Round Corner Packing Machine: The Complete Buying Guide In 2025

Uniqueness engages customers, so various brands have introduced the round corner packing machine to grab customers’ attention & improve profitability. These round corner pouches, sachets, and stick packs are created by one-and-only round corner packing machine.

A round corner packing machine is an important solution for efficient, smooth, and creative packaging. This machine is a prime component in packaging lines, so different makes and models of this equipment are seen in the market.

Are you considering installing a round corner packing machine in your plants? Then it is our expert recommendation to carefully read this blog post. We bet by the end you will be confident in your selection.

1.How to Define Round Corner Packing Machine?

Round corner packing Machine

A round corner packing machine is a specialized machine that creates a round corner packaging container instead of a typically straight one. This machine forms pouches or stick packs with circular edges instead of straight sharp edges.

Round corner packing machine forms, fills, and seals round corner packaging corners.

This machine increases the marketability and branding of the packaging containers by creating exclusive packaging containers that stick out in the crowd of typically straight-type pouches. These packaging containers provide a distinctive edge to the brands as rounded corners set them apart from rectangular corner pouches or stick packs.

2.How is a Round Corner Packing Machine Significant for Production?

A round corner packaging machine is highly beneficial for businesses, generating optimized quality products and impacting every aspect of production. Some of the prime advantages of round corner packing machine are discussed below:

Smoother Sealing for Safety of End-users

Smoother Sealing with Round Corner Packing Machine

Using the round corner packing machine brings advantages for end-users. This machine creates smooth round corner seals that do not pose the risk of injury to the user which is possible with sharp corners of other packaging. These corners can cut the fingers of consumers but round corner packing containers are safe for usage.

Faster Speeds for Increased Production

Faster Speed with Round Corner Packing Machine

Some models of the round corner packing machine operate at a higher speed, consequently boosting the productivity of the production. This machine has a higher output rate than a normal pouch packing machine, producing more pouches or other product containers in the small-time window.

Precision for Consistent Product Quality

Precision for Consistent Product Quality

Round corner packing machine works precisely and accurately by forming and filling consistent quality packaging containers. By adding the round corner packing machine in production, there is batch-to-batch uniformity, upholding brand standards and fulfilling patrons' demands.

Shelf Appeal for Appealing Customers

Shelf Appeal with Round Corner Packing Machine

Round corner packing machine adds a flare of creativity in the pouch, stick pack, and sachet packing that improves the shelf appeal of the brands and excites the customers. This plays an important role in creating a professional and attractive look that increasingly influences customer impulse buying.

Lower Human Error for Higher Efficiency

Lower Human Error with Round Corner Packing Machine

With its automation, round corner packing does not need labor supervision. This lowers the chance of human error that is inevitable in hand packaging. These errors are unavoidable and negatively impact product efficiency, as incorrectly packed products always lead to product rejection and recall.

3.How to Classify Round Corner Packing Machine?

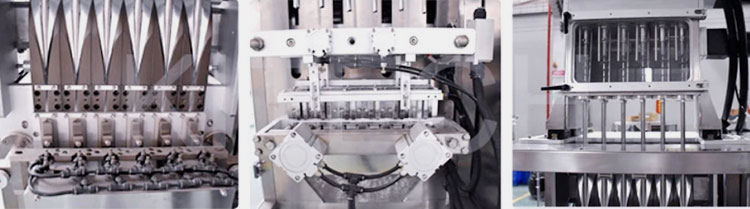

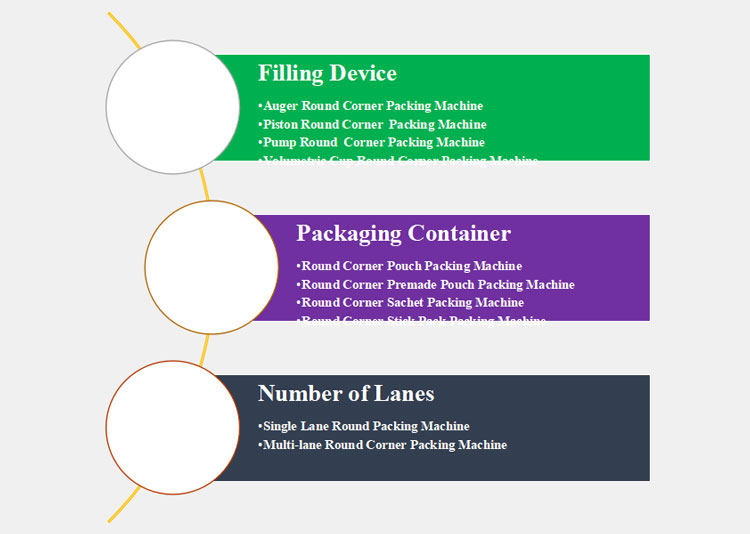

A round corner packing machine is classified into broad categories that are differentiated based on their filling technology and their packaging container. Here is the classification chart and its explanation for simplified understanding:

Filling Device

Auger Round Corner Packing Machine

Auger Round Corner Packing Machine

This machine relies on a closed-filling device called an auger. In this machine, auger screws rotate to move the powders or granules inside the auger plate. These products go from auger plates to the filling nozzles from where these products are deposited inside the packaging containers. This machine is a favourite among manufacturers because it lowers contamination risk.

Piston Round Corner Packing Machine

Piston Round Corner Packing Machine

This machine comprised of pistons and cylinders. To and fro movement of the piston in the cylinder doses the viscous or free-flowing liquids inside the packaging containers. It is a highly accurate machine that measures the exact quantity of liquids and dispenses them in pouches or other flexible containers.

Pump Round Corner Packing Machine

Pump Round Corner Packing Machine

As the name indicates, this machine has several distinct pumps that rotate to fill the packaging container. The gear, lobe, and cavity pump complete one rotation to load and dispense liquids in one cycle. It is a positive displacement machine that packs a wide range of liquids inside the pouches. It dispenses foamy, viscous, stringy, and thinner consistency products.

Volumetric Cup Round Corner Packing Machine

Volumetric Cup Round Corner Packing Machine

For filling products by volume, the volumetric cup round corner packing machine is used. These are often used for dosing dry powders in round corner stick packs or sachets. It consists of cups in which a pre-measured amount of powders is loaded from the hopper. This machine does not generate over and underfilling results.

According to Packaging Container

Round Corner Pouch Packing Machine

Round Corner Pouch Packing Machine

It is a smaller footprint, high-speed machine that custom-made round corner pouch pack. It is an adaptable unit, creating and filling numerous pouches. This machine has an advantage over traditional vertical, form, fill, and seal machines of improved product appeal. It is a highly favored type of round corner packing machine.

Round Corner Premade Pouch Packing Machine

Round Corner Premade Pouch Packing Machine

This kind of round corner pouch packing machine fills and seals ready-made round-corner pouches. It is a flexible manufacturing unit that generates highly secure sealing results. It works at far faster rates than a simple round corner pouch packing machine and consequently has quicker loading and sealing cycles.

Round Corner Sachet Packing Machine

Round Corner Sachet Packing Machine

It is a specialized kind of equipment that produces round corner sachet instead of simple standard edges. It is highly popular in industries because it fabricates highly appealing pouches. It encloses the round corner sachet on three or four sides. Different filling systems, like auger, net weigh, and other volumetric fillers are present in this machine.

Round Corner Stick Pack Packing Machine

Round Corner Stick Pack Packing Machine

This machine has specialized cutting and sealing components that make stick packs with round corners instead of regular stick packs. It has one or more lanes that improve the processivity rate of the round corner stick pack packing machine. The sides of stick packs are closed using heat, pressure, or ultrasonic waves.

According to the Number of Lanes

Single Lane Round Packing Machine

Single Lane Round Packing Machine

It is a simplified category of round corner packing machine. It is a more convenient design that forms, fills, and seals small sachets and stick packs as it only has one forming unit and two sets of sealing jaws. It is usually seen in smaller and medium setups because it only loads one pack at a time. Single lane round packing machine is less expensive.

Multi-lane Round Corner Packing Machine

Multi-lane Round Corner Packing Machine

This type of round corner packing machine has several forming and sealing stations, so this machine loads and seals numerous packs in one go. It has higher productivity; therefore, it is best for bulk processivity setup. It has a somewhat complicated design, consequently, it is more costly.

4.Where is a Round Corner Packing Machine Found?

Application of Round Corner Packing Machine

A round corner packing machine has far-ranging applications. Its application spans several industries. It is because of its efficiency and quick output. Some of the industrial uses of the round corner packing machine are:

Pharmaceutical Industry

Use of Round Corner Packing Machine in Pharmaceutical Industry

A round corner packing machine is a phenomenal piece of equipment that is important in the pharmaceutical industry because of its rapid and correct dosing of pharmaceutical powders, liquid syrups, and emulsions in round corner stick packs and sachets. This machine assures the accuracy of dosage without making errors and contaminating the product.

Nutraceutical Industry

Use of Round Corner Packing Machine in Nutraceutical Industry

Like the pharmaceutical industry, this machine is also utilized in the nutraceutical industry, as it packs the nutraceutical, dietary, protein, probiotics, prebiotics, and other supplement powders with a great deal of exactness and precision in round corner packs. It also loads energy drinks and other supplement drinks with error-free speediness.

Food Industry

Use of Round Corner Packing Machine in Food Industry

A round corner packing machine dispenses food products like dressings, pastes, herb mixes, spice blends, condiments, and sauces in the round corner sachets and stick packs to increase product aesthetics and engage customers. This machine is also found in the food industry because of its ability to rapidly package products.

Beverage Industry

Use of Round Corner Packing Machine in Beverage Industry

This machine is increasingly utilized in the beverage industry because it delivers results without any human error. A round corner machine packs juices, bubble drinks, soft drinks, tea, and, coffee in the round corner pack to attract and captivate customers.

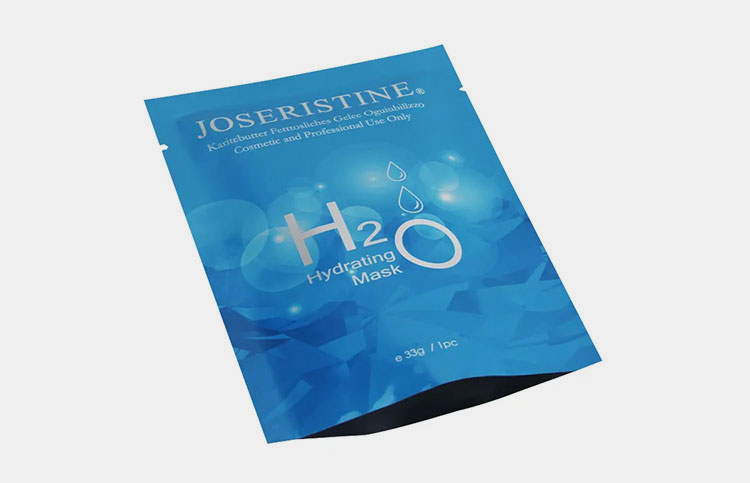

Cosmetic Industry

Use of Round Corner Packing Machine in Personal Care Industry

Product presentation and outlook have due importance in every industry but it is a must for the cosmetic industry. Therefore, cosmetic brands specially employ the round corner packing machine to create exclusive, stylish, and premium samples and regular-use cosmetic round-corner packs. This machine loads foundation, lip gloss, creams, gels, dyes, lotions, etc. in the round corner pack.

Personal Care Industry

Use of Round Corner Packing Machine in Personal Care Industry- Picture Courtesy: Dieline

This machine has also found its use in the personal care industry. It has a prime role in the packaging of shampoos, face wash, body wash, liquid soap, hand sanitiser, and many more in the round corner packs.

5.How Does the Round Corner Packing Machine Work?

The working round corner packing machine works is simplified and includes three main steps. However, we are giving a detailed description, so you can learn more about the round corner packing machine:

| Step 1: Placement of Packaging Film

In the first step, the operators or robotic arms put the packaging film over the film holder. This film is unwound by the rotating film holder and moves over rollers. These parts maintain film tension. |

Placement of Packaging Film |

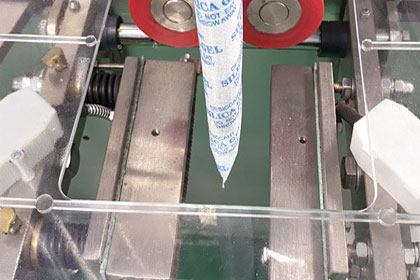

| Step 2: Forming of Packaging Container

In the next step, the film reaches the conical-shaped part called the forming tube. By folding and wrapping, the forming tube and forming collar fashions a pouch or sachet-like structure. The bottom part is fused by the horizontal sealer. |

Forming of Packaging Container |

| Step 3: Vertical Sealing

The vertical sealer converts a pouch or sachet-like structure into the proper pouch by sealing its longitudinal sides. These sealers also form a middle seal depending upon the type of pouch. |

Vertical Sealing |

| Step 4: Filling

The filling devices measure and dispense precise quantities of solids and liquids into the filling nozzles. These parts rapidly fill the pouch or sachet. |

Filling |

| Step 5: Horizontal Sealing

When the filling stops, the top part or seam is melted and joined by the horizontal sealer. These sealers seal the top side of one packing container and the bottom side of another packing container. |

Horizontal Sealing |

| Step 6: Cutting and Discharging

Lastly, the two packing containers are disjoined from one another by the sharp blade. The finished round corner packing container is discharged on the product conveyor or outfeed chute. |

Cutting and Discharging |

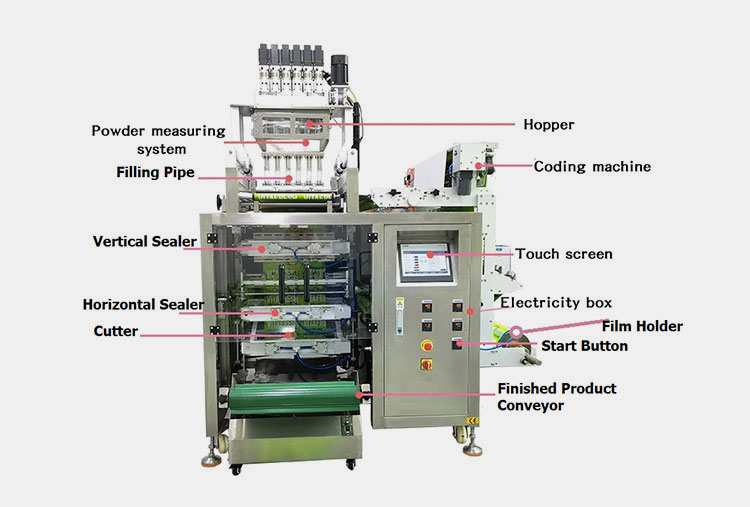

6.What are the Structural Components of Round Corner Packing Machine?

The structural configuration of the round corner packing machine is somewhat difficult and is hard to understand. Therefore, we are detailing important parts to increase your understanding of the round corner packing machine.

Parts of Allpack Round Corner Packing Machine

| Powder Measuring System | This part of round corner packing machine determines and calculates the amount of powders moving in the filling pipes. It is very important for the accuracy of the machine. |

| Hopper | This part of the machine is found at the uppermost part of the machine and has a cone or rectangular shape. The feed pipes load huge quantities of powder and liquids into the hopper. |

| Filling Pipe | These pipes connect the filling devices and the filling nozzles. |

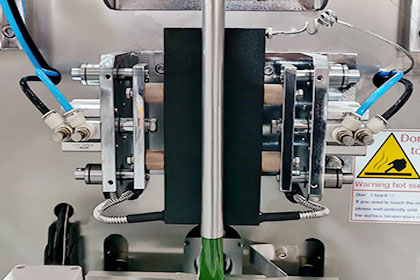

| Vertical Sealer | The vertical seams of the stick pack or sachets are sealed by the vertical sealers. These sealers are essential in forming stick packs and other round corner packs. |

| Horizontal Sealer | These are the horizontal sealers that join the top and bottom corners of the packaging container. These sealers work at the end of the filling. |

| Cutter | These are found in the centre of sealing jaws and sharp cutter trims the edges of two successive packaging containers. |

| Coding Machine | This device prints and codes dates and bar codes on the stick packs or sachets. |

| Touch screen | It is a modern piece of technology and is an intuitive display screen with which operators perform programming of the machine operation. The operator quickly inputs parameters by going through pre-saved data recipes present in the memory of HMI. |

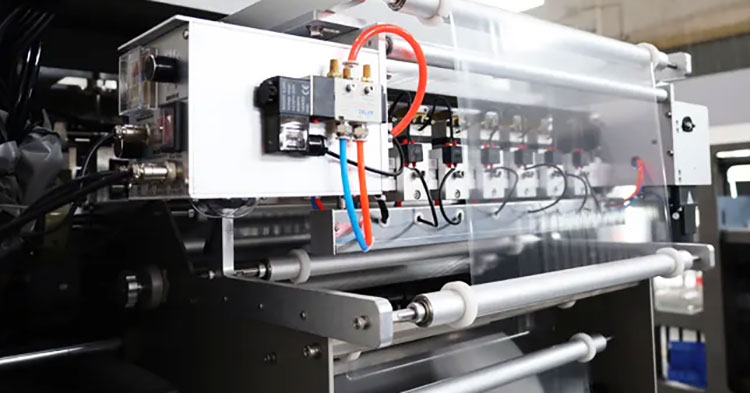

| Electricity Box | It is the powerhouse of the machine because it contains different wires and cables for running the machine. |

| Film Holder | This film holder is a robust stand on which packaging film is placed. |

| Start Button | This button is pressed to turn on the machine. |

| Finished Product Conveyor | The finished packs are discharged on this rectangular product conveyor. |

7.Can Round Corner Packing Machine Handle Packing Containers of Different Sizes?

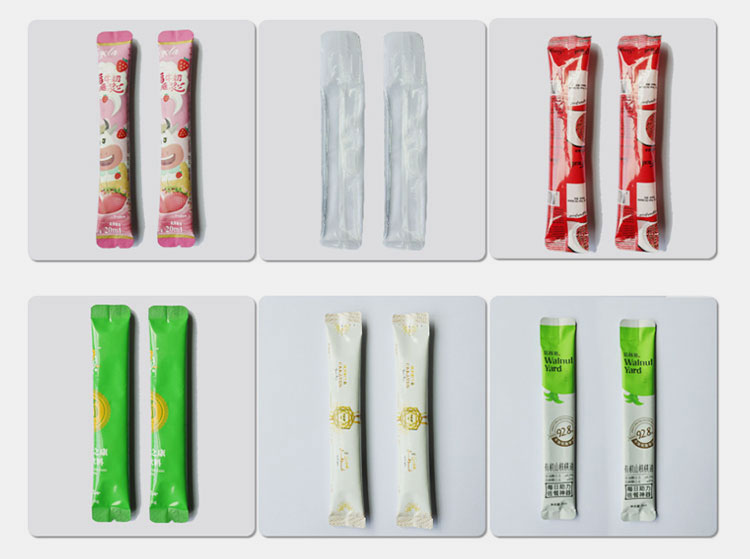

Yes, the round corner packing machine can easily handle packing containers of different sizes with a simple adjustment in the machine settings. The operators can program different settings of bag lengths, widths, and heights to produce bags or pouches with different designs. Here are some examples of different pouch and sachet designs handled by the round corner packing machine:

| Sachet

It is a small one-serve pouch that typically has rectangular or square shapes. It is mostly used for serving condiments and other spices with delivery foods. |

Sachets |

| Stick pack

It is a long tubular pack that also houses a one-time quantity of the products. It is best for storing instant coffee, sugar, and salts. |

Stick pack- Picture Courtesy: kenhigh |

| Irregular Shape Round Corner Sachet

There are various irregular shape sachets used for packaging of cosmetic, medicinal products, and confectionery items can be packed by round corner packaging machine. |

Irregular Shape Round Corner Packing |

8.Does Round Corner Packing Machine Have Space Limitations?

The space limitation of the round corner packing machine greatly relies on the design, its additional components, and type of the operation. When purchasing the machinery, the size of the production plant must be kept in mind, otherwise, you will not be able to set up the equipment.

Sachet Round Corner Packing Machine

Generally, the VFFS round corner packing machine and round corner sachet packing machine do not need large space in the production plant. They have smaller footprints as these machines have smaller widths than their height.

These kinds of round corner packing machines are not equipped with conveyors or large outfeed chutes.

Round corner stick pack packing machine has more footprint depending upon its number of lanes. The higher the number of lanes in the round corner packing machine, the higher will be its footprint.

9.Does Round Corner Packing Machine Have Cost-Saving Features?

Business always wants to earn higher profits with less investment and it is a question in everyone's mind will a round corner packing machine save money? The answer is yes. Round corner packing machine has some cost-saving features.

A round corner packing machine optimizes the use of packaging film, in turn lowering the film waste and decreasing demand for more film purchases. This saves operation expenses. Moreover, this machine has energy-efficient parts like motors and electric components that consume less amount of energy. This translates into lower utility bills.

Due to the automation of the round corner packing machine, the need for managing human operators is less. This machine performs its jobs seamlessly, so a smaller number of operators supervise and program it. This characteristic round corner packing machine leads to a significant cut down in labour costs.

Last but not least, the round corner packing machine runs 24/7 and does not take a break while running. This decreases downtimes and it seldom encounters any problems, consequently, saving more repair costs.

10.What are the Sanitation Requirements of Round Corner Packing Machine?

To process any product, a round corner packing machine must be GMP complied. There are important sanitary requirements that this machine must fulfil. Here is a list of some basic sanitation requirements:

If processing food products, the components of the round corner packing machine must be food-grade to avoid the release of harmful substances in the food products. This machine must be made with rust-resistant components.

The machine must have a hygienic design and it must be formed with accessible and easily reachable components that are conveniently removed for cleaning. The surfaces of the machine should be smooth so that they can be easily cleaned.

It is important to adhere to a proper cleaning schedule to fully clean important area like sealing jaws, cutting knives, filling devices, and filling nozzles that comes in contact with packaging.

11.Tips and Tricks- How to Resolve Common Problems in Round Corner Packing Machine?

A round corner packing machine can face some occasional problems that may disrupt the smooth flow of packaging. So, we are writing some tips and tricks to solve such problems in the round corner packing machine.

Nonuniform or Unreliable Pouch/Sachet Seals

Sometimes, the packing containers have poor or insufficient seals.

Cause

- This problem may be because of defective or old sealing jaws. Over time, the sealing jaws lose their work efficiency.

- Low sealing temperature and pressure are the causes of improper bonding between film edges.

- The presence of dust and debris on the film and sealing bar can hamper with bonding between the film.

Solution

- Check the sealing jaws and replace them if needed.

- Increase the sealing temperature and pressure for consistent film bonding.

- Properly clean film and sealing jaws before use.

Equipment Overheats

Equipment Overheats

The temperature of the machine is very high.

Cause

- Accumulation of dust and debris in the machine which hinders the airflow.

- Inadequate lubrication of machine parts results in high frictional force that produces heat.

- The motor or other electrical components are running beyond their working capacity.

Solution

- Properly clean every surface of the machine daily to avoid overheating issues.

- Lubricate the machine part once of week to prevent the buildup of frictional force.

- Run motor and other electric components within their specified electrical limit.

Irregular Round Corner of Pouch/Sachet

Irregular Round Corner of Pouch/Sachet

The shape of the round corner pouches or sachets is inconsistent.

Cause

- Incorrect positioning and alignment of the cutting knife in the sealing jaws.

- Dull edges of cutting knife can also cause irregularity in cut corners.

- Improper alignment of sealing jaws.

Solution

- Properly align and position the cutting knife.

- Sharpen the edges of the cutting blade.

- Realign the sealing jaws.

Inconsistencies in Pouch Sizes

Inconsistencies in Pouch Sizes

There are variations in the lengths of pouches

Cause

- Incorrect timing of sealing and cutting parts.

- The bag pull components are defective or old.

Solution

- Reprogram the timings of sealing and cutting parts.

- Check and replace the bag-pulling parts.

Slippage of Film

Slippage of Film

- The film is not placed correctly on the film holder.

- Improper unwinding of film can also cause its off-positioning.

- Film belts are not properly aligned.

Solution

- Properly place the film on the holder,

- Guide the film correctly over rollers so it can unwind correctly.

- Realign the film belts.

Conclusion

Dear Readers! Hope you found this blog engaging and interesting. A round corner packing machine is a miracle of science and technology. Investing in this machine brings valuable and worthy professional and monetary benefits. By creating premium quality round corner packs, you can boost the standing of your brand in the eyes of customers. If you have more queries regarding this useful equipment and are indecisive in your selection, then immediately message us. We, the Allpack team will guide you and will answer all your queries.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide