Sachet Packing Machine: The Complete Buying Guide in 2025

Single-serving of products is acquring traction among end-users, hence to meet this rising demand, sachet packing machine is employed in businesses. It is used for dosing single-serve of granular, powdery, pellet, pasty, free-flowing liquids inside the sachet.

It is an efficient solution that fulfill growing demand because of its high production capacity. Nowadays, sachet packing machine is seen in every industry. Its little to no downtime brings high sale margin to industries.

Are you in quest for an ideal sachet packing machine and are wondering what kind of sachet packing machine will be best for your business? Then you have landed in right place. In this blog we will guide you in your selection process.

1.How Can You Define A Sachet Packing Machine?

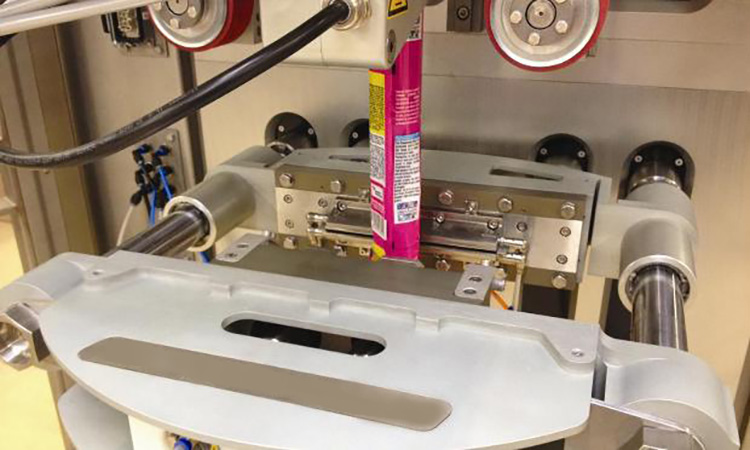

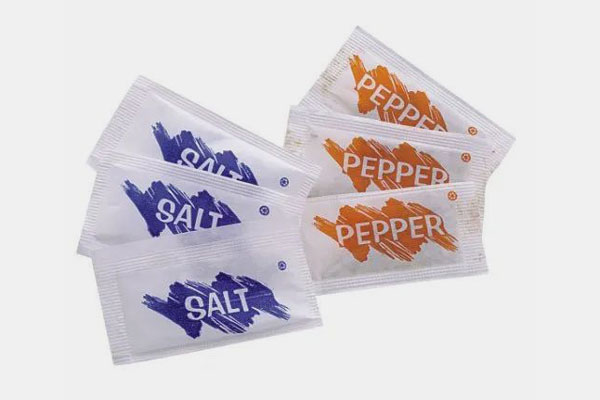

Sachet Packing Machine-Picture Courtesy: Mentpack

A sachet packing machine is an equipment that encloses a one-time serve of powder, pellets, creams, granules, pastes, semi-fluids, and other solid and liquid products is a sachet. The sachet is manufactured using plastic, aluminum foil, cloth, non-woven fibers, and paper.

This machine is employed for packing both in food and non-food items. It is used to create sachet and fill small quantities of products in rectangular or square shaped sachets. These sachets are extremely popular among end-users because of their affordability and portability that are compatible with on-the-go routine.

Due to its increased efficiency and fast packaging, sachet packing machine is routinely seen in pharmaceutical, nutraceutical, food, cosmetic, and many more industries.

2.Why Sachet Packing Machine is Widely Employed in Businesses?

Although this machine has a compact construction, it has tons of benefits that allow manufacturers to earn huge profits, due to this it is a significant part of packaging businesses. Some of the important benefits of this handy unit are:

Cost-effectiveness

Cost-effectiveness

A sachet packing machine is a cost-effective solution because of its compact structure that in turn decreases its price cost. Furthermore, sachet packing machine uses minimal packaging material and generate lower wastes. This saves pricey packaging film, consequently, lowering the need to purchase and saving money.

Boost in Production Capacity

Boost in Production Capacity- Picture Courtesy: Packaging of the World

In contrast with manual filling and packaging, the sachet packing machine is a proficient solution furnished with automated controls and high-tech gadgets that play a pivotal role in boosting production capacity and aid in timely packaging. This feature allows these machines to meet the throughput in large enterprises.

Flexibility in Product Handling

Flexibility in Product Handling

Sachet packaging is one of the most operated units in the production lines, due to its high adaptability. Because of customizable filling devices, it can fill every kind of product belonging to a wide range of spectrum. It is considered a flexible unit, because it is tailored with different kinds of filler, for instance, auger, net-weigh, pump, and piston fillers.

Consistent Packaging

Consistent Packaging

Real-time monitoring sensors and electronic controls measure the filling volume during product packaging, consequently, achieving accuracy and consistency in product dosing. aids in achieving accuracy and consistency in every batch. Moreover, PLC controls and computerized fillers decrease the error rate in filling, in turn attaining batch-to-batch consistency.

Versatility for Present and Future Needs

Versatility for Present and Future Needs- Picture Courtesy: Dieline

One of the prime advantages of a sachet packing machine is its versatility. It can process packaging films belonging to a wide range of the spectrum, for instance, PP, LPDE, aluminium, and paper, to name a few. It can be tailored to output a vast array of sachet, for example, 3 side seal sachet, central seal sachet, four-side seal sachet, etc.

3.What are the Industrial Applications of a Sachet Packing Machine?

Because of partiality for sachet, the demand for a sachet packing machine is characteristically high in every industrial sector. This machine offers a boost in productivity and, therefore is well-liked by brands belonging to the following industries:

Food Industry

Use of Sachet Packing Machine in Food Industry- World Band Design Society

This industry exercises a bigger number of the sachets packing machine. Its flexibility makes it an attractive choice for food brands. Also, the convenience of single-serve sachets has led to the high use of a sachet packing machine in the food sectors for packing dressings, ketchup, sauces, sugar, salt, sweeteners, mayonnaise, oils, pastes, spices, seasoning, herbs, creams, etc., in the sachet.

Beverage Industry

Use of Sachet Packing Machine in Beverage Industry- Picture Courtesy: XMiles

Sachet packing is widely favoured in the beverage industry for filling instant juice powders, energy drinks, coffee, squash, etc in the single-use sachet. Its automation has led to its increased usage in the beverage industry.

Pharmaceutical and Nutraceutical Industry

Use of Sachet Packing Machine in Pharmaceutical and Nutraceutical Industry- Picture Courtesy: Amcor

Because of the safe, contamination-free and hygienic dosing of a sachet packing machine, it is a great addition to the pharmaceutical and nutraceutical industry. The Pharma sector employs this machine for the packing of pharmaceutical powders, granules, emulsions, syrups, vitamin supplements, probiotics, prebiotics, and many more in the sachets.

Cosmetic Industry

Use of Sachet Packing Machine in Cosmetic Industry-Picture Courtesy: Cosmetic Design Europe

The rise of consumerism has directed the use of a sachet packing machine in the cosmetic industry. It is employed for filling sunscreen, liquid foundation, face creams, lotions, gels, dyes, etc, in the one-use sachet. The utility of the sachet packing machine in the cosmetic industry is because of its extreme astronomical accuracy and meticulousness.

Household Industry

Use of Sachet Packing Machine in Household Industry- Picture Courtesy: BNB Supplies

In the household industry, a sachet packing machine is utilized for packaging one-time servings of detergents, liquid dishwashers, stain removers, cleaning agents, bleach, etc. This machine has prominence in the household industry because of its swift packaging and reduced footprint.

Hospitability Industry

Use of Sachet Packing Machine in Hospitability Industry- Picture Courtesy: Behance

With the surge in the hospitability business, this machine is increasingly employed in these businesses for dosing of single-serve amenities for instance, shampoo, liquid soap, body wash, sanitiser, shower gel, hair conditioners, and lotion in the individual sachets.

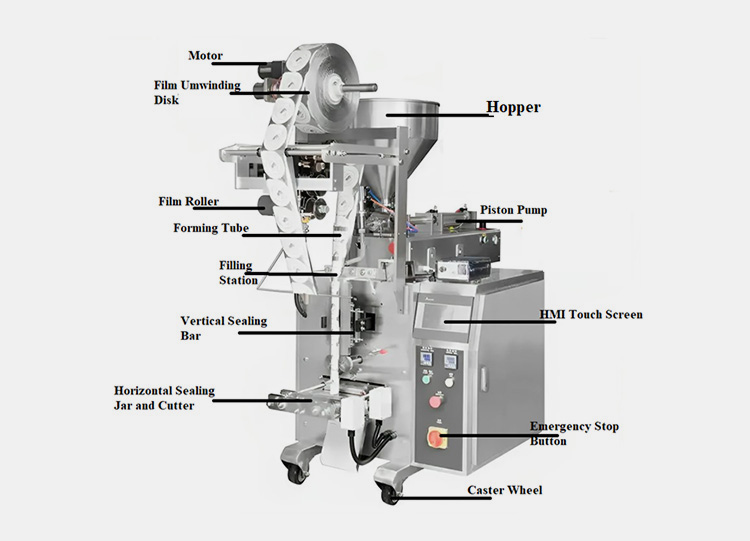

4.What are the Technical Parts of the Sachet Packing Machine?

Knowledge about technical parts present in the sachet packing machine aids in quick changeover and machine diagnosis in case of failure. Therefore, to increase your information, here is a detail about important sachet packing machine parts.

Parts of Sachet Packing Machine

| Motor | It is the part that powers other machine parts and aids in their right working order. The movement of the film and film roller, dancer arm, and sealing units occurs because of the energy supplied by the motor. |

| Film Unwinding Disk | This part rotates to unfurl the packaging film. |

| Film Roller | There are different types of rollers, for example, nip roller that keep the firm under constant tension and are essential in preventing the spillage of film. It allows the right film alignment and is also used for tracking the film. |

| Forming Tube | It is the main part of the sachet packing machine that is responsible for folding packaging film and then fashioning it to fabricate the sachet. |

| Filling Station | The filling station has filling nozzles and filling devices, for instance, a pump, auger, and volumetric piston for filling the sachet with powders. |

| Vertical Bar | These parts heat and seal the two edges of the film sideways. High temperature and pressure are employed for melting and fusing the two sides. |

| Horizontal Sealing Bar | Horizontal sealing bars are responsible for sealing the horizontal edges of the sachet, as the name suggests. |

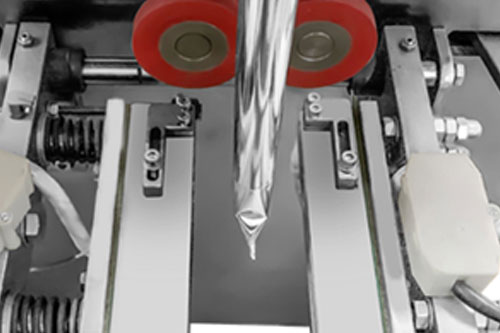

| Cutting Blade | The function of the cutting knives is to separate two adjoining sachets from each other. It cuts the edges of the sachets. |

| Hopper | It is a conical or rectangular-shaped device typically present at the top of the sachet packing machine. It stores bulk quantities of food and non-food products for continuous packaging. Its function is to supply the feed to the filling system. |

| Caster Wheel | These parts are present at the bottom of the instrument and help in its balance and mobility, the latter is achieved by rotation of wheels. |

| HMI Touch Screen | It is an intelligent touch screen that aids the operators to quickly program and change over the machine. It also allows the operator to check the progress of the operation. Moreover, the HMI component aids in smart diagnosis and troubleshooting. |

| Emergency Stop Button | It is the red colored button and in case of machine failure, it allows the workforce to stop the machine without waiting for routine stoppage that takes time. It is a safety feature that prevents accident risks. |

| Piston Pump | It is a cylindrical device that moves to and fro to draw the product from a hopper into filling nozzles. |

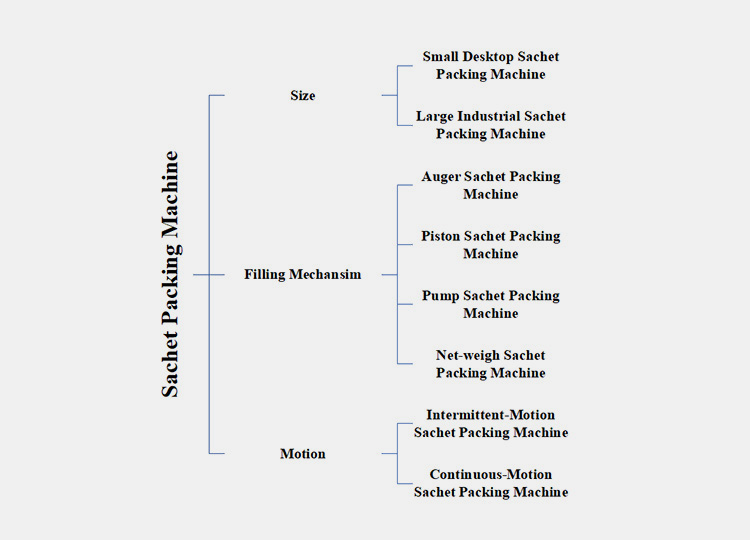

5.What are the Types of a Sachet Packing Machine?

There are diverse types of a sachet packing machines in the market, differing in size, packaging motion, and filling devices. These kinds are discussed in detail below:

Classification Based on Size

Small Desktop Sachet Packing Machine

Small Desktop Sachet Packing Machine- Picture Courtesy: Xiamen Link Machinery Technology Co. Ltd

It is a small compact machine, mostly found in small and medium-scale enterprises. Based on functionality, it comes between simple hand sachet filling and large industrial units. It is an affordable unit, beneficial for manufacturers entering the packaging business.

Since the loading of products and unloading of the sachet are executed by the operator while fabricating and packaging the sachet is automated; hence this machine allows industries to boost their packaging volume without the heavy investment needed for large industrial sachet packing machines.

Large Industrial Sachet Packing Machine

Large Industrial Sachet Packing Machine- Picture Courtesy: Gleovfs

It is a large-scale packing machine used in giant food, beverage, and other industries. It is equipped with a vast array of computerized parts that contribute to precise and accurate product filling. The biggest industries with high-out needs favour this type of sachet packing machine due to its quick processing.

It is equipped with easy-to-use features, safety gadgets, alarms, sensors, and, PLC controls that completely automatesachet packing.

Classification Based on Filling Mechanism

Auger Sachet Packing Machine

Auger Sachet Packing Machine

This machine is frequently utilized to fill dry powders and granules inside the individual sachet. It is a closed system that reduces product contamination. With the rotation of auger screws, the powdery product from the hopper slowly passes through auger plates into the sachet.

It is a volumetric sachet packing machine that loads a precise volume of product in one cycle.

Piston Sachet Packing Machine

Piston Sachet Packing Machine

It is mostly utilized for packing semi-solid, free-flowing, and pasty liquids inside the sachet. The filling device in this equipment is comprised of a hopper and piston cylinder that aids in fluidity of products. The forward and backward motion of the piston in the cylindrical devices forces the products from the hopper into sachets.

Pump Sachet Packing Machine

Pump Sachet Packing Machine- Picture Courtesy: Western Packing

This machine is used for volumetric dosing of all kinds of liquids including particulate and chunky products in the sachet. The rotation of pumps, such as gear, cavity, and lobe exert the force on the products and then dispense them inside the newly made sachet. It is more affordable than a piston sachet machine.

Net-weigh Sachet Packing Machine

Net-weigh Sachet Packing Machine- Picture Courtesy: Glopak

These are the machines that fill the granular, liquid, and irregular-shaped items inside the sachet by accurately measuring the weight of products instead of their volume. This machine uses a sensitive load cell to dispense the pre-estimated weight of the product into the sachet.

It is mostly for filling pharmaceuticals and other expensive items that cannot afford to even a smaller difference in their fill weight.

Classification Based on Motion

Intermittent-Motion Sachet Packing Machine

Intermittent-Motion Sachet Packing Machine- Picture Courtesy: Marchesini Group

It has limited processivity as the machine pauses during the forming, filling, and sealing of the sachet. It is best for medium-scale ventures, where packaging speed is not as perilous. Intermittent-motion sachet packing machine has discontinuous cycles as the machine stops during packaging operations. It has slight variations in filling because of its intermittent filling.

Continuous-Motion Sachet Packing Machine

Continuous-Motion Sachet Packing Machine- Picture Courtesy: TurPack

This machine is employed in large businesses that have rapid and massive packaging flow because of its continuous packaging. The machine operates without pausing for filling, forming, and sealing operations.

It has a more precise filling rate. Furthermore, it has a complicated design configuration.

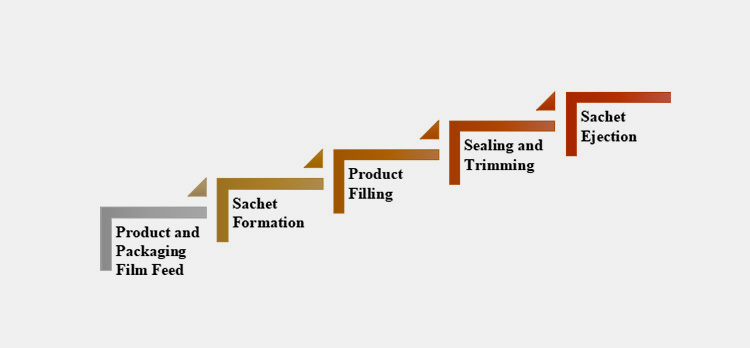

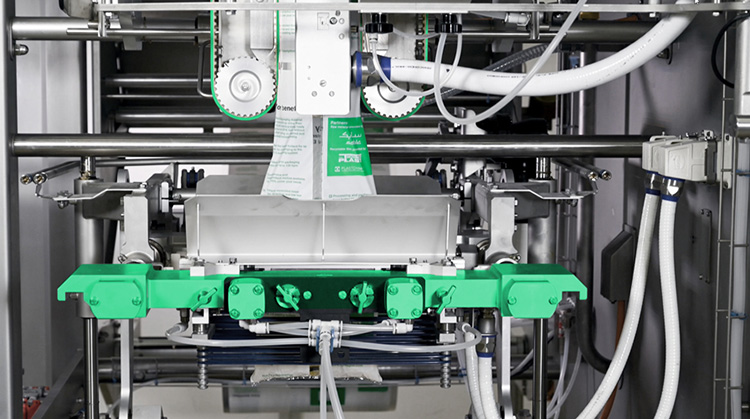

6.What are the Working Steps of Sachet Packing Machine?

The sachet packing machine has an intricate yet meticulous working type. It has the same working principle as that of the vertical form, fill, and seal machine. The working steps are penned below for your understanding:

Product and Packaging Film Feed

Product and Packaging Film Feed- Picture Courtesy: C-P Flexible Packaging

At the start, the bulk quantity of product is fed inside the hopper located at the top side of the equipment while the packaging film for forming the sachet is placed on the large film roll.

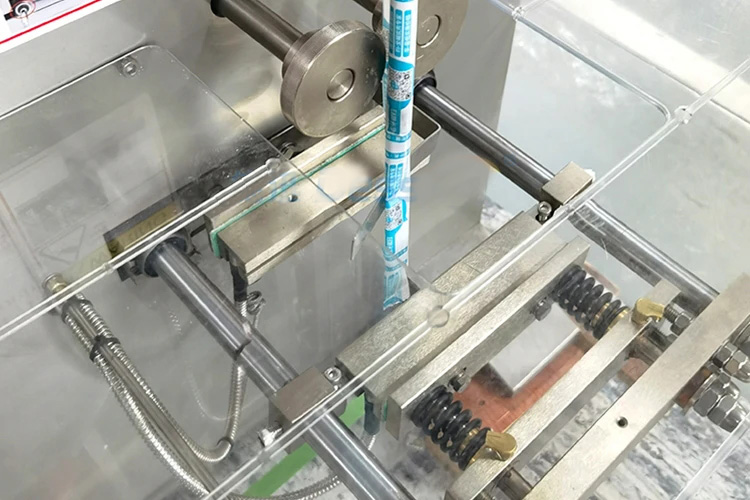

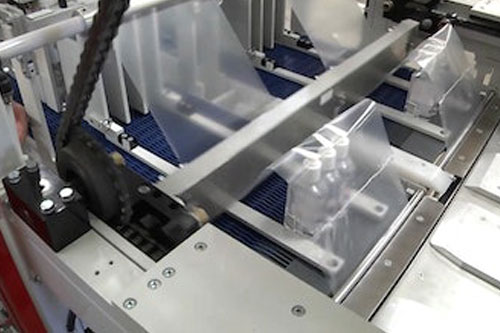

Sachet Formation

Sachet Formation

The film unwinds via an unwinding disk and is guided over the roller that tracks the film and keeps it aligned. The Film reaches the conical forming tube after moving over the roller. The forming collar part of the forming tube aids in shaping the sachet.

It folds and packages a sachet with the action of vertical sealing jaws. These sealing bars seal the edges of the film longitudinally, leading to the fabrication of a sachet.

Product Filling

Product Filling

In this step, with the signal from the PLC unit, the product present in the hopper travels down gradually and with the aid of filler, such as auger, piston, and pump, it is loaded into the newly fabricated sachet.

Sealing and Trimming

Sealing and Trimming- Picture Courtesy: Sywen

Upon loading, the sachet is sealed horizontally via horizontal sealing jaws to create a hermetic seal. Afterwards, the cutting blade present in the middle of the horizontal sealing jaws trims the edges of two continuous pouches.

Sachet Ejection

Sachet Ejection- Picture Courtesy: Packaging Strategies

The sachet is removed from the machine and collected in the outfeed unit after cutting. The collected sachets are taken for boxing.

7.What are the Sealing Methods in Sachet Packing Machine?

There are different kinds of sealing methods employed in the sachet packing machine for airtight and accurate sealing of sachets. These methods are discussed in detail below:

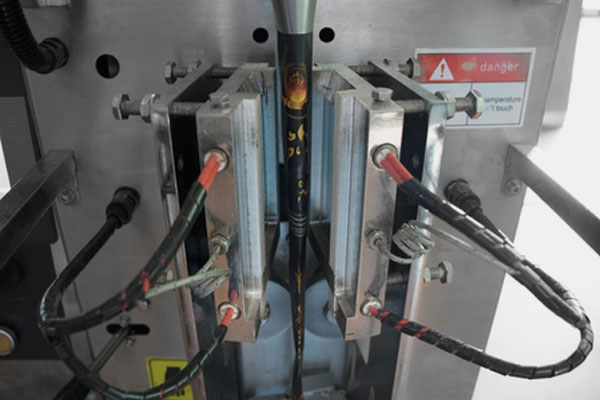

Heat Sealing

Heat Sealing-Picture Courtesy: Infopack

It is one of the most frequently employed sealing method in sachet packing machine. Heated sealers exert high pressure to melt the inner side film and bond two edges of film together. This creates a tenacious and strong seal.

Ultrasonic Sealing

Ultra-Sonic Sealing- Picture Courtesy: Packaging News

It is the second most commonly used method for creating a seal. In this method, high-frequency sonic waves are applied to heat the film area for fusion, thus melting and bonding the film sides. It is used for film materials that may degrade at high temperatures.

Cold Sealing

It is an uncommon method for fusing cold-liable film at low temperatures. These materials activate in cold settings and apply sealing pressure. It is also called the pressure sealing method and is used for products requiring sterile sealing.

8.How Do A Sachet Packing Machine and A Pouch Packing Machine Differ From Each Other?

Both sachet packing machine and pouch packing machines dominate the packaging sectors and operate on the principle of form, fill, and seal. However, there are some significant differences between these devices.

| Sachet Packing Machine | Pouch Packing Machine |

| This machine is employed for forming small flat-lay sachet. Sachets have a smaller area for labeling. | It is employed for fabricating zipper pouches, standups, gusset pouches, quad seal pouches, etc. The pouch features more area for branding. |

| It packs one-time-serve quantities of products. | It fills multiple servings of products inside the pouch. |

| The Sachet packing machine has a simple design. | It is complicated in construction, having multiple parts. |

| It is less pricey. | It is pricier. |

| The Sachet packing machine is perfect for products that need individual packaging. | A pouch packing machine is best for packaging versatile and irregularly shaped items. |

9.What Sachet Types are Handled by the Sachet Packing Machine?

Diverse sachet types differing in shapes and sealing are handled by sachet packing machines, such as:

Sachet Type According to Sealing

| Three-Side Seal Sachet

This type of sachet has a sealing on three sides while one side is folded. It is employed for packing amenities in the hospitality industry. |

Three-Side Seal Sachet- Picture Courtesy: Ilapak |

| Four-Side Seal Sachet

It has seals on all sides- two longitudinal seals and two horizontal seals. A variety of food and pharma products are packed in a four-side seal sachet. |

Four-Side Seal Sachet- Picture Courtesy: Gitu.net |

Sachet Type According to Shapes

| Rectangular and Square Shaped Sachet

It is a widely formed sachet type by the sachet packing machine. These sachets have typical rectangular and square shapes having distinct four sides |

Rectangular and Square Shaped Sachet- Picture Courtesy: Good Mockups |

| Oval Sachet

The Sachet packing machine is customised to fabricate oval or round-shaped sachets. They are good for storing cosmetic and skin care products like gels, lotions, etc. |

Oval Sachet- Picture Courtesy: Hehu Packaging |

| Bottle Shaped Sachet

A sachet packing machine can also form bottle shaped sachet for storing energy drinks, juices, and personal care products. |

Bottle Shaped Sachet |

| Irregular-shaped Sachet

To stand out among competitors, brands use irregular-shaped sachet packing machines to produce unique irregular-shaped sachets, like triangles, fruits, tubes, hearts, hands, etc. These distinct shapes are deployed as a marketing strategy. |

Irregular-shaped Sachet |

10.What are the Safety Features of the Sachet Packing Machine?

Safety Features of Sachet Packing Machine-Picture Courtesy: Innomation

Sachet Packing machine includes diverse kind of safety features for the health safety of the operators. Moreover, this machine is designed with safe controls that prevent the risk of fire and electrical accidents. Some of the safety features are:

The Sachet packing machine features a prominent emergency stop button on the touch screen to quickly turn off the machine in case of fire or electric hazard. Moreover, there are physical barriers and glass enclosures present in the machine to minimize unintentional machine access while it is running. This lowers the risk of electric shock to the operators.

Some models of sachet packing machines have infrared sensors that detect the presence of an operator in the danger zone and sound alarm. It often has a circuit breaker that trips in case of power overload in the machine.

The Sachet packing machine also has a smart diagnosis function that troubleshoots the machine in case of jamming of film belts, malfunctioning sealers, etc. This functionality also suggests remedies to correct faults in the equipment.

11.How Can You Troubleshoot the Sachet Packing Machine?

Sometimes, unanticipated problems are a reason for headaches for manufacturers and if they are not remedied timely, it could lead to lengthy downtimes. But do not worry as we are penning some basic problems in sachet packing machine and their troubleshooting.

| Cause | Problem | Image |

| Adhesivity of Film to Sealing Bars | ||

| Extreme sealing temperature

High pressure exerted by sealing bar The rough surface of sealing bars Poorly cleaned sealers |

Set the sealing temperature as recommended by the manufacturer.

Adjust the sealing pressure Replace the worn-out sealing bar. Thoroughly clean the sealers. |

Adhesivity of Film to Sealing Bars |

| Loss of Seal Integrity | ||

| Failure in heating of sealers

Improper alignment of upper and lower sealing jaw Inaccurate positioning of sealers on the sachet |

Check the circuit breaker and restart the machine. Replace worn-out heating elements

Realign the upper and lower sealers Reposition the sealers in the middle of the sachet. |

Loss of Seal Integrity |

| Poor Sachet Cutting | ||

| Incorrect positioning of cutting knife in the lower jaw.

Blunt edges of the blade |

Adjust the position of the sealing jaw

Sharpen the edges of the cutting blade |

Poor Sachet Cutting |

| Film Does Not Go to the Forming Station | ||

| Incorrect level of inclination roller, for instance, inclination rollers are positioned either too elevated or too low | Fix the level of the inclination roller. |

Film Does Not Go to Forming Station- Picture Courtesy: Sywen |

| Film Tearing or Spillage | ||

| High tension in the film upon its unwinding. | Adjust the brake component so that it offers steady tension. In this way, the film will travel smoothly to the forming station. |

Film Tearing or Spillage- Picture Courtesy: Packaging World |

| Film Belts Get Struck | ||

| Very taut film belts

Out-of-order drive gears Damaged bearings of a drive shaft |

Decrease the tension of film belts

Replace old drive gears Repair or replace the drive shaft |

Film Belts Get Struck |

| Variation in Length of Sachet | ||

| Film tension at the dancer’s arm is not accurate

Dirty film belts |

Adjust the film tension, especially at the dancer’s arm

Wipe the film belts with a clean cloth and then dry them. |

Variation in Length of Sachet- Picture Courtesy: minipak.net |

12.What are the Future Trends of a Sachet Packing Machine?

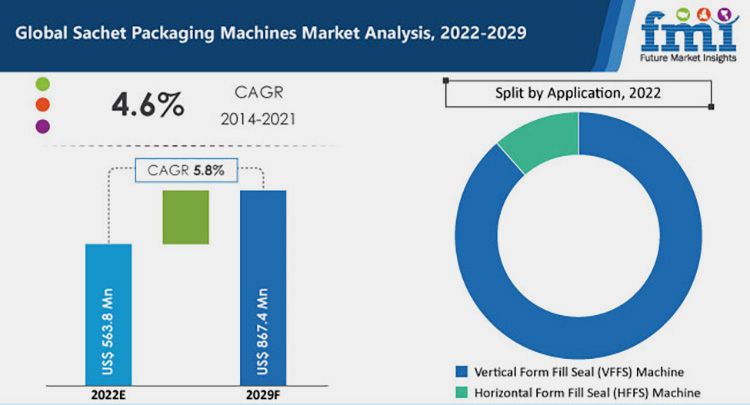

Future Trends of Sachet Packing Machine- Picture Courtesy: Future Market Insights

Over recent years, an upsurge has been observed in the sachet packing machine market. It is anticipated that this will expand to US$ 867.4 Mn in 2029 from US$ 563.8 Mn in 2022. During this period, the sachet packing machine market will progress with a CAGR of 5.8% in contrast with a CAGR of 4.6% from 2014 to 2021.

Industry 4.0 technology like artificial intelligence and the Internet of Things (IoT), propel the increase in the sachet packing machine market. The upcoming sachet packing machine will be easily maintained and cleaned using predictive maintenance. These technologies will also aid in the remote diagnosis of machines in case of breakdown and also in making data-driven decisions for smooth and seamless operation.

Furthermore, because of environmental concerns, the latest sachet packing machine will use sustainable materials like mono-materials and paper-based materials that are recycled easily. It will be equipped with controls that monitor fuel consumption. In this way, it will have a lower carbon footprint.

Conclusion

The sachet packing machine is dominating the packaging world due to the partiality of end-users for one-use sachet. It is a highly versatile unit present in far and wide industries because of its ability to handle a variety of products with simple and easy format changes. Automation, speed, and consistency are key benefits of a sachet packing machine that increase the sales margin of industries. Diverse film types are accommodated in the sachet packing machine for fulfilling present and future sachet styles. Keen on buying this equipment, so lock on Allpack machinery. We provide the best of the best machines at fair prices.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide