Salad Sauce 3 Side Sealing Packing Machine: The Complete Buying Guide In 2025

Unpasteurized fresh foods require extra care and the appropriate tools to package them safely and securely. Nevertheless, sauce packing is a sensitive procedure that needs to adhere to strict hygiene regulations. Investing in sauce packaging equipment that enables you to complete packing at the right temperature might increase your profitability.

Picture Courtesy: AAK Foodservice

In food packaging machinery, the salad sauce 3 side sealing packing machine stands as a beacon of light, particularly in the efficient and hygienic packing of liquid and semi-liquid products. As the demand for ready-to-eat food is increasing due to convenience, investing in the perfect salad sauce 3 side sealing packing machine is essential for food businesses.

Are you also looking for an option to streamline your production? It must be smothering by looking at the heft of options available. Then look nowhere else!

This comprehensive buying guide is equipped with all the necessary information you need to know about the salad sauce 3 side sealing packing machine. Without any further delay, let’s get down to the topic.

1.What is a salad sauce 3 side sealing packing machine?

Salad Sauce 3 Side Sealing Packing Machine – Picture Courtesy: Propac

The salad sauce 3 side sealing packing machine is a high-performance tool that can make sachets of various sizes and shapes from a film roll of packaging material, accurately fill those sachets with liquid and semi-liquid materials, such as paste and sauces, and then seal the sachets from 3 sides (1 side folding) to ensure the product’s safety, in a quick succession of time.

The machine is highly versatile and provides diverse applications across industries for multiple goods. It is an indispensable component of the manufacturing food industry used for packaging sauces, honey, etc. However, it can also be adopted by other sectors dealing with semi-liquid products, like cosmetic creams, chemical pastes, and others.

The device is an efficient tool that offers quality 3 side sealing of sachets with precise filling at a rapid rate. Moreover, it can be customized to create modified 3 sided sealed packages, such as zippers, valves, sprouts, etc.

2.What type of sauces can be packaged using a salad sauce 3 side sealing packing machine?

A salad sauce 3 side sealing packing machine is an excellent device for efficiently packaging a variety of sauces. Some of the popular sauces that can be packaged using a salad sauce 3 side sealing packing machine are;

Barbecue (B.B.Q) Sauce

Barbecue Sauce

The BBQ sauce is difficult to handle due to its high viscosity. However, the salad sauce 3 side sealing packing machine can be customized to satisfy your needs and package it efficiently.

Tomato Sauce/Ketchup

Tomato Sauce/Ketchup

The salad sauce 3 side sealing packing machine can efficiently package tomato sauce with varying viscosity into sachets.

Soy Sauce

Soy Sauce

The soy sauce density depends on the packaging quality. Quality and effective packaging can be achieved by using a suitable salad sauce 3 side sealing packing machine.

Chili Sauce

Chili Sauce

It is a sticky sauce and needs to be managed properly. A salad sauce 3 side sealing packing machine can help you precisely package the chili sauce in sachets.

Pasta Sauce

Pasta Sauce

Consistency is an important factor to look for in the pasta sauce. Consumers like a consistent sauce with better-quality packaging. It can be achieved using a salad sauce 3 side sealing packing machine. The effective sealing aids in keeping the sauce fresh.

Mayonnaise

Mayonnaise

It is a dense and sticky sauce and can be packaged by a salad sauce 3 side sealing packing machine.

3.What are the benefits of using a salad sauce 3 side sealing packing machine?

Investing in a salad sauce 3 side sealing packing machine can add greater value to your business. If you want a boost in your manufacturing efficiency, a salad sauce 3 side sealing packing machine is the perfect option, as it offers a range of striking benefits.

Some key benefits it provides are listed below;

Enhances Efficiency

Enhanced Efficiency

The device can process multiple sachets simultaneously and work continuously with accuracy, cutting down the operator’s workload and maximizing the output.

Reliability

Reliability – Picture Courtesy: Sealed Air

The device is a reliable equipment that ensures a uniform packaging of sachets, at a quick rate, with similar filling and sealing of each sachet.

Precision

Precise Filling – Picture Courtesy: Sealed Air

Uniformity in the filling process is the key benefit a salad sauce 3 side sealing packing machine offers. It guarantees that the sauce or other materials are measured accurately, preventing operational inaccuracy.

Flexibility

Versatile Device – Picture Courtesy: Propac

The salad sauce 3 side sealing packing machine is a versatile device that can package several materials in various sachets of different shapes and sizes.

Cost-effectiveness

Cost-effectiveness – Picture Courtesy: SRM

Investing in a salad sauce 3 side sealing packing machine reduces labor and error expenses, resulting in a cost-effective operation.

Hygienic

Hygienic Operation – Picture Courtesy: Delta Pharma

The device operates in a stringent hygienic environment, preventing the contamination of the product during processing, thus maintaining the quality.

4.What are the fundamental parts of a salad sauce 3 side sealing packing machine?

Parts of a Salad Sauce 3 Side Sealing Packing Machine

The salad sauce 3 side sealing packing machine is composed of multiple mechanical and electrical components working together for efficient and accurate operation. Here we will explore the major machine parts and their function.

| PARTS | FUNCTION |

| Material Hopper | It is an enclosed container capable of holding a significant amount of liquid material to precisely guide it to the inlet section for filling sachets. Its size and shape can be varied. |

| Film Roll | It is a roll of packaging material that is guided to the forming tube where it transforms into the desired form of sachets. |

| Forming Tube | It is a main component of the device that receives the packaging film and transforms it into the specific shape and dimension sachets which are then further processed to be filled from the liquid. |

| Material Inlet | It is a section under which the sachets get filled from the liquid. It may have a piston or a pump mechanism installed, to fill the sachet with the desired volume. |

| Vertical Sealing Bar | It is one of the components of the sealing station. The vertical sealing bars seal the packaging sachets from the longitudinal edges to convert them into a pouch (1 side folded), which is then detached from the continuous film via cutter and processed for filling. |

| Horizontal Sealing Jaws | The horizontal sealing jaws are responsible for sealing the liquid-filled sachets, which are then directed to exit the device. |

| Universal Wheel | It helps in the device’s portability from one place to another conveniently. |

| Display Screen | It is a crucial component that displays all the processing parameters that can be monitored and adjusted. |

| PID Temperature Controller | This component maintains a steady temperature of the sealing clamps/bars as per the requirements of the packaging material, to ensure an efficient and good quality seal. |

| Power Switch | It connects the device with the power source to run the machine. |

5.How does a salad sauce 3 side sealing packing machine work?

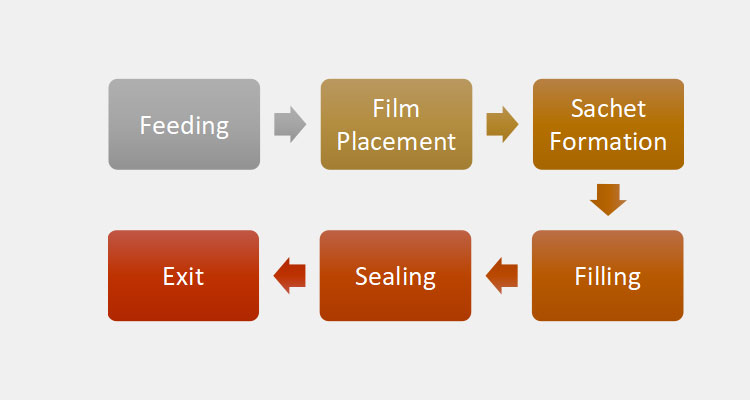

Working of a Salad Sauce 3 Side Sealing Machine

You would be amazed to know that the device is so easy to operate. The salad sauce 3 side sealing packing machine comprises basic parts that collaborate to fill sauces into formed sachets. The following are the key steps of operation;

Steps of the Process

Sauce Feeding

The liquid (sauce, honey, ketchup, or other) is first heated or liquefied for better handling and then poured into the hopper. This step can be done manually or by utilizing an automatic mechanism.

Film Roll Placement

A large film roll of the desired packaging material is well-placed on the film roller, which is then unwound by the machine to process it to the forming tube.

Sachet Formation

The film is then shaped into the desired shape and dimension by the shaping/forming tube, one side is folded while the two sides are edge-sealed by vertical sealing bars, converting it into a pouch. The formed pouches are then detached from the film by cutting blades.

Sachet Filling

The specified volume of liquid is then poured into the fabricated sachets using a filling nozzle or other tool.

Sealing

The filled sachets are sealed using horizontal sealing clamps.

Sachet Exit

After sealing filled sachets, they are directed to exit the device via an outlet for further processing or delivery.

6.What are the different variants of the salad sauce 3 side sealing packing machine available?

If you have ever been to the market, you must have found a variety of 3 side sealing devices. Yes, a salad sauce 3 side sealing packing machine comes in various configurations and unique models, each having different characteristics and advantages.

Here we will discuss some of the common variants of the salad sauce 3 side sealing packing machine;

Classification Based On Orientation

Vertical Form Fill Seal (VFFS) Salad Sauce 3-Side Sealing Packing Machine

Vertical Form, Fill, and Seal Salad Sauce 3 Side Sealing Packing Machine (VFFS) – Picture Courtesy: Makwell

The vertical form, fill, and seal salad sauce 3 side sealing packing machine is designed to form the packaging sachet/pouch from the film roll, accurately fill the liquid paste/sauce into the formed sachets, and seal them vertically.

It is a widely employed device in the food industry due to its compact design and efficient operation. It can be equipped with an automatic feeding pump, minimizing labor. It is a versatile device that can be customized as per the requirements.

The stirring and liquid heating tools can be attached based on the material properties.

Horizontal Form Fill Seal (HFFS) Salad Sauce 3 Side Sealing Packing Machine

Horizontal Form Fill Seal (HFFS) Salad Sauce 3 Side Sealing Packing Machine – Picture Courtesy: PPi Tech

The horizontal form, fill, and seal salad sauce 3 side sealing packing machine is designed for large-spaced industries as the device has a horizontal orientation and occupies a large area. It is an efficient and robust device that can form, fill, and seal the liquid sauces/paste in a supine orientation. Each processing step has its specific station, placed close to one another.

Classification Based On The Filling Mechanism

Piston Filler Salad Sauce 3 Side Sealing Packing Machine

Piston Filler Salad Sauce 3 Side Sealing Packing Machine (Equipped with Mixing & Heating Function) – Picture Courtesy: LinkedIn

The piston filler salad sauce 3 side sealing packing machine is a specialized device often utilized for high-viscosity liquids such as sauces. The device uses volumetric filling with the help of a piston that pushes the specific volume of liquid to the sachets consistently. It has a smooth filling operation.

The device’s productivity relies on the number of filling nozzles it has. If your objective is increasing the production rate, choose a device with several filling nozzles.

Peristaltic Pump Filler Salad Sauce 3 Side Sealing Packing Machine

Peristaltic Pump Filler Salad Sauce 3 Side Sealing Packing Machine – Picture Courtesy: LinkedIn

This type of salad sauce 3 side sealing packing machine utilizes a peristaltic pump for measuring and filling liquid into sachets. The accuracy and filling range of the pump depend on the servo motor. It is a suitable device for thinner and medium-viscosity sauces.

Classification Based On The Number Of Lanes

Single Lane Salad Sauce 3 Side Sealing Packing Machine

Single Lane Salad Sauce 3 Side Sealing Packing Machine

The single-lane salad sauce 3 side sealing packing machine is a device that is designed for small to medium enterprises. It has a single processing lane, which can process a single sachet at a time. It has a relatively lower production rate.

Multi-Lane Salad Sauce 3 Side Sealing Packing Machine

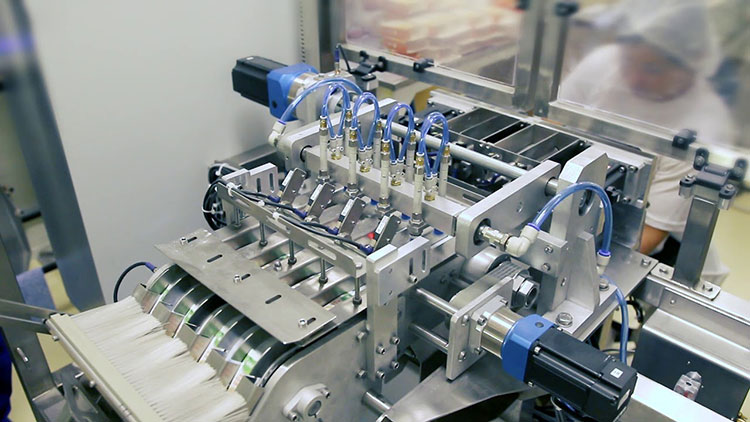

Multi-Lane Salad Sauce 3 Side Sealing Packing Machine – Picture Courtesy: Solution-Pack

It is an advanced packaging equipped with multiple processing lanes and can process several sachets simultaneously, depending on the number of lanes installed. It has a high production rate and is a suitable device for large manufacturing firms.

7.How many sachets can a salad sauce 3 side sealing packing machine produce per minute?

Productivity Rate (package per minute/ppm)

The speed of a salad sauce 3 side sealing packing machine is expressed in finished packages per minute (ppm). This number indicates the final output per minute. The speed of a salad sauce 3 side sealing packing machine relies on the product, package type, environment of the industrial unit, and budget.

Calculate the equivalent ppm if you have specific target sachets. A manual or semi-automatic device can be preferred for varying manufacturing needs. Whereas, automatic operation speeds up the whole process.

8.What role does the liquid viscosity play in its packaging?

Picture Courtesy: Stlukes

The term “Viscosity” describes the opposition to the liquid flow. The viscosity of individual liquids varies, depending on the intermolecular forces and the liquid’s molecular structure.

The complex molecular structured liquids have high viscosity and do not flow easily while the fluids having less complex molecular configuration have low viscosity and flow easily.

Uniformity is an important consideration in selecting a salad sauce 3 side sealing packing machine. The type of filler employed depends on the viscosity of the packing fluid; which must exert the required force to allow the liquid to flow without overfilling the package.

9.What are the common defects encountered in a salad sauce 3 side sealing packing machine and how to troubleshoot it?

Skipping maintenance shifts might increase productivity, but you should know that it would be short-term and result in costly repairs. Even with regular care and maintenance, a salad sauce 3 side sealing packing machine can encounter some issues. Here are some commonly experienced issues and their potential remedies.

Jamming or Clogging

Machine Jamming – Picture Courtesy: Somapak

The device could be jammed or clogged for several reasons, including foreign material obstructions within the device or lack of lubrication in the moving parts.

Solution: follow the regular maintenance schedule and lubricate the moving parts properly to avoid abrasion.

Wrinkled Film

Wrinkled Film – Picture Courtesy: Market Prospects

The film creasing can be because of improper alignment, fault in the dancing rollers or film support, or poor quality film.

Solution: align the film, tighten/replace the film support or dancing rollers, and purchase a good-quality film.

Faulty Sealing

Faulty Sealing – Picture Courtesy: Greener Corporation

The fault in sealing may be because of improper adjustment of sealing bars/clamps temperature, insufficient pressure force or sealing time, impaired bars or clamps, or dirty sealing surface.

Solution: ensure the proper adjustment of temperature, pressure force, and time, repair or replace the impaired clamps/bars, and clean the sealing station regularly.

Uneven Filling

Uneven Filling

The inconsistency in filling could be caused by clogged/worn nozzles, trapped air, inconsistent fluid, piston not moving correctly (in the case of piston filler), or inaccurate parameter settings.

Solution: Replace or clean the nozzles, remove the air from the system, adjust the consistency of fluid, validate the parameter settings, and repair or replace the piston.

Packaging Size Variability

Variations in Size of Package

The reasons for variations in package dimensions are impaired shaping tubes, obstructed film supply, or faulty cutting blades.

Solution: replace/repair the shaping tube or cutting blades, avoid the shortage of film, and align the film roll properly.

10.What do you mean by preventive maintenance of a salad sauce 3 side sealing packing machine?

Preventive maintenance means the act of scheduled maintenance of equipment to avoid any unexpected breakdown. Like any other machine, the salad sauce 3 side sealing packing machine also requires regular maintenance to keep it in optimal functional condition and prolong its lifespan.

In this section, we will go through the fundamentals of device care and offer advice to keep your salad sauce 3 side sealing packing machine in good shape.

Daily Maintenance

Regular Cleaning – Picture Courtesy: Yuyama

Maintaining your gadget regularly is essential to keep it functioning properly. Some tips for daily maintenance are;

- Examine the sealing clamps and cutting blades for deterioration.

- Clean the sensors, cutters, and sealing bars/clamps with a smooth cloth or a suitable cleansing solution.

- Verify the processing parameters, like sealing temperature and pressure.

- Wash the hopper and nozzles with water or other recommended liquid to prevent clogging.

- Check the feed of the film roll and liquid to avoid downtime.

Weekly Maintenance

Weekly Maintenance – Picture Courtesy: Viking Masek

Apart from the daily maintenance, you should also perform a weekly maintenance procedure. Some tasks to perform every week include:

- Disassemble the device and clean the components with a fabric or a cleansing solution.

- Lubricate all the dynamic parts to prevent abrasion.

- Inspection of the wiring and other electrical parts should be done.

- Validate the temperature and pressure accuracy.

Monthly Maintenance

Monthly Replacements & Maintenance – Picture Courtesy: Synda

Following the daily and weekly maintenance, monthly maintenance should also be carried out to ensure the top condition of the device. It includes:

- Repair or replace any damaged or deteriorated machine component, like cutting blades, sealing clamps, filling nozzles, etc.

- Thoroughly clean the entire machine.

- Gauge the settings of temperature and pressure to guarantee accurate functioning.

By following the daily, weekly, and monthly maintenance protocols, it can be ensured the device is smoothly and efficiently working for a long period.

11.What are the factors to consider when investing in a salad sauce 3 side sealing packing machine?

Selecting the right salad sauce 3-side sealing packing machine is crucial for your industry. Some factors you should keep in mind while shopping for a salad sauce 3 side sealing packing machine:

Viscosity of the Sauce

Sauce Viscosity – Picture Courtesy: Harrisons Sauces

The viscosity of the liquid plays a crucial role in the working efficiency of the salad sauce 3 side sealing packing machine. Certain variants only handle viscous or non-viscous fluids while some have the adaptability feature and can effectively handle both kinds of fluids.

The filler you select must be able to manage the liquid’s density. Thus, its viscosity must be considered.

Automation Level/Capacity

Increasing Automation Level Increases Productivity

Before purchasing a salad sauce 3 side sealing packing machine, you should know how many sachets you need to be manufactured daily. This will aid you in the capacity requirement of the device.

The device you opt for must be flexible enough to adapt to different needs. Moreover, the level of automation requirement also depends on the production demands.

Budget

Balance the Price & Value – Picture Courtesy: Marketing Donut

Different models have different prices depending on their characteristics. Assess your budget and production needs. When you are perspicuous, you can narrow down the options and select the most suitable variant with optimal performance according to your needs.

Compliance

Standard Certifications

Always acquire your salad sauce 3 side sealing packing machine from an accredited manufacturer to guarantee an efficient and high-quality device. The device certifications ensure that the standard requirements are satisfied.

It is important to establish the safe and hygienic manufacturing of consumer goods, particularly edible items to ensure the client’s safety.

Warranty

Warranty & Technical Support – Picture Courtesy: Madico Window Films

Mental peace is priceless for any entrepreneur and a warranty/agreement provides that. You should procure the device from a firm offering an extended warranty and technical support for your device. This will ensure the protection from unforeseen repair expenses.

CONCLUSION

The salad sauce 3 side sealing packing machine is an essential component of the food industry that plays a crucial role in preserving the quality and freshness of sauces. By understanding the multiple options and their unique advantages, you can choose the ideal machine based on your needs and maximize the manufacturing output. So, if you want to invest in the salad sauce 3 side sealing packing machine and bring its benefits to your business, reach out to AllPack, one of the most reliable salad sauce 3 side sealing packing machine manufacturers.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours