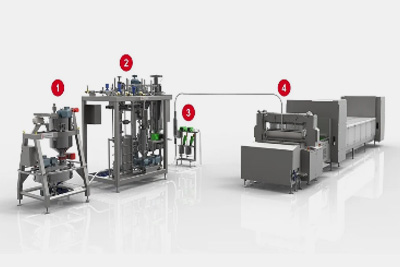

6.How semi automatic gummy machine produces gummies?

The magic of making gummies by semi automatic gummy machine

The semi automatic gummy machine produces excellent batches of gummies by following the discussed below steps:

STEP 1: COOKING

Cooking phase- Picture Courtesy: Aipak

In this step, all the required raw materials are added to the cooking unit or dissolving tank. The dissolving tank is accompanied by a heating system that allows constant heat inside the tank. Upon heating the material inside the holding tanks starts melting. This is observed that materials melt fully around 108-110°C. now the slurry is prepared and perfectly to transfer to the depositing unit. The cooking time is mostly taken place around 15 to 20 minutes to form a thick syrup. The recommended storage temperature is around 60 to 70 °C. During storage, the tank is accompanied by an agitator that mixes the syrup gently throughout the procedure and storage.

STEP 2: DEPOSITING

The gummy formation phase

The syrup is transferred to the semi automatic gummy machine manually or by transferring pipes. The manual placement of the molds are taken place where machine nozzles drop an accurate volume of syrup into each cavity. Upon filling the molds, manually remove the depositing molds followed by positioning the next one accordingly.

STEP 3: COOLING

The cooling tunnel- Picture Courtesy: Aipak Pharma

Place the gummy depositing trays into the cooling tunnel where chilled air helps in acquiring gummies to create a shape.

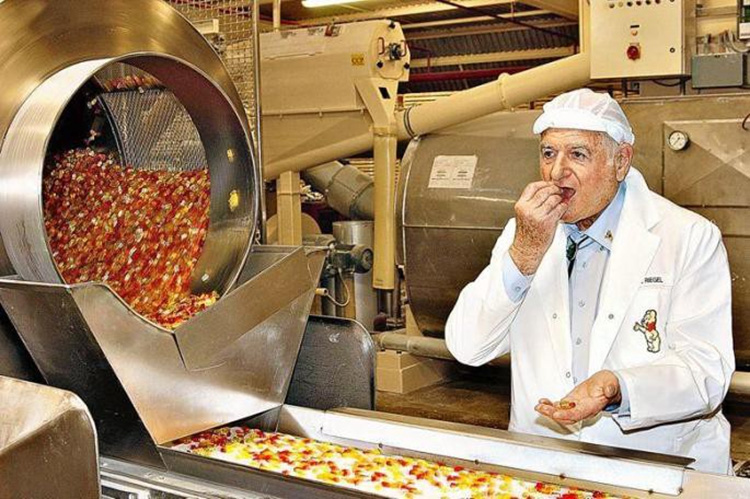

STEP 4: GUMMY POLISHING

Gummy polishing- Picture Courtesy: Haribo

To improve the appearance of gummies, the gummies are now transferred to a gummy coater where oil and sugary spray is poured onto the revolving bed of the gummies to give a shiny and smooth look.

STEP 5: DRYING

The drying Stage- Picture Courtesy: The gummy guide

This is the last step where prepared gummies are subjected to a drying room for 8 to 24 hours. This is followed to evaporate the moisture content present inside the gummies to make a composed shape.

7.What ancillary machines are used with semi automatic gummy machine?

The auxiliary machines play an important role in the proper functioning of the semi-automatic gummy machine. These ancillary machines that are used with the semi-automatic gummy machine, include;

Gummy Drying Trays

This is one of the auxiliary equipment used with semi-automatic gummy machines, it is an essential part of semi-automatic machines that have a big impact on how gummies turn out in the end. These drying trays are considered a significant portion that is involved in the post-depositing step and help for the determination of the final product's consistency, texture, and shelf stability.

Tray Dollies

Tray dollies are another significant auxiliary machine that is used with semi-automatic machines. In the production steps, these tray dollies play significant roles and are used for various purposes. It is applicable for transporting gummy materials, basically, it is used for ensuring precision and consistency of the gummy materials, minimizing handling risk, and also helps to optimize the efficiency of the product.

Coating and Polishing Machine

In the last phases of gummy production, the polishing machine is used for coating and polishing the final product of the semi-automatic gummy machine with sugar or sand, or with the oil. This polishing or coating machine plays a crucial function in the maintenance of the product and also the texture of the final gummy product. It also has a significant role in maintaining the quality of the final item for consumption. This machine adds an additional layer of sophistication and improves the visual appeal and consistency of the completed products. So, we can get a fine product with a high visual appeal having good texture because it provides uniform coating and maintains the quality of the product.

Elevating Conveyor

The elevating conveyor is also a significant part of the semi-automatic gummy machine because it facilitates the smooth and effective transportation of components from one step to other steps throughout the manufacturing operation. Besides them, it also has numerous significant applications, such as being used to transport material vertically, it also provides continued and in-line movement of products and maintains consistency during handling materials.

8.What shapes can be produced by semi automatic gummy machine?

The beauty of gummies lies in their rubbery and smooth texture and in shapes. The semi automatic gummy machine can make various popular shapes easily. The following listed shapes are discussed below.

| Name | Description | Picture |

| Gummy Bears | This is the first and the most popular shape that has taken the attention of people worldwide and the reason of gummies fame. This is mostly preferred by kids and they’ love to consume gummies in this shape. |  |

| Gummy Worms | This is mostly designed with various colors and coated with a sugary powder that has an addicted taste. These gummy worms are popular among teenagers as a nighttime or routinely sweet confectionery. The semi automatic gummy machine is suitable for making the gummy worms easily. |  |

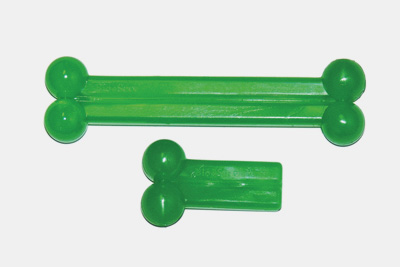

| Gummy Bones | This shape of gummies is mostly prepared to appeal pets to consume the required medicine. Side by side, bones shaped gummies are also manufactured as confectionery. |  |

| Gummy Alphabets | This is another attractive way of eating gummies; children love them as an eatable and fun way of learning. |  |

| Gummy Ring | Gummy rings are simple, and fun filled gummies that’s loved by kids and adults. The gummy rings are round in shape that can be spin in your fingers. |  |

| Gummy Bottle | The gummy bottles are famous among the soda lovers. They’re mostly prepared in bi-layered or tri-layered designs presenting an excellent appealing gummies shape. |  |

| Gummy Hearts | The semi automatic gummy machine is an ideal machine to form heart shaped gummies that are highly in the demands during celebrations such as parties, wedding, birthdays etc., the heart shaped gummies are tiny and fun-filled bites available in various colors. |  |

| Gummy Teeth | This is the most popular gummy shape giving the craziest and memorable moments to people. You can prank and enjoy the sweet rubbery gummies. |  |

| Gummy Belts | The colorful and vibrant gummy belts manufactured by semi automatic gummy machine are a sweet surprise to children who love and play with them before eating. They are also mostly prepared via sugar coating with enhanced sweetest taste. |  |

9.What is the difference between semi automatic gummy machine and automatic gummy machine?

| Semi-automatic gummy machine | Automatic gummy machine |

| Human Involvement | |

| It requires more human power to handle. Because some jobs can be completed automatically by it, but others require human work. | It requires minimal involvement of human beings to operate it. |

| Output | |

| It generally provides lower production output. It is suitable for companies that produce specialized and unique gummy goods in small quantities or those with lower to moderate production levels. | It gives more production output. It is an ideal machine for industrial businesses on a big scale with substantial manufacturing demands. Gummies can be produced by automatic devices in large quantities quickly. |

| Ingredient Loading | |

| Operators may need to load ingredients by hand. | With this machine, no need for human is required to load ingredients. |

| Flexibility | |

| It is flexible because it is frequently more able to adapt to modifications in the design of the product or adjustments to recipe composition. Different gummy sizes, forms, or flavors can readily be accommodated by operators by making little modifications. | It offers less manual flexibility, performs high-volume manufacturing that is continuous, and quickly adapts to different recipes. |

| Consistency and Accuracy | |

| Due to manual modifications, semi-automatic gummy machines may vary in accuracy and consistency. | Automatic gummy machines are the best in accuracy and consistency because computerized controls guarantee precise and consistent manufacturing throughout batches. |

| Cost Effectiveness | |

| It is more cost-effective. | It is a more expensive machine. |

10.How you can extend shelf life of semi automatic gummy machine?

To extend the shelf life of semi automatic gummy machine, its cleaning and maintenance are primarily important. These procedures are now not performed by conventional methods like washing with hot water etc.,.

Using CIP and SIP System for Cleaning

The semi automatic gummy machine cleaning units- Picture courtesy: GMdix

This is a fast and reliable method to clean and maintain semi automatic gummy machine by vanishing minute and sticky particles which later harms the production or inducing cross-contamination hence leaving the machine at its peak performance.

The CIP which is ‘cleaning in place’ and SIP means ‘steam in place’, is the finest method of clean inside the entire circulatory system of the machine including cleaning of pipes, vessels, filters, tanks, etc without needs to dissembling them. For that chemical detergent, high water and steaming is required which is run inside the fitted pipes hence you dnt need to clean them manually.

The semi automatic gummy machine cleaning with CIP and SIP system offering unlimited benefits such as increased production time rather than manual cleaning, highly improved sanitization, low chances of manual fatigue, saving water and steam as it consumes required concentration and realized when a machine is cleaned fully. Plus, no chances of wear and tear inside the machine.

11.What is future prospect of the semi automatic gummy machine?

Semi automatic gummy machine

Future prospects for semi-automatic gummy machines show great promise as the confectionery business develops and customer preferences continue to diversify. The below modifications on the machines would be applicable to enhancing the efficiency of the semi-automatic gummy machines, these are:

| Production on a Small to Medium Scale | Semi-automatic machinery is advantageous for startups and businesses of all sizes. These machines may turn out to be the greatest choice for businesses in the future that want to strike a balance between cost-effectiveness and the ability to produce a wide range of gummy products. |  |

| Exertions to support

Imperishable |

The incorporation of green technology and processes in semi-automatic gummy machines may result from the increased attention on sustainability and eco-friendly practices around the world. Future machine designs might emphasize sustainable qualities as a fundamental component. |  |

| Versatilities and Customization | The demand from customers for distinctive and personalized gummy items is growing. Because they can quickly switch between different recipes and adapt, semi-automatic machines might discover a niche in satisfying these changing requirements |

|

| Technical Developments | The technology improvements are likely to influence the direction of semi-automatic gummy machines. To improve the effectiveness, accuracy, and connection of these machines, smart automation, and the Internet of Things (IoT) may be combined. |  |

|

Cost-Effectiveness |

Semi-automatic devices may be viewed favorably by organizations with limited resources due to their cost-effectiveness. In particular markets, their capacity to provide a balance between automation and manual control may be an edge in competition. |  |

Conclusion

After reading the blog on semi automatic gummy machine, we assure you that now your preference and vision about this machine will be crystal clear. Remember, a good machine is a gateway to success; your gummy making business would skyrocket if you purchase the required equipment and add-on from a reliable manufacturing company. So, don’t worry! Allpack is here to sort out your problems by presenting world-class innovative machines on a friendly budget! Please contact us for more information and Free Guidance. Our experts would love to hear from you.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide