Sachet Filling Machine: The Complete Buying Guide in 2025

Sachet is a significant solution for every general to specified items! Do you know why?

This is due to its convenience, affordability, individuality, and aesthetic appearance. You would be surprise to know sachets are ideal for broad spectrum packaging carrying from food to medicines, beauty to general products and other.

Cosmetic sachet mockup- picture Courtesy: Mockups Designs

A sachet filling machine is the greatest solution for accomplishing filling task. This is available in various presentations depending on capacity, production size, number of different products, states and much more. In this guide, our experts have suggested various aspects, classifications, advantages, certain problems and solutions related to sachet filling machine. If you want to purchase a sachet filling machine, then we would recommend to go through this blog.

1.What is Sachet?

The sachet is a four-seal packaging that offers maximum safety to prevent product leakage. It offers to carry product safely everywhere without worrying about wastage and makes your product pretty attractive in terms of graphic design, since it is possible to print and express the qualities of the brand and the product itself.

2.What is a Sachet Filling Machine?

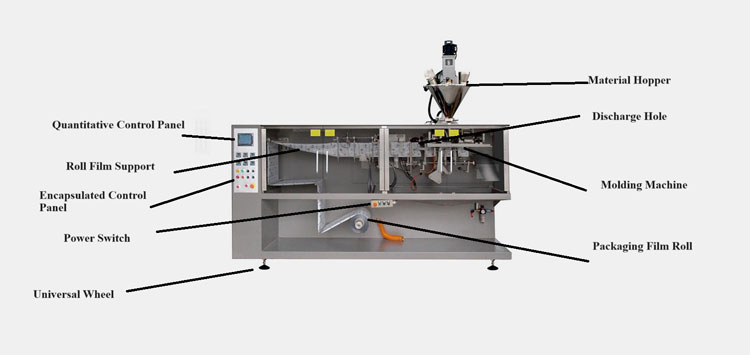

Allpack sachet filling machine

A sachet filling machine is a significant equipment used for packaging of items in a small sachet which is useful for one time usage. The machine is capable of dealing materials made up of different types such as paper, aluminium, etc, that can fill product of various states such as granules, powder and other.

Plus, the machine is perfect for offering you sealing with various edges that prevent leakage of products such as three-side, four-side, or two-side sealing. So, now you can get.

3.What are Benefits of Sachet Filling Machine?

The benefits of sachet filling machine are given below:

Various Sealing Format

Form fill sealer- picture courtesy: packaging Digest

A sachet filling machine is offering you greatest flexibility to achieve sealing patterns for sachet as per you need. Such as, two-sided, three-sided etc. Now it is possible to attain attractive sachet patterns to confined products against chances of leakage.

Consistent & Controlled Filling

Fillcon sachet- Picture Courtesy: Fillcon

You can maintain your quality standards of your product by using sachet filling machine as formulation filling in each sachet is entirely adhered to your requirements.

High User Compliance

Core supplement packet & sachets- Picture Courtesy: Spack Machine

Sachet filling machine offering a nice packaging solution as it is easy to operate and advantageous for smooth functionality.

Controlled Filling Products

Organic classic balsamic- Picture Courtesy: Matrix packaging Machine

This machine is utilizing limited sachet formation materials and beneficial for controlled filling of product so less wastage of formulation and ultimate excellent filling solution.

100% Hygienic Sachet Filling Process

The sachet filling machine is designed to maintain a safe and hygienic filling procedure to minimize the risk of cross-contamination and ensuring safe product filling and formulation stability till reached by end user.

Promising Production Demands

Vitamin C- Picture Courtesy: Emenac Packaging

A sachet filling machine is significantly important in meeting your production demands and contributing its highest role in offering highly efficient production demands.

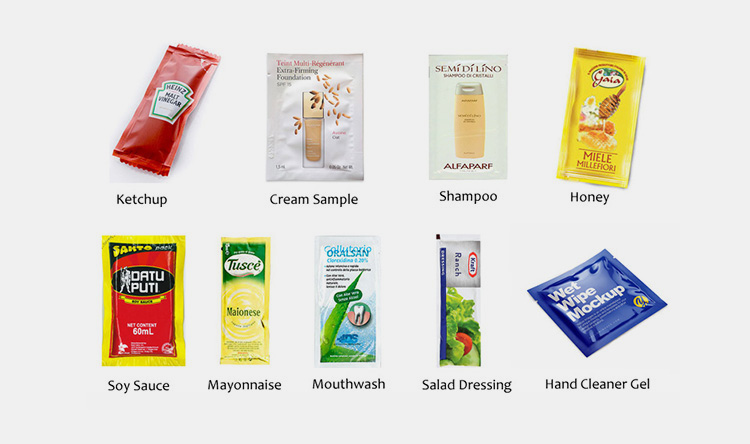

4.What are Industrial Applications of Sachet Filling Machine?

The sachet filling machine is widely used in the various sectors of packaging industries. Let’s take a look at the most common fields where sachet filling machine is used.

Pharmaceuticals Industry

Calcium with Vitamin C Pharma Sachet

A sachet filling machine is utilized in pharma packaging industries for filling and packaging of medicines available in solid, granular, and liquid state, such as instant powdery medicines, capsules, tablets, etc.,

Food & Beverage

Use of sachet filling machine in food & Beverage Industries

A sachet filling machine is commonly used in food and beverage industries for the filing of products like chips, spices, ketchups tea bags, single serving meaty bites, etc.,

Beauty Products

Cosmetic products in sachets

A sachet filling machine is used for the packaging department of cosmetic industry including solid and liquid state beauty products such as facial products, serums, shampoo, conditioners, and other.

Agriculture Industry

A sachet filling machine is suitable option for packaging of agricultural relevant products like fertilizers, plant boosters, seeds, and other broad range products like insecticides, herbicides, and pesticides, etc.,

Research And Development Industry

R&D assessment sachets

R&D industry basically involved with various samples that are commonly available in sachet formulation. The sachet filling machine is the best choice for packaging sensitive products such as blood assessment chemicals, bio-analysis samples etc in sachets.

Chemical Industry

The chemical industry needs sachet filling machine during production, processing, and packaging departments for filling of various chemical formulations. Such as, buffers, acids, alkali, bleaches, etc in sachets.

5.What is Working of Sachet Filling Machine?

The working steps of the sachet filling machine is given below:

| Loading Of Ingredients | Formulating ingredients of any product that is to be filled in sachet such as condiments, sauces, shampoo, medicine or any other item required is inserted inside the hopper of machine. This works as a product feeder, that is structurally located at the top part of the equipment. The working thus becomes convenient for dispensing of the product. |

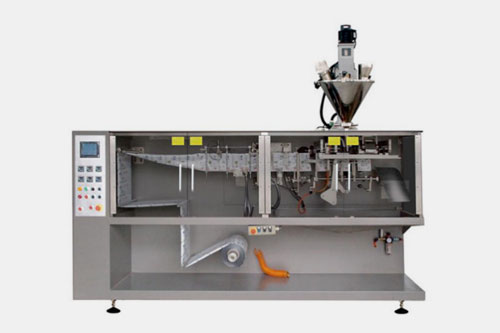

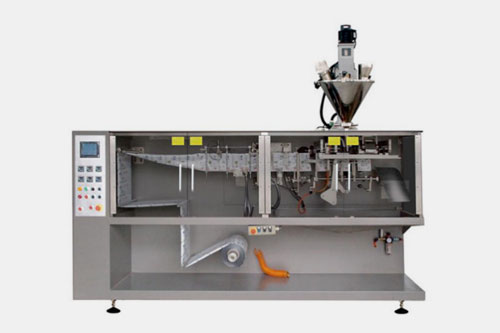

Sachet Filling Machine |

| Sachet Formation | The film roll is unwounded from the equipment’s assembly and the sachet is created. Sachet formation takes place by heat sealing the material involving the use of tube former, leaving one section opened. |  |

| Filling | The hopper dispenses the product into the formed sachets. Type of filler depends on the type of product that is dispensed . For e.g.: Volumetric fillers are used for filling granules, Auger filler is used for filling of powders and piston fillers are used for filling liquids. |

Sachet filling machine |

| Sealing and Cutting | Next comes the step of sealing and cutting. Once the desired product is filled the sachet is sealed from the top forming an airtight barrier. The sachet packet is then cut off from the continuous film roll by a heat cutter or a blade. |

Aipak Horizontal Sachet filling machine |

| Ejection and Collection | Sachets are now ready to be dispensed so they are ejected and packaged for delivery. |

Sachet filling machine |

6.What are the Types of Sachet Filling Machine?

There are different types of sachet filling machines , each of them have variance in specifications and characteristics, such as sachet filling machines based on type of automation, type of working and type of product it can handle. You’ll be seeing some of these categorized types below:

ACCORDING TO AUTOMATION

| Manual Sachet Filling Machine | This sachet filling machine is operated by a user interference during the working procedure of the filling. Users need to input the sachet, fill it with desired product and then seal and cut them manually. Manually operated sachet filling machines are appropriate for use in small scale industries that are set on a startup basis usually at less production volume. |  |

| Semi-automatic Sachet Filling Machine | Semi-automatic sachet filling machines do not require an operator for whole process however some steps do require human interaction. Operator would require input of sachets into the machine, and setting and controlling parameters for overall working.

These machines find it’s purpose in medium scale industries. |

|

| Automatic Sachet Filling Machine | As the name suggests automatic sachet machine works on it’s own without requiring any human efforts as such. It might only need setting of instructions through PLC control. Fully automatic sachet filling machines are highly automated and can carry out loading of sachets, filling of product into them, sealing the sachets and even packaging without requiring monitoring of the processes. Automatic machine find it’s application in greater volume production lines where a high degree of efficiency and speed are necessary. They are found in industries having large-scale production output. |  |

ACCORDING TO THE TYPES OF MATERIAL

| Powder Sachet Filling Machine | Powder sachet machine is an automatic working equipment used to fill powderous or granular types of product such as tea , coffee, sugar , flour, salt ,some spices and some medicinal powders too. The loading of sachets can be easily handled along with feeding of required parameters on which you want the equipment to operate. This machine is constructed of stainless steel which makes it resistant to corrosion. It can also work for longer time period without any disruption. However, it should not be used for dispensing fluids or liquid materials into sachets. |  |

| Liquid Sachet Filling Machine | Liquid sachet filling machine can be used to fill and pack sachets with liquid products such as sauces like ketchup, chili sauce, soups, oils, shampoo, soap and even cosmetic creams. Similar to powder sachet filling machines they can also run for long duration without the need for repair. It possesses an external suction pump for dispensing light weight materials such as water or sauces. It efficiently works in a single step process by filling and sealing in a single procedure cutting down on extra labor efforts. |  |

ACCORDING TO WORKING

| Vertical Form Fill Seal (VFFS) Machine | VFFS machines are widely used for filling and sealing of powders and granular products in a vertical manner. The equipment functions by vertically pouring required material into sachets that is beneficial for gravity based dispensing. |  |

| Horizontal Form Fill Seal (HFFS) Machine | HFFS machines function in a horizontal manner and are usually employed for packaging of products that require gentle handling. Products that are having a certain configuration such as biscuits or electronic parts are packed using this machine. |  |

7.What are the Parts of the Sachet Filling Machine?

A sachet Filling Machine

Material Hopper

This part denotes the storage space of the equipment where the raw materials are placed that are supposed to be fed in the sachets later on when filling and packaging them.

Packaging Film Roll

Packaging film is a roll of material that is used to create sachets or the outer layer of packaging. Materials that are used are plastic, paper or any composite films.

Quantitative Control Panel

Control panel is the system involving electronic components that are securely placed in a safe casing. This part regulates and controls the working of overall machinery. Packaging control panel foresees processes such as filling, sealing and labeling and packaging.

Roll Film Support

The support rod enables structural balance to the whole packaging system.

Molding Machine

It is a part of packaging machine which shapes the packaging film into required shape of bag before it is further processed for filling of product. The material in a ready form arrives for further transportation and delivering.

Encapsulated Control Panel

This portion of the machine is used to offer operational keys which is encapsulated with safety sheet to protect the unit.

Power Switch

You can on and off by featured power switch of the machine.

Separator

The formed sachet is detached from the row of sachets by a separator.

Safety Cover

This section protects the content from spilling outside the machine.

Universal Wheel

A universal wheel is required to manoeuvre and drive the equipment in any required direction. It is used in such machines that require smooth and easy mobility.

8.What Packaging Material is Used by Sachet Filling Machine?

Diversified categories of packaging materials are utilized by sachet filling machines for packaging purposes. What material you will select can be decided upon the type of your product that is to be packaged, its desired shelf life, and any certain requirements. The packaging materials generally used by a sachet filling machine are:

Paper

Paper sachet- Picture courtesy: shopee Malaysia

Paper based material is specifically used to enclose powderous products in paper sachets. A paper sachet is packaged by many industries like food, pharmaceuticals, and personal care. Paper is selected as a packaging material where there is a requirement for environment friendly and sustainable packaging.

Plastic

Manufacturer Face Cream Small Refill Bag-Plastic Sachet

Usage of plastic sachets are enormously used in the packaging industry due to their flexibility, strength, and low cost. Further selection of type of plastic material depends on the type of product that is being packaged, the desired barrier properties (in terms of product safety against environmental conditions) and any other specific requirements.

Aluminium

Pack free package mockup- Picture courtesy

Aluminum foil is a commonly used material in sachet filling machines, especially for products that need environmental barrier against conditions from temperature, light, humidity, and gases. Aluminum foil provides excellent properties, making it a suitable material for packaging items such as pharmaceutical medicines, food items, and some chemical based sensitive products.

9.What Products Can be Filled by Sachet Filling Machine?

A sachet filling machine is useful in filling various product’s belonging to broad spectrum industrial goods. The commonly used product names are listed below:

Powders

The products in small powders are accurately packed in individual packaging by sachet filling machines such as:

Powder sachet- Picture Courtesy: Delt Foods

- Milk powders

- Protein or nutraceutical items

- Spices

- Medicinal or pharmaceutical powdery items.

Granules

Recade granules for oral suspension- Picture courtesy: Pakistan trade portal

The tiny granular substances whether pharmaceutical, chemical, cosmetics or any other items; a sachet filling machine can flexibly pack them in each sachet for single serving. For instance:

- Salts

- Sugar

- Pepper

- Coffee

- Surf or detergents, etc.,

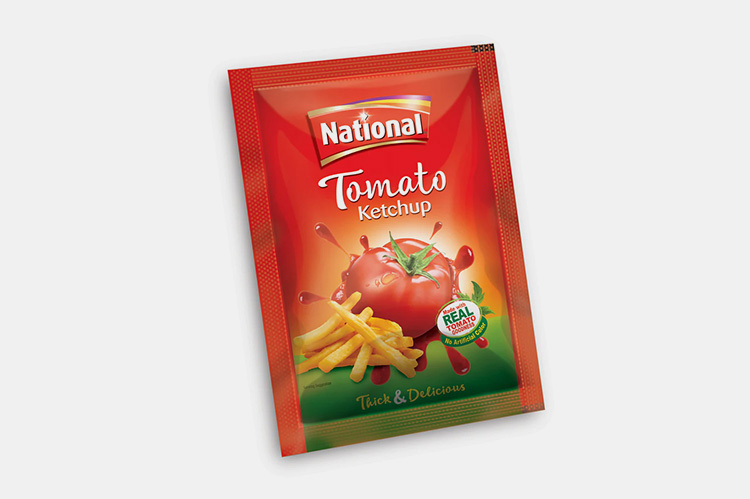

Liquids Creams & Sauces

Various viscous and non-viscous items can be dispensed by sachet filling machine in single and individual sachets.

National tomato ketchup-picture courtesy: QnE

- Ketchup

- Cooking oils,

- Hair gels,

- Face washes

- Dishwash liquids

- Mustard pastes, condiments,

- Toothpastes. Etc.,

10.What are the problems and solutions of sachet filling machine?

A sachet filling machine requires to be working with efficiency and therefore it needs accurate functioning. However, like other equipment’s face some troubles while operation, this too encounters various problems. But our professional team has outlined their respective suitable solutions alongside the basic problems faced during the use of this machine. Read further to understand.

Inaccuracy In Filling

Problem

The machine may incorporate sachets with an imprecise quantity of product, either filling too much or too little amount of your product.

Solution

Filling component must be regularly inspected and calibrated to keep a check and monitor if any disturbance or wear and tear has occurred. This needs to be maintained so that product efficiency in terms of weight is not affected.

Sealing Issues

Sealing issues- Picture Courtesy

Problem

Improper sealing can cause leakage of your products or contamination with any external agents.

Solution

You must check the sealing mechanism for any issues in alignment or damage to the parts. Check for adjustments in the heat-sealing temperature and pressure according to your product specifications.

Jamming or Blockages

Problem

In case any products or packaging material gets stuck in any part of the machinery it may cause blockages or jams in the machine disrupting the normal functioning.

Solution

You must clean and analyze the machine for presence of any foreign particles. Make sure the conveyor belts and other mobile parts are accurately aligned.

11.What factors should be considered when purchasing a sachet filling machine?

When purchasing a sachet filling machine, discussed below factors must be considered in order to find the machine up to your requirements. What those points are? Let’s see below points to consider before making a final decision.

Your production capacity

Production capacity assessment before purchasing- Picture Courtesy: Sernee

We would recommend determining the production capacity of your production line such as number or sachet required per minute, and production speed. Once it is determined, you can easily opt for right choice such as semi-automatic or automatic sachet filling machine.

Product’s Filler Type

A sachet filling machine can be of various filling types, such as volumetric, auger, or liquid, So if you know your filling product types, then you can directly select the right machine needed for your packaging.

Space Need

Space requirement for sachet filling machine

We would suggest assessing your space when looking for purchasing the sachet filling machine. your measurement would be helpful to choose right machine that would be suitable for easy installation and workflow within working department.

Supplier Status & Support

Good reputable company offer promising equipment- Picture Courtesy: Everypixel

Look for reputable profile manufacturing and supplying company for purchasing a reliable sachet filling machine. For this, you need to assess their customer review via google, ratings, and websites.

Conclusion

In a nutshell, a sachet filling machine is a significant equipment that boosts up your business profile and offering excellent intended applications. It is crucial to verify machine mechanism, parts, problems and solution for truly marvelous performance throughout machine’s life. To understand how a sachet filling machine particularly helps in your business, it would be great to invest in it. If you have any questions about a sachet filling machine buying guideline; please message us now to unlock the journey of success and coordinate with us. Allpack is always here to welcome customers for purchase and solve queries. Contact us Now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours